EuroPower EP10000E H/MA User manual

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 1 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

EP10000E H/MA –EP12000TE-IP54 H/So

EP12000TE-IP54 H/GTS–EP13500TE H/S

EP12000E H/S –EP16000TE H/S

EP14000E H/S –EP18000TE H/S

Content:

0. INTRODUCTION

1. SAFETY INSTRUCTIONS

2. CE-MARK, NOISE LABEL AND PICTOGRAMS

3. SHORT DESCRIPTION OF THE GENERATING SET

4. DESCRIPTION OF THE CONTROL PANEL

5. USE OF THE GENERATING SET

6. INCORPORATION OF THE GENERATING SET

7. PARTS LIST

8. ELECTRICAL SCHEMES

9. BUILDING-IN DIMENSIONS

10.MAINTENANCE

11.TRANSPORT AND STORAGE

ORIGINAL INSTRUCTION MANUAL

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 2 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

0. INTRODUCTION

Please read this manual carefully before using the generating set. If you

act as stated in this manual, your generating set will guarantee you a

smooth functioning for years.

First read the engine and alternator manual. These manuals are supplied

with each generating set and explain the use, the maintenance and the

dangers in case of improper use.

If you have any questions concerning your generating set, please contact

EUROPOWER Generators through www.europowergenerators.com.

All data in this manual are based on the standard versions of the EP10000E

–EP12000TE-IP54 - EP13500TE with Honda GX630 engine, EP12000E - EP16000TE

with Honda GX690 engine and EP14000E –EP18000TE with Honda iGX800 engine.

Generating sets with options can have slightly different data. Contact your

dealer for more information.

1. SAFETY INSTRUCTIONS

•Read and understand the owner’s manual before using the generator,

opening it or working on it. This can prevent personal injury or

equipment damage. When this manual is not 100% clear to you, please

consult an authorised dealer.

•Place the generator on a levelled surface.

When the generator is tilted, fuel spillage may result.

Place the generator, when in use, at least 1m away from buildings or

other equipments.

Keep children and pets away from the generator when it is in

operation.

•Gasoline is extremely flammable and explosive under certain

conditions.

Refuel only in a well-ventilated area with the engine stopped.

Do not smoke or allow flames or sparks in the area where the engine

is refuelled or where gasoline is stored.

Wipe up spilled fuel at once.

Avoid repeated or prolonged contact with skin or breathing of vapour.

•If you decide to use a gasoline containing alcohol (gasohol), be sure

its octane rating is at least as high as that recommended by

EUROPOWER. There are two types of ‘gasohol’: one containing ethanol,

and the other containing methanol. Do not use gasohol that contains

more than 10% ethanol.

Do not use gasoline containing methanol (methyl or wood alcohol) that

does not also contain cosolvents and corrosion inhibitors for

methanol. Never use gasoline containing more than 5% methanol, even

if it has cosolvents and corrosion inhibitors.

•Fuel system damage or engine performance problems resulting from the

use of fuels that contain alcohol is not covered by the warranty.

EUROPOWER cannot endorse the use of fuels containing methanol since

evidence of their suitability is as yet incomplete.

Before buying fuel from an unfamiliar station, try to find out if the

fuel contains alcohol. If it does, confirm the type and percentage of

alcohol used. If you notice any undesirable operating symptoms while

using a gasoline that contains alcohol, or one that you think

contains alcohol, switch to a gasoline of which you know that it does

not contain alcohol.

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 3 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

•Use automotive gasoline with a pump octane number of 86 or higher, or

a research octane number of 91 or higher. Unleaded gasoline is

preferred to minimize combustion chamber deposits.

•It is allowed to use the generating set in the rain (according to

EN60529-protection class IP23). This means that the generating set

can support water in the form of rain till max. 60° in respect of the

perpendicular line. Do not use the generating set in the snow. Only

use it in spaces where there is no explosion hazard.

•The generator is a potential source of electrical shocks when

misused. Do not operate the generator with wet hands.

•Connections for standby power to a building’s electrical system must

be made by a qualified electrician and must comply with all

applicable laws and electrical codes.

Never connect the generating set to the public mains or any other

electrical power source! Improper connections can allow electrical

current from the generator to back feed into the utility lines. Such

back feed may electrocute utility company workers, and when utility

power is restored,

the generator may explode, burn or cause fires in the building’s

electrical system.

•The muffler becomes very hot during operation and remains hot for a

while after stopping the engine.

Be careful not to touch the muffler while it is still hot.

Let the engine cool down before storing the generator indoors.

To prevent scalding, pay attention to the warning marks attached to

the generator.

•Keep in mind the maximum weight a person is allowed to carry if you

move the generating set by hand.

•Make sure the generator operates in a well-ventilated room. In case of

insufficient cooling and/or ventilation severe damage can occur.

Exhaust gases also contain poisonous carbon monoxide.

•Never use the generator when the cover plates are removed from the

engine or alternator.

•Do not wear loose clothes near the generator.

•Let maintenance be carried out by trained technicians only. For example,

according to art. 233 of the Belgian AREI –General Regulation on

Electrical Installations - this means that maintenance can only be

carried out by “warned persons” (code BA4) or “authorised persons”

(code BA5).

If local rules differ, the most rigid of both rules should be followed.

•Never work on the generator while it is still running.

•Never connect appliances that need more power than the generator can

provide. This could seriously damage the generator.

•Be very careful while using a welder on any type of generator. Welders

might damage the alternator. Always consult a EUROPOWER specialist

first to make sure that the power of the generating set matches the

requested power of the welder.

•If the appliance you want to connect is of an electronic kind

(computer, radio, TV, plastic welder, …), always consult a EUROPOWER

specialist first. Such appliances might not work or even break down

in combination with some alternators. Alternators with a low harmonic

distortion are best suited for connection of electronic appliances.

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 4 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

