Eurotec i-box BA X003 User manual

BA_X003

Operating instructions

EUROTEC Antriebszubehör GmbH | Bildstock 37 | DE-88085 Langenargen | [email protected] | www.eurotec.global | 05.03.2021 | Page 1 of 6

Product group: Limit switch box i-box Product type: IV...-IA DE

Certifications:

IV-IA

Table of Contents

1. Device description.................................................................................................................................................................................................2

2. Intended use ......................................................................................................................................................................................................... 2

3. Labeling................................................................................................................................................................................................................. 2

4. Safe activation.......................................................................................................................................................................................................3

5. Assembly on actuators ......................................................................................................................................................................................... 3

6. Assembly on manual valves ................................................................................................................................................................................. 3

7. Electrical connection ............................................................................................................................................................................................ 4

8. Disassembly..........................................................................................................................................................................................................4

9. Adjusting the swivel range....................................................................................................................................................................................4

10. Connecting magnetic coils.................................................................................................................................................................................. 5

11. Outdoor use.........................................................................................................................................................................................................5

12. Maintenance........................................................................................................................................................................................................ 5

13. Malfunctions........................................................................................................................................................................................................ 5

14. Item number ....................................................................................................................................................................................................... 5

15. EU Declaration of Conformity ............................................................................................................................................................................. 6

BA_X003

Operating instructions

EUROTEC Antriebszubehör GmbH | Bildstock 37 | DE-88085 Langenargen | [email protected] | www.eurotec.global | 05.03.2021 | Page 2 of 6

Thank you for choosing a EUROTEC product. In doing so, you have chosen a quality product. To ensure functionality and your own safety,

please read these operating instructions carefully before beginning with the installation. Nevertheless, should you have any further

questions, please contact:

EUROTEC Antriebszubehör GmbH

Tel. +49 (0) 7543 93463 - 0 | Fax. - 10 | sales@eurotec.global | www.eurotec.global

1. Device description

Limit switch boxes serve to provide feedback and control the position of industrial valves, which are activated using pneumatic actuators.

The shaft of the limit switch box has a positive connection with the shaft of the actuator and is rotated with the rotational movement of the

actuator. The actuating cams attached to the shaft, activate the installed sensors, which support the electronic signal transmission.

The i-box Ex ia limit switch boxes type IV, depending on version, is equipped with 1 to 2 mechanical microswitches or separately certified

intrinsically safe inductive V3 sensors.

2. Intended use

The i-box Ex ia limit switch boxes by EUROTEC Antriebszubehör GmbH, in conjunction with intrinsically safe circuits per

DIN EN 60079-25:2010, are intended for use in explosive areas zone 1 and 2 with gases, mists or vapours and zones 21 and 22 with

combustible dusts.

ATEX / IECEx EAC Ex (TR-CU-012)

II 2G Ex ia IIB T4/T6 Gb 1 Ex ia IIB T6/T4 Gb X

II 2D Ex ia IIIC T80°C Db Ex ia IIIC T80°C Db

EPS 14 ATEX 1641 X / IECEx EPS 14.0015 X

Use is permitted at the following ambient temperature range: -25°C...+70°C

The permissible ambient temperature varies according to housing and installed switch type. You can find the ambient temperature in the

corresponding data sheet and on the product label.

The electrical input ratings are determined by the separately certified intrinsically safe inductive sensors that are used. You will find the

values for Ui, Ii, Pi, Ci and Li on the product label of your limit switch box as well as in the instruction manual of the sensor. The following

values may not be exceeded: Ii: 250mA und Pi: 650mW

For mechanical gold contact switches, the following rates have to be respected: Ui: 11V, Ii: 15mA, Pi: 35mW

3. Labeling

The labelling on the housing is shown in Fig. 1 and varies depending on the installed switch type. You can find the number of the indicated

responsible office for the QM system and the serial number below the CE mark. It consists of the year of manufacture and the respective

order number.

