Euroboor EBS.500 User manual

INSTRUCTION MANUAL

EBS.500

PORTABLE BAND SAW

SAFETY RULES

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND WRENCHES. Form a habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in

Damp or wet locations, or expose them to rain. Keep work area well lighted.

5. KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

6. MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

7. DO NOT FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

8. USE RIGHT TOOL. Do not force tool or attachment to do a job for which it was not designed.

9. USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. Choose

the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the

next heavier gage. The smaller the gage number, the heavier the cord.

10. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelet or other

jewelry, which may get caught in moving parts. Non-slip footwear is recommended. Wear protective

hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES AND EAR PROTECTION. Also use face or dust mask if cutting operation

is dusty. Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to hold work when practical. It's safer than using your hand and

it frees both hands to operate tool.

13. DO NOT OVERREACH. Keep proper footing and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits, cutters, and

the like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position before plugging

in.

17. USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended accessories. The

use of improper accessories may cause risk of injury to persons.

18. NEVER STAND ON TOOL Serious injury. Could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function - check for alignment of moving parts, binding of moving parts, breakage of

Portable band saw

parts, mounting, and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation of the blade

or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave tool until it comes to a

complete stop. To lock the main switch in the OFF position, remove the switch key from the switch.

Place the key in a location that is inaccessible to children and others not qualified to use the tool.

(1) WEAR EYE PROTECTION.

(2) DO NOT REMOVE CUT-OFF PIECES UNTIL BLADE HAS STOPPED.

(3) MAINTAIN PROPER ADJUSTMENT OF BLADE TENSION, BLADE GUIDES, AND TRUST BEARING.

(4) ADJUST UPPER GUIDE TO JUST CLEAR WORKPIECE.

(5) HOLD WORKPIECE FIRMLY AGAINST TABLE

Material to be cut

The tool is intended to cut matter material like steel. Iron, copper, etc. NEVER USE THIS TOOL TO CUT WOOD

AND EXPLOSIVE METAL MATERIAL.

USE A CORRECT PLUG

As different countries may use different plug, so the user shall install the right plug approved in your

country.

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified

electrician. Improper connection of the equipment-grounding conductor can result in risk of electric shock.

The conductor with insulation having an outer surface that is green with or without yellow stripes is the

equipment-grounding conductor.

If repair or replacement of the electric cord or plug is necessary, do not connect the Equipment-grounding

conductor to a live terminal. Check with a qualified electrician or service personel if the grounding

instructions are not completely understood, or if in doubt as to whether the tool is properly grounded.