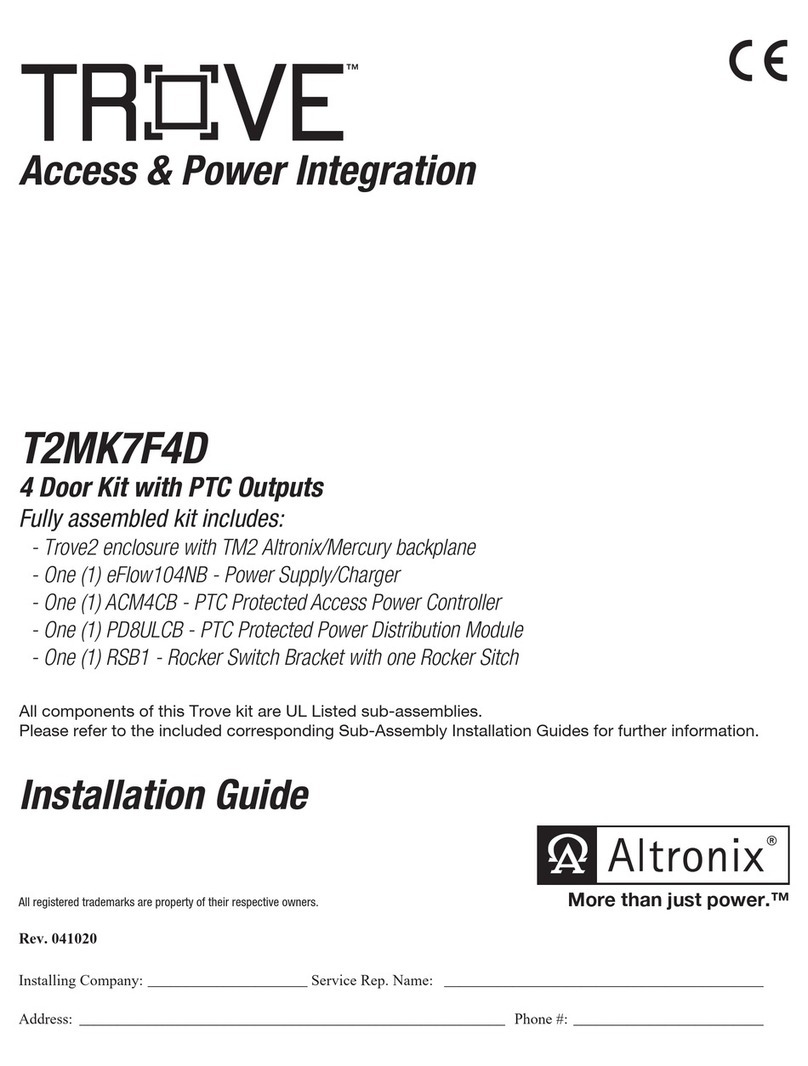

2. CE-MARK, NOISE LABEL AND PICTOGRAMS

2.1. CE-marking and noise label:

These are examples of a EUROPOWER type indication plate and a noise label.

The type indication plate can be found on every generator. The noise label

only appears on generators that comply with the European standard

2000/14/EC. More information on this can be found in the EUROPOWER

documentation or on our web site www.europowergenerators.com.

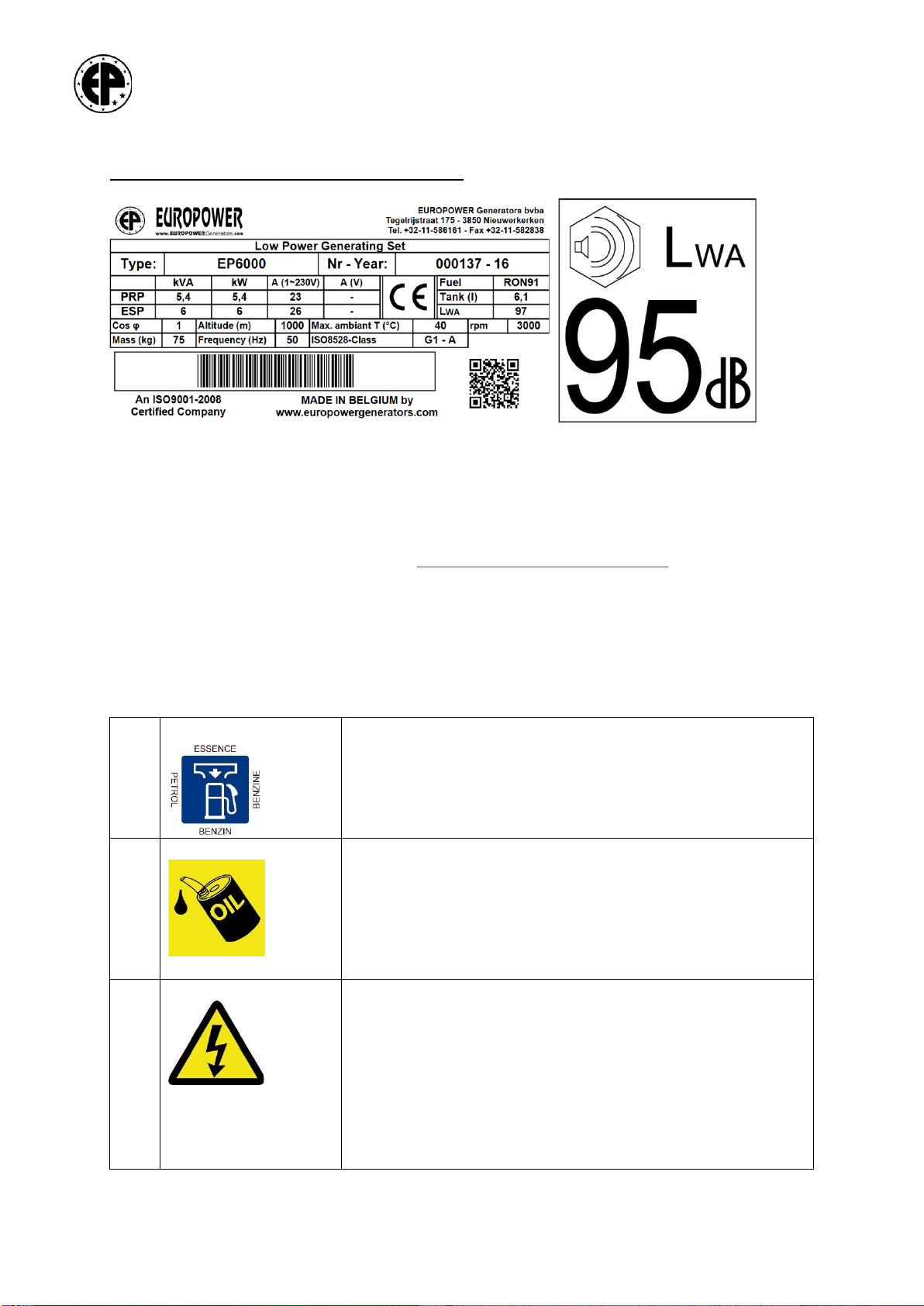

2.2. Pictograms:

Some of these pictograms are typical for a certain option or special type

of generating set. Therefore, not all pictograms necessarily appear on the

standard generating set.

EP_B

(1)

-

Here you can fill the tank with fuel. Remove the fuel filler cap and

check the fuel level. Refuel carefully to avoid fuel spillage. Do not

fill the tank to the top. You might have to lower the fuel level,

depending on operating conditions. After refuelling, reinstall the

fuel filler cap and tighten it securely. Spilled fuel causes

environmental damage. Wipe up spilled gasoline at once.

(4)

-

Here you can fill the oil by loosening the oil filler cap or dipstick.

Fill carefully to avoid oil spillage. Spilled oil should be wiped up

immediately in a correct and environmentally friendly way.

Respect the local regulations. Do not pour oil into the ground or

down the drain.

(11)

-

WARNING! –Electric shock hazard.

