User manual - Compact-Pro 60 & 80 202006-438A-ENGP8

3. YOUR MACHINE

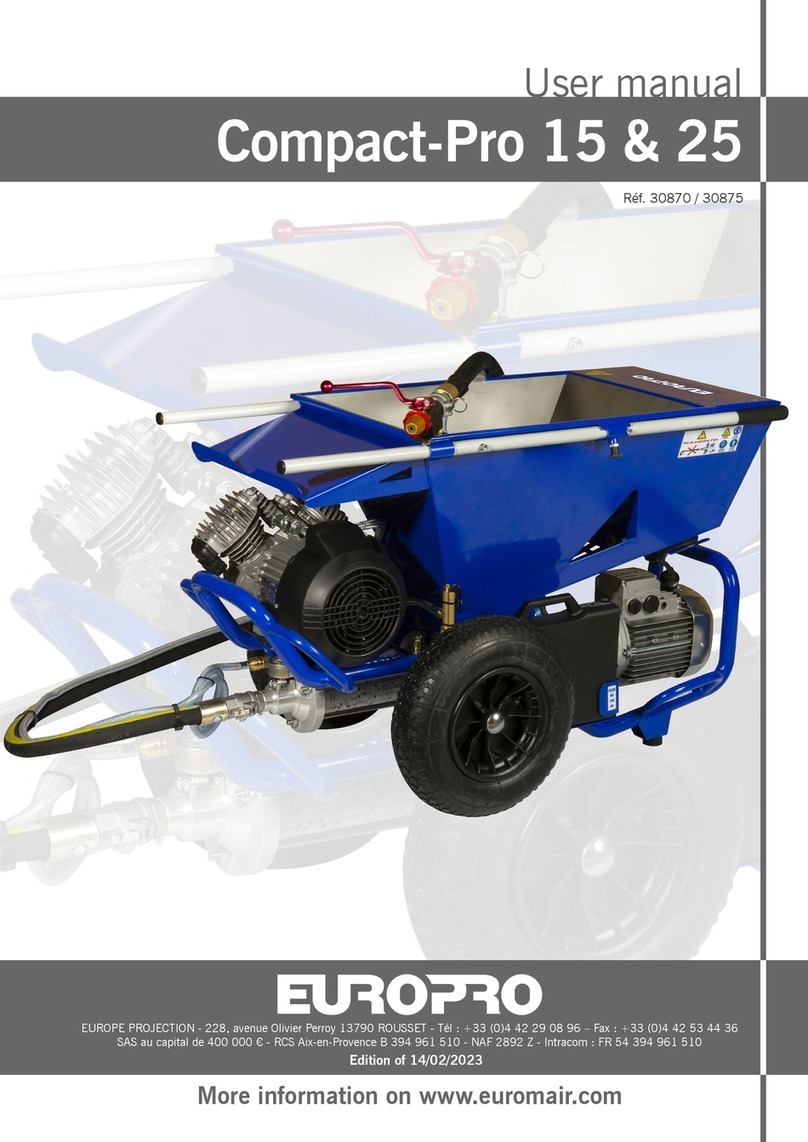

3.1. DESCRIPTION

Compact-Pro 60 and 80 are equipped with a liquid-cooled diesel engine that drives a double gear pump that provides

the hydraulic ows required by the equipment.

The 400 L/min, 4 bar compressor is positioned on a plate for easy adjustment of the drive belt tension.

The screw and mixer rotation drives are driven by two orbital type motors and the hydraulic distribution by industrial

components whose controls are manual. The components have been selected according to strict quality criteria.

The safety devices comply with the standards in place and the hydraulic circuits are protected against possible blockages

of the rotating elements. An air cooler ensures that the oil temperature is maintained within the correct range.

3.2. TECHNICAL CHARACTERISTICS

Compact-Pro 60 Compact-Pro 80

Noise level 101 dB

Motorization

Kohler 3-cylinder liquid-cooled LDW

1003 engine

used at 2500 rpm

Kohler 4-cylinder liquid-cooled LDW

1404 engine

used at 2500 rpm

Electric starting up battery 12V - 50Ah - 400A

Air lter cartridge

Diesel reservoir capacity 25 L

Hydraulic reservoir capacity 28 L

Screw pressure 200 bar

Mixer pressure 150 bar

Washer pressure 150 bar

Lifting jack pressure 60 bar

Mixer

capacity 200 L

hydraulic drive with two directions of rotation

mixer stop safety at grid opening - loading height of 87 cm

Hopper hydraulic drive with two directions of rotation

screw stop safety at the grid opening - drain plug for cleaning

Centralized control panel includes

engine dashboard

starting up of the various functions (pump, mixer, lift)

adjustment of pump and mixer speeds - engine speed adjustment

Compressor with pistons set at 4 bar

Compressor ow-rate 400 L/min

Screw pump

standard : from 0 to 60 L/min max. at

40 bar max.

optional: up to 167 L/min

standard : from 0 to 80 L/min max. at

40 bar max.

optional: up to 200 L/min

High pressure washer 11 L/min at 140 bar

Weight 720 kg

(fuel tank full, oil level done)

735 kg

(fuel tank full, oil level done)

Delivered with

- a MAP 11 pump

- a Ø35 x 13,30 m product hose M50 x F35

- a Ø35 x 13,30 m product hose M35 x F35

- a Ø25 x 5 m hose M35 x M25

- a Ø10 x 33 m air hose

- a spraying lance with eight nozzles (Ø8, 10, 12, 14, 16, 18, 20 & 22)

- three grouting nozzles (Ø10, 12 & 14)

- two Ø30 and two Ø50 cleaning balls

- a greasing pump with a grease cartridge

- a pressure controller with adapter

- a complete high pressure washer lance with a 10 m high pressure washer hose

- a storage carry-case and a suspension strap