Evenlite Aperion LED User manual

Table of contents

Popular Security Sensor manuals by other brands

Tinker & Rasor

Tinker & Rasor AP/W instructions

Paradox

Paradox Paradome DG467 instructions

C.P. Electronics

C.P. Electronics MWS5-DD-SA-C installation guide

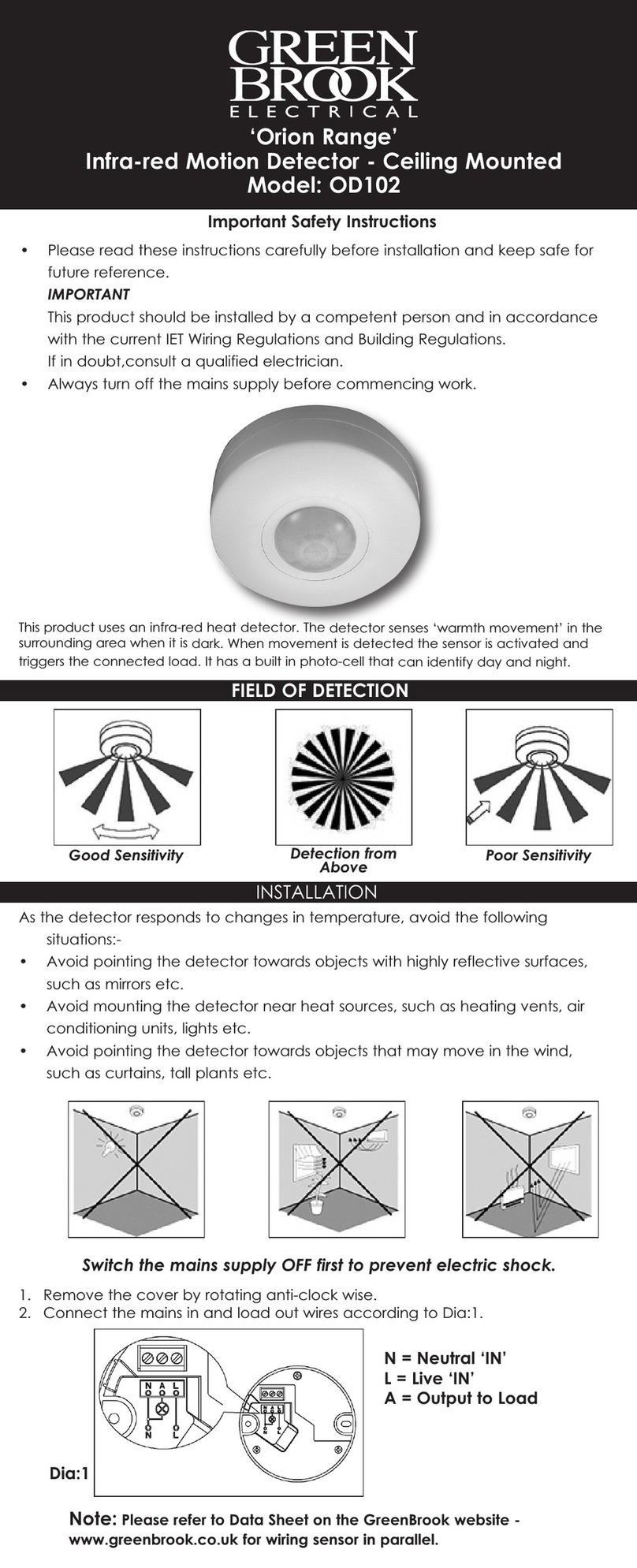

Green Brook

Green Brook Orion Range OD102 Important safety instructions

C.P. Electronics

C.P. Electronics MWS3A-AD installation guide

