Euroheaters EUROB1016 User manual

1

www.euroheaters.com

EUROB1016 Intelligent Pressure Gauge

Operation Manual

2

www.euroheaters.com

Welcome for choosing and using our EUROB1016 intelligent pressure gauge. This manual enunciates

the functions and methods for use of intelligent pressure gauge in detail. Before using this intelligent

pressure gauge, please refer to this manual for your correct use.

Functions and Purpose of Use

Researched and manufactured by our company, EUROB1016 intelligent pressure gauge is a control

instrument, first of it’s kind produced in Europe. Not only does it assimilate the strongpoint of the similar

foreign products, but also it boasts its own characteristics, especially applicable for measuring and

controlling temperature and pressure at an identical point for high-temperature melting articles. This

instrument features fine appearance and complete functions with excellent anti-jamming performance,

which ensures reliable operation of the system.

This instrument adopts two-level four-bit led, respectively displaying actual pressure value and setting

value. Annunciate or be possessed of pressure upper limit or lower limit, which can be output via relay

contact, voltage pulse, bi-directional silicon-controlled trigger, and two-circuit constant current (or constant

pressure). Programs can be debugged fully automatically through panel operation and what you should do

for system calibration is just to push down buttons lightly. This instrument employs three kinds of anti-

jamming methods to ensure reliable functioning of the instrument: firstly, separate input from

microprocessor via photoelectric isolation circuit; secondly, adopt anti-jamming methods by applying of

software to ensure steady operation of software; and lastly, apply hardware program to monitor the system

and to enable automatic recovery of system program to normal operation after being jammed. It has been

proved through practice that high reliability can be ensured of system software by using the above

anti-jamming methods. System can thus function steadily and reliably.

This instrument is widely used for measuring and controlling of pressure of high-temperature melting

articles in industries such as petroleum, chemical fibers and plastics.

Main Technical Specifications and Performance

01).Digital display: two-level four-bit display;

01).Internal resolution: 32000;

02).External resolution: pressure, 0.01Mpa, 0.02Mpa,

0.05Mpa panel switch (power-off protection

installation

≥40

years);

04).Nonlinearity: 0.5%±1 word, 0.2%±1 word, 0.1%±1

word, 0.05%±1 word;

05).Two-circuit alarm setup: pressure upper limit:

0~99.99Mpa, lower limit:

0~99.99Mpa;

06).Rated value of relay: 250VAC, 5A;

07).Operation environment:-10~+50℃,80%RH;

08).Power supply: 85~265VAC;

09).Continuous working time: long period;

10).Aperture size: 90×90×110(mm).