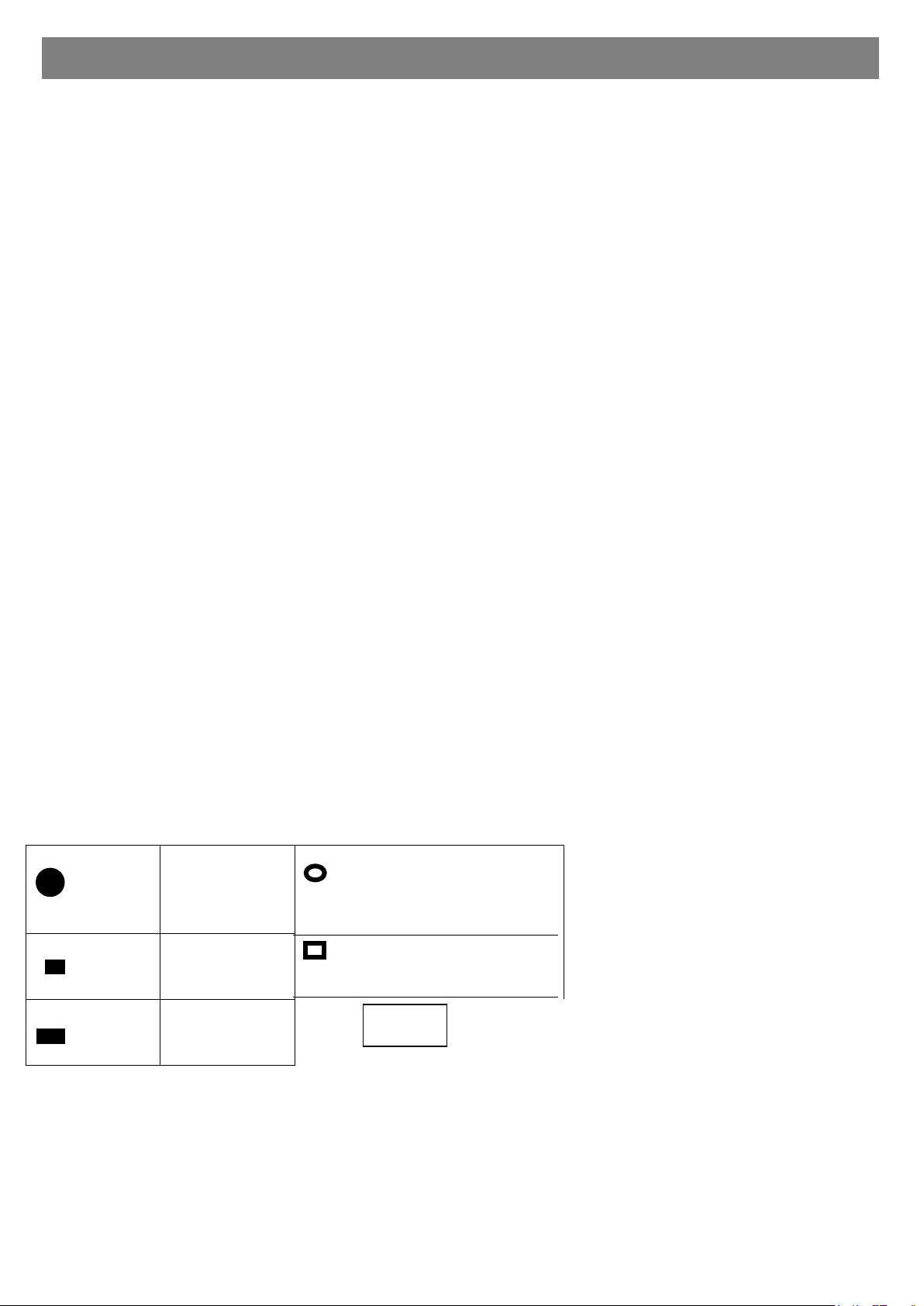

FIG B

Portable band saw

Running in the blade

To safe guard the life and quality of a new blade, the first two or three cuts must be made exerting slight

pressure on the piece so that the cutting time is almost twice the one normally needed (see cutting table).

Correct positioning of the piece in the clamp

Pieces to be cut must always be held firmly in the clamp, directly between the two jaws and without

inserting other objects. For flat profiles, bars or particular shapes, refer to the examples in fig .B

To cut a long work piece, use roll stand to support it.

Choosing the blade Fig c

Warning:

1. NEVER USE BANDS WHICH ARE DAMAGED OR DEFORMED.

2. NEVER CLEAN THE SAW BAND WHILST IT IS IN MOTION

The choice of the right blade and its toothing depends on the type of material you have to cut

And on its section. Your band saw is fitted with a 1325mm x 13mm, 0.65mm thick metal blade. Blades with

6-10 teeth per inch are available as replacement.

Requirements, indicated in the “cutting table”(fig c).

Maintenance

1. Be careful: before every cleaning or maintenance operation, ensure that the plug is not in the electric

supply socket.

2. Keep the cutting machine free from residue by means of a vacuum cleaner or a brush, passing it also

over the blade guides. Keep the band saw in good condition: if it is not to be used for a long time, put it

away in its original packing in a damp-free place. In these cases it is advisable to slacken the blade so as

not to keep it under tension unnecessarily.