Fig. 1: Labelling

The housings are not intended to be used as stepladders, to climb into the system. This can lead to damaging

them and having a negative effect on their function. If the housing is damaged, water as well as dirt and

combustible material can accumulate inside the housing. This can lead to a short circuit. Furthermore, the

device can heat up severely due to the accumulation and can cause an explosion.

BA_X003

Operating instructions

EUROTEC Antriebszubehör GmbH | Bildstock 37 | DE-88085 Langenargen | [email protected] | www.eurotec.global | 05.03.2021 | Page 3 of 6

4. Safe activation

To avoid mistakes, only specialists are permitted to set up, connect and put the devices into operation. The specialist must have expertise on

the ignition protection type intrinsic safety (Ex ia/ib) as well as all relevant regulations and provisions for operating materials in explosive

areas. The limit switch boxes are developed in compliance with the following harmonised standards:

EN IEC 60079-0:2018 (IEC 60079-0, Ed. 7.0)

EN 60079-11:2012 (IEC 60079-11, Ed. 6.0)

It is imperative to observe the following safety instructions prior to initial operation:

Failure to observe the safety instructions in these operating instructions and using or handling the device

improperly, releases us from any liabilty. Furthermore, the warranty for the devices and accessory components

will expire.

Check on the labelling, whether the existing device is suitable for your case of application.

Observe national regulations and provisions as well as the corresponding installation specifications.

Take suitable measures, to prevent unintentional activation or improper interferences with the device.

Remove any existing sealing plugs just before inserting the wires to avoid dirt in the housing.

Make sure the strain is sufficiently relieved on the connecting cables or lay them securely.

Check the approved conductor cross-sections as well as the approved tightening torques in the documentation for cable connections

Effectively protect the devices and cables against damages.

Avoid static charge on plastic devices and cables. Therefore, only clean the device with an anti-static or damp cloth.

Housing components made of metal must be included in the potential equalisation by means of appropriate assembly.

This device may only be operated in a fully assembled condition.

Never disconnect the connector cables while they have power.

Only connect the limit switch box to approved intrinsically safe circuits with EC type-examination certificate and do not exceed the

maximums of the respective sensor for Ui, Ii, Pi, Ci and Li.

Each box has a separate, intrinsically safe circuit inside the box. For 2 sensors we recommend one of the following 2-channel switch

amplifiers as the associated electrical equipment:

IFM, N0533A / P+F, KFD2-SR2-Ex2.W / Turck, IM1-22EX-R

5. Assembly on actuators

Using the enclosed mounting material, the modules can be quickly and easily assembled to the provided actuator according to VDI

(Association of German Engineers)/VDE (German Electrical Engineering Association) 3845. It can only be directly mounted to actuators with

a 80x30 mm hole pattern and a drive shaft height of 20 or 30 mm. The maximum drive shaft diameter is 32 mm. For all other actuators you

will need our adjustable height and width mounting bracket IMBHV.

1. Adjust your actuator to the final position, in which the groove of the drive shaft is parallel to the drive housing.

2. Attach the two included mounting screws to the actuator. They can be installed on either side.

3. Now place the box on the actuator and secure from the side with the two included point set screw. For a shaft height of 30 mm, remove

the shaft extension (SI-WV10) from the shaft.

4. Unscrew the four cover screws and open the housing. Make sure you do not unscrew the screws too far; they should remain in the

cover.

5. Insert the system cable into the housing through the cable gland and connect the individual wires to the terminal block. When doing so,

please refer to the terminal diagram on the respective data sheet or on the cover of the housing and connect the housing to the

equipotential bonding.

6. Close the housing using the cover. When attaching the cover, please make sure that the seal is correctly positioned and tighten the

cover screws.

