EV-POWER BCU-PPAK User manual

BCU-PPAK INSTALLATION MANUAL 1.0

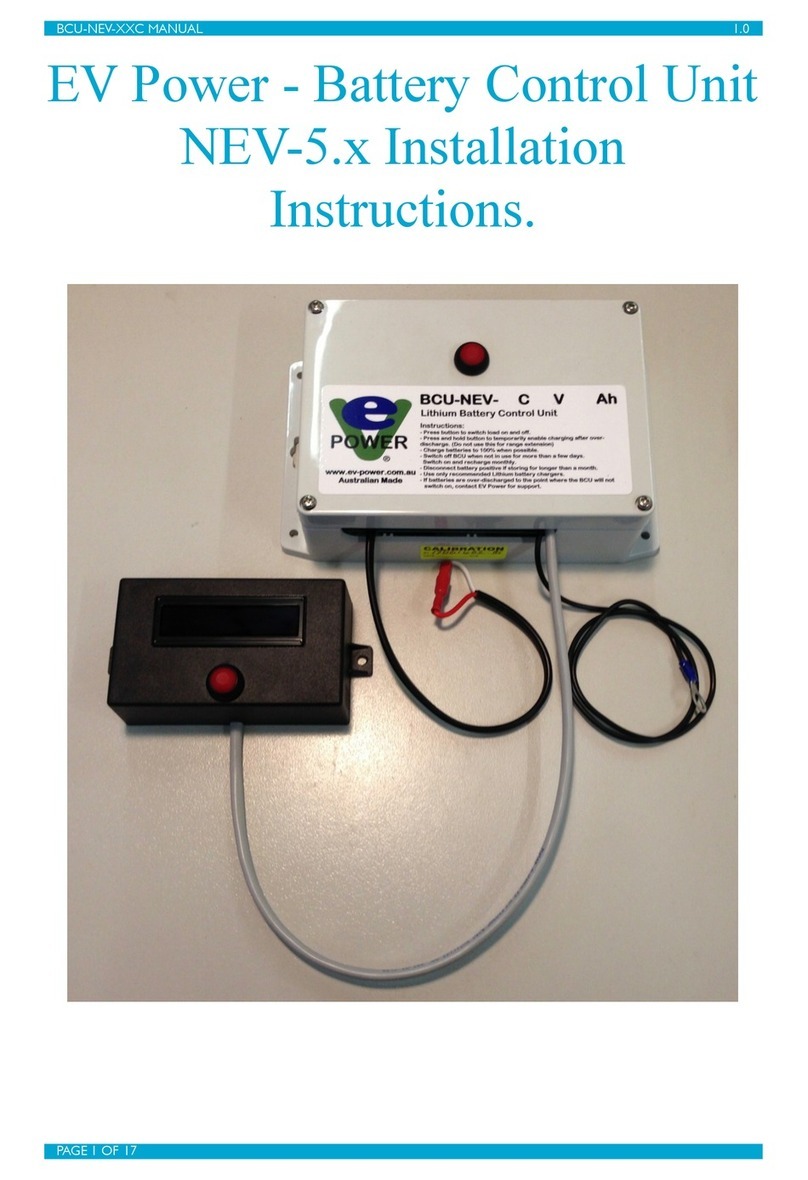

EV Power BCU-PPAK

Battery Control Unit Installation.

PAGE 1 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

BCU-PPAK Features

- Simple to install and use, microprocessor control.

- Low power requirement, just 15mA when switched on with relay active.

- Prevents overcharge and over-discharge o LFP batteries.

- 12V (4 cell) operation.

- 240A (or 3 x 80A) capacity with normal relay, 500A capacity with optional high power relay.

- Capable o controlling multiple batteries in parallel.

- Plug and play with EV Power Pak 12V batteries.

- Works with any charger that is suitable or LFP batteries.

BCU-PPAK+4C Specifications

- Supply Voltage - 8 - 15VDC

- Power Consumption - <5mA (o ), 15mA (on) @ 13VDC

- Switching current - 240A (80A per pole)

- Dimensions - 150 x 90 x 55mm : control enclosure

- Weight - 520g

- Environmental - -20 to +60 Celsius

bjective of this manual

This manual will help with installation and operation o the PPAK-4C battery control unit in conjunction with EV Power

PowerPaks.

