norweco Hydra-Max User manual

INSTALLATION AND OPERATION MANUAL

DECHLORINATION SYSTEM

INTRODUCTION

The Hydra-Max dechlorination system is designed

to provide automatic dosing of dechlorination tablets

to remove chlorine residual from pressurized water

ows. Constructed of 6061-T6 high strength, aircraft

grade aluminum for maximum strength and durability,

the Hydra-Max system requires no electro-mechanical

components. It can accommodate ows from 150 to

900 gallons per minute (GPM). The compact size and

built-in handle on the system

provide easy transportation

between jobsites. The device

comes equipped with a 2 ½"

NST coupling at the inlet and

a ow directional swivel elbow

on the outlet. This unique

feature allows the direction of

the outow to be locked into

place. When properly installed

and operated, the Hydra-Max

system will provide complete

removal of free and combined

chlorine. Please familiarize

yourself with the contents of

this manual before proceeding

with installation and operation.

SYSTEM APPLICATION

The Hydra-Max dechlorination

system is designed to accept

2⅝ " d i a m e t e r E n v i r o - C o r

Bio-Max dechlorination tablets. The most common

application for the Hydra-Max system is dechlorination of

water ows during re hydrant ushing. The system can

also be utilized for ushing new water mains or backushing

swimming pools. An aluminum tablet cartridge contains

multiple ¼" ow ports to provide the proper amount of

mixing and contact with tablets. This allows for complete

neutralization of chlorine and chloramines while keeping

chemical waste to a minimum. The Hydra-Max system

provides a fast and simple set-up that saves operators time

and money. There are no mechanical parts that require

adjustment or components that can be easily damaged

or broken. The compact, durable one piece construction

offers operators a low cost, low maintenance system.

HOW THE HYDRA-MAX®SYSTEM WORKS

The Hydra-Max system is a ow rated device designed

to safely apply chemicals in pressurized applications to

remove residual chlorine. The Hydra-Max dechlorination

system provides consistent and precise neutralization of

chlorine to meet stringent water treatment requirements

mandated by Federal, State and Local regulations.

The Hydra-Max system can be used for treating water

ows discharging from re hydrants, swimming pools

and new water mains. When

backushing swimming pools or

ushing new water mains, the

Hydra-Max system is typically

installed at the discharge

point of the water ow and

connected to a hose specied

for these applications. The

Hydra-Max system incorporates

a 2 ½" NST coupling for easy

and fast connection to any re

hydrant. The outlet incorporates

2 ½" NST male threads for use

with hoses, pilot gauges or

other test equipment. During

operation, ow enters through

the inlet hub and is channeled

through the compact dosing

chamber. As ow passes

through the system, it dissolves

the dechlorination tablets to

provide complete removal of

free and combined chlorine from

the ow. It is recommended that you check the removable

tablet cartridge after 15 minutes of operation. If needed,

add tablets and continue ushing.

SYSTEM PERFORMANCE

The Hydra-Max dechlorination system has been designed

for a ush rate of 150 to 900 GPM with chlorine levels

up to 4 ppm. The complete set-up time is 1-3 minutes

and typically requires only one operator. The Hydra-Max

system provides a fast and easy way to dechlorinate

pressurized ows in the most cost effective and efcient

manner when utilizing Norweco’s Enviro-C or Bio-Max

dechlorination tablets.

HYDRA-MAX®DECHLORINATION SYSTEM

GENERAL INSTALLATION INSTRUCTIONS

The Hydra-Max dechlorination system is most commonly

utilized for re hydrant ushing. Follow the instructions

below for fast and easy installation to any re hydrant.

Norweco's Enviro-C dechlorination tablets, manufactured

from pure Vitamin C, are the recommended tablets for this

application to obtain the most effective treatment.

1. Secure the Hydra-Max system to the re hydrant

utilizing the 2 ½" NST coupling.

2. Position the outlet ow directional swivel elbow to

desired location. Secure with the locking collar.

3. Remove threaded cap and tablet cartridge. Fill

cartridge with eight Enviro-C tablets.

