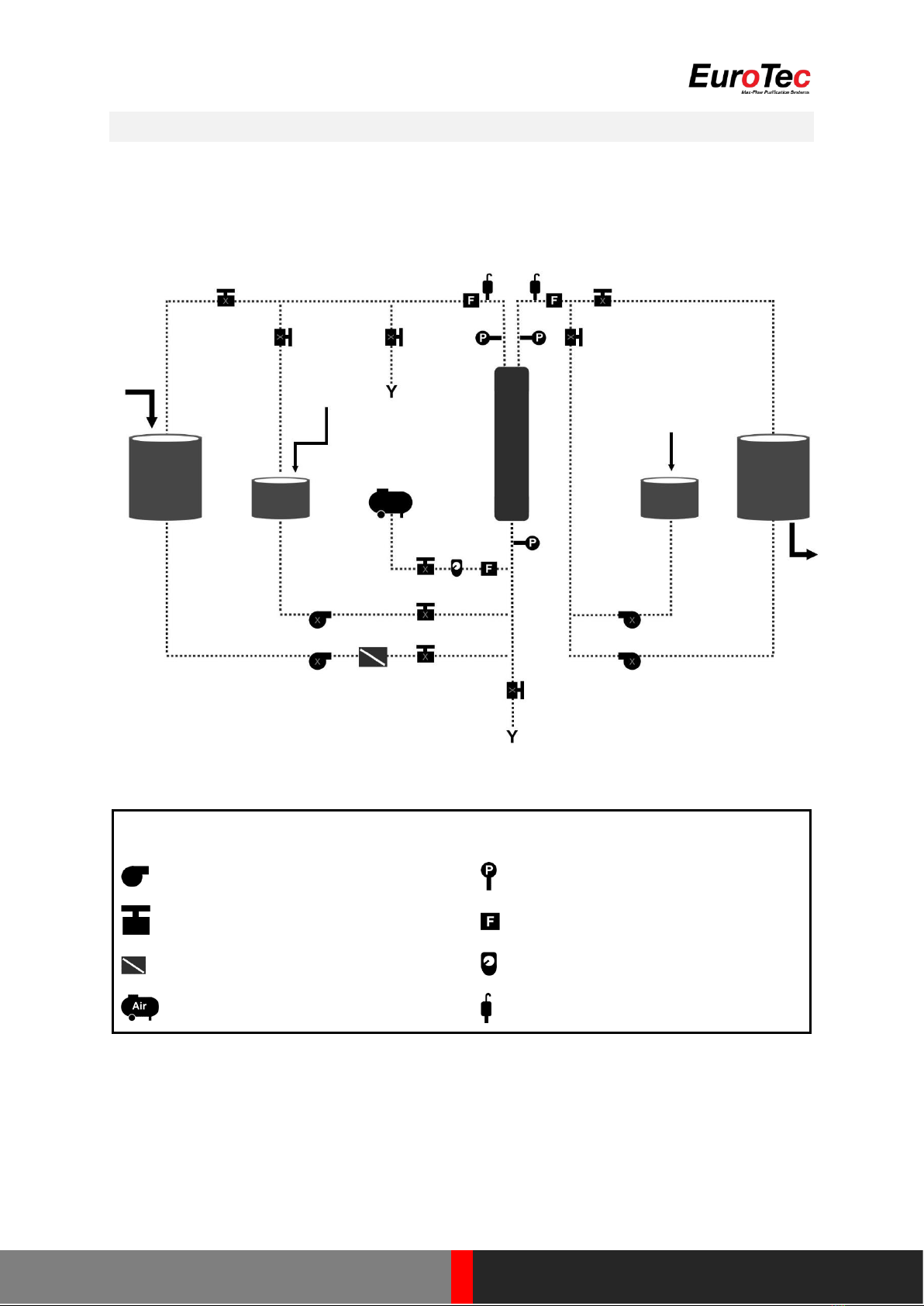

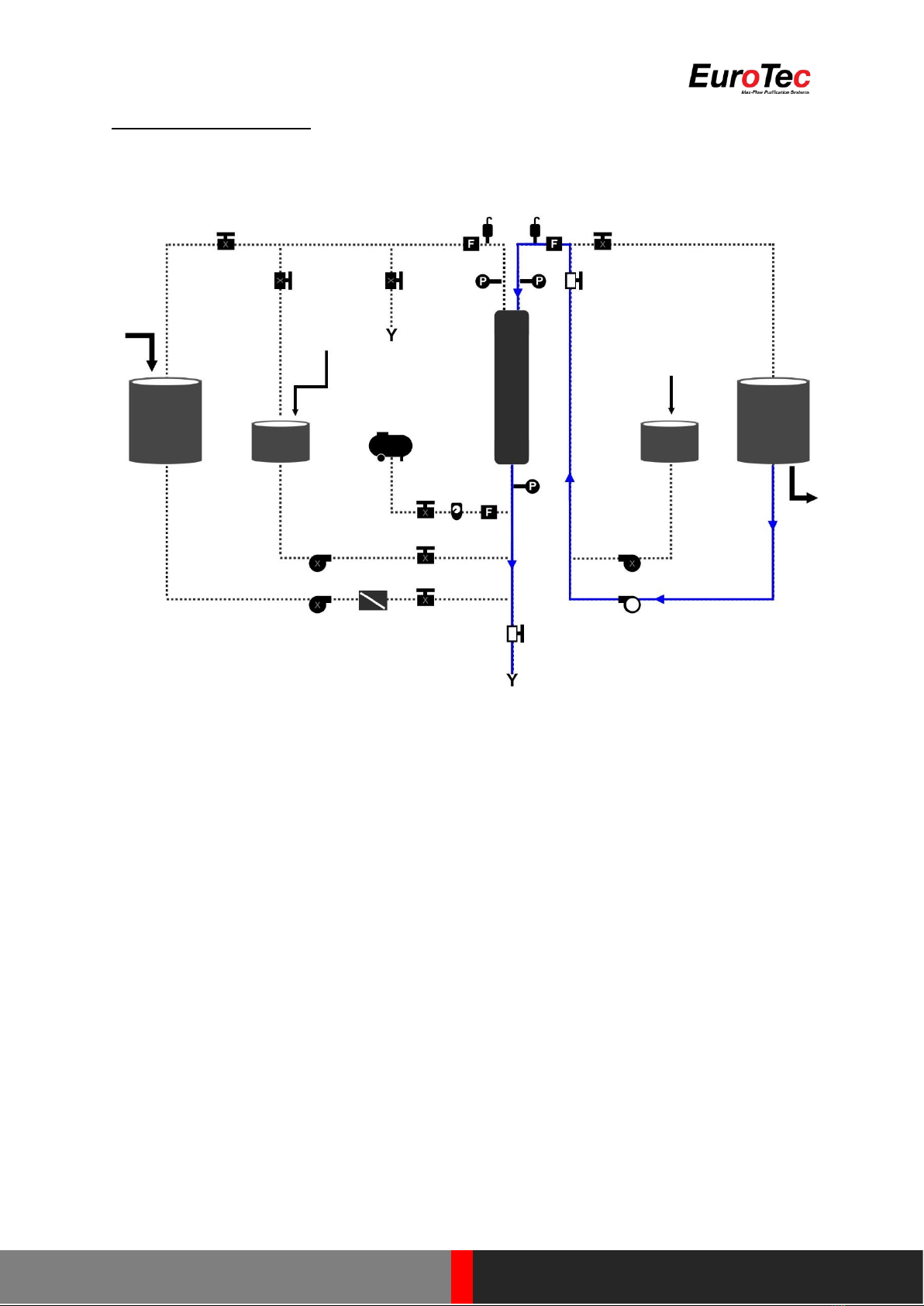

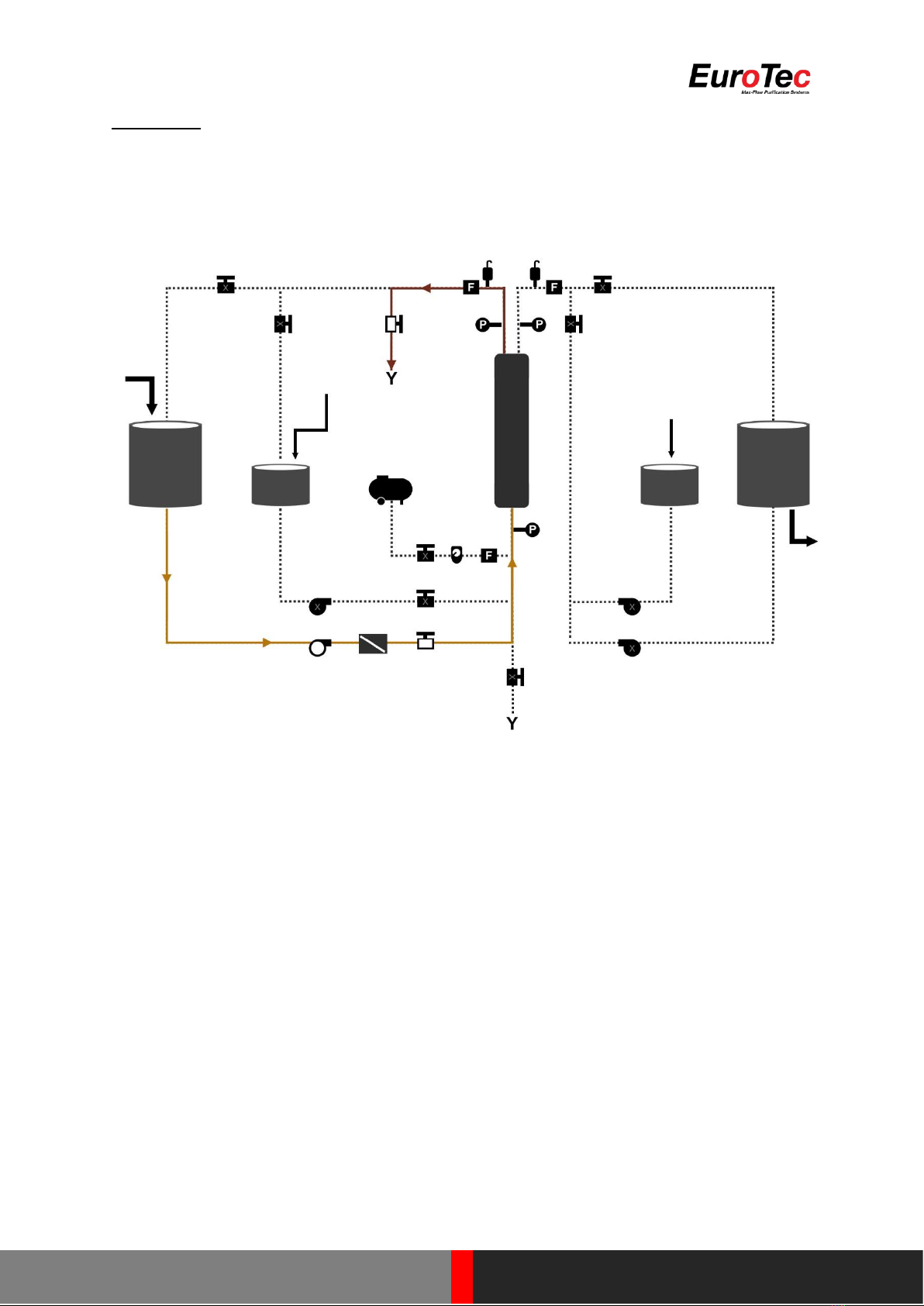

▪Backwash pump

The backwash pump(s) should provide the required backwash flow with suitable allowance at

a pressure no greater than the stated backwash pressure limit.

The backwash pump should be controlled by a VFD or an equivalent device, which is linked to

the control system. This is because, similar to the feed pump, higher pressure will be required

to maintain the backwash flow as the membrane becomes increasingly fouled.

A single backwash pump may be used to service several skids as they take turns to be

backwashed. Thus, the sizing of the backwash pump is dependent on the number of modules

that are flushed at a time. The number of pumps needed is, in turn, dependent on the number

of skids and the frequency of the backwashes.

The selection of the material of the pump is also dependent on the conditions of the filtrate

water and the environment where the pump is located.

Backup/ standby backwash pumps are generally recommended, especially for large systems

or critical operations.

▪CIP pump

The material of the CIP pump should be appropriate for the chemical cleaning solutions used

and the environment in which it is operating.

Similar to the backwash pump, a single CIP pump may be used to service several skids as they

take turns to be cleaned. Thus, the sizing of the CIP pump is dependent on the number of

modules that are cleaned at a time and the recirculation flow per module.