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 5 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

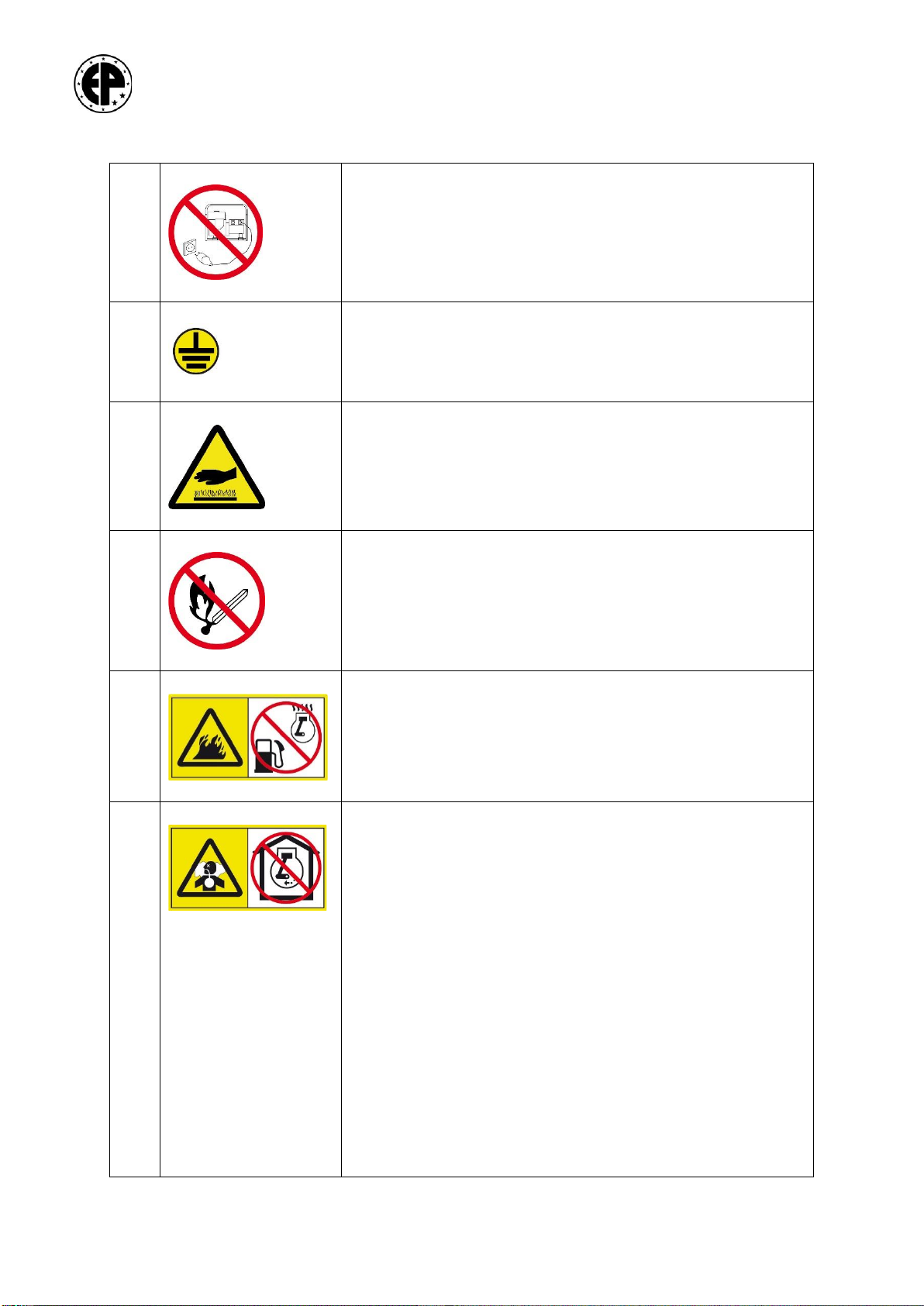

(12)

-

Never connect the generator to an installation which is also

connected to a public mains. Improper connections can allow

electrical current from the generator to back feed into the utility

lines.

Such back feed may electrocute utility company workers, and

when utility power is restored, the generator may explode, burn or

cause fires in the building’s electrical systems.

(13)

-

Here an earth pin can be connected. Follow the instructions in

this manual concerning the use of an earth pin.

(22)

-

WARNING! –Hot surface. Can cause burns. Hot engine and hot

exhaust system can cause serious and even lethal injuries. Never

work on the generating set before it has sufficiently cooled down.

(23)

-

Do not smoke nor allow sparks or flames near the generating set,

the fuel pipe, the fuel filter, the fuel pump or other possible

sources of spilled fuel or fuel vapours.

(24)

-

Fuel is highly flammable and explosive and you can be burnt or

seriously injured when refuelling. Turn the engine off and let it cool

down before refuelling.

(25)

-

The engine‘s exhaust gases contain poisonous carbon monoxide.

You can be killed or seriously hurt. Do not run the engine in a

closed environment. The exhaust system should be leak-tight and

it should be inspected regularly.

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 6 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

(27)

-

Only use a hoist according to local safety regulations.

Never allow sharp bends in lifting cables and chains.

It is strictly forbidden to dwell or stay in the risk zone under a lifted

load. Never lift the unit over people or residential areas. Never

leave a load hanging on a hoist. Lifting acceleration and

retardation shall be kept within safe limits.

To lift heavy parts, a hoist of ample capacity, tested and approved

according to local safety regulations, shall be used.

Lifting hooks, eyes, shackles, etc. shall never be bent and shall

only have stress in line with their design load axis.

The capacity of a lifting device diminishes when the lifting force is

applied at an angle to its load axis.

For maximum safety and efficiency of the lifting apparatus all

lifting members shall be applied as near to perpendicular as

possible.

A hoist has to be installed in such a way that the object will be

lifted perpendicular.

If that is not possible, the necessary precautions must be taken to

prevent load-swinging, e.g. by using two hoists, each at

approximately the same angle not exceeding 30° from the vertical.

(28)

-

WARNING! –Consult the instruction and maintenance manual of

the engine and the alternator before carrying out maintenance.

Improper maintenance, or failure to correct a problem before

operation, can cause a malfunction in which you can be seriously

hurt or killed.

Always follow the inspection and maintenance recommendations

and schedules mentioned in the instruction and maintenance

manual of the engine and the alternator.

3. SHORT DESCRIPTION OF THE GENERATING SET

Type: EP10000E H/MA: 10 kVA max. / 9 kVA cont. –39 A 1x230 V

Type: EP13500TE H/S: 13.5 kVA max. / 12 kVA cont. –20 A 1x230 V / 14 A

3x400 V

Type: EP12000TE-IP54 H/So: 12.5kVA max. / 11kVA cont. - 17A 1x230V / 13A

3x400V

Type: EP12000TE-IP54 H/GTS: 12.5kVA max. / 11kVA cont. - 23A 1x230V / 13A

3x400V

Type: EP12000E H/S: 12 kVA max. / 10.8 kVA cont. –47 A 1x230 V

Type: EP16000TE H/S: 16 kVA max. / 14.4 kVA cont. –23 A 1x230 V / 16 A

3x400 V

Type: EP14000E H/S: 13.5 kVA max. / 12 kVA cont.–52A 1x230V

Type: EP18000TE H/S: 17.5 kVA max. / 16 kVA cont.–23A 1x230V / 18A

3x400V

Weight:

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 7 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

- EP10000E H/MA: 146 kg, EP12000TE-IP54: 148 kg, EP13500TE H/S: 149 kg

- EP12000E H/S: 150 kg, EP16000TE H/S: 155 kg

- EP14000E H/S: 162 kg, EP18000TE H/S: 165 kg

All TYPES:

Frequency: 50 Hz

Engine:

- EP10000E-EP12000TE-IP54-EP13500TE:

HONDA GX630, 2 cylinder, 688 cm³, 3000 rpm, air-cooled

- EP12000E-EP16000TE:

HONDA GX690, 2 cylinder, 688 cm³, 3000 rpm, air-cooled

-EP14000E-EP18000TE:

HONDA iGX800, 2 cylinder, 779 cm³, 3000 rpm, air-cooled, injection

Fuel tank: 20 litres

Dimensions: L = 102cm (83cm without tank), W = 55cm, H = 60cm

Noise level:

EP10000E/EP13500TE/EP12000TE/EP12000E/EP16000TE: LwA100

EP14000E/EP18000TE: LwA 101

This generating set does not comply with the European Noise Directive

2000/14/EG: see also “Mounting instructions” to be found with “Declaration

of Incorporation according to 2006/42/EG”.