C.P. Electronics

C.P. Electronics MWS1A-PRM-VFC installation guide

C.P. Electronics

C.P. Electronics EBDHS-B-CB-DD installation guide

C.P. Electronics

C.P. Electronics EBMHS-PRM-SA-C installation guide

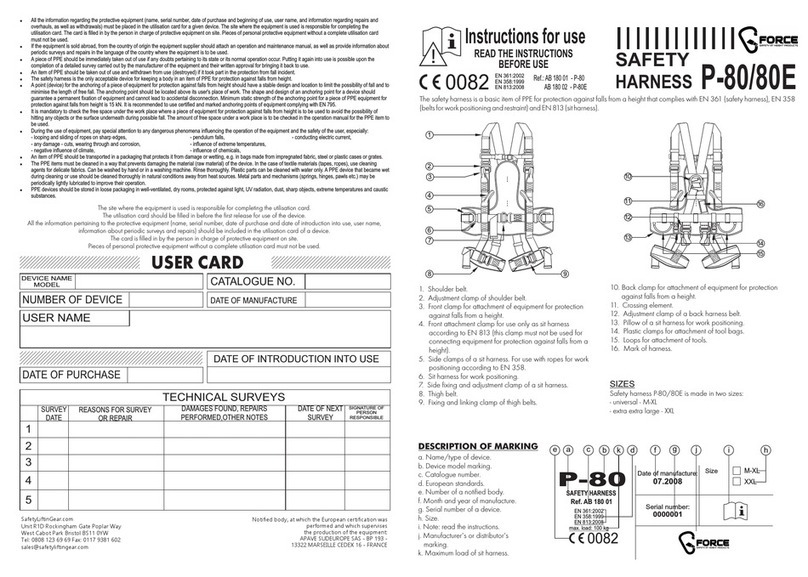

G-Force

G-Force P-80 Instructions for use

C.P. Electronics

C.P. Electronics MWS3A-AT-DD installation guide

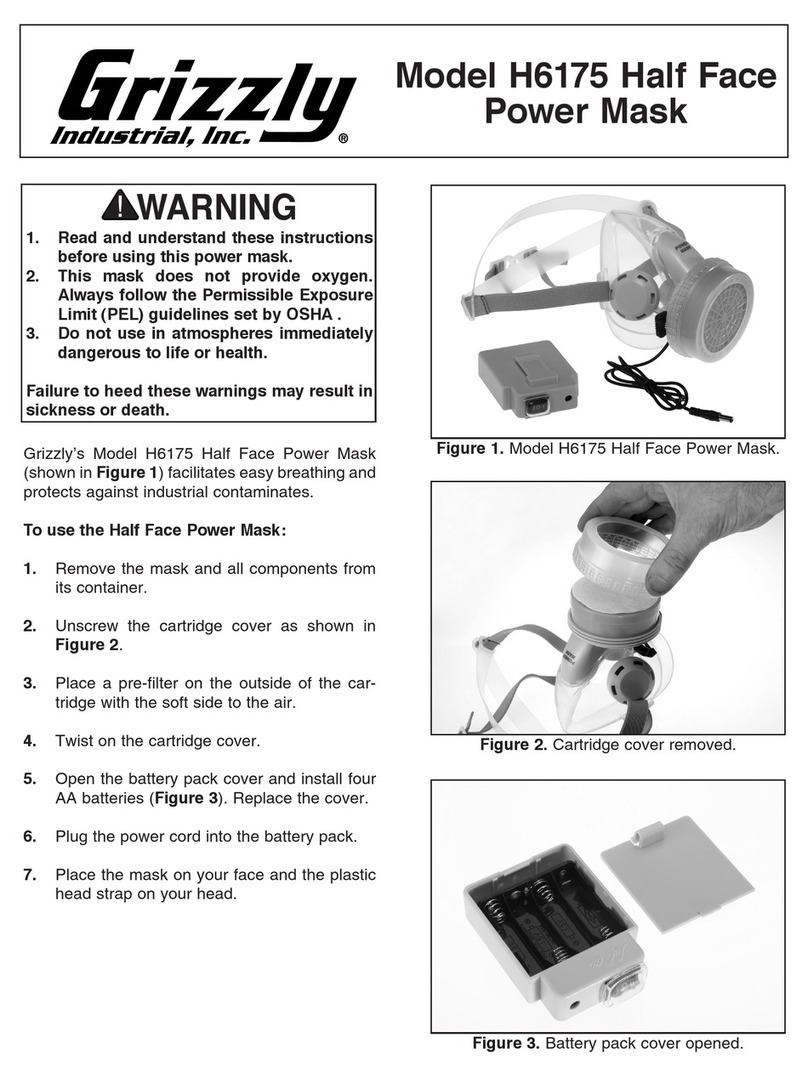

Grizzly