Fig. 2: Prepare actuator Fig. 3: Shaft extension Fig. 4: Position box Fig. 5: Secure box

6. Assembly on manual valves

The boxes can also be mounted to manually operated valves using our "MSH" assembly kit. It is important that your manual valve has a

head flange according to ISO 5211 and a threaded hole in the shaft. Please use the “MSH” instruction manual for detailed assembly

instructions.

BA_X003

Operating instructions

EUROTEC Antriebszubehör GmbH | Bildstock 37 | DE-88085 Langenargen | [email protected] | www.eurotec.global | 05.03.2021 | Page 4 of 6

7. Electrical connection

You can find the approved cable diameter in the corresponding data sheet for the limit switch box. You can find the terminal diagram for the

wiring either on or in the cover of the housing as well as on the corresponding data sheet for the limit switch box. Each sensor has a

separate, intrinsically safe circuit.

When tightening the cable gland, please make sure that the base body of the cable gland, which is screwed in

place in the housing, does not rotate as well. This could make the sealing washer shift and it would then no

longer provide proper sealing. It is best to use 2 open-ended spanners for this purpose. One to secure the base

body of the cable gland and one to tighten the screw nut.

Standard terminal:

Terminal Manufacture

r

Conductor cross-section Tightening torque Strip length Colour

AK100... PTR single-wire rigid: 0.2 - 4.0 mm2

finely stranded flex.: 0.2 - 2.5 mm2

with cable-end sleeve: 0.2 - 2.5 mm2

0.45 - 0.50 Nm 7 mm light blue

Fig. 6: Standard terminal

8. Disassembly

During dismantling you must observe the instructions in Chapter 4.

1. Disconnect the housing from power.

2. Open the cover of the housing by unscrewing the 4 cover screws. Make sure that you do not unscrew the screws too far; they should

remain in the cover and not be able to fall out.

3. Disconnect the cables in the system from the terminal strip in the limit switch box.

4. Now loosen the two point set screws securing the box to the actuator and remove the limit switch box from the actuator.

9. Adjusting the swivel range

The actuators are always preset to a swivel range of 0-90° by the EUROTEC Antriebszubehör GmbH. Should you require a different

swivel range for your application, please carry out the following steps:

a. Move the actuator to the required final position 1 and adjust the actuator for the bottom switch. To do so, loosen screw 1 at the top of

the actuator and move it to the position in which the bottom switch is activated. The screw can also be moved to a different hole to

change the swivel range (e.g. to 120°). Then tighten the screw.

b. Move the actuator to the required final position 2 and adjust the actuator for the top switch. To do so, loosen screw 2 at the top of the

actuator and move it to the position in which the top switch is activated. The screw can again be moved to a different hole to change

the swivel range. Then tighten the screw.

c. Finally, check your default setting by switching the actuator several times.

Fig. 7: Do not loosen! Fig. 8: Screw 1 Fig. 9: Screw 2

BA_X003

Operating instructions

EUROTEC Antriebszubehör GmbH | Bildstock 37 | DE-88085 Langenargen | [email protected] | www.eurotec.global | 05.03.2021 | Page 5 of 6

10. Connecting magnetic coils

Depending on the style, i-box Ex ia limit switch boxes by EUROTEC can be used to connect one to two intrinsically safe magnetic coils (Ex i).

Boxes suitable for connecting a magnetic coil have "-MA" added in the item number. With this version, a 500 mm-long cable is already

connected to the terminal strip in the housing and exits the box through a cable gland. The wires of the cable now need to be connected to

the connector of the magnetic coil. Follow the operating instructions of the magnetic coil manufacturer and the terminal diagram on the

housing cover or in the technical data sheet. The same applies when connecting two magnetic coils. This version "-2MA" added in the item

number and has 2 cables, 500mm in length each. On "-MA3", an intrinsically safe magnetic coil (Ex i) can be connected to pins 7-9 on the

terminal strip.