3

www.euroheaters.com

Outside and structural dimensions

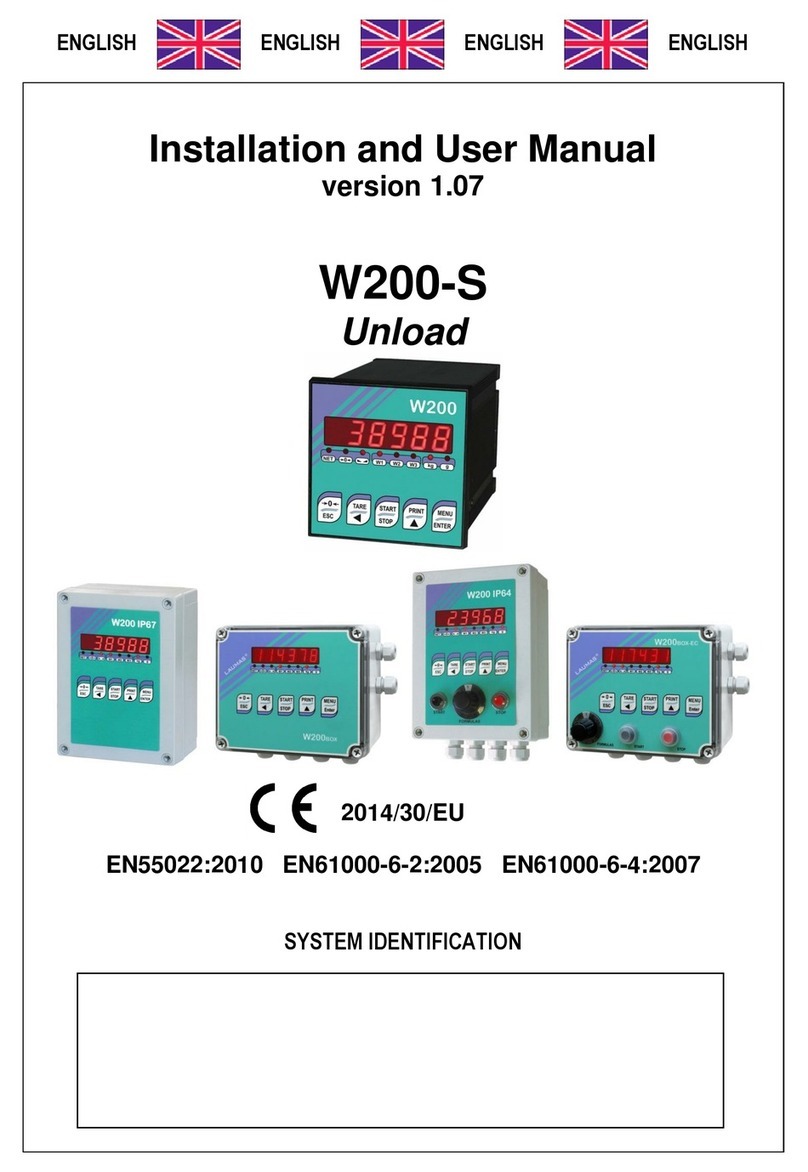

Display Window

Upper display window: displays measured value of actual pressure as well as parameter codes when

modifying internal parameters.

Lower display window: displays measured value of actual pressure as well as parameter amended

when modifying internal parameters.

Function Keyboard

AC: Reset zero key: (if pressed with switch key simultaneously, reset; press AC key for more than

5 seconds and zero, i.e. zero in calibration, can be recovered;

Cal: Calibration key: if pressed with switch key simultaneously, calibration can be done automatically.

Conversion key

Shift key

Down key

Up key

Signal Lamp

AL1: Alarm signal lamp for pressure upper limit

AL2: Alarm signal lamp for pressure lower limit

Cal: Signal lamp for calibration state (if calibration done automatically, the lamp flashes)

Diagram of installation dimensions

Methods of Use

●Connection of instrument with pressure transducer:

Connection for transducer plugs is as follows: (numerically marked plugs are of Type I alphabetically

marked plugs are of Type II. Please give clear indication if order)

1. A……………S+Positivesignal(blue)

2. B……………E+Negativebridge pressure(red)

3. C……………S-Negativesignal(yellow)

4. D.E…………E-Negativebridge pressure(white)

5. F……………C Calibration (green)

Connect all leads with the connection terminal at the back of temperature and pressure gauge (there

are signs on connection terminal) and earth the shielded wire.

4

www.euroheaters.com

●Connection signs on rear panel of temperature pressure gauge are as follows;

●Switch on;

1

Switch on power supply and the instrument goes through power-on self-test (POST).

Meanwhile, value of pressure measurement range is displayed on upper display window;

2

Value of temperature measurement range is displayed on lower display window. Two

3

seconds later, pressure division value is displayed on upper display window; temperature

4

division value and the code of transducer are displayed on lower display window 5

6

9 S

+

10E

+

11S

-

12E

-

13C

14

●Measuring working state

7

220VAC

8

15

+

16

-

Measured values for pressure on upper and lower display windows respectively. If time drift exists after

being switched on, press AC Clear key consistently and meanwhile, press inconsistently Shift key to clear

current zero. If malfunctioned in zeroing, press AC key for more than 5 seconds and return to zero before

calibration.

●Adjustment state of internal parameters:

a)、Press Shift key for more than 5 seconds in measuring and the system enters into adjustment state of

internal parameters;

b)、Each time the Shift key is pressed, internal parameters are output sequentially. Symbols of internal

parameters are displayed on upper display window and currently set parameter values, lower display

window;

c)、Use Shift key, Up key and Down key to modify currently set parameter values;

d)、Press Shift key to confirm and store newly set values and call the next parameter;

e)、Press Shift key for more than 5 seconds or no key is pressed for more than one minute, the system will

automatically return from the adjustment state of internal parameters back to measuring state; f)、Press AC

key and meanwhile, point press Shift key, pressure zero can be cleared. Press AC key for more than 5

seconds and the actual pressure zero of last calibration can be recovered;

g)

、

Press Calibration key and point press Shift key simultaneously, the system goes to automatic

calibration. Please refer to related section on calibration for system pressure.