30

50

115 max

8/12

6

6

30x s.1

40x s2

50x s.5 max

14

14

8/12

30

40

115 max

8/12

6

6

30x s.1

50x s.2

14

14

25x35

40x50

115x153 max

8/12

6

6

Fig C

Portable band saw

Portable band saw

ELECTRICAL PART LIST

CIRCUIT DIAGRAM

Item

Specifications

Item

Specifications

Voltage

110~230 V

Blade size

13 x 0.65 x 1325mm

Motor

(800W)

Bow-Saw

Aluminum

Cutting

capacity 90°

Circular bar: 85mm,

rectangular bar: 100 x85mm

Dimension

650 mm x 310 mm x 450 mm

Cutting

capacity 45°

Circular bar: 85mm,

rectangular bar: 60 x 65mm

Packing

660 mm x 320 mm x 470 mm

Function

Manual Cutting: ST-G510s

Optional

Accessories:

n/a

Blade speed

35~80 MPM

NOISE LEVEL

The noise level for the tool is about 60 dB (A)

Item Description

Description and function

Technical data

1 SB1

TR26-21C-13D/L SM-8

4P Switch with lighe

IP54:250Vac

CE

2

Supply Cable

Ac 600V, 10A,3G/0.75mm

for 800W motor

3 M

motor

800W/230V,IP54

4 SQ1

ZIPPY

Micro

Switch,VMN-15,15A

20.5A 125 / 250 Vac

CE

5 FR1

Over Load

3.7A / 250 Vac

CE

Portable band saw

OPERATION AND ASSEMBLY INSTRUCTIONS

FIG 1

This view shows the:

Machine body (A) Handle (B)

Switch (C) Knob (D)

Rod (E) Locking Handle (F)

MANUAL CUTTING

For the spring !

You have to tight the screw(E) to make the steel plate (F)

at around 45degree.

FIG 2

To start the machine move switch (H of FIG2) to ON (I)

position press the button (B of FIG1) while manual Cutting.

This machine is designed for cutting without cooling.

So it will increase the heat in the saw blade and do not operate

the machine without any stop more than 70min.

! WARNING: WHEN THE TOOL IS NOT IN USE. THE SWITCH SHOULD BE LOCKED IN THE OFF (O)

POSTION.

ADJUSTMENTS

FIG8 Adjusting the distance Set Bracket

If you have to cut several pieces, all the same length,

Use the Set Bracket (D of FIG1) provided with the band saw.

In order to avoid repeating the measurements.

FIG7 Adjusting the blade guide

Your cutting machine is provided with a sliding guide (I of FIG3)

with built-in protection, which guides the part of the blade

necessary to make the cut, and at the same time, protects the

part of the blade not in use. To do this, simply slacken the

locking handle (J of FIG3) and slide the blade guide (I of FIG3)

so as to bring it closer to or farther from the piece that is to be cut.

Portable band saw

FIG3

A

D

F

B

C

E

Fig2.

H

I

J

U

FIG4 Adjusting the cutting angle

The band saw can cut an angle varying from 0° to

60°. Slacken the locking handle (K of FIG9) and

turn the Bow-Saw (L of FIG9) until the scale to the

desired angle. Then tighten the locking handle.

FIG5 Blade replacement

Raise saw head to vertical position and open the blade

guards. Loosen tension screw knob (A of FIG5) sufficiently to allow

the saw blade to slip off the wheels. Install the new blade

with teeth slanting toward the motor as follows:

1. Place the blade in between each of the guide bearings (N of FIG5).

2. Slip the blade around the motor pulley (bottom) with the left hand and hold in

position.

3. Hold the blade taut against the motor pulley by pulling the blade upward with

the right hand, which is placed, at the top of the blade.

4. Remove left hand from bottom pulley and place is at the top aide of the blade

to continue the application on the upward pull on the blade.

5. Remove right hand from blade and adjust the position of the top pulley to

permit left hand to slip the blade around the pulley using the thumb. Index

and little finger as guides.

6. Adjust the blade tension knob (M of FIG5) clockwise until it is just right

enough so no blade slippage occurs. Do not tighten excessively.

7. Replace the blade guards.

8. Place 1-2 drops of oil on the blade.

Transportation

Before transporting the tool, be sure to lock the upper

And lower side as shown in FIG.6.

Then lift the tool as shown in FIG.7.