An understanding o electrical principles and competence with electrical tools is required. Ability to use the volts, amps

and Ohms setting o a multimeter is a prerequisite.

PAGE 2 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

Disclaimer

This is a guide only. Potentially lethal voltages and currents are involved when working with batteries. It is the

responsibility of the installer to have the appropriate qualifications and skills for working with high voltages. No

liability whatsoever will be assumed by EV Power for injury, accidents or damage resulting from the use of these

instructions.

Read these instructions several times be ore commencing installation.

Do not try to charge or discharge Lithium (LFP) batteries without the BCU installed. One over-charge or

over-discharge WILL cause permanent damage.

Every e ort has been made to make this apparatus as reliable and robust as possible. However electronics can ail. The

BCU-PPAK is designed to be the last line o battery protection and should not be relied upon to disconnect the battery

under normal operating conditions. Connected loads and chargers should have inbuilt low/high voltage cuto mecha-

nisms. EV Power assumes no responsibility or battery damage resulting rom ailure o the BCU other than statutory

warranty requirements.

Introduction

The EV Power Battery Control Unit is designed or Lithium Iron Phosphate (LiFePO4, LFP) batteries o capacity 40-

400Ah and nominal voltage o 12.8V. These batteries are generally used in applications where light weight, high power

and long li e are required.

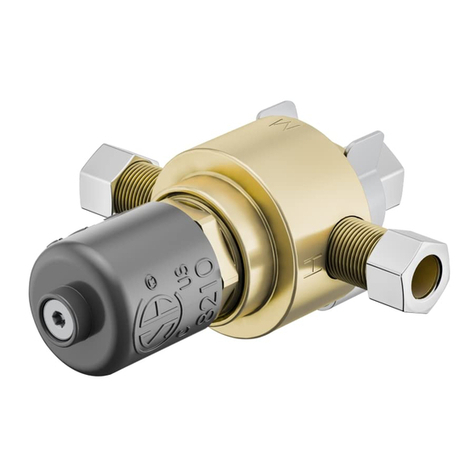

The BCU-PPAK+4C is designed to control 4 cell (12V) battery packs. It monitors overall battery voltage and also the con-

dition o each cell via the patented one wire link to BMS cell modules.

It is designed to be the simplest possible method o providing complete LFP battery protection.

This overall system consists o a single Battery Control Unit (BCU) and multiple cell modules that bolt directly on top o

each cell. The cell modules per orm the cell balancing unction during charging and connect together via a one wire inter-

ace. The BCU controls a relay that interrupts power to/ rom the load/charger in the event o a battery problem.

No battery uel gauge unctions are incorporated in the system and there are no digital outputs available to inter ace with

external devices. No temperature monitoring is done.

In combination with an approved switch mode charger the BCU-PPAK+4C will provide automated charging o EV Power

Paks or LFP cells with EV Power BMS modules attached.

PAGE 3 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

How it works - Usage

The BCU per orms a number o unctions:

1) It monitors the battery voltage, i the voltage alls below 11.6V or rises above 15.0V (4 or 5 red LED lashes) or more

than 15-20 seconds the relay will open. Then will be no LEDs and the BCU will revert to a low power mode.

2) It monitors the BMS cell module loop. I any cell goes below 2.5V or above 4.0V (2 lashes red LED) or more than 15-

20 seconds the relay will open. Then will be no LEDs and the BCU will revert to a low power mode.

3) I the battery voltage is below 11.6V or above 15.0V and the BMS cell loop signals an error on one cell the relay will

immediately open, no delay. Then will be no LEDs and the BCU will revert to a low power mode.

The BCU is operated by pressing the ON/OFF button on the ront.

- One press to switch on

- One press to switch o

- Press and hold to override and engage relay a ter a dropout. Use this only i necessary and only to enable charging.

The BCU ON/OFF button has a Red LED to indicate that the relay is switched ON.

This LED will lash to indicate battery error conditions.

- Two red lashes, one or more cell modules is registering a cell ault. (< 2.5V or > 4.0V)

- Four red lashes, low battery voltage, <11.6V

- Five red lashes, high battery voltage, > 15.0V

- No LEDS, BCU has dropped the contactor and switched itsel OFF.

The relay is a special type called a magnetic latching relay. It consumes no power when switched on. The downside o

this is that it can remain on i power to the BCU is removed or i the BCU ails or any reason. Check that the relay is op-

erating correctly occasionally by switching o and on the BCU.

