2

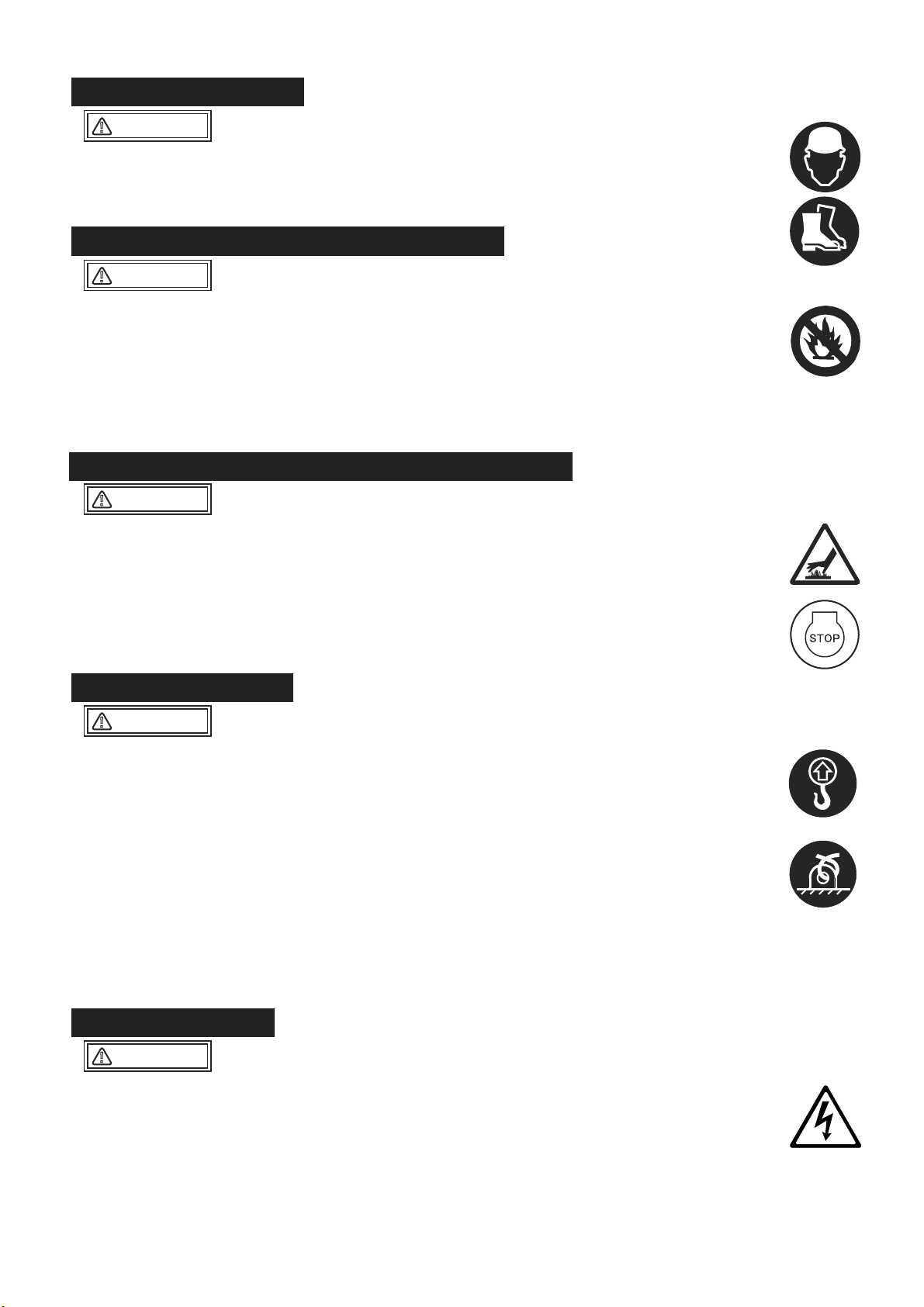

To work safely, wear work clothes of appropriate size, and use suitable protective gear

such as helmet and safety shoes. The work clothes that do not fit the body size might

result in unpredicted injury because the clothes easily get caught by rotating part of the

machine.