4. Replace tablet cartridge into the main body, pushing

the cartridge to the bottom of the chamber.

5. Reinstall the threaded cap. Hand tighten only.

6. Initiate ushing and rell tablets as necessary.

ROUTINE MAINTENANCE

The Hydra-Max system requires little maintenance

other than periodic cleaning and rell of the aluminum

tablet cartridge. When performing any maintenance,

always wear proper gloves and safety goggles or a face

shield. Follow the procedures outlined in the handling

instructions for the chemicals being used with the system.

Before relling the tablet cartridge, check the inside

of the tube and rinse any residue with a low pressure

hose. Occasionally, the tablet cartridge may need to

be cleaned with a brush. The liquid ow will normally

prevent accumulation of sediment or debris during routine

operation. Lodged sediment or debris within the system

can be removed with the cleaning brush or a gloved hand.

If the use of a brush is required, reference the Cleaning

Brush section for detailed instructions.

HYDRA-MAX®INSTALLATION AND OPERATION MANUAL

FILLING AND INSTALLING TABLETS

Before handling any chemical tablets, carefully read the

product container label and the CAUTION section of these

instructions. When lling the removable aluminum tablet

cartridge, always wear gloves and safety goggles or a face

shield for proper protection. Follow all handling instructions

for the chemical tablets being used. To ll the aluminum

tablet cartridge, remove it from the main body. Rinse the

cartridge tube thoroughly with fresh water. Dry as required.

Hold the aluminum cartridge at a 30° to 45° angle and slide

the chemical tablets into the open end of the cartridge, one

tablet at a time. Insure that each tablet lies at against the

next and evenly on top of one another. Carefully return the

tablet cartridge to the main body. Be sure the aluminum

cartridge is fully engaged into the system. Replace the

threaded cap to secure the aluminum tablet cartridge in

place. Utilize the Chemical Consumption Record on the

back of this manual to track the chemical rell pattern.

CLEANING BRUSH

A brush for cleaning the removable aluminum tablet

cartridge and main body is available from your local

Hydra-Max system distributor. The cleaning brush can

also be used to clean the inlet and outlet hubs of the

system if necessary. To use the cleaning brush, wet the

brush with fresh water and hold the cartridge over a clear

area. Gently swab the aluminum cartridge to remove any

buildup of tablet residue. Lower brush into the main body

to clean the dosing chamber and inside of the system. If

required, the brush can also be used to clean the inside

of the ow directional swivel elbow. Thoroughly rinse

the brush and the system with fresh water to nish the

cleaning process. Dry as needed. Store the brush in an

area away from debris for future use.

TABLETS MUST LIE FLAT IN THE CARTRIDGE

HYDRA-MAX®ATTACHED TO HYDRANT

BIO-DYNAMIC®TABLET FEEDERS

HYDRA-MAX®INSTALLATION AND OPERATION MANUAL

ENVIRO-C®DECHLORINATION TABLETS

If the Hydra-Max system is to be used for the

dechlorination of water or wastewater, a (5 lb., 10 lb.,

or 35 lb.) supply of Enviro-C dechlorination tablets

is available from your local distributor. Enviro-C

dechlorination tablets use the unique chemistry of Vitamin

C to neutralize chlorine and chloramines from water,

wastewater and process water applications. Containing

75% ascorbic acid, Enviro-C tablets assist in meeting

stringent discharge limitations in a fast and effective

manner. Each tablet is 2 ⅝" diameter, compressed to a 1"

thickness, weighs approximately 4 ounces and is orange in

color for easy identication. Enviro-C tablets incorporate a

beveled edge to enhance the chemical dissolution pattern.

The Enviro-C tablets provide a consistent reduction

or elimination of chlorine residual without signicantly

reducing dissolved oxygen. This tablet can be used in all

major gravity and pressure rated tablet feeders or other

devices such as diffuser equipment. Enviro-C tablets

are non-toxic to sh and other aquatic life. When dosed

correctly, it will take 1 gram of ascorbic acid to neutralize

1 mg/L of chlorine per 100 gallons of water.