The main components of the generating set are: GX630/GX690/iGX800 air-

cooled gasoline engine (3000rpm) with starting control panel, the

alternator, the alternator control panel, the fuel tank and the frame.

For engine and alternator specifications we refer to the engine and

alternator manual supplied with each generating set.

Specifications for the control panel can be found in chapter 4.

4. DESCRIPTION OF THE CONTROL PANEL

The engine control panel contains:

-Starting key

-Hour counter

-Low oil level LED

(For EP14000E and EP18000TE, the LED functions also as an Error

Indication, see also the engine manual for more information)

-Choke knob (not for EP14000E and EP18000TE)

-Fuse(s):

oOnly for EP10000E/EP13500TE/EP12000TE/EP12000E/EP16000TE:

▪30A fuse (12V circuit protection - inside the engine

control panel)

oOnly for EP14000E and EP18000TE (the fuses are on the side of

the engine, next to the oil dipstick)

▪30A fuse (load current)

▪15A fuse (main)

-Throttle lever (only for EP10000E, EP12000TE-IP54 and EP13500TE)

The alternator control panel contains:

-Thermal-magnetic breaker

-2 sockets

-A.I.S.-module (Automatic Idle System) (only for EP12000E, EP16000TE,

EP14000E and EP18000TE)

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 8 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

-Switch A.I.S. OFF / ON (only for EP12000E, EP16000TE, EP14000E and

EP18000TE).

5. USE OF THE GENERATING SET

-Operating points: 2 sockets with thermal-magnetic protection, A.I.S.

switch (only for EP12000E, EP16000TE, EP14000E and EP18000TE),

starting key, choke knob and throttle lever (only for EP10000E,

EP12000TE-IP54 and EP13500TE).

5.1. Starting the engine:

-check the oil level

-check the fuel level

-open the fuel cock

OPEN

-pull the choke button when the engine is cold (not for EP14000E and

EP18000TE)

-move the throttle lever to the MAX. position (only for EP10000E,

EP12000TE-IP54 and EP13500TE)

-switch A.I.S. OFF (only for EP12000E, EP16000TE, EP14000E and

EP18000TE)

-first put the starting key in the position “ON” (initiation injection

system) (only for EP14000E and EP18000TE)

-start the engine with the starting key

-close the choke slowly after a few seconds (not for EP14000E and

EP18000TE)

-let the engine warm up for a few minutes before charging

-as soon as the generating set has been started you can turn on the

A.I.S. system (= switch in the ON position, only for EP12000E,

EP16000TE, EP14000E and EP18000TE)

-connect the users.

5.2. Charging the generating set:

-on the type indication plate of the generating set you can find the

maximum charging current of the generating set

-in case of overcharge, the thermal-magnetic protection in the control

panel will switch off after some time. Check the load, reduce it if

necessary and switch on the thermal-magnetic protection again

-in case of short-circuit, the thermal-magnetic protection will switch

off immediately! First check the cause of the short-circuit and then

switch on the protection again.

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 9 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

5.3. Stopping the generating set:

-let the generating set cool down at no load for a few minutes before

stopping the engine

-stop the engine with the starting key

close the fuel cock.

CLOSE

5.4. Automatic Idle System (only for EP12000E, EP16000TE, EP14000E and

EP18000TE):

-to switch on the A.I.S. system you have to turn the switch to the ON

position

-the generating set will automatically turn to a reduced speed (2300

200rpm for GX690 and 2000 rpm for iGX800) when there is no load

connected, or when the load has been removed. When a minimum load

(100 to 200W) is connected it will return to its nominal speed

(3000rpm).

Note:

-it can happen that the A.I.S. function does not react on some small

(electronic) charges. When this occurs, turn off the A.I.S. system by

turning the switch to OFF position

-“OFF DELAY” is set at 60 sec (-25% + 50%).: this means that the

engine will automatically turn to a reduced speed +/- 60 sec after

switching off the charge. This is to prevent excessive ON/OFF

switching of the engine.

-the “OFF DELAY”-regulator is sealed. It is forbidden to change this

setting.

5.5. Cooling

-make sure that there are no obstructions at the fresh air intake

grid, which provides cooling air for the engine and the

alternator.

-make sure that the hot cooling air from the engine and the

alternator, as well as the exhaust gasses, can easily be abducted.

-never let the generator run in an inappropriately ventilated room!

(danger of CO poisoning)

5.6. Protections:

-engine: low oil level protection

-alternator: thermal-magnetic protection.

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 10 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

5.7. Maintenance (see also chapter 10):

All maintenance points (air cleaner, oil level dipstick, oil drain

bolt, oil filler cap, oil filter, fuel filter, valves, spark plugs) are

very good accessible. For normal maintenance activities, check the

engine manual. For engine or alternator repair, consult your dealer.

5.8. Safety for the users:

The standard version of the generating sets EP10000E –EP12000TE-IP54 -

EP13500TE - EP12000E - EP16000TE - EP14000E –EP18000TE are connected

following the IU electrical scheme. This means that for connection of

charges class 1 (charges with earth) there is a maximum of 1 charge

only, and for charges class 2 (charges with double insulation, to be

recognized by the “double square” pictogram on the machine) there is no

limitation in the quantity of charges connected at the same time on the

generating set. Contact your distributor for details on the above

subject.

Still you have to respect the minimum square (mm²) and maximum length

of the cables you are using (to assure the correct switching off of the

thermal-magnetic protection in case of short-circuit).

Insulation protection or earth leakage protection are available as an

option.