S ME L ADS AND CHARGERS HAVE INTERNAL CAPACIT RS WHICH DRAW LARGE INRUSH

CURRENTS WHEN C NNECTED. THIS MAY CAUSE THE RELAY C NTACTS T FUSE CL SED. SUITABLE

PRE-CHARGE CIRCUITS SH ULD BE INC RP RATED IN THIS CASE.

D N T DISC NNECT P WER T THE BCU WHILE THE RELAY IS IN THE N STATE, battery protec-

tion will be removed.

I the BCU cuts o the battery during discharge the battery is most likely nearly empty. DO NOT RESET AND CONTIN-

UE DISCHARGE! Reset and charge the battery immediately.

I the relay is pulsing on/o that would mean it is hitting the low voltage threshold under load. More likely on cold days

and with cold batteries.

Note that the 11.6V cuto threshold equates to approximately 2-5% remaining battery capacity, more or less. The battery

should be considered to be lat at this level to allow or a sa ety bu er.

Note that even when switched o the BCU consumes a small parasitic current. It will take some months to drain a ull

battery at this rate but it is best to either leave the battery on continuous loat charge 13.6-13.8V or to disconnect the

BCU i the battery is to be stored or long periods.

PAGE 4 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

I the relay opens during charging it means either the charge voltage has gone to high or the cells are unbalanced. Try

reseting and charging a ew times. I one red LED on the BMS cell modules on the battery comes on long be ore the oth-

ers then that cell is running too high. Contact EV Power or advice in this instance.

The BCU is the last line of defence for the battery pack. It should not be relied upon to disconnect the

battery every time it is used. It is there as a safety backup.

Battery Storage

When a battery is to be le t unused or a period it is important to make sure it is ully charged irst.

Lithium batteries last longer i stored not ully charged but this is not a problem as the BCU will provide a small current

draw to ensure it is not quite ull.

Continuous charging is not recommended during storage.

The new BCU-PPAK+4C (or 8C) is meant to be set to 11.6V low voltage cut on the main contactor.

It should be calibrated +/- 0.1V.

We do a ull QC burn-in test on all units.

The low voltage cutout is adjustable via a small trimpot next to one o the terminal blocks. Anticlockwise to turn it down

lower.

The new BCU also has a hardware cutout that inhibits power to the BCU itsel i it drops below ~7.5V.

This helps prevent total battery discharge i the unit is orgotten about or weeks or months.

It does also mean that some external trickle charge may be required to get the battery back up to the switch on thresh-

old.

When storing a battery, ully charge it irst, then switch

o the BCU and ensure a ull recharge is done every two or

three months.

PAGE 5 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

PAGE 6 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

PAGE 7 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

High Power Applications

For batteries in parallel one pole o the relay is required per battery to prevent high current damage i one cell ails in one

pack. The standard relay has three poles which may be used to control up to three battery packs in parallel. Just remove

the copper bus bar rom the battery side o the relay.

Current drain may be 80A per parallel pack. So two batteries in parallel = 160A capability.

For applications which require more than 80A continuous per battery a high power contactor option is available. It can

supply up to 500A . Please advise when purchasing.

PAGE 8 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

Remote Enable Chargers

A very ew types o charger have a remote enable connection. This is a two pole terminal block. I the poles are bridged

then the charger will activate. I open circuit then the charger is disabled. It is a use ul unction which the BCU-PPAK can

used to enable the charger. This means the charger may be connected directly to the battery terminals, via a suitable

use or circuit breaker.

PAGE 9 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

General Battery Guidelines

LFP cells should be housed in a battery box away rom dust, excessive heat and moisture. Appropriate restraints should

be used that are capable supporting at least 5 times the battery weight in the event o a vehicle rollover. All restraints

should be well insulated so as not to short out battery terminals.

PAGE 10 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

Ensure that a dry powder type ire extinguisher is accessible. Lithium Iron Phosphate batteries do not generally catch ire

even under extreme abuse. However they will burn i heat is applied rom another source such as a short circuit. They

contain organic solvent electrolyte which is lammable when released.

Be care ul when working on batteries with metal tools, short circuits can occur very easily with catastrophic

consequences. The handles o metal tools should be insulated with heat shrink or plastic duct tape.