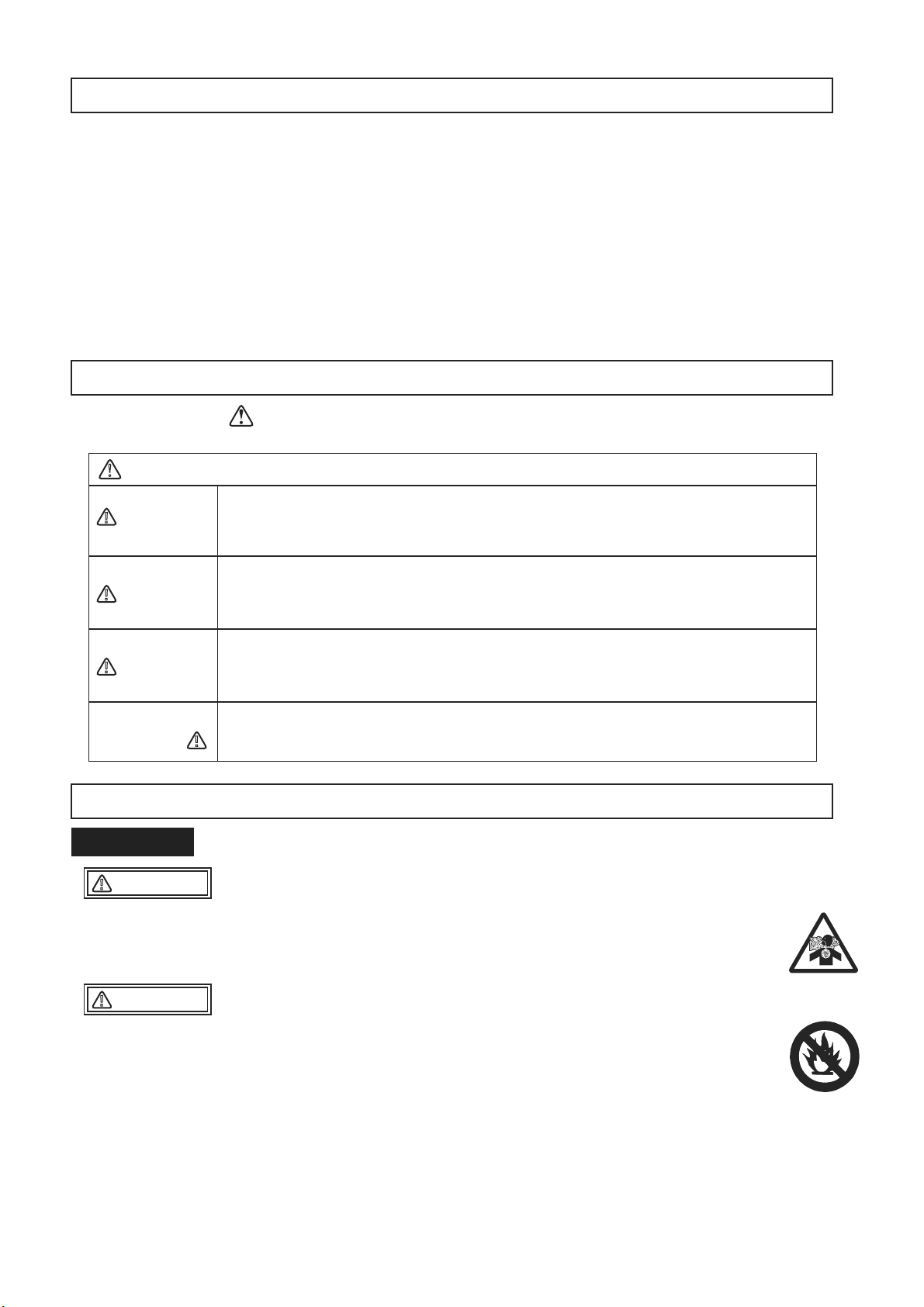

When adding fuel

If fuel is filled to the top, it might overflow, and is dangerous.

After refueling, securely tighten the tank cap.

Start your work after the machine temperature drops. Especially, the muffler gets very

hot, and it will pose a danger of burn accident. Also, engine and engine oil as well as

vibrator become hot. Be careful not to get a burn.

If maintenance work is started with the engine running, injury might occur because you

might get caught by the rotating part such as pulley and V-belt. Always stop the engine

before maintenance.

Before maintenance work, remove the starter key of the engine.

Before starting maintenance, always remove the minus (-) terminal of the battery.

When lifting the machine body and the engine, always use a crane. When lifting the

machine and the engine, follow the cautions listed below. If the machine or the engine

is dropped, a serious accident might occur.

To operate a crane, a crane handling qualification is required. Have someone qualified

to handle and operate a crane do this work.

Before lifting, check the parts (especially, hook and anti-vibration rubber) of this

machine for damage and loosening/lack of bolts to secure safety.

Before lifting, stop the engine and shut the fuel cock.

Use sufficiently strong wire rope.

For lifting, use only the lifting hook. Do not use other part for lifting.

Never allow anyone or any animal come under the lifted machine.

For safety, do not lift to the height more than necessary.