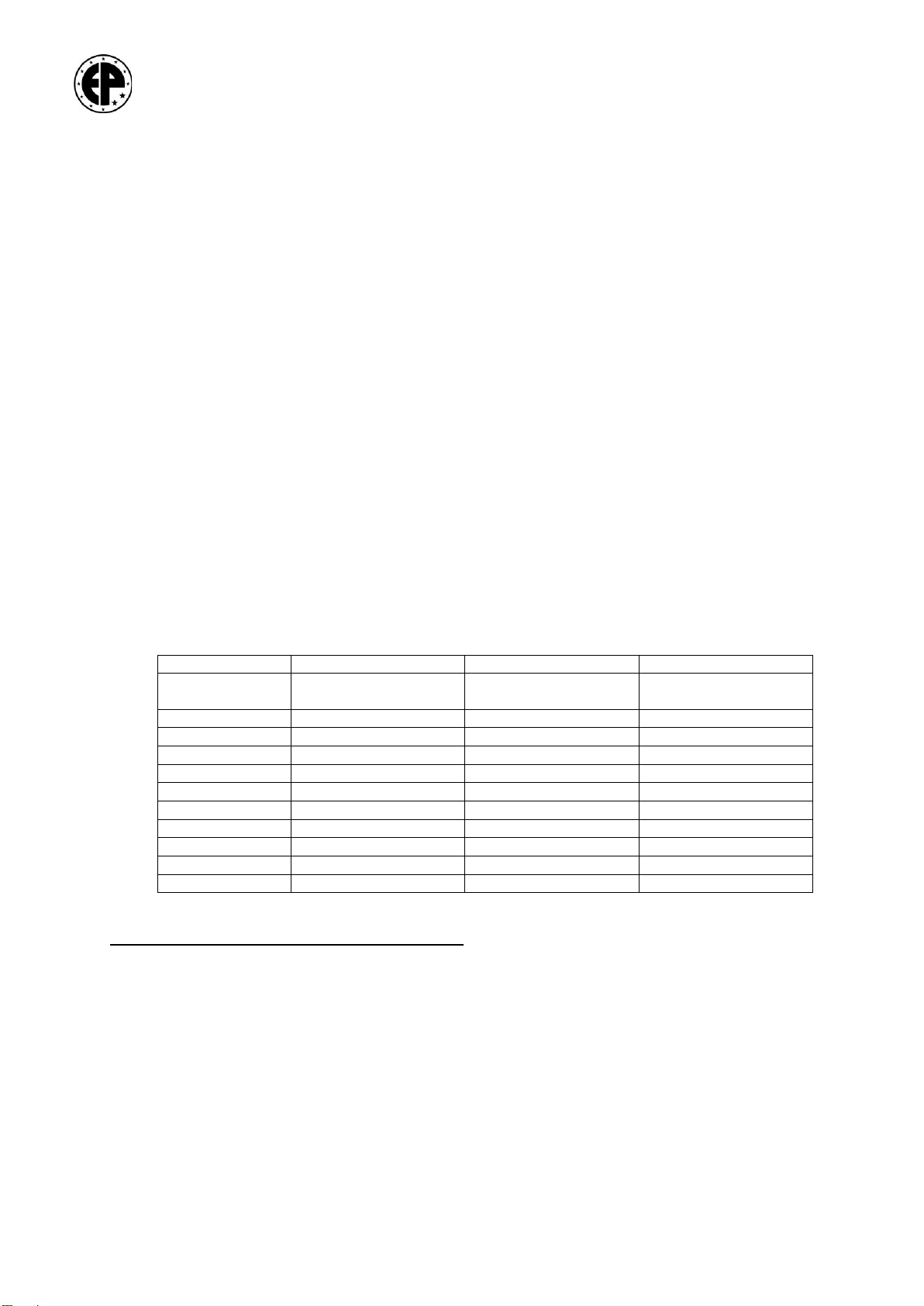

Table: of minimum cable section (in mm²) and maximum cable length (in

m) in function of the current (in A)

Cable length

Cable length

Cable length

Current in A

0 to 50 metres

> 50 to 100

metres

> 100 to 150

metres

6

1.5mm²

1.5mm²

2.5mm²

8

1.5mm²

2.5mm²

4mm²

10

2.5mm²

4mm²

6mm²

12

2.5mm²

6mm²

10mm²

16

2.5mm²

10mm²

10mm²

18

4mm²

10mm²

10mm²

24

4mm²

10mm²

16mm²

26

6mm²

16mm²

16mm²

36

6mm²

25mm²

25mm²

50

10mm²

25mm²

35mm²

6. INCORPORATION OF THE GENERATING SET

Consult your EUROPOWER dealer or EUROPOWER Generators.

See the “Mounting instructions” to be found with “Declaration of

Incorporation according to 2006/42/EG” for generating sets that do not have

the EC Declaration of Conformity IIA.

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 11 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

7. PARTS LIST

This parts list is based on the standard versions of the EP10000E –

EP12000TE-IP54 - EP13500TE - EP12000E –EP16000TE - EP14000E –EP18000TE

generating set. For generating sets with options (e.g. insulation

protection, remote control, automatic start/stop system…) there can be

small differences! Please contact your dealer for info on parts for these

options.

Art. nr. Description

7.1. GENERATING SET

120000050 silent-bloc A 50/40 M1028 (alternator)

120001043 silent-bloc B 40/30 M823 (engine)

170000000 battery 12V 24 Ah

170000026 protection battery clamp (black)

199000058 support high box RI 300200120

199000090 cap for jerrycan

199000096 jerrycan 20 litres

199000098 frame for jerrycan

202000010 S20F-200/A 12kVA 230V Mecc-Alte alternator (EP10000E)

217000012 FK2MFS 12 kVA 230V Sincro alternator (EP12000E)

217000014 FK2MGS 13.5kVA 230V Sincro alternator (EP14000E)

217000113 FT2MES 13.5kVA 230/400V Sincro alternator (EP13500TE)

217000116 FT2MFS 16kVA Sincro alternator (EP16000TE)

217000118 FT2MGS 18kVA 230/400V Sincro alternator (EP18000TE)

217714139 SSG132LA2-R IP54 AVR 12kVA 230/400V SAEJ609B 3000tpm

(EP12000TE-IP54-So)

218000112 DWG 12,5/6-2EE IP54 12,5/6kVA 230/400V GTS alternator

(EP12000TE-IP54-GTS)

300000221 GX630R VEP4 3000rpm Honda engine (EP10000E–EP12000TE-IP54 –

EP13500TE)

300000251 GX690R VXE4 3000rpm Honda engine (EP12000E–EP16000TE)

300000281 iGX800 VX-E4-OH 3000rpm Honda engine (EP14000E–EP18000TE)

910000018 U-profile Alu 210mm, battery fixation

910000026 rod M6 210mm, battery fixation

910000115 frame type 6

7.2. CONTROL PANEL

175001008 metal box 300200120 mm, IP66

180000000 socket, Schuko type 16A 230V, with lateral earth pins

180000001 socket, Schuko type 16A 230V, with central earth pin

181000000 terminal 6mm² (EP12000E-EP12000TE-IP54 -EP13500TE-EP16000TE-

EP14000E-EP18000TE)

181000004 terminal 6mm², earthed (EP12000E-EP12000TE-IP54 -EP13500TE-

EP16000TE-EP14000E-EP18000TE)

181000005 terminal 10mm², earthed (EP10000E)

181001016 thermal-magn. protection 2-poles 16A, C-character (EP10000E-

EP12000E-EP14000E)

181001032 thermal-magn. protection 2-poles 32A, C-character (EP10000E-

EP12000E-EP14000E)

181001040 thermal-magn. protection 2-poles 40A, C-character (EP14000E)

181002636 2 position switch –for AIS system (EP12000E-EP16000TE-

EP14000E-EP18000TE)

181002640 normal open contact for 181002636 (EP12000E-EP16000TE-

EP14000E- EP18000TE)

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 12 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

181003013 thermal-magn. protection 3-poles 13A, C-character

(EP12000TE-IP54 -EP13500TE)

181003016 thermal-magn. protection 3-poles 16A, C-character (EP16000TE)

181004020 thermal-magn. protection 4-poles 20A, C-character (EP18000TE)

181030332 CEE socket, blue 3 poles 32A 230V (EP10000E-EP12000E-

EP14000E)

181030516 CEE socket, red 5 poles 16A 400V (EP12000TE-IP54 -EP13500TE-

EP16000TE)

181030532 CEE socket 5 poles 32A 400V (EP18000TE)

390401051 ecologizer unit (A.I.S) (EP12000E–EP16000TE-EP14000E-

EP18000TE)

7.3. MAINTENANCE PARTS

217990050 diode + varistor + condensator (EP12000E)

217990074 brushes with holder FT (with 1 diode bridge)

390700056 brushes with holder FT (with 2 diode bridges)

