BA_X022

Operating instructions

EUROTEC

Antriebszubehör

G

mbH

|

Bildstock

37

|

DE-88085

Langenar

gen | [email protected] | www.eurotec.global | 29.10.2020 | Page 4 of 5 Standard terminals:

Klemme Hersteller Bescheinigung Leiterquerschnitt Mehrleiter Anzugsdrehmoment Abisolierlänge Farbe

MSB 2,5-RZK Phoenix PTB 08 ATEX 1075U 0,5 - 2,5mm2keine Zugfeder 8 mm grau

2703208... Phoenix PTB 06 ATEX 1034U 0,5 - 2,5 mm22x1,50 mm20,6 - 0,8 Nm 8 mm grau

If you have installed another Ex e terminal in the housing, then please find the connection data in the corresponding data sheet and the

corresponding type examination certificate for the terminal. (Minimum cable cross-section: 0.5 mm2/ max. power: 4A)

Standard cable glands:

Cable gland Manufacturer Certificate Size Cable diameter Material Colour

ESKE... WISK

PTB 13 ATEX 1015 X M20x1,5 red. 4 - 13 mm PA6 black

ESKE... WISK

PTB 13 ATEX 1015 X M20x1,5 7 - 13 mm PA6 black

GHG... CEAG PTB 99 ATEX 3128 X M25x1.5 8.0 - 17 mm PA6 black

If you have installed another Ex e terminal in the housing, then please find the connection data in the corresponding data sheet and the

corresponding type examination certificate for the cable gland.

8. Disassembly

During dismantling you must observe the instructions in Chapter 4.

1. Disconnect the device from the power supply.

2. Open the cover of the housing by unscrewing the 4 cover screws. Make sure that you do not unscrew the screws too far; they should

remain in the cover and not be able to fall out.

3. Disconnect the cables in the system from the terminal strip in the limit switch box.

4. Now, unscrew the 4 screws with which the bracket of the box is attached to the actuator and remove the limit switch box from the

actuator.

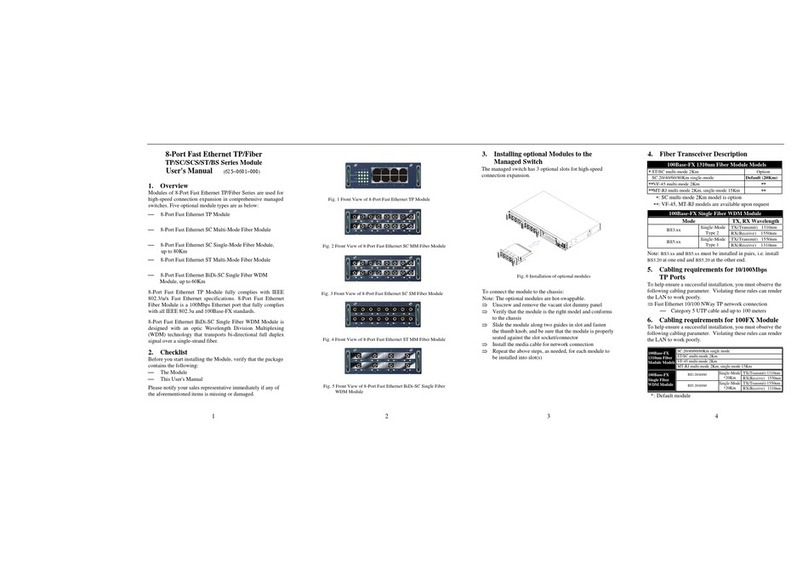

9. Adjusting the swivel range

The actuators are always preset to a swivel range of 0-90° by the EUROTEC Antriebszubehör GmbH. Should you require a different swivel

range for your application, please carry out the following steps:

1. Move the actuator to the required final position 1 and adjust the bottom actuator. To do so, press the actuator down on the outer ring

and turn it to the position, in which the switch is pressed. Let the actuator snap back up into the gearing again. (Fig. 4)

2. Move the actuator to the required final position 2 and adjust the top actuator. To do so, press the actuator down on the outer ring and

turn it to the position, in which the switch is pressed. Let the actuator snap back up into the gearing again.

3. Finally, check your default setting by switching the actuator several times.

10. Connecting magnetic coils

The flex Ex de t limit switch boxes from EUROTEC offer the option of connecting a maximum of two magnetic coil in one of the types of

protection Ex m, Ex dm or Ex d. (I max. 6A, min. 0,5mm²) For the connection of a magnetic coil replace one Ex e protection plug by an Ex e

cable gland M20x1,5 together with a suitable seal insert for your cable diameter. Ensure that the IP protection class as well as the ambient

temperature of your cable gland match at least the characteristics of the flex box housing. Verify that with the data sheet of your cable

gland. Matching cable glands can be purchased from EUROTEC:

Cable diameter: 7 - 13mm Part number: SE-KVM20x1,5SZ-EX

Cable diameter: 4 - 13mm Part number: SE-KVM20x1,5SZ-EX-RK

The cable for the magnetic coil connection needs to match the terminal block as well as the cable gland.

The wires of your cable need to be connected to the terminal block and possibly as well with the magnetic coil. Consider the referring

operation instructions of the coil manufacturer and the wiring diagram inside the switch box cover or on the technical data sheet of the limit

switch box. For the solenoid connection applies a minimum wire cross-section of 0,5mm2and a maximum current of 6A.

11. Outdoor use

If you would like to use the limit switch boxes outdoors (outdoor installation), the limit switch boxes should be equipped with an Ex e

pressure compensating element. The pressure compensating element prevents water condensation in the housing in the event of outdoor

temperature fluctuations. Please check whether or not there is a pressure compensating element. If not, you have to order respective limit

switch boxes. In this case, the addition to the item number is “-DAE”.