Veris Industries Hawkeye H608 User manual

Other Veris Industries Switch manuals

Veris Industries

Veris Industries Hawkeye H609 User manual

Veris Industries

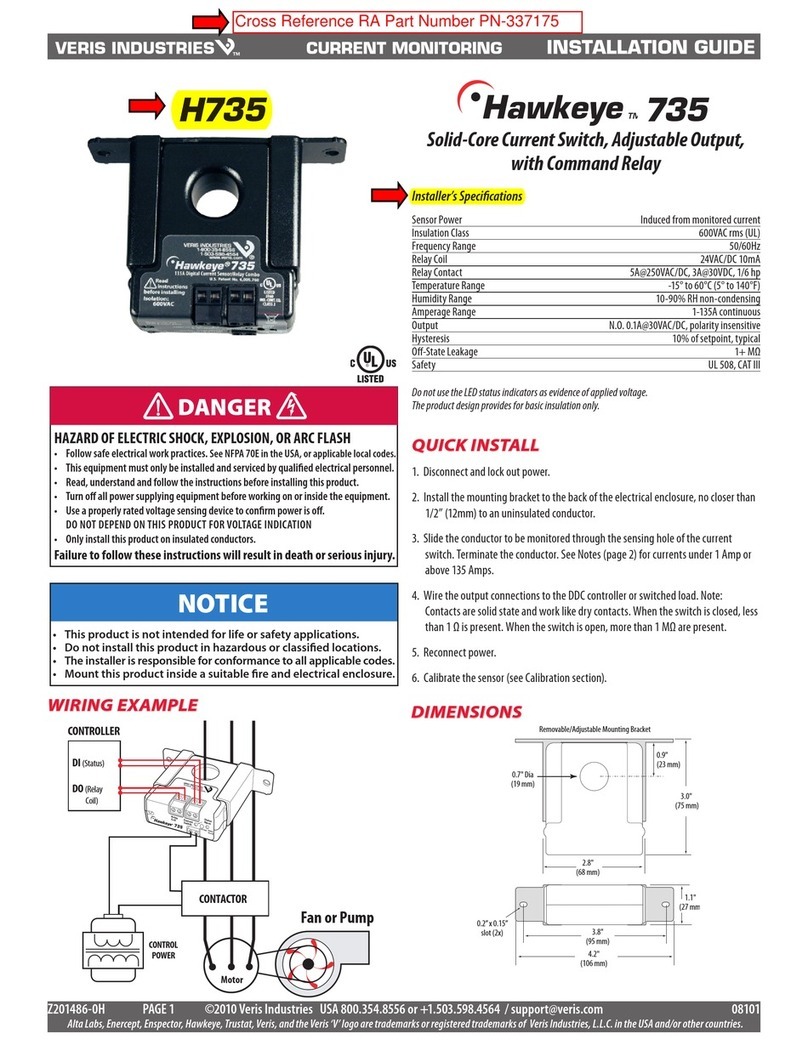

Veris Industries Hawkeye 738 User manual

Veris Industries

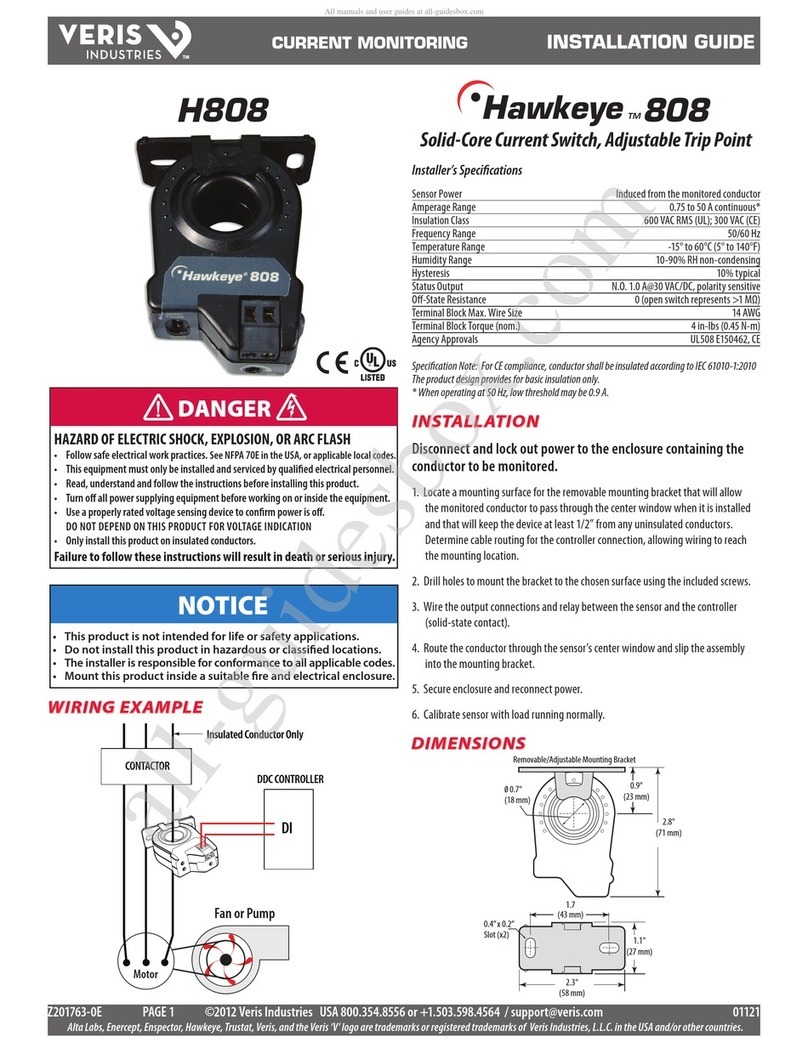

Veris Industries Hawkeye H808 User manual

Veris Industries

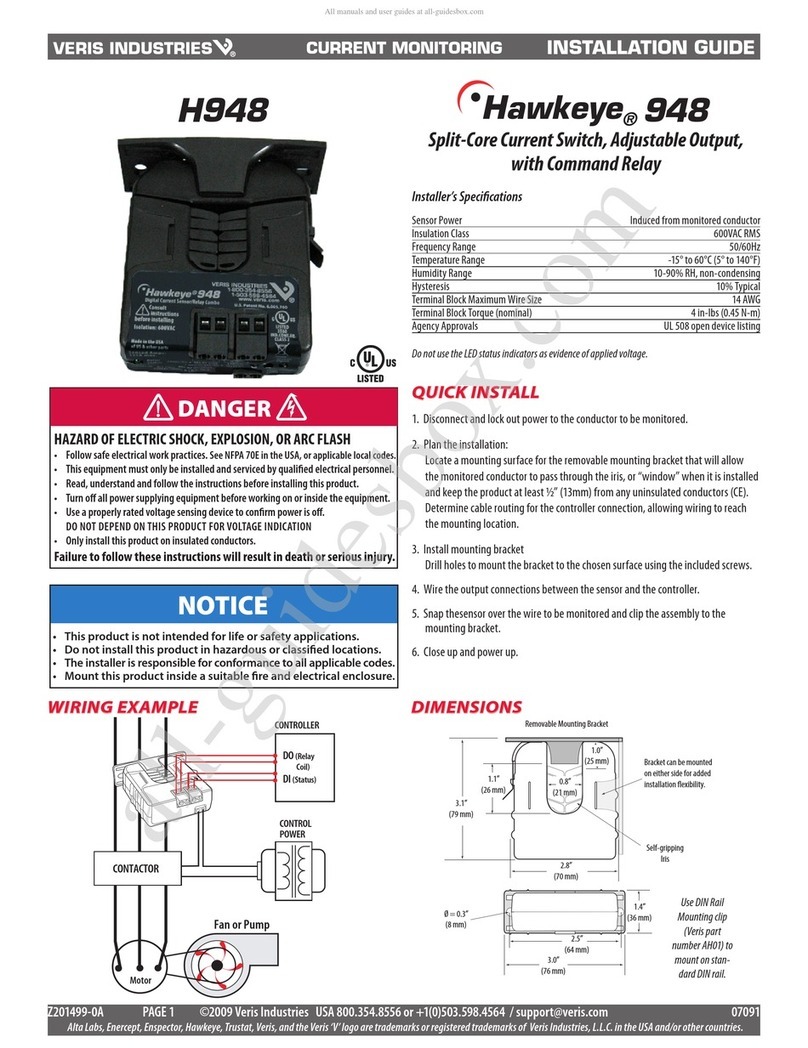

Veris Industries Hawkeye H948 User manual

Veris Industries

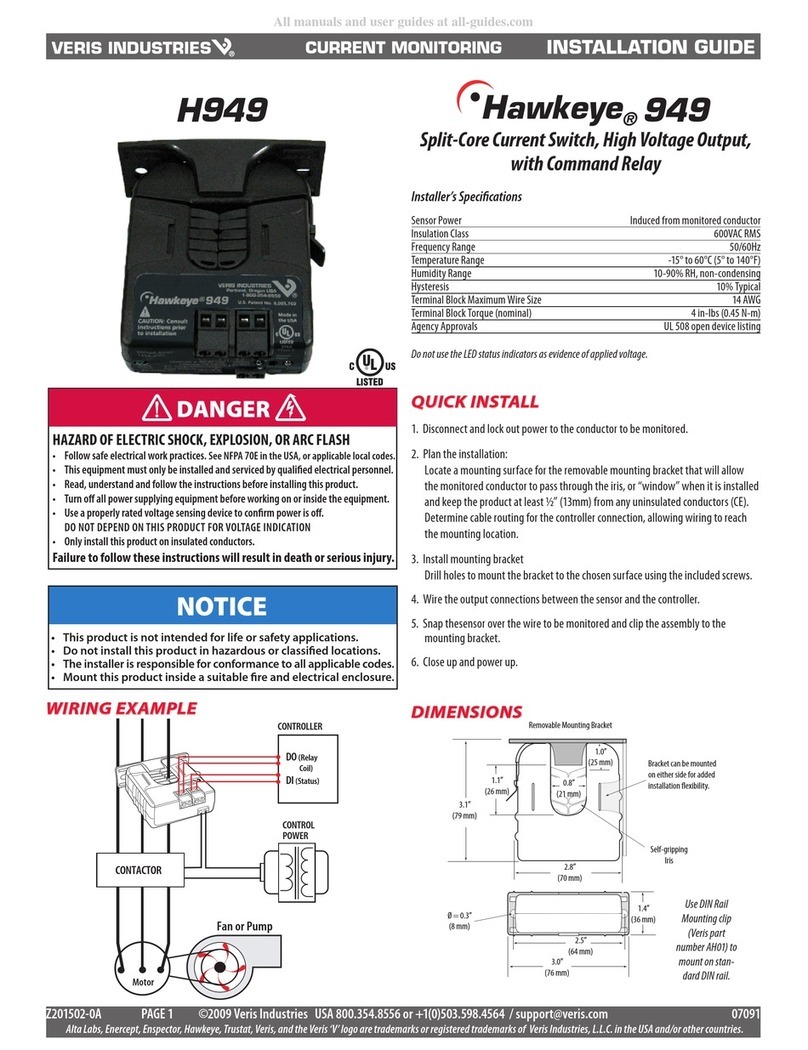

Veris Industries Hawkeye H949 User manual