398000630 air cleaner element GX630/GX690/iGX800

398200630 oil filter GX630/GX690/iGX800

399000030 condensator 30µF (EP12000E)

399000035 condensator 35µF (EP12000E)

A00002000 spark plug GX630/GX690

A00002001 gasoline filter 20µm GX630/GX690

A00002014 valve cover seal GX630/GX690/iGX800

A00002200 spark plug iGX800

A00002201 gasoline filter 10µm iGX800

-brushes DWG12.5/6-2EE (EP12000TE-IP54)

390400012 diode D2/125 25A (EP10000E)

-varistor (EP10000E)

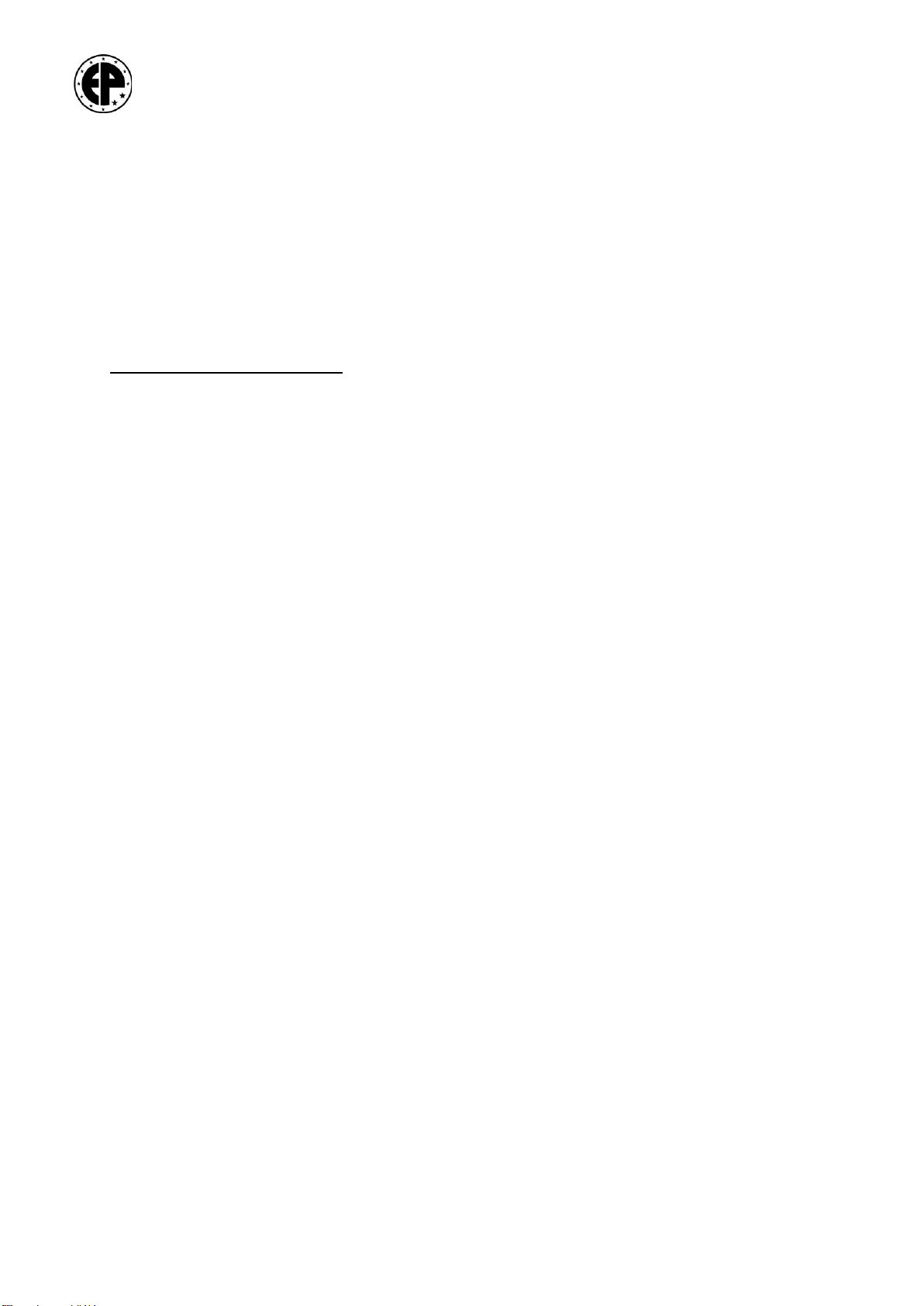

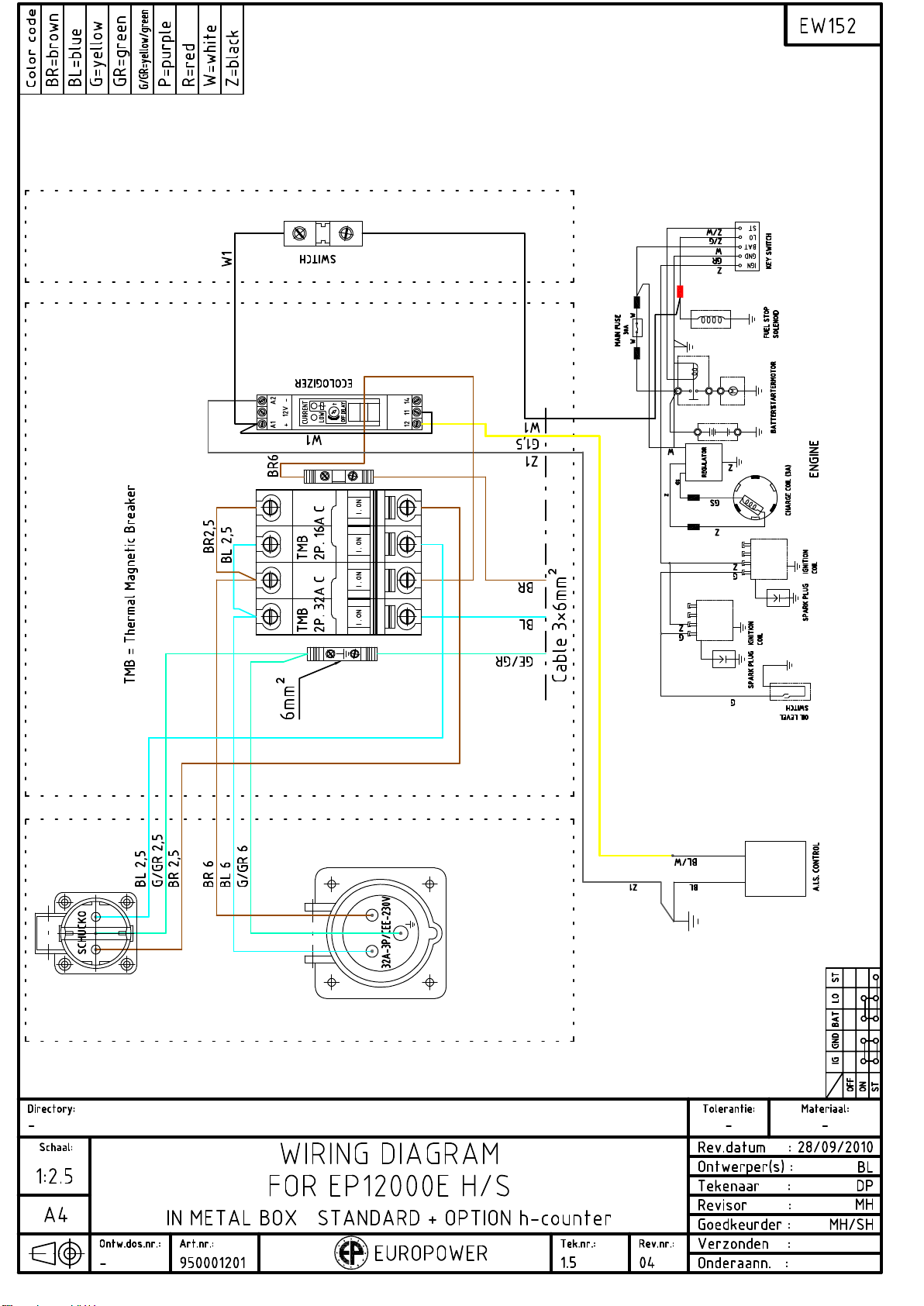

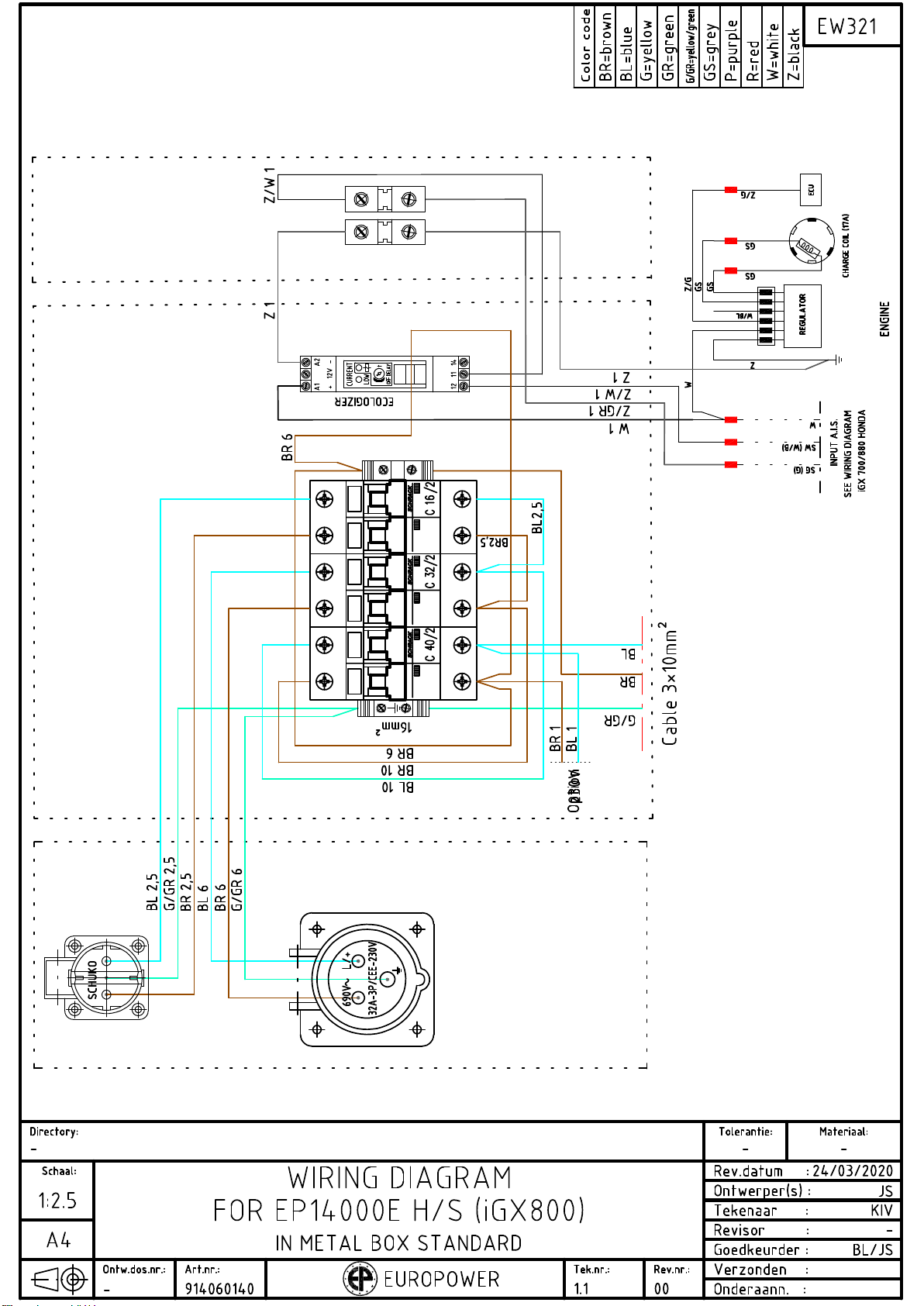

8. ELECTRICAL SCHEMES

See the electrical schemes in the engine and alternator manual and the

enclosed EUROPOWER electrical schemes.

9. BUILDING-IN DIMENSIONS

To be asked at your EUROPOWER dealer.

10. MAINTENANCE

10.1. Alternator:

Alternator: besides regular visual control of the different alternator

parts, the alternator only needs a check of the rotor bearing on every

general engine maintenance.

For the alternators with brushes (EP12000TE-IP54 -EP13500TE-EP16000TE-

EP18000TE): the brushes should be checked at every general engine

maintenance. The expected lifetime of the brushes is 2500 to 3000 hours.

www.EUROPOWERgenerators.com

EP10000E-EP12000TE-IP54-EP13500TE-EP12000E-EP16000TE-

EP14000E-EP18000TE

Pg. 13 / 13

Doc.nr.:0004598

Opsteller: MH Revisie:02 Revisor: BL

Opsteldatum: 15/04/2020 Goedkeurder: GD Revisiedatum: 28/06/2021

10.2. Engine:

See engine manual for maintenance intervals.

Remark: in the factory, the engine has been filled with 15W40 oil (for