5

www.euroheaters.com

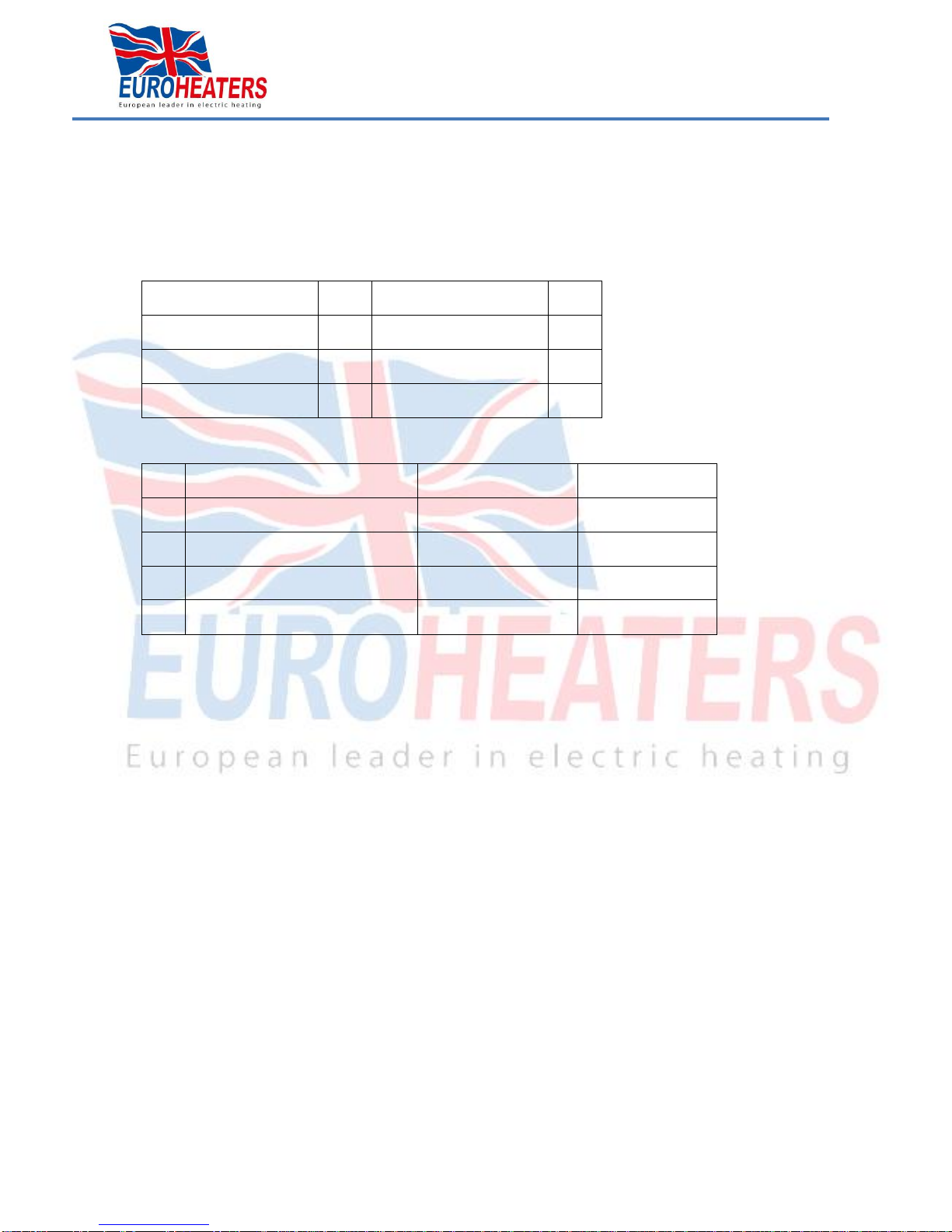

Interior parameter list

Symbol

name

Enactment range

explain

Ex-factory initial value

measurement

range

10.00MPa~100.0MPa

Pressure measurement rating

supplementary

transdu

cer measurement range

Pressure

division value

0.01MPa

0.02MPa

0.05MPa

The least solution Of Pressure

Measurement

Rating

recommended:

0-20Mpadv setup 0.01

0.02MPa

Pressure upper

limit

00.00~99.99MPa

Set up the alarm value of

pressure upper limit

REN80%

Pressure alarm

difference

0~2.00MPa

Setup for Pressure

alarm difference

0.00MPa

Temperature

upper limit

Temperature 0~

measurement range

Set up the alarm value

of temperature upper limit

80% of

temperature

measurement

range

Digital lock

0000: can modify parameter.

