EVAPCO 017-00464P User manual

Doc. NO.1000624

Inventory P/N: 100029 Page 1

MODEL 017-00464P

Mechanical Switch

Installation Manual

5151 Allendale RD.

Taneytown, MD, USA

Tel: 1-410-756-2600

www.evapco.com

Revision: D

Doc. NO.1000624 Page 2

This bulletin should be used by experienced personnel as a guide to the installation of the Model 017-00464P vibration switch.

Selection or installation of equipment should always be accompanied by competent technical assistance. We encourage you to

contact Evapco or its local representative if further information is required.

IMPORTANT: BEFORE PROCEEDING TO INSTALL AND WIRE THE UNIT, READ AND THOROUGHLY UNDERSTAND

THESE INSTRUCTIONS.

THE SWITCH MODEL NUMBER SHOULD BE CHECKED TO CONFIRM THAT YOU HAVE THE CORRECT HAZARDOUS

AREA RATING FOR YOUR APPLICATION. SEE HOW TO ORDER INFORMATION "A".

ELECTRICAL RESET AND STARTUP LOCKOUT:

The optional electrical reset circuit consists of an electri-

cal solenoid in series with a thermistor. If the rated volt-

age is continuously applied to the reset circuit at machine

startup, the reset solenoid energizes for a fixed time in-

terval (approx. 30 sec.), after which time the solenoid is

automatically de-energized by the thermistor. This action

provides a trip lockout during machine startup rough-

ness. The voltage must be removed from the reset cir-

cuit when the machine is stopped to allow the thermistor

to cool off. The switch mechanism can then be reset

electrically by a momentary application of the reset volt-

age or it can be reset manually.

NOTE: If the machine is restarted immediately after a

shutdown, the lockout period will be shortened because

the thermistor will be hot. An increase in the ambient

temperature will also shorten the lockout period.

INSTALLATION:

1) The sensitive axis of the vibration switch is perpendicular to the

mounting base. The preferred mounting is with the sensitive axis in

the horizontal plane, since most machines vibrate more in that

plane. Mount the switch solidly to the frame of the machine.

2) Remove the cover and wire the switch(es) into the alarm or shut-

down circuit. Extra care should be taken to not damage the

spring mounted on the underside of the cover. Damage to this

spring could prevent the switch from being reset. Do not exceed

switch contact ratings listed in the specifications. Keep field wiring

away from the moving part of the mechanism.

3) Observe all local electrical codes.

Observe the following for ATEX installations:

4) All power must be switched off before opening of the enclosure in

an explosive atmosphere.

5) The Vibration Switch must be electrical connected by means of a

flameproof cable gland or stopping box certified to EN 50018.

6) For ambient temperatures below –10°C and above +60°C use

field wiring suitable for both minimum and maximum ambient tem-

perature.

7) Reinstall the cover by first insuring the sealing gasket is in place

and properly seated in the grove in the housing. Place the cover on

the unit and install the four cover bolts. Torque the four bolts to 16ft/

lbs. Caution should be used to not over torque the bolts as this could

damage the housing and compromise the seal.

8) The temporary conduit entry plugs are placed in the housing to

provide physical protection for the treads during shipping. Once the

unit is installed in the field these plugs must be replaced. These tem-

porary plugs do not provide adequate environmental protection for

the switch when installed in the field.

SETPOINT ADJUSTMENT:

1) The vibration setpoint adjustment is accessible externally. Turn-

ing the setpoint adjustment clockwise (CW) increases the vibration

setpoint.

2) When the switch is shipped from the factory, the setpoint adjust-

ment is set to 2g when installed in the vertical position and 1g when

installed in the horizontal position (with reference to the setpoint

adjustment shaft).

3) To check factory calibration, place unmounted unit in your hand

and rotate per diagram D. The switch(es) should activate at dead

bottom position. If necessary, adjust setpoint using the setpoint

adjustment screw.

4) To preset switch at other than factory setpoint, start with step

three (3) and then rotate adjustment screw 1/8 turn per g until you

reach the required set point.

5) To adjust setpoint when installed on the machine, mount and wire

the unit. Reset the switch by depressing the reset plunger and start

the machine. When the machine has reached full speed, slowly turn

the vibration setpoint adjustment counter-clockwise until the switch

trips. Then turn the adjustment clockwise a small amount (approx.

1/8 turn). Reset the switch and restart the machine to determine

whether the machine starting roughness will cause the switch to trip,

in which case it may be necessary to increase the setpoint.

Doc. NO.1000624 Page 3

SPECIFICATIONS

Function: Armature mechanism trips on

high vibration and operates snap action

switch(es).

Amplitude Range: See How to Order. "C"

Frequency Range: 0 to 3600 RPM.

Setpoint Adjust: 0 to 100% of range.

External setpoint adjustment.

Reset: Local reset, plus optional remote

reset electrical coil. See How to Order. "D"

Start Delay: Applying reset coil voltage at

start up holds mechanism from tripping for

20-30 seconds, after which the switch is

active. Requires electric reset option.

Temperature Range: -40°C to 70°C

Enclosure: High strength copper-free (4/10

of 1% max) Aluminum alloy.

Environmental Rating: NEMA 4, IP 65 &

CE Mark (NEMA 4X OPTIONAL)

Switch Contact(s) Rating: 15 amps, 125,

or 480 Vac; 1/8 hp, 125 Vac; 1/4 hp, 250

Vac; 1/2 amp, 125 Vdc; 1/4 amp, 250 Vdc.

Hazard Rating: See How to Order. "A"

Weight: 1.8 kg (4.0 lbs.)