Veris Industries

Veris Industries H909 User manual

Veris Industries

Veris Industries Hawkeye 939 User manual

Veris Industries

Veris Industries Hawkeye 730 User manual

Veris Industries

Veris Industries Hawkeye H950 User manual

Veris Industries

Veris Industries Hawkeye H906 User manual

Veris Industries

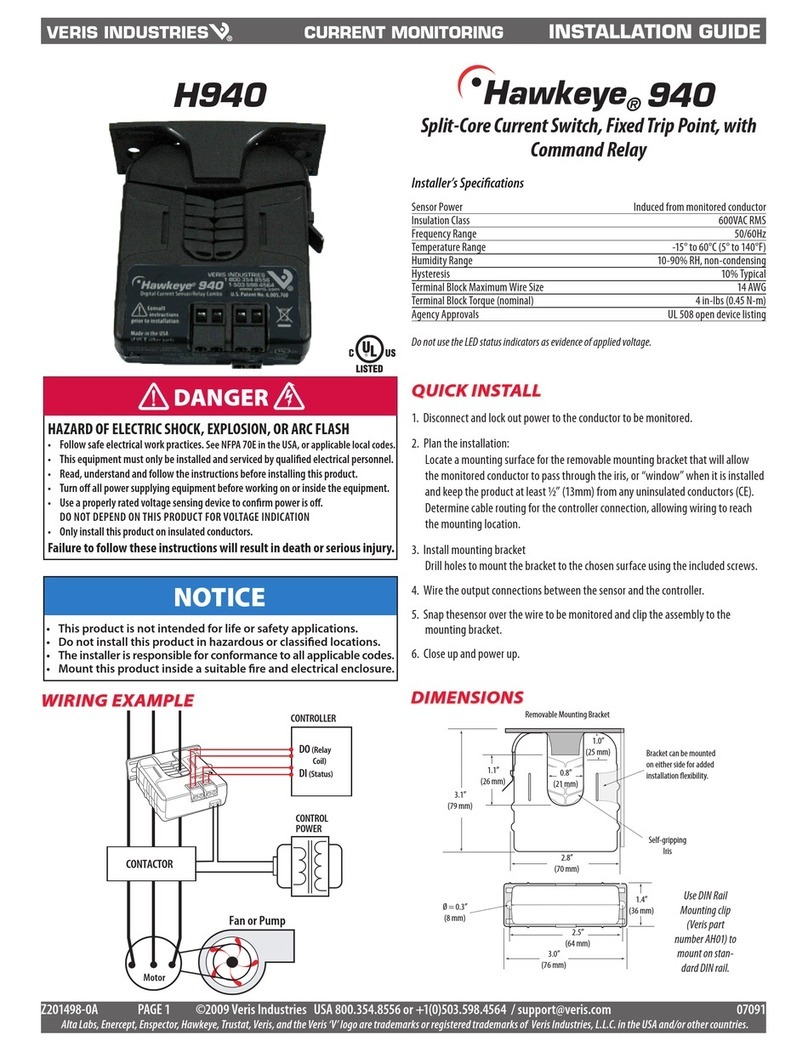

Veris Industries Hawkeye H940 User manual

Veris Industries

Veris Industries Hawkeye 949 User manual

Veris Industries

Veris Industries Hawkeye 949 User manual

Veris Industries

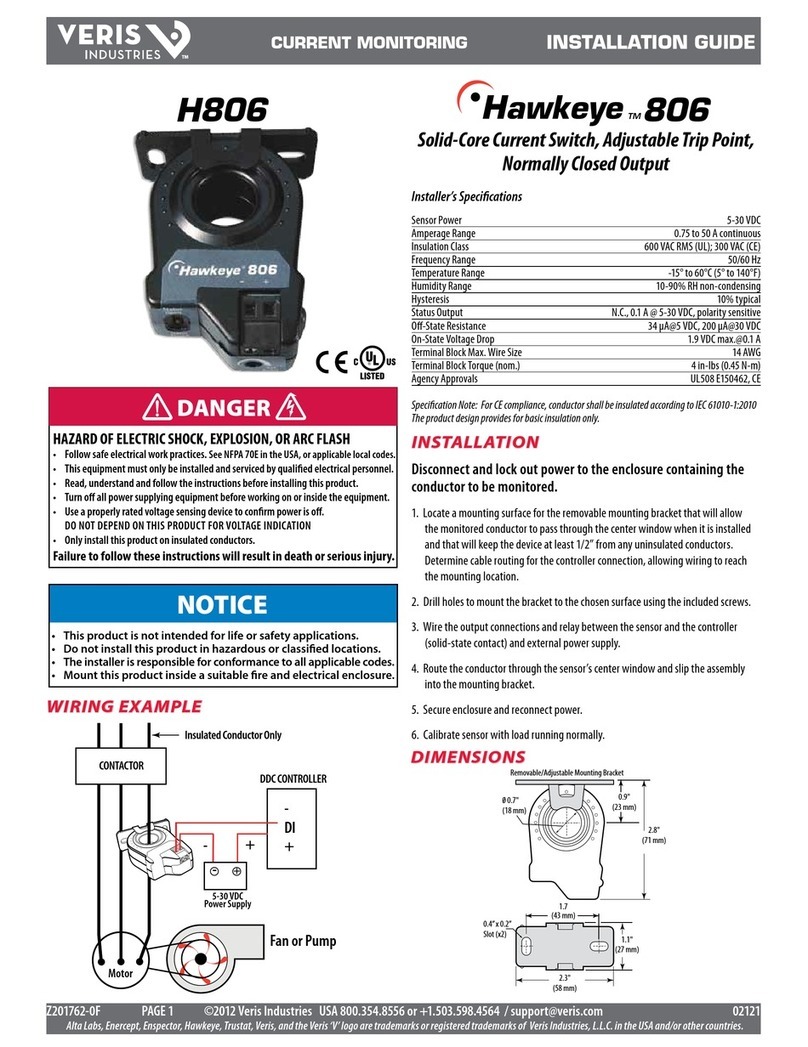

Veris Industries H806 User manual

Veris Industries

Veris Industries Hawkeye H11D User manual

Veris Industries

Veris Industries Hawkeye 959 User manual

Veris Industries

Veris Industries Hawkeye 949 User manual

Veris Industries

Veris Industries Hawkeye 949 User manual

Veris Industries

Veris Industries Hawkeye 909 User manual

Veris Industries

Veris Industries Hawkeye 908 User manual

Popular Switch manuals by other brands

SMC Networks

SMC Networks SMC6224M Technical specifications

Aeotec

Aeotec ZWA003-S operating manual

TRENDnet

TRENDnet TK-209i Quick installation guide

Planet

Planet FGSW-2022VHP user manual

Avocent

Avocent AutoView 2000 AV2000BC AV2000BC Installer/user guide

Moxa Technologies

Moxa Technologies PT-7728 Series user manual

Intos Electronic

Intos Electronic inLine 35392I operating instructions

Cisco

Cisco Catalyst 3560-X-24T Technical specifications

Asante

Asante IntraCore IC3648 Specifications

Siemens

Siemens SIRIUS 3SE7310-1AE Series Original operating instructions

Edge-Core

Edge-Core DCS520 quick start guide

RGBLE

RGBLE S00203 user manual