The panel keys are available.

0001: can modify parameter.

The panel

keys are unavailable but

conversion key.

The panel keys and all

parameters can be locked up

through the setup of digital lock

0000

Orders explain: please order according to the explain as follows

The basic product: Temperaturepressure gauge

Type:EUROB1016

Function

Explain for functions

1

、double deck four-digit pipe display the actual value of

pressure and temperature separately

4、choice for measurement range panel

2、relay output(pressure and temperature upper limit)

5、choice for least resolution

3、automatically calibration system

6、parameter setup and lockup function

Pressure measurement range

measurement range

number

measurement range

number

0~10MPa

010

0~40MPa

040

0~15MPa

015

0~50MPa

050

0~20MPa

020

0~60MPa

060

0~25MPa

025

0~70MPa

070

0~30MPa

030

0~80MPa

080

0~35MPa

035

0~100MPa

100

6

www.euroheaters.com

Pressure output:Direct ratio with temperature and pressure, and recorders and PID adjustors can use it.

Output format

number

Output format

number

No output

200

0~10mA(maximum6V)

203

0~5V(maximum 20mV)

201

0~20mA(maximum6V)

204

1~5V(maximum 20mV)

202

4~20mA(maximum6V)

205

Alarm

figure

The first digit

The second digit

The third digit

0

No alarm

No alarm output

No alarm signal lamp

1

Pressure upper limit

Relay output

LBD signal lamp

2

Temperature upper limit

Controlled silicon output

3

Pressure and temperature upper limit

Voltage pulse output

Note: If the number of the item is 311, the first digit expresses the alarm of Pressure and temperature upper

limit; the second digit expresses relay switch output; and the third digit expresses LBD signal lamp.

Controlled silicon two-end output 600V/5∧

Order format:

EUROB1016 –[Pressure range code] –[Output signal code] –[Alarm parameters]

Example:

EUROB1016-050-205-311-J

Pressure range of 0 ~ 50 Mpa, the output signal to 4 ~ 20 mA, alarm parameters for 311.

Self-calibration for system zero pressure: connect high-temperature fusion pressure transducer with

EUROB1016 intelligent temperature & pressure gauge according to operation manual. Properly connect 220

V AC power supply. Press

‘cal’

key and point press Shift key simultaneously after system POST, and then

the system starts fully automatic self-calibration. Calibration lamp starts flashing. Press Shift key all the

time during calibration until calibration is completed and the system returns automatically back to working

state.

Caution: System must be unlocked before self-test, i.e. set LCK parameter in internal parameter list to

7

www.euroheaters.com

zero. Otherwise there will be no response when pressing

‘cal’

key and Shift key. This function is to prevent

on-the-spot operators from Misoperation. Parameter for measurement range RN can either be set before

self-calibration or after that. Zero pressure must be ensured for induction head of transducer when

self-calibrating.

Attentions:

1

.

Transducer head must be free from collision and properly screw its protection cap when being

stored;

2

.

The instrument should be kept in humidity-free environment;

3

.

The instrument should work with rated voltage, otherwise it may result in unusual failures;

4

.

The instrument has functioned of temperature zero tracking. Generally, it can zero automatically.

But if temperature drift is so wide that it exceeds the automatic tracking range, press AC key and

point press Shift key simultaneously to calibrate zero pressure. If zeroing by accident, press AC

key for more than 5 seconds and zero calibrated in normal temperature is recovered.

Maintenance:

1

.

Numerical display

’88.88’

or ‘--‘indicates broken transducer leads or improper contact. Connect

properly.

2

.

No numbers displayed: check if 220 V AC power is connected. If not, check if there is output

from switch power supply.

3

.

Unstable numbers displayed: generally, it means that ground wire is improperly connected with

ground. Connect shielded wire properly with ground.

4

.

If major failures occur due to misoperation in connecting wires by clients, please contact us for

replacement of parts such as power board, CPU board, or display panel.

5

.

If repair work is beyond

customers’

capability, please directly send to us. We ensure one-year

responsibility of repair and life-long maintenance.

6.

Ex-factory supplementary components

Serial

number

name

unit

Quantity

remark

1

EUROB1016 Intelligent Temperature

Pressure

Gauge

set

1

2

Transducer

piece

1

In term of

the

customer’s

request

3

Cable

wire

Meter

3

One end with socket

4

Installation frame

piece

2

5

Operation Manual

sheet

1

6

Pass certificate

sheet

1

Table of contents