TRI-MAX®TABLET FEEDER

The Tri-Max tablet feeder is a dry chemical dosing system

for water, wastewater or process water treatment. It

provides operators a way to use chemical tablets without

installing traditional feeders to existing plant piping or

assembling liquid chemical dosing systems in the eld.

The Tri-Max system is constructed of heavy duty stainless

steel for maximum strength and durability. It is designed

to accept 2 ⅝" diameter chemical tablets and is equipped

with three feed tubes. The Tri-Max tablet feeder may be

installed at grade, in-line, mounted in the contact tank or

below grade within a manhole or secondary enclosure.

The system contains handles on the outer two feed tube

housings to assist with installation of the tablet feeder

and transportation between jobsites. When utilizing the

Tri-Max tablet feeder for disinfection, contact time is

required after the ow passes through the system.

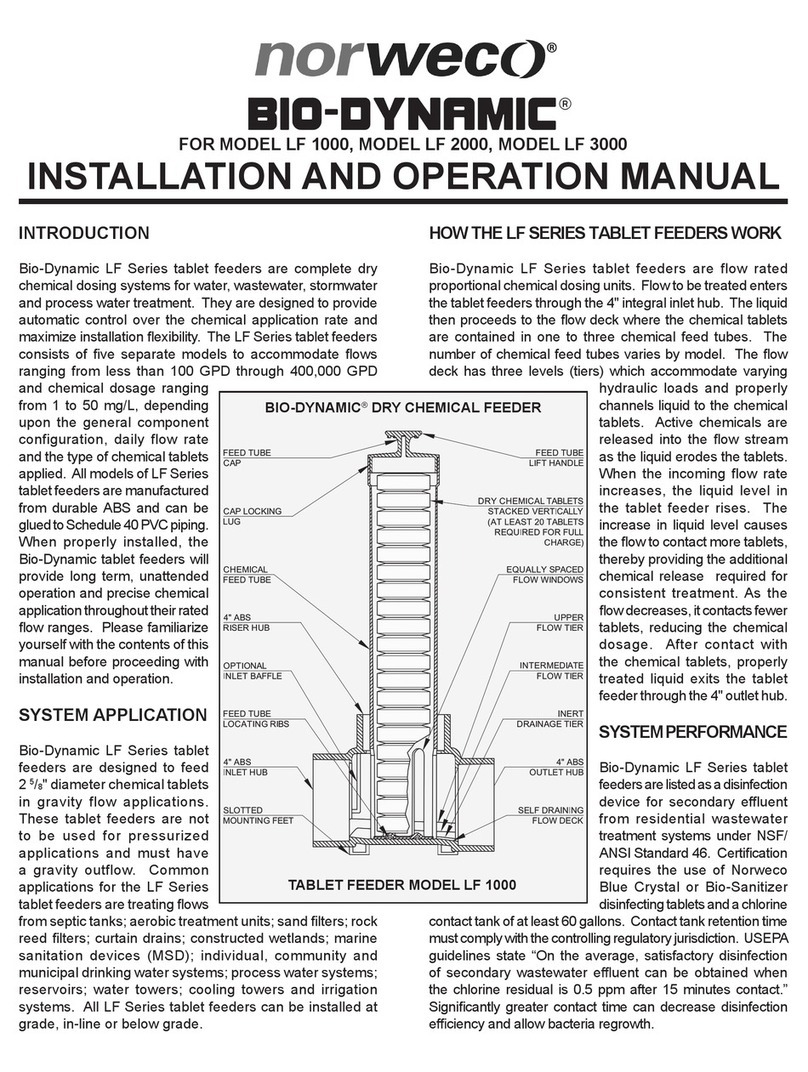

BIO-DYNAMIC®TABLET FEEDERS

Bio-Dynamic tablet feeders are self-contained dry chemical

dosing systems for the treatment of water, wastewater or

process water. A low cost, low maintenance and effective

method of chemical treatment, Bio-Dynamic feeders have

no mechanical components and require no electricity.