FIG4

Portable band saw

FIG6

FIG7

K

L

N

M

FIG5

LOCKED POSITION

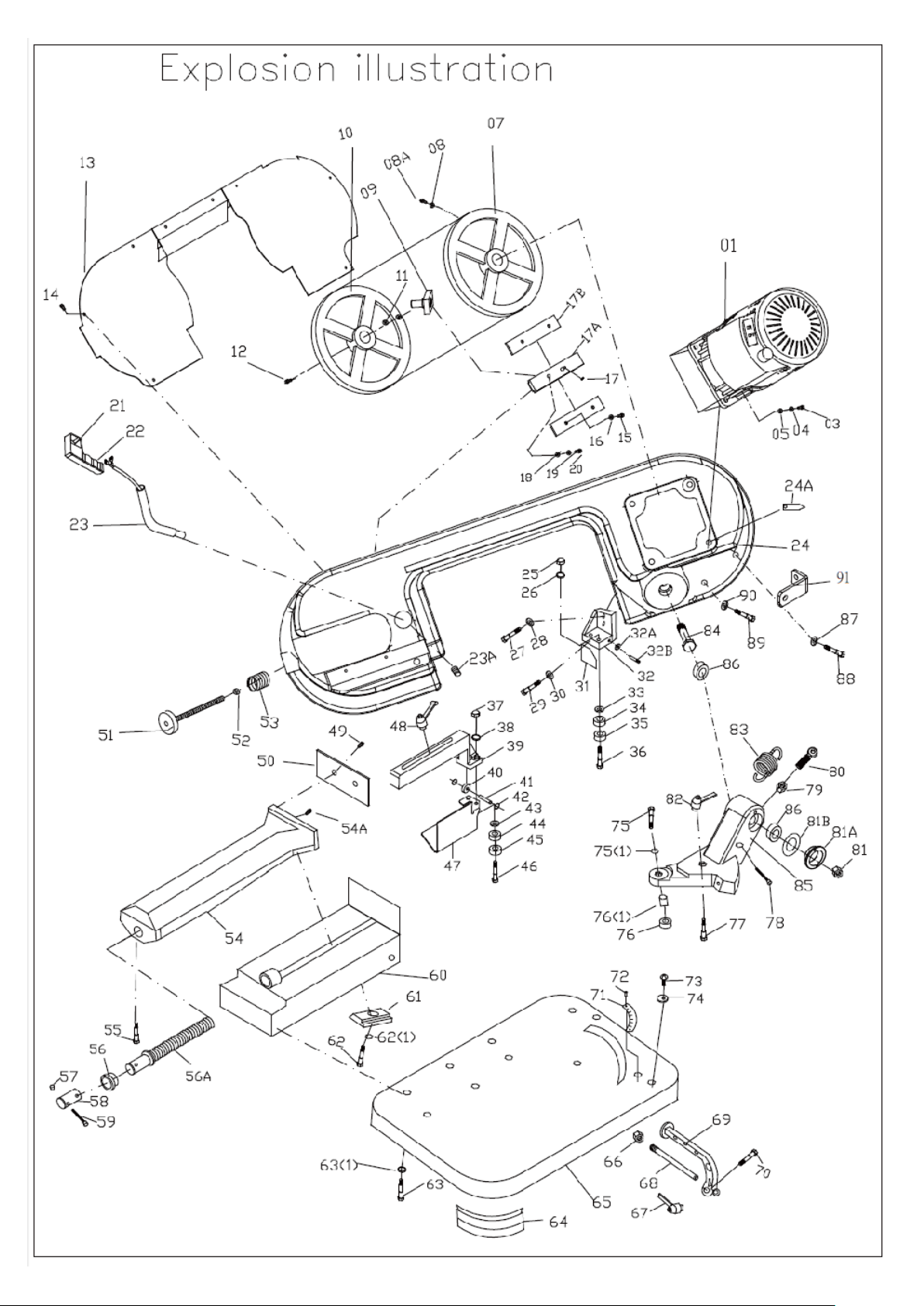

SPARE PART LIST

No.

Qty

used

Art.nr.

Description

No.

Qty

used

Art.nr.