(For the typical recirculation flow per module, refer to Section 4.8).

▪CEB pump

The material of the CEB pump should be appropriate for the chemical cleaning solutions used

and the environment in which it is operating.

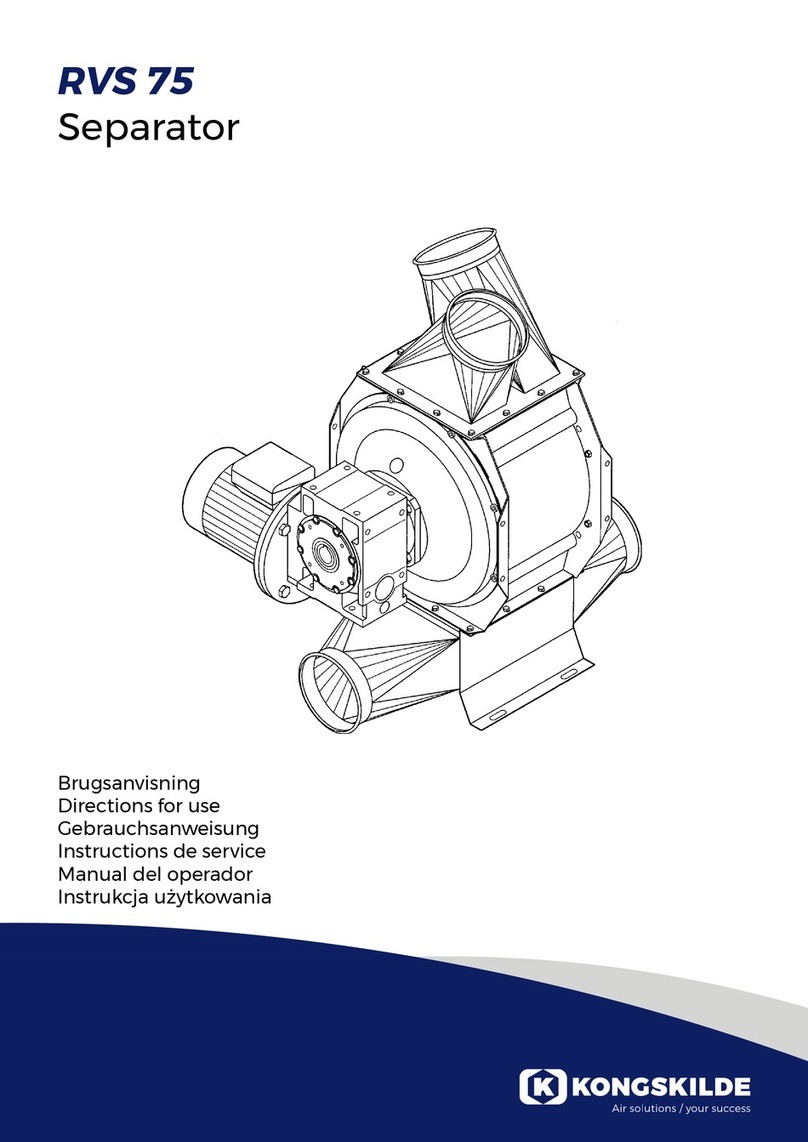

▪Air equipment

Air is required for the air scouring of the membranes as well as the operation of pneumatic

equipment/ instruments (e.g. auto-vales) in the system. Thus, having a suitable and reliable

air source (e.g. air compressor) is important.

The process air should be oil and moisture-free.

Air pressure and flow control are especially critical. Pressure regulators, valve terminals, flow

control valves and indicators are required. Uncontrolled air flow/ pressure may cause module

and membrane fiber damage.

Air release valves are recommended especially, for (but not limited to) the concentrate and

filtrate lines. Improper handling of process air may lead pressure buildup within the system

that may result in module and/ or membrane damage.