Fig. 10: -MA Fig. 11: -2MA Fig. 12: -MA3

11. Outdoor use

If you would like to use the limit switch boxes outdoors (outdoor installation), the limit switch boxes should be equipped with a pressure

compensating element. The pressure compensating element prevents water condensation in the housing in the event of outdoor

temperature fluctuations. Please check whether or not there is a pressure compensating element. If not, you have to order respective limit

switch boxes. In this case, the addition to the item number is “-DAE”.

12. Maintenance

Never open the wave Ex ia limit switch boxes for ATEX areas during operation or in explosive atmospheres. Maintenance may be performed

inside the Ex area, as the circuits are intrinsically safe.

When operated outdoors for extended periods and when using the limit switch boxes in very high or very low ambient temperatures, the

seals on the shaft and inside the housing cover may become brittle. Safe operation is only guaranteed inside a sealed housing. Seals must

be replaced when worn or at the latest after 5 years. The necessary seals are available from EUROTEC. In addition, the cover screws can

loosen due to strong vibration or temperature fluctuations. Retighten the screws every two years. Any other modifications to the device are

prohibited!

13. Malfunctions

In the event of malfunctions, please check the lines, line connectors and the position of the cams. Furthermore, please check whether

condensation has accumulated in the housing and whether the valve and the actuator are functioning properly. Rectify any possible errors.

If this does not rectify the malfunction, disconnect the housing from the power supply voltage and contact one of the manufacturer’s

authorised and trained specialists.

14. Item number

Please refer to the related order code of the switch box series i-box.

BA_X003

Operating instructions

EUROTEC Antriebszubehör GmbH | Bildstock 37 | DE-88085 Langenargen | [email protected] | www.eurotec.global | 05.03.2021 | Page 6 of 6

15. EU Declaration of Conformity

EU-Declaration of Conformity

according to the Directive 2014/34/EU (ATEX-Directive)

We herewith confirm that the following named equipment for the use in hazardous areas does fulfill the requirements of the Directive

2014/34/EU in the delivered execution:

IV...IA... i-box. Housing vestamid

The equipment has been developed and designed in consideration of the following harmonised standards:

EN IEC 60079-0:2018 Explosive atmospheres -

IEC 60079-0 Ed. 7.0 Part 0: Equipment - General requirements

EN 60079-11:2012 Explosive atmospheres -

IEC 60079-11, Ed. 6.0 Part 11: Equipment protection by intrinsic safety "i"

