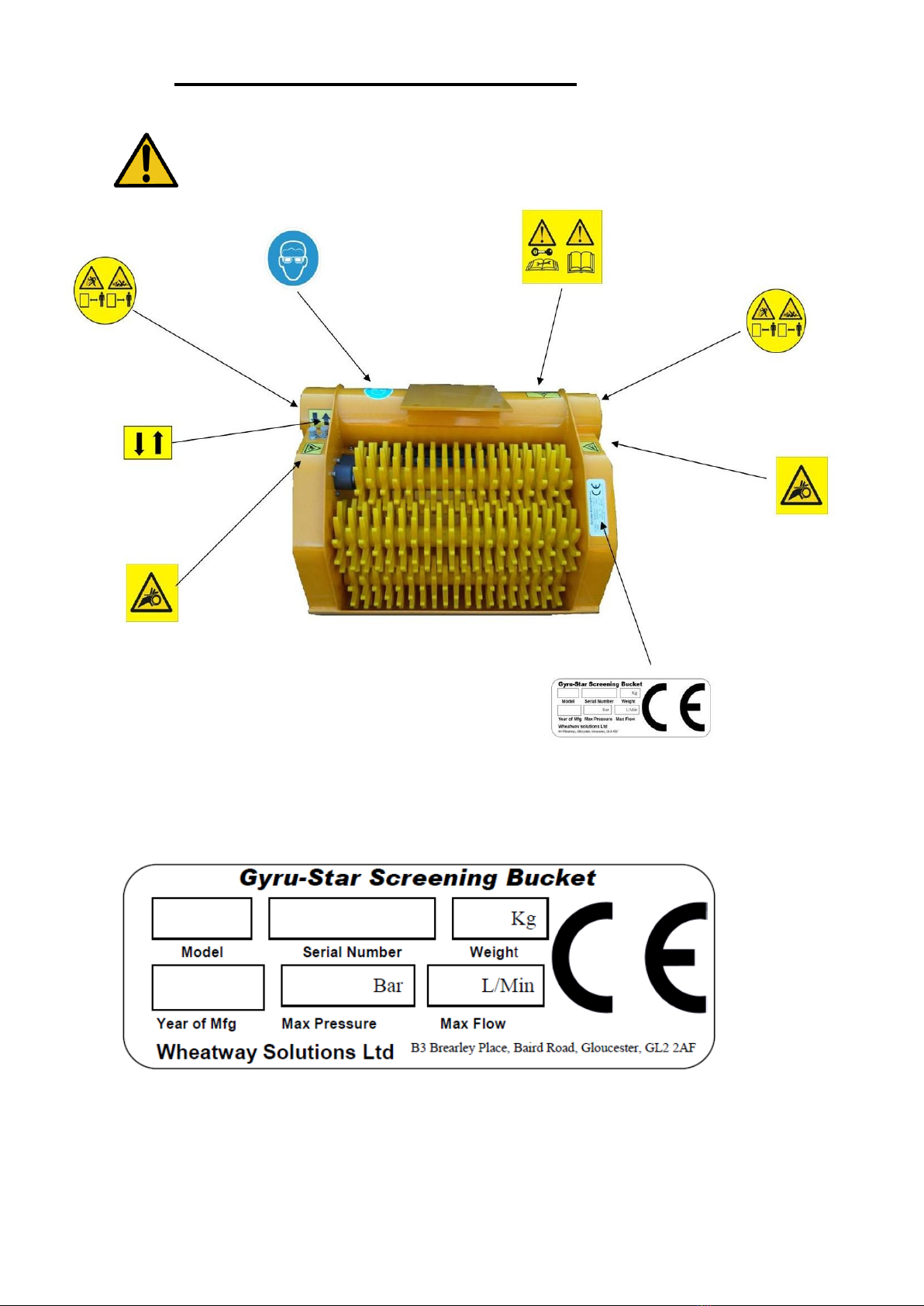

3. Safety Instructions

WARNING

Special attention must always be paid to the safe use and maintenance of the

GYRU-STAR Screening bucket.

The GYRU-STAR Screening bucket should only be used by a trained and

competent operator and must have read and understood the operator’s manual

before operating the GYRU-STAR Screening bucket.

Before operating the operator must ensure the GYRU-STAR Screening bucket

is suitable for the carrier and ensuring when fully loaded it does not exceed the

carriers’ safe working capacity

Before operating the GYRU-STAR screening bucket the operator must ensure it

is fitted correctly to the excavator or wheel loader, ensuring all locking devices,

mounting pins and hydraulic connections are made correctly.