temperatures up to -10°C). The minimum specification of this oil has to be

API SJ/CF-4.

If the ambient temperature is lower, 10W30 oil (up to -15°C) or full

synthetic 5W30 oil (up to -25°C) should be used. Here the minimum

specification also has to be API SJ/CF-4.

11. TRANSPORT AND STORAGE

To prevent fuel spillage when transporting or during temporary storage, the

generator should be secured upright in its normal operating position, with

the engine switch in position “OFF”.

When transporting the generators:

•Close the fuel cock

•Do not overfill the tank (there may not be any fuel in the filler

neck).

•Do not use the generator while it is placed in a vehicle.

•Take the generator off the vehicle and use it in a well-ventilated

place.

•When placing the generator in a vehicle, avoid a place exposed to

direct sunlight. When the generator is left in an enclosed vehicle

for a longer period of time, high temperature inside the vehicle

could cause fuel to vaporise resulting in a possible explosion.

•Do not drive on a rough road for an extended period with the

generator on board. If you must transport the generator on a rough

road, drain the fuel from the generator beforehand.

Before storing the unit for an extended period ( > 2 months):

•Make sure the storage area is free of excessive humidity and dust.

•For gasoline generating sets: drain the fuel.

•Turn the fuel cock “ON” (if present), loosen the carburettor drain

screw and drain the gasoline from the carburettor into a suitable

container.

•Turn the fuel cock “OFF” (if present) and tighten the carburettor

drain screw securely.