Marking: II 2G Ex ia IIB T4/T6 Gb

II 2D Ex ia IIIC T80°C Db

EU-Type Examination Certificate: EPS 14 ATEX 1 641 X

Bureau Veritas Consumer Products Services Germany GmbH

Businesspark A96, DE-86842 Türkheim

Ident.-No.: 2004

EU-Certificate Quality Assurance: EPS 19 ATEX Q 057

Bureau Veritas Consumer Products Services Germany GmbH

Businesspark A96, DE-86842 Türkheim

Ident.-No.: 2004

2021-03-05

Date General Manager: Melissa Berge

Table of contents

Other Eurotec Switch manuals

Popular Switch manuals by other brands

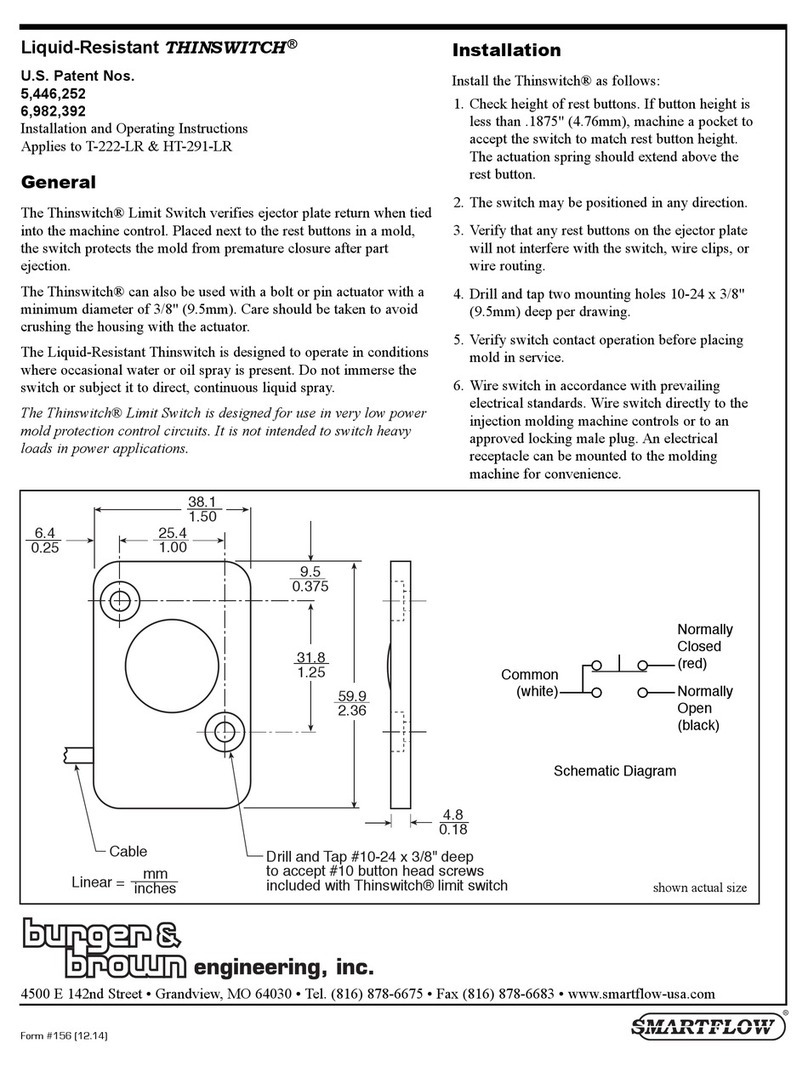

Burger & Brown

Burger & Brown Smartflow Thinswitch Installation and operating instructions

Data Video

Data Video SE-2850 instruction manual

Tripp Lite

Tripp Lite NGI-M08POE8-L2 owner's manual

i-Vac

i-Vac SWITCH BOX SB24013-UK-A Handbook

AirLive

AirLive INJ-1G-30W-1248 user manual

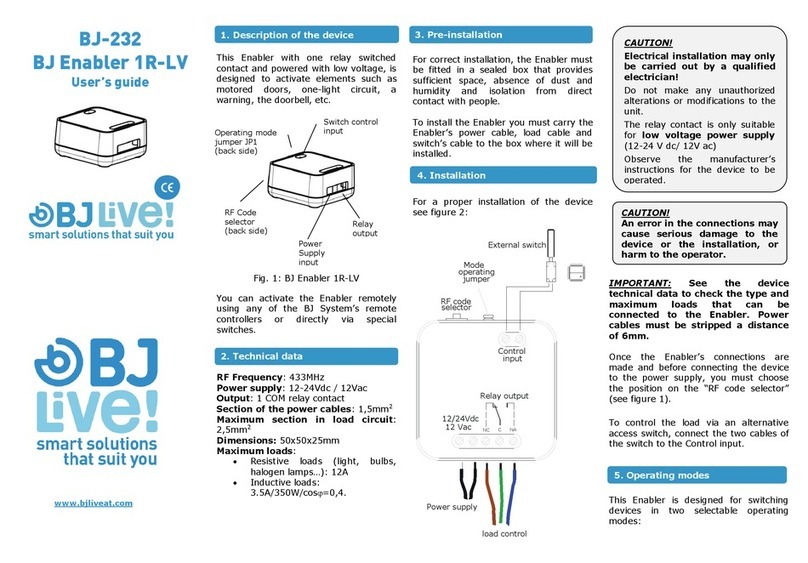

BJ Live

BJ Live BJ Enabler 1R-LV user guide