Everglow HK Series Instruction Manual

FOR YOUR SAFETY

The installation of this gas lamp

must conform with all local codes

or, in the absence of local codes,

with the latest edition of the Na-

tional Fuel Gas Code ANS Z21.42-

1993

FOR YOUR SAFETY

Do not place combustible materials

near this appliance.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

FOR YOUR SAFETY

If You Smell Gas

1. Shut off gas to appliance.

2. Extinguish any open flame.

3. If odor continues, immediately

call your gas supplier

GAS LAMPS, PARTS, INSTALLATION AND

MAINTENANCE

MODELS: HK, GG AND HJ SERIES

SPECIAL NOTE

Lamps are set for 7" Water Column pressure on natural gas and 11" W.C. pressure for LP gas.

THESE INSTRUCTIONS SHOULD BE LEFT WITH THE CONSUMER.

KEEP THES INSTRUCTIONS FOR FUTURE REFERENCE.

LAMP CAGE AND BASE ARE NOT

AVAILABLE SEPARATELY

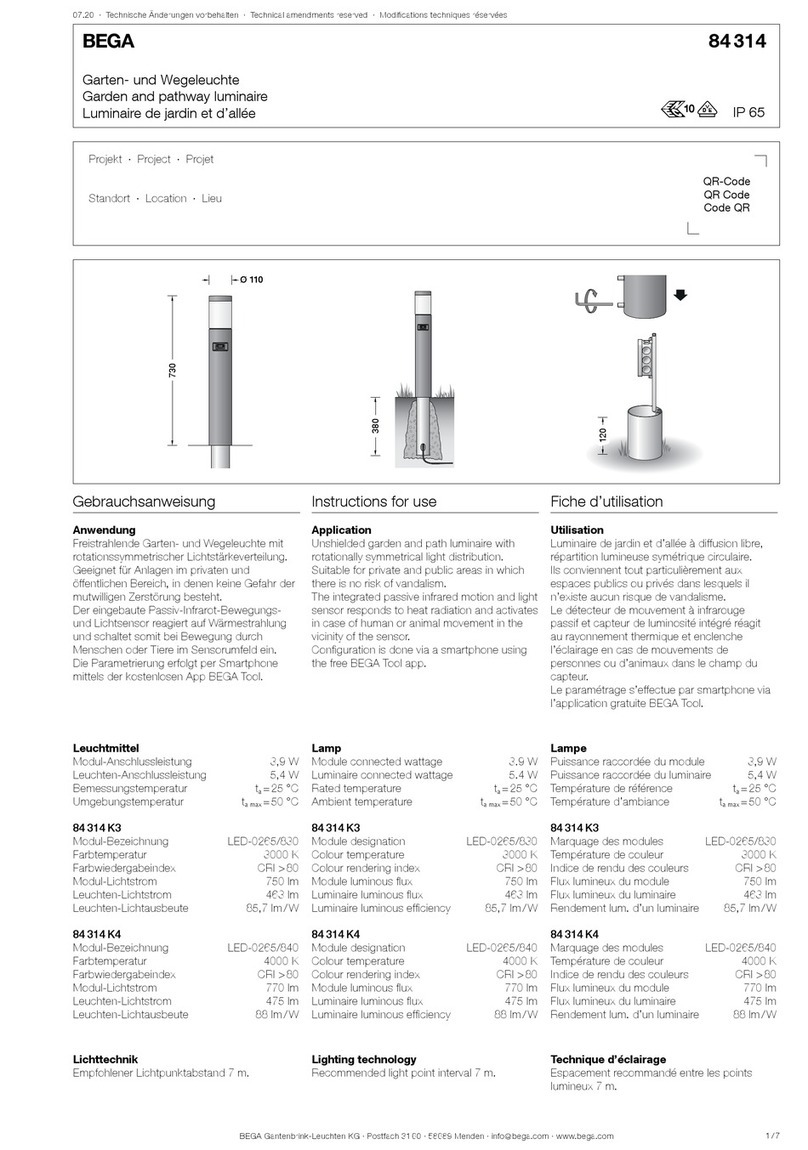

1

2

3

4

5

6

7

8

DMI

13

14

15

11