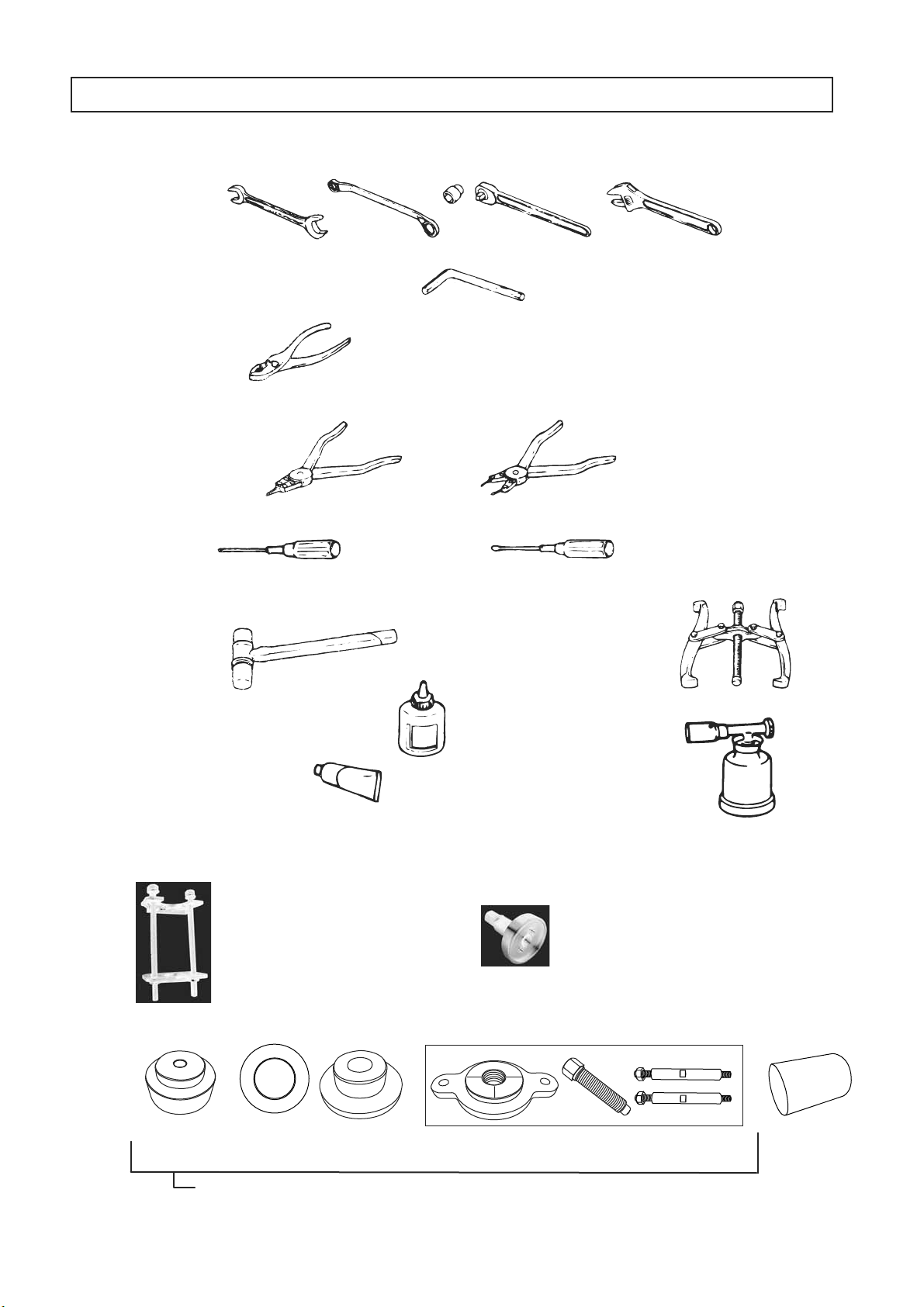

Use an appropriate tool. If the tool that is not suitable for the part is used, not only the

damage on the part, but also unpredicted accident might occur.

Before starting maintenance, always remove the minus terminal of the battery. If short

circuit occurs, ignition might occur.

The battery gas might become a cause of explosion. Do not put fire nearby.

Especially, during charging, flammable gas is released. Do not put fire nearby.

The battery fluid is very toxic. Be careful when handling. If the battery fluid gets on your

skin, eye or on your clothes, wash it off with plenty of water, then see a doctor.

Always refuel in the well ventilated area.

Always refuel after the engine stopped and cooled sufficiently.

Select a flat surface location away from flammable material and Do not overfill

the tank. If spilled fuel, wipe it off well.

Never put fire near the refueling area. (Never refuel while smoking.)

3.2 Clothes And Protective

3.3 Cautions During Refuelinglothes And Protective

3.4 Prevention Of Burn And The Accident Of Getting Caught

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

WARNING

䟿

3.5 Tools And Equipment

WARNING

䟿

3.6 Handling Of Battery

WARNING

䟿

CAUTION

䟿

CAUTION

䟿

䕿

䕿

䕿

䕿