Before operating GYRU-STAR Screening bucket the operator must carry out a

visual inspection of the general condition of the bucket and the hydraulic hoses,

Ensuring all guards are fitted and are in good order. Any defects are to be

reported and rectified.

Always detach and store the GYRU-STAR Screening bucket on a firm level

surface.

Do not carry out any inspections, maintenance, adjustments, or cleaning until

the excavator or wheeled loader is stopped and the auxiliary hydraulics are

isolated.

Do not leave the excavator or wheeled loader while the rotor are turning.

Do not go under GYRU-STAR Screening bucket in any circumstances.

Allow hydraulic oil to cool down and any pressures to decay. Always wear

correct PPE before disconnection hydraulic hoses.

Always ensure a safe working area of 10 meters in case of flying material.

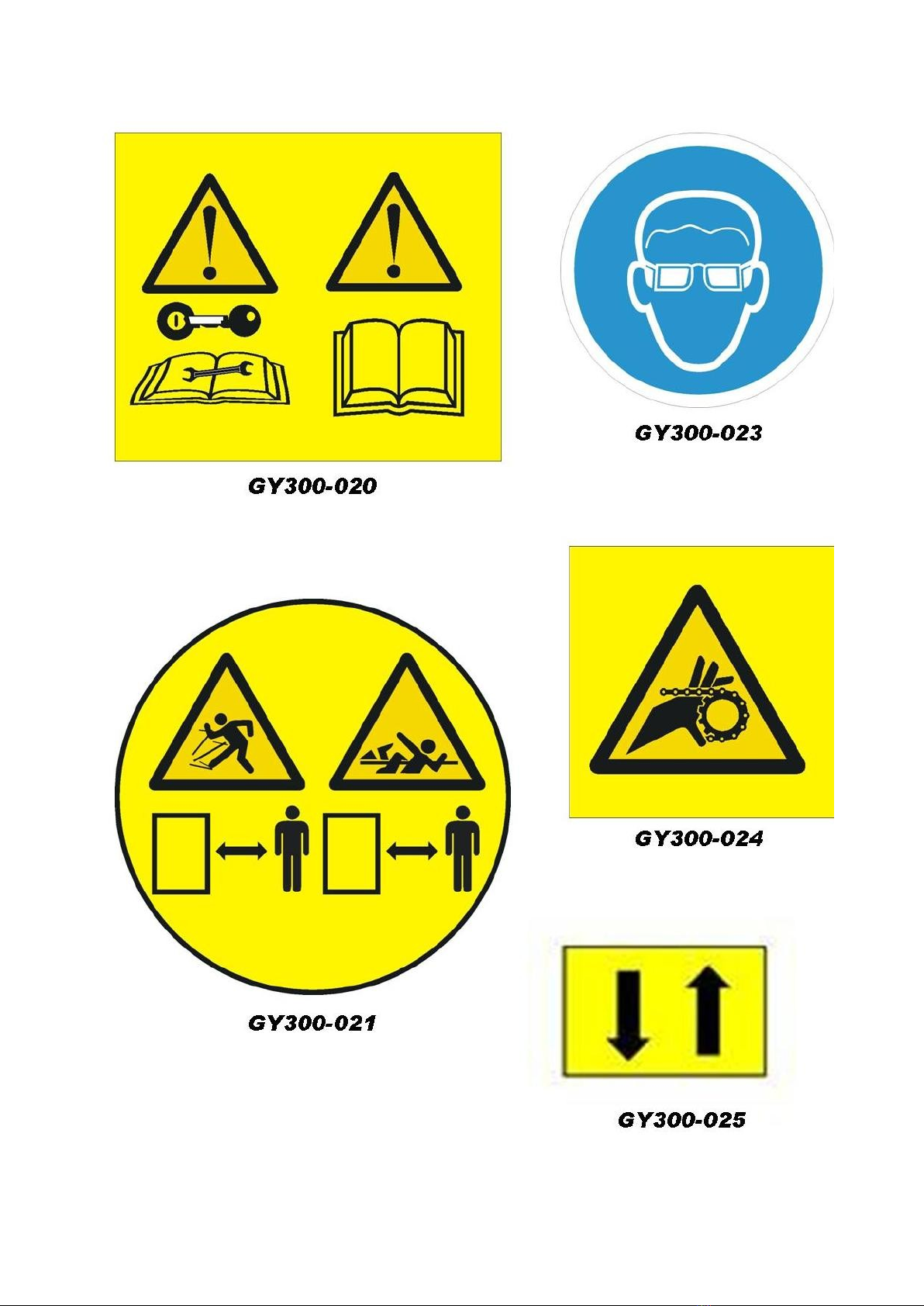

Before operating the GYRU-STAR Screening bucket ensure all guards are

fitted securely and all safety decals are in good order.