DO NOT ALLOW YOUR BATTERY TO RUN DEAD FLAT. IT MAY BE PERMANENTLY DAMAGED AND

EV-POWER CAN TAKE NO RESPONSIBILITY FOR THIS.

THE BATTERY SHOULD BE CHARGED ONCE A MONTH IF BEING STORED.

Cell Module Installation

This is covered in another manual. Install the cell modules irst. It is not required or the pre abricated EV Power Pak bat-

teries.

Mains Charger Control

EV Power supplies a wide range o mains chargers speci ically designed or LFP batteries. LFP chargers have a special

charge curve that works with the BMS cell balancers to aid balancing.

That said, most standard switch-mode Lead Acid chargers will work when set to the GEL or SLA setting.

Ideally any charger used should charge to 3.55 - 3.65V x the number o cells in the battery. Four cells or a LFP battery

is 12.8V nominal. 14.2 - 14.6V Peak.

It is important that once the peak voltage is reached the charger should begin to taper the charge current and switch o

or all to a lower voltage when the current alls to 1% o the Ah capacity.

Charge to 14.4-14.6V then loat inde initely at 13.3-13.8V. The charger may be le t on when the battery is not in use i it

has this characteristic.

Do not use chargers which have an “equalization” phase higher than 14.6V (unless it can be disabled). This will try to

charge the battery too high and may damage it. Equalization can be use ul i it is in the correct voltage range. In this case

the battery can normally be charged to 14.0V with an occasional equalization charge.

The best or charging is to use the charge enable output o the BCU. It remains enabled even when a low voltage has

tripped the main relay.

It can switch up to 50mA 60V to power a small relay, make sure to use a snubber diode. It needs external power which

can be tapped o the 12V rail.

Use a relay such as this:

https://www.jaycar.com.au/solid-state-relay-4-32vdc-input-240vac-40a-switching/p/SY4084

DC-DC Charger Control

There are a number o DC-DC battery chargers on the market. These are used to boost the vehicle battery voltage and

charge an auxilliary battery such as a LFP battery.

Set to GEL or Sealed battery type, boost charge voltage 14.2V, Float charge voltage 13.6-13.8V. Be sure to disable

“Equalization” charge.

Alternator Charge Control

PAGE 11 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

Alternators are a special case or charging. They o ten charge at higher currents so should be set lower to minimise the

chance o battery disconnection under charge.

The Balmar MC-614 regulator says that in the programming the Absorption voltage must be less than the bulk voltage

and by a minimum o 0.1 volt. What do you recommend or the Bulk and Absorption settings that will meet the Balmar

program requirements?

Set alternator or 14.0V bulk and 13.9V absorption. Max absorb time 15 mins.

Commissioning the system

First double check all the connections.

Switch on the BCU.

A ter double checking all high voltage connections connect the AC power to the charger input. The charger should com-

mence charging. I not then check that all the green cell module LEDs are illuminated and all the cell module and signal

wires are correctly connected.

Do this or a ew seconds and switch o the charger at the wall.

Disconnect one o the signal wires between the cell modules. The red LED on the BCU will lash A ter a delay o about

10 seconds the relay will switch o . Switching on the charger at this time should have no e ect, that is, it will not switch

on. Switch the charger o at the wall and reconnect the signal wire.

Reset the BCU by switching OFF/ON again.

Switch on the charger, it should now work. Charge until the battery is ull and the charger switches o . I the BCU

switches o then an overcharge has been attempted. Reset and recharge while watching the battery closely.

The battery should now be ready or use.

General Charging Tips

Once the battery pack is balanced it can be used and charged as required. Occasional partial recharges are acceptable

but should not be the rule or the balance o the battery may be a ected.

I there is a battery error the BMS will terminate charging. This may not be serious i the battery is slightly out o balance

a ter a ew partial charges or deep discharges. However i it persists it may be necessary to check the battery.

I the battery has been discharged to a point where one or more o the cells is below 2.5V the BCU will disconnect the

battery. In this case reset the BCU by switching OFF/ON and recharge immediately.

I the BCU keeps terminating charging not do not persist or worse battery damage may result. Check the battery and

charge i required using a small current (1A max).

Never tap a portion of the battery for powering lower voltage peripheral devices. Use a DC-DC

converter.

About Lithium Iron Phosphate Batteries

A “battery” is made up o “cells”. Each cell is an individual unit that cannot be split into a lower voltage component.