With fteen different models, Bio-Dynamic feeders have

multiple installation options that provide maximum exibility

and accommodate ows ranging from less than 100 GPD

through 400,000 GPD. All Bio-Dynamic tablet feeders

have a built-in tiered ow deck that allows for consistent

chemical application during low, sustained, variable,

intermittent and surge ows. Additional chemical dosage

control options are available in many models.

BIO-MAX®DECHLORINATION TABLETS

If the Hydra-Max system is to be used for the

dechlorination of water or wastewater, a 48 lb. supply of

Bio-Max tablets is available from your local distributor.

Containing 92% sodium sulte, the tablets are

manufactured to neutralize both free and combined chlorine.

Bio-Max tablets incorporate beveled edges to enhance the

chemical dissolution pattern. Each tablet is 2 ⅝" diameter,

compressed to a " thickness, weighs approximately 5

ounces and is green in color for easy identication. The

tablets dissolve slowly, releasing controlled amounts of

chemical for the instantaneous removal of residual chlorine

from the water or wastewater ow. Bio-Max tablets assist

plant operators in meeting stringent chlorine discharge

limitations in a low cost, low maintenance, environmentally

safe manner. This tablet can be used in all major gravity

or pressure rated tablet feeders and other devices such as

diffuser equipment. The chemical application rate of the

tablets remains consistent at peak ow factors as high as

four. Bio-Max tablets are formulated to remove chlorine

residuals to non-detectable levels.

CAUTION: The improper handling or use of Enviro-C

or Bio-Max tablets may cause personal injury or

property damage. All chemicals, chemical feed

systems and components should be handled with

care. Keep out of the reach of children and do not

allow the tablets or feed tubes to contact skin, eyes

or clothing. Tablets may be fatal if swallowed and

tablet dust is irritating to the eyes, nose and throat.

Do not handle the tablets or feed tubes without

carefully reading the product container label, safety

data sheet (SDS) and the safety, handling and storage

instructions. For additional information about these

products, contact your local distributor.

13 16

HYDRA-MAX®INSTALLATION AND OPERATION MANUAL

220 REPUBLIC STREET

NORWALK, OHIO, USA 44857-1156

TELEPHONE (419) 668-4471

FAX (419) 663-5440

www.norweco.com

DISTRIBUTED LOCALLY BY:

Norweco®, Norweco.com®, Singulair®, Modulair®, Travalair®, Singulair Green®, Ribbit Rivet®, Hydro-Kinetic®, Hydro-Kinetic Bio-Film Reactor®,

Evenair®, Lift-Rail®, Microsonic®, Bio-Dynamic®, Bio-Sanitizer®, Bio-Neutralizer®, Bio-Kinetic®, Bio-Static®, Bio-Gem®, Bio-Max®, Bio-Perc®,

Blue Crystal®, Phos-4-Fade®, Enviro-C®, ClearCheck®, ChemCheck®, Tri-Max®, Hydra-Max®, Service Pro®, MCD®, TNT®, WASP®, Grease Buster®

and “BUSTER” logo®are registered trademarks of Norwalk Wastewater Equipment Company, Inc.

©MMXVI NORWECO, INC.

The Hydra-Max dechlorination system is backed by a

comprehensive ten year limited warranty. The purchaser

is protected from defects in material and workmanship,

under normal use and service, for a period of ten years.

The Hydra-Max system distributor will provide detailed

warranty information to each purchaser. This warranty

shall be determined by the original date of purchase.

If the Hydra-Max system or tablet cartridge requires

service or replacement, do not use the system. Contact

your local, authorized Hydra-Max system distributor to

arrange for replacement of the system or component.

After inspection, the distributor will return the system

or component to the factory and replace the necessary

items according to the terms of the limited warranty.

Use of chemical tablets not produced or approved by

Norweco may affect the integrity of your Hydra-Max

dechlorination system and void the ten year limited

warranty.

HYDRA-MAX®CHEMICAL CONSUMPTION RECORD

For your reference, please document chemical consumption and maintenance on the following chart:

DATE DESCRIPTION

SYSTEM SAFETY

Only authorized personnel should have access to the

Hydra-Max system and its components. Maintenance of

the system should be performed after each use. Proper

gloves and safety goggles or a face shield should always be

worn when providing service to any chemical feed system.