Grizzly H6175 user guide

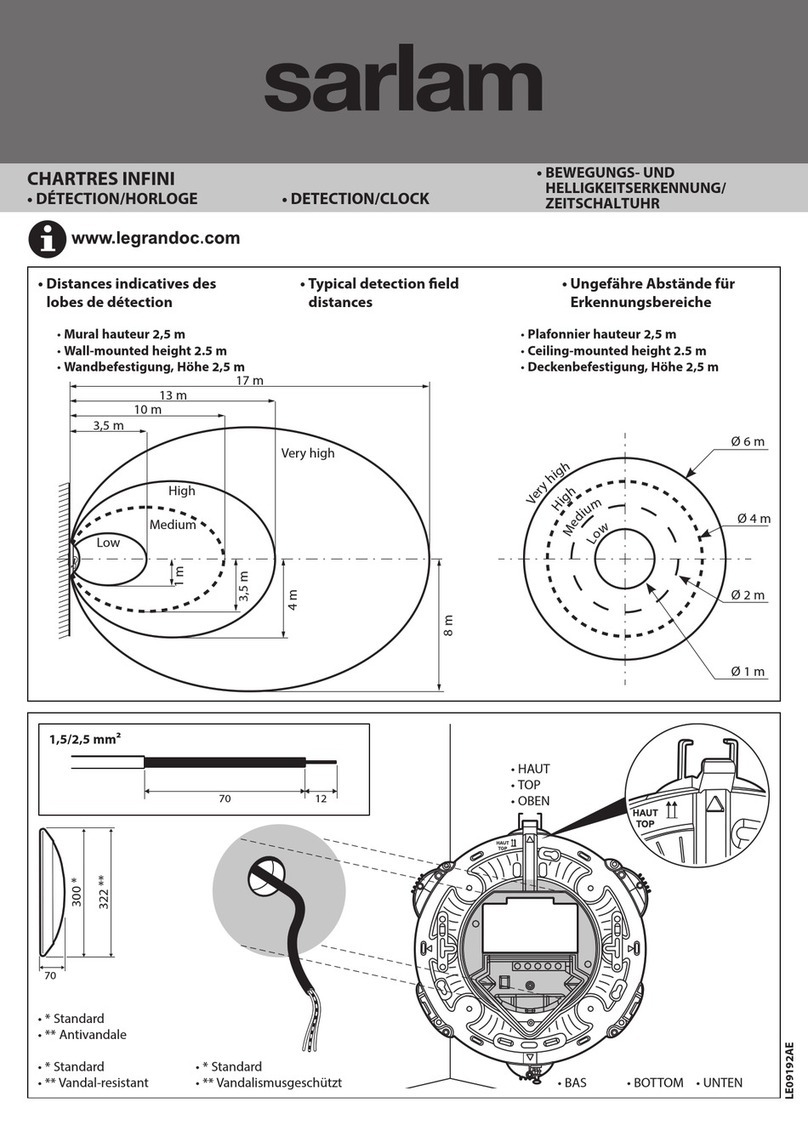

LEGRAND

LEGRAND SALARM SL532072 manual

Baumer

Baumer UNCK 09G8914 quick start guide

PCB Piezotronics

PCB Piezotronics 492B Installation and operating manual

Dedrone

Dedrone RF-310 instruction manual

MSA

MSA Vautex Elite S operating manual

ESYLUX

ESYLUX PROTECTOR KRF TCV 2G Installation and operating instruction

Schulz

Schulz hidro lav 2950W instruction manual