LFP cells have a nominal voltage o 3.2-3.4V. This is the voltage that the cells drop back to when at rest. They will stay

around 3.2V until about 90% discharged when the voltage will begin to decrease until ully discharged at 2.5V. It is highly

recommended to discharge less than 80% o the cells total Amp Hour capacity. This will help to maximize the cell li e.

LFP cells may be connected in “series” (+ to – to + etc) to obtain a higher nominal voltage. This creates a “battery”. They

may also be connected in “parallel” (+ to +, - to -) to increase the Ah capacity. Under no circumstances should cells or a

battery be short circuited, that is the + connected directly to the – to create a loop. This will damage the cells and most

likely the operator also.

Under no circumstances should the cell voltage be allowed to all below 2.5V or a sustained period. Permanent damage

will result. It is possible that this situation may occur i the battery is allowed to stand or a long time (ie. months). In this

situation the BMS will not allow recharge because a cell is outside the sa e range. To try and recti y the problem a small

4.5V 300mAh DC plug pack type power supply can be applied to individual cells one at a time until the cell voltages rise

PAGE 12 OF 13

BCU-PPAK INSTALLATION MANUAL 1.0

above 2.5V and the BMS will allow normal charging to commence. Care must be taken with the irst ew charges as the

battery may be severely unbalanced.

A visual check o the battery pack during charging should be made every 3 months. Switch o the BCU and on again to

check that the contactor is operating correctly. Check the cells or corrosion or other damage.

Important Notes

•Take care with the routing of power cables

Electric motors such as those used in electric winches are electrically “noisy” and can cause large inductive voltage

spikes when switched on and o . Inverters can do the same. This may cause the BCU to reset and disconnect the

load in some instances. Make sure the BCU and its attached cables are away rom any large power cables and mo-

tors. I you are having trouble try rerouting cables. Keep the BCU input cables close together. I necessary use errite

chokes on the BCU power inputs.

•Recharge fully at regular intervals

LFP batteries do not have a memory, however continuous partial recharges may cause the battery to become unbal-

anced and lead to dropouts during charging. During daily usage it is important to occasionally charge the battery

pack completely until the charger switches o . Continual partial recharges will prevent the BMS balancing the pack

and so may result in premature charger disconnects when the battery is next ully charged.

•Never tap a portion of the battery for powering lower voltage peripheral devices.

This will unbalance the battery and result in continual charging errors. Use a suitable DC-DC converter to power low

voltage devices.

•Do not bypass the BMS during charging.

It is designed to protect your battery but cannot do so i it is disconnected. I there is a problem with the BMS do not

charge the battery until it is corrected.

•Do not allow the battery to go flat. The battery should be periodically charged when it is being stored to prevent

sel discharge. The BMS uses a small amount o power whether the battery is used or not so regular charging is im-

portant.

•Do not charge a dead flat battery with a high charge current. Trickle charge (<1A) is important when recovering

a very lat battery. Once the battery is back above 11.6V it may be charged normally.

Glossary

Cell - one individual unit o a battery. Lithium (LFP) cells have a nominal voltage o 3.2-3.3V

Cell Module - a small electronic device that connects between the positive and negative terminal o a lithium cell. It regu-

lates the cell voltage during charging and reports back to the master unit i a cell alls outside its sa e operating voltage o

2.5-4.2V.

Battery - a number o cells connected in series and/or parallel.

Relay - a switch controlled by an electrical signal.

Contactor - a big relay.

LiFePO4 - Lithium Iron Phosphate used in the EV Power battery chemistry. Also known as LFP.

Series connection - electrical connection o cells daisy chained positive to negative to increase the battery voltage. Bat-

tery voltage = cell voltage x number o cells in series.

Parallel connection - electrical connection o cells positive to positive, negative to negative. This increases the amp hour

capacity but maintains the same cell voltage. Battery capacity = cell capacity x number o cells in parallel.

Amp hours (Ah) - a measure o the capacity o a cell or battery. This is the number o amps x number o hours the cell

can supply. For lithium cells the rate is usually calculated over a one hour period.

Nominal Voltage - the resting voltage o a charged cell. For Lithium cells this is normally 3.2-3.3V.

Watts (W) - a measure o electrical Power. Watts = Amps x Volts , (P = I . V)

PAGE 13 OF 13

Table of contents

Other EV-POWER Control Unit manuals