All safety and handling procedures for chemical tablets

must be followed completely. Thoroughly read chemical

container label before use. Only trained personnel using

the proper safety procedures and approved equipment

should be allowed in the vicinity of a treatment system.

Make sure the system and all other treatment processes

are secured for safety and to prevent unauthorized access.

Before proceeding with installation and operation of the

Hydra-Max system, it is recommended that you familiarize

yourself with the contents of this manual. Please contact

your local Hydra-Max distributor for additional installation

information or recommended chemical treatment products

for your application.

HYDRA-MAX®LIMITED WARRANTY

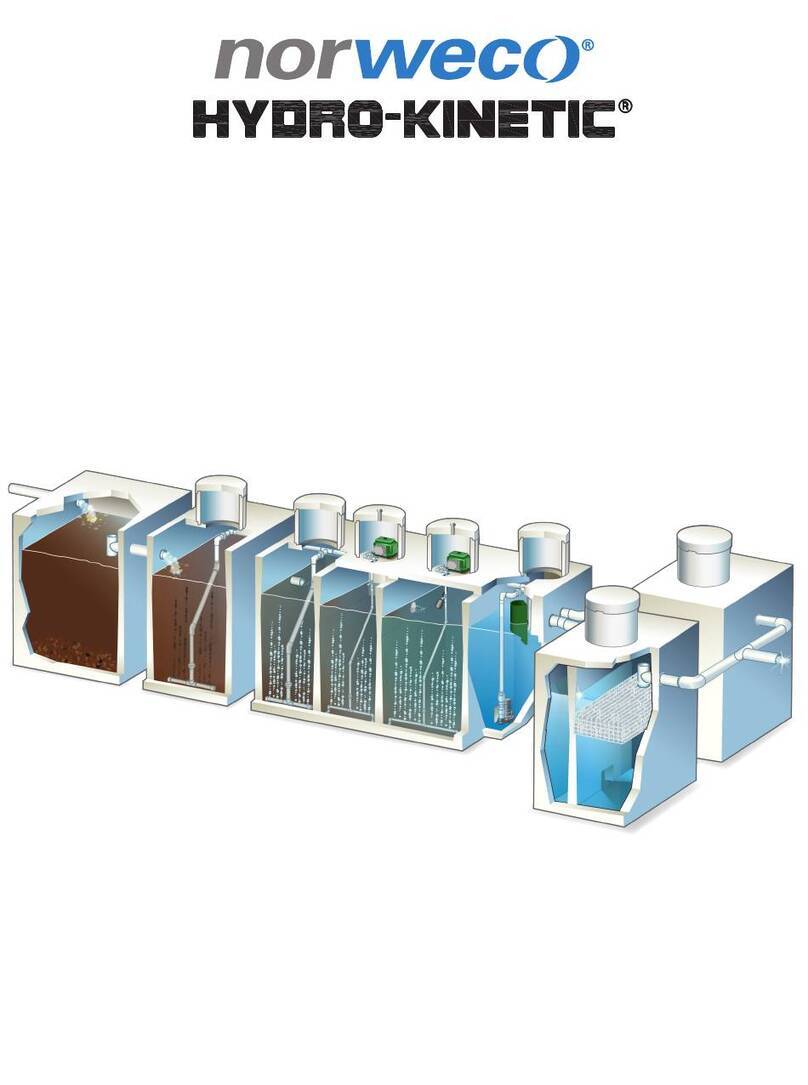

Other norweco Water Filtration System manuals

norweco

norweco Singulair 960 User manual

norweco

norweco SINGULAIR BIO-KINETIC 960 User manual

norweco

norweco Singulair Bio-Kinetic Configuration guide

norweco

norweco BIO-DYNAMIC LF 1000 User manual

norweco

norweco HYDRO-KINETIC 3780L User manual

norweco

norweco Singulair Green User manual

norweco

norweco SINGULAIR GREEN BIO-KINETIC User manual

norweco

norweco HYDRO-KINETIC 1260L User manual

norweco

norweco BIO-DYNAMIC LF 4600 User manual