A□Hazard Area Rating

0 = None

1 = UL, cUL Explosion Proof, Class I, Groups C & D, Div 1

Class II, Groups E, F & G, Div 1

2 = UL, cUL Explosion Proof, Class I, Groups B, C & D, Div 1

Class II, Groups E, F & G, Div 1

3 = CENELEC Flameproof, EEx d IIB T6 DEMKO 02 ATEX 0212409

4 = CENELEC Flameproof, EEx d IIB+H2 T6 CE 1180 II 2 GD

5 = Non-Hazardous, Gold Contacts

B

□Contacts

1= SPDT 2= DPDT

3= SPDT Gold Contacts, 1A 4= DPDT Gold Contacts, 1A

C

□Full Scale Range

1= 5 g †2= 2 g 3= 10 g

D

□Reset Coil & Start Up Delay

0= None 1= 115 VAC 2= 230 VAC 3= 24 VDC 4= 115 VDC

E□Wiring Entry/Mounting Plate (retrofit)

1= 3/4” NPT/Metrix 5173 or 5175

2= 3/4” NPT/Metrix 5097; VS-2-EX; 366

3= 3/4” NPT/Metrix 5078; 365

4= M20 x 1.5/Metrix 5097; VS-2-EX; 366

6= M20 X 1.5 / METRIX 5173 or 5175

7= 3/4” NPT / PMC/BETA 440

8= M20 X 1.5 / METRIX 5078; 365

F□Environmental Rating

0 (or blank) = NEMA 4, IP 65, CE

1 = NEMA 4X, IP 65, CE

MODEL A B C D E F

017-00464P -□□□-□□□

Example: 017-00464P-221-010

Note: When option A1 or A2 is specified, options E4, E6

and E8 are not allowed.

†When Option C=2, Option D can not equal 3 for opera-

tion in the horizontal axis.

Tested for Compliance

with the applicable EC

Electromagnetic Com-

patibility Requirements

DIMENSIONS IN mm (inches)

Mounting Plate for E=1, 6 Shown

Doc. NO.1000624 Page 4

Popular Switch manuals by other brands

Sima

Sima VS-HD51 user manual

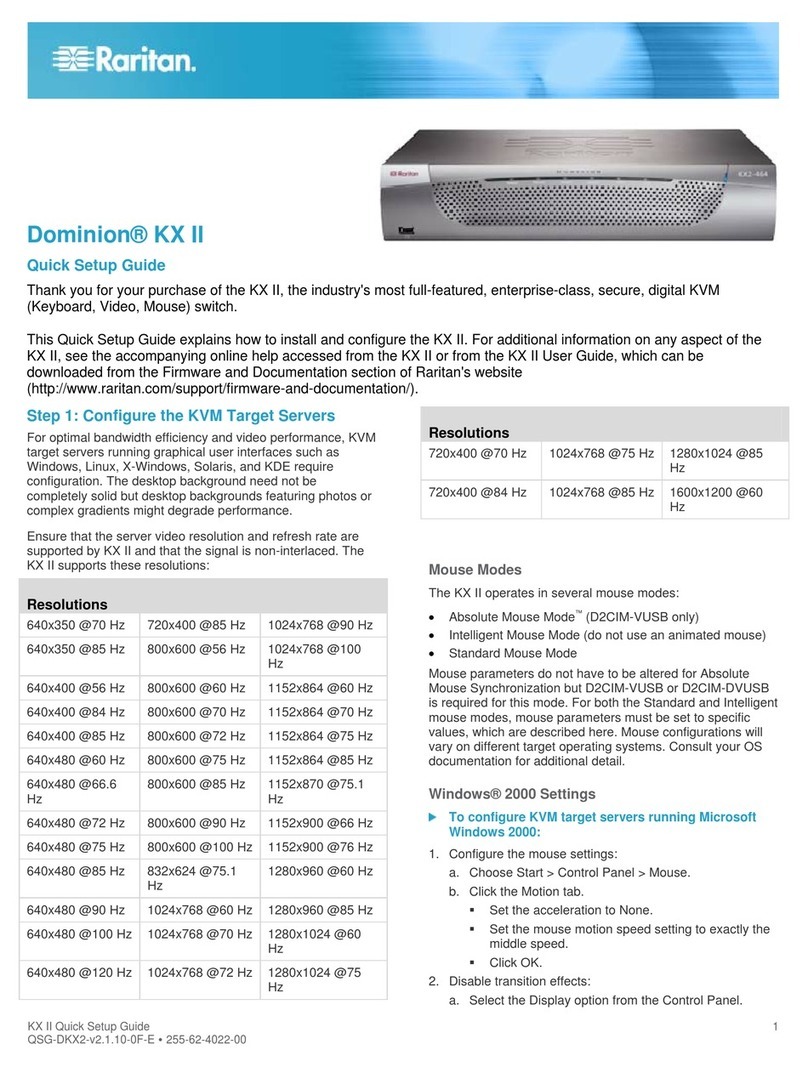

Raritan

Raritan Dominion KX II Quick setup guide

Aruba

Aruba 6400 Series Installation, Safety, and Regulatory Information

Rosewill

Rosewill RC-410X Quick installation guide

Extron electronics

Extron electronics SW4 12G HD-SDI Setup guide

SignaMax

SignaMax 065-7111F Series user guide

abaco systems

abaco systems NETernity RM921N Hardware reference manual

Girard Systems

Girard Systems 98GC230 installation guide

schmersal

schmersal AZ201-I2-CC-T-1P2P Operation and assembly instructions

HP

HP 316095-B21 - StorageWorks Edge Switch 2/24 installation instructions

Cabletron Systems

Cabletron Systems 9F426-02 user guide

SPROLINK

SPROLINK NeoLIVE R2 PLUS user manual