Description

1

1

500.0002 220v

Complete Motor with Gear

28

2

not available

not available

1

1

500.0002 110v

Complete Motor with Gear

29

1

500.0029

Screw cap 5*10

3

4

500.0003

Screw Cap 8*25

30

1

not available

not available

4

4

500.0004

Spring Washer M8

31

1

500.0031

Chip fence

5

4

not available

not available

32

1

500.0032

Fixed blade guide plate

7

1

500.0007

Motor Fly wheel

32A

1

500.0032A

Bearing 625

8

1

not available

not available

32B

1

500.0032B

Pin

8A

1

not available

not available

33

2

not available

not available

9

1

500.0009

Dog Pin

34

2

500.0034

Bearing 607

10

1

500.0010

Return Fly wheel

35

2

500.0035

Bearing 607

11

2

500.0011

Bearing 6202

36

2

500.0036

Bias axis

12

1

500.0012

Screw Cap 8*16

37

2

not available

not available

13

1

500.0013

Body cover

38

2

not available

not available

14

4

not available

not available

39

1

500.0039

Arm

15

4

not available

not available

40

2

500.0040

Bearing 625

16

4

not available

not available

41

2

500.0041

Pin

17

1

500,0017

Set screw 8*16

42

2

not available

not available

17A

1

500.0017A

Blade tension sliding block

43

2

not available

not available

17B

2

500.0017B

Slide

44

2

500.0044

Bearing 607

18

4

not available

not available

45

2

not available

not available

19

4

not available

not available

46

2

not available

not available

20

4

500.0020

Screw cap 8*25

47

1

500.0047

L.Blade guard

21

1

500.0021

Limit switch

48

1

500.0048

Bolt

22

1

500.0022

Handle

49

1

not available

not available

23

1

500.0023

Tube

50

1

500.0050

Vice Plate

23A

1

not available

not available

51

1

500.0051

Handle wheel

24

1

500.0024

Body Frame

52

1

not available

not available

24A

1

500.0024A

Blade

53

8

not available

not available

25

2

not available

not available

54

1

500.0054

Vice

26

2

not available

not available

54A

1

not available

not available

27

2

500.0027

Screw cap6*25

55

1

not available

not available

continues ->

No.

Qty

used

Art.nr.

Description

No.

Qty

used

Art.nr.

Description

56-59

1

500.0056

Acme screw set

84

1

500.0084

Axis

60

1

500.0060

Fence base

85

1

500.0085

Miter plate

61

1

500.0061

Locking Seat

86

2

500.0086

Bearing

62

1

not available

not available

87

1

not available

not available

62(1)

1

not available

not available

88

1

not available

not available

63

6

500.0063

Screw Cap 8*16

89

1

not available

not available

63(1)

1

not available

not available

90

1

not available

not available

64

4

500.0064

Rubber Pad

91

1

500.0091

Screws

65

1

not available

not available

M1

1

500.1001

Main shaft

66

1

not available

not available

M2

1

500.1002

Key

67

1

not available

not available

M3

2

500.1003

Bearing

68

1

500.0068

Rod stock stop

M4

1

500.1004

C-ring

69

1

500.0069

Stop Bracket

M5

1

500.1005

Gear

70

1

not available

not available

M6

1

500.1006

key

71

1

not available

not available

M7

1

500.1007

Gear shaft

72

1

not available

not available

M8

1

500.1008

Gear Box

73

2

not available

not available

M9

2

500.1009

Bearing

74

2

not available

not available

M10

1

500.1010

oil seal

75

1

not available

not available

M11

1

500.1011

Gear

75(1)

1

not available

not available

M12

1

500.1012

Up cover

76

1

500.0076(1)

Bushing

M13

1

500.1013

Screws

76(1)

1

not available

not available

M14

1

500.1014

Nut

77

1

not available

not available

M15

1

500.1015

Fan

78

1

not available

not available

M16

1

500.1016

screw

79

1

not available

not available

M17

1

500.1017

Electric board

80

1

500.0080

Spring holder

M18

1

500.1018

oil seal

81

1

500.0081

Bearing Nut

M19

1

500.1019

Motor

81A

1

500.0081A

Bushing

M20

1

500.1020

Switch

81B

1

500.0081B

Bearing cover

M21

1

500.1021

Down cover

82

1

500.0082

Bolt

M22

1

500.1022

plug

83

1

500.0083

Spring

M23

1

500.1023

Handle wire

Other manuals for EBS.500

1

Table of contents

Other Euroboor Saw manuals