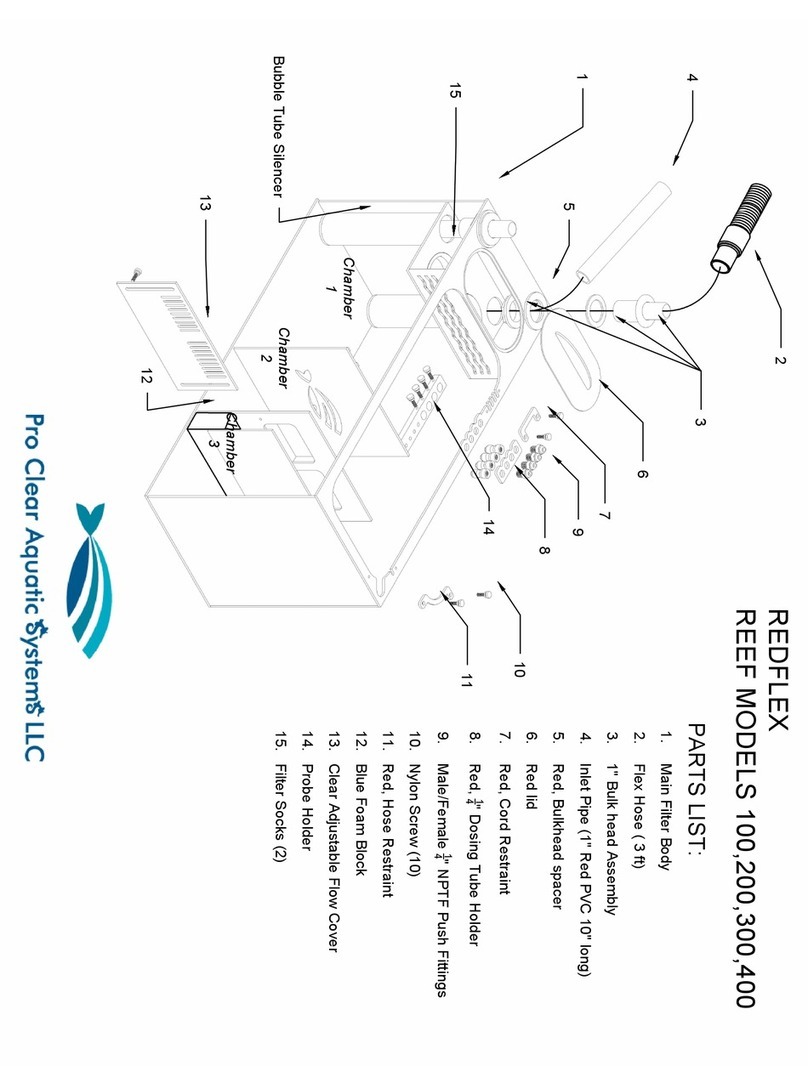

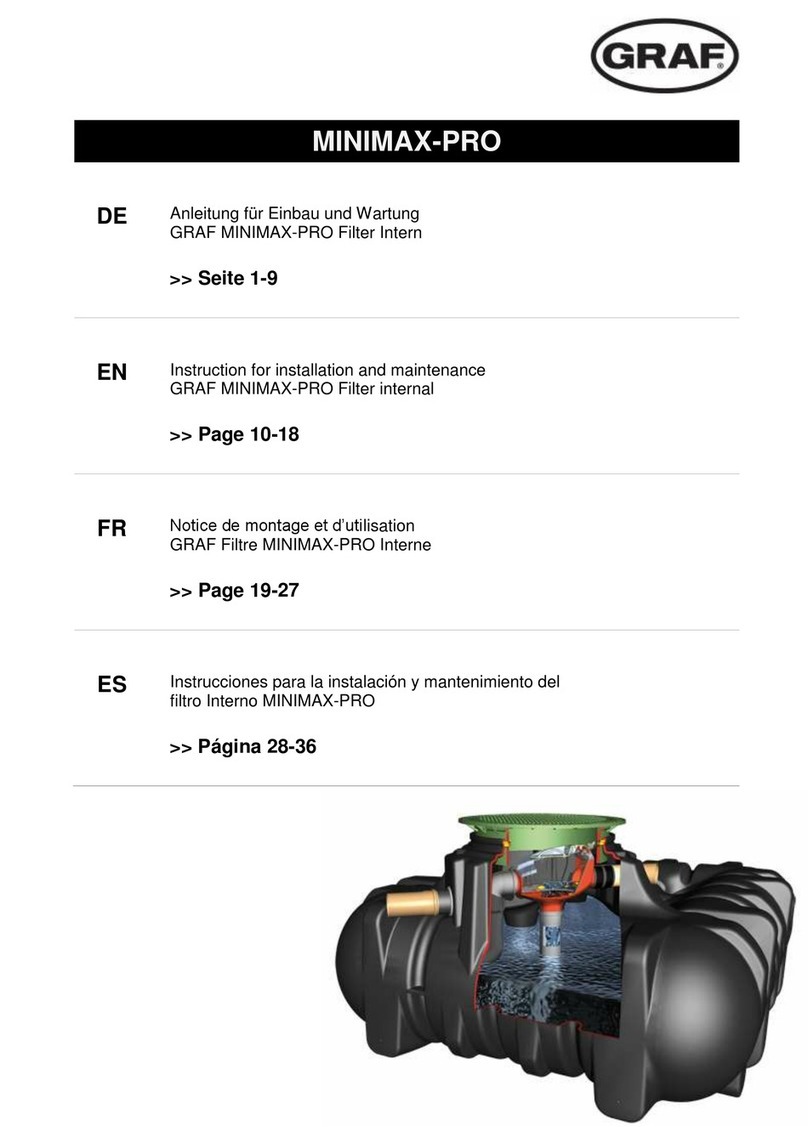

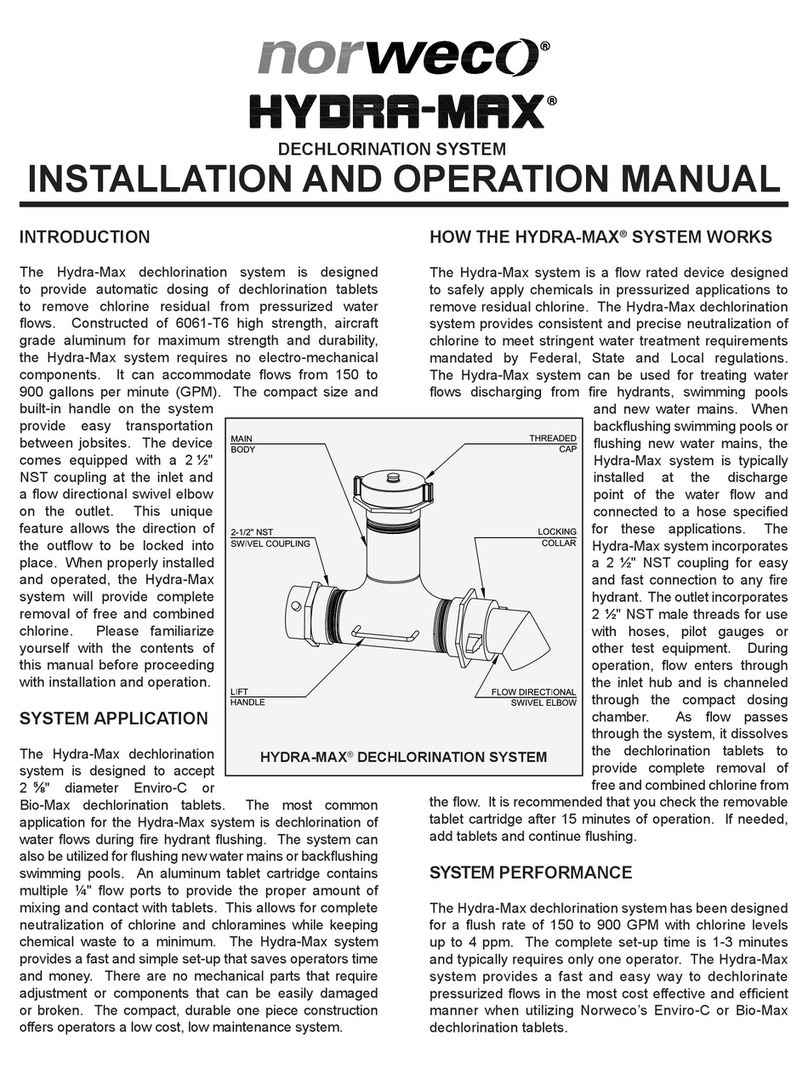

▪Pre-filter

The role of the pre-filter is to protect the UF membranes from damage by large particulates.

Essentially, it is a guard filter.

The pore size ratings required for a typical UF system and its operation range from 50 –200

microns, depending on the feed water constituents.

▪Control system

For most cases, the operation of the UF system is largely automated. As such, a suitable control

system (typically a Programmable Logic Control or PLC system) and an appropriate user

interface are required.