•WARNING

Gasoline is extremely flammable and explosive under certain

conditions.

Do not smoke or allow flames or sparks in the area.

•Remove the spark plugs and pour about a tablespoon of clean engine

oil into the cylinders. Crank the engine several revolutions to

distribute the oil, then reinstall the spark plugs.

•Reinstall the spark plug caps on the spark plugs securely.

•Refresh the engine oil.

•Remove the battery and connect it to a battery charger. This way you

will increase the life span of the battery.

I1IONTfDA O

lGX 70lr/800 Gontrolbox'rypes wiring diagram

CONTROL BCX -

BLACK

YELLOW

_ BLUE

FI ECU DLC CAN SW SG I

I

!

L

i

I

I

I

t

(wo-sv) DIODE FI RELAY MAIN RELAY

GREEN

RED

WHITE

VIOLET

BROWN

ORANGE

SKY BLIE

LIGHT GREEN

PINK

GRAY

BEIGE

GROUND/MARKING

-l

I

I

I

l

I

I

I

B

L

G

R

w

BR

r. -

ECU J2

(BLACK) ECU J1

(GRAY) HOUR

METER COMN

SW

i.F:

i,'!,El!,'li*;,;lro tiri=tittr:.,io9 ,{,

lii r

??'!2

INDICATOR

IGN

colL 1

S-PLUG 1 BATTERY STARTER FUSE

'l54

o-

SB

LG-_.

P

GR-

.BE

COLOR COMB:

RA r:

w/L:

REG

RECT

R/B

-

Y/B

-

I

I

I

I

I

I

-I Only on engine with SV on control box

Only on engine with Oil level switch

I Not all model have SV wire

OIL PRESS SW

To equipment own warning

17A

!

i

f

IGN

colL 2

l

I

l

I

I

I

L

l

I

i

i

I

l

I

FUSE

30A REG

RECT CHARGE

colL

(17A)

FUSE

404 CHARGE

corL

(26A)

FUEL TMAP TE TH I OIL TEARTH INJ 2 INJ 1 PULSER COIL

PUMP SENSOR SENSOR MOTOR i LEVEL

iSW

,tWO-lrfir iL (26A)

O 2019 Honda Motor Co., Ltd. R0ZCS000

S.PLUG 2

(17A)

This manual suits for next models

7

Table of contents

Other EuroPower Portable Generator manuals

Popular Portable Generator manuals by other brands

Sincro

Sincro EP Series Use and maintenance manual

Impax

Impax IM1500I instruction manual

King Canada

King Canada PowerForce KCG-1501GX instruction manual

SEFRAM

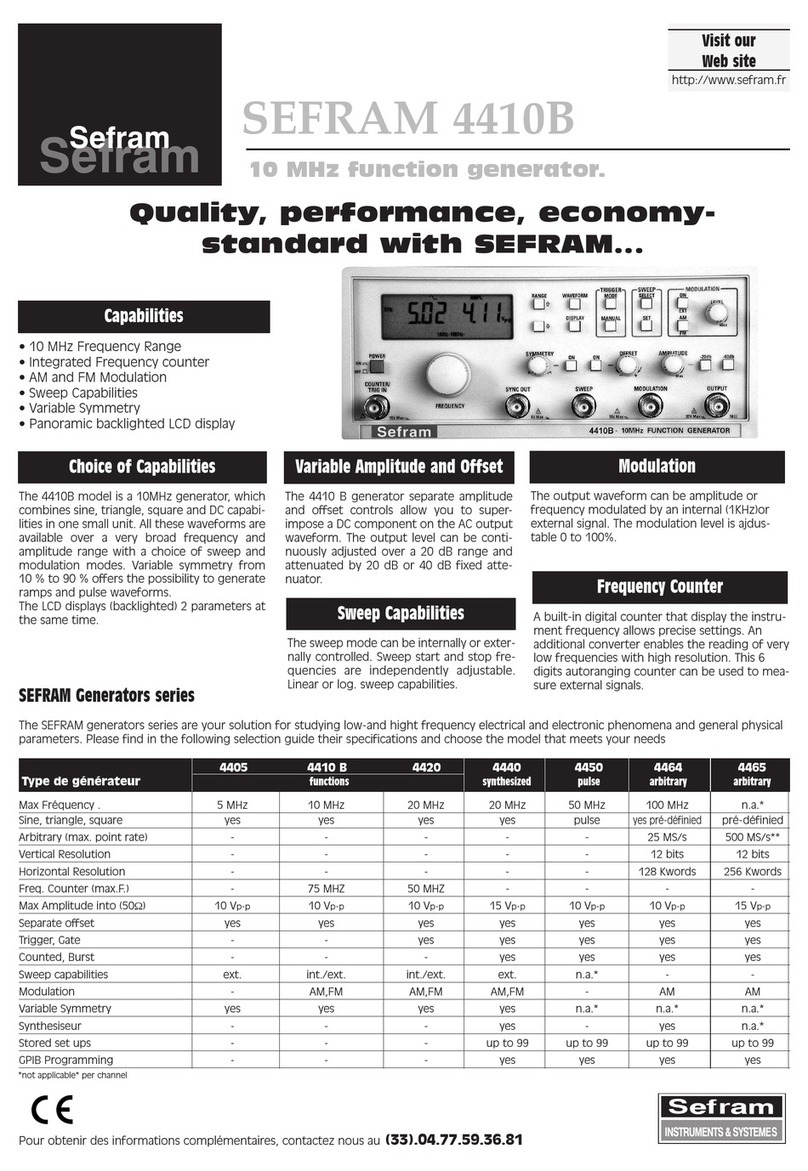

SEFRAM 4410B quick start guide

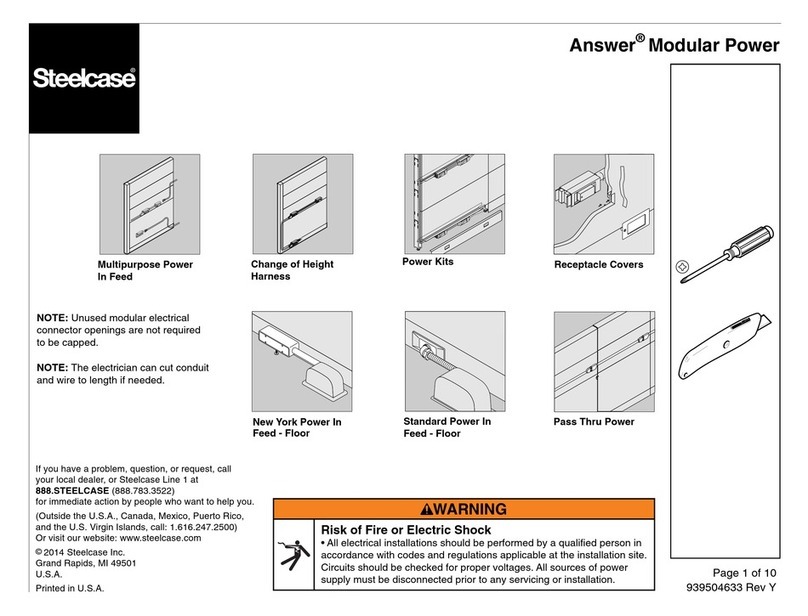

Steelcase

Steelcase Answer Modular Power manual

Generac Portable Products

Generac Portable Products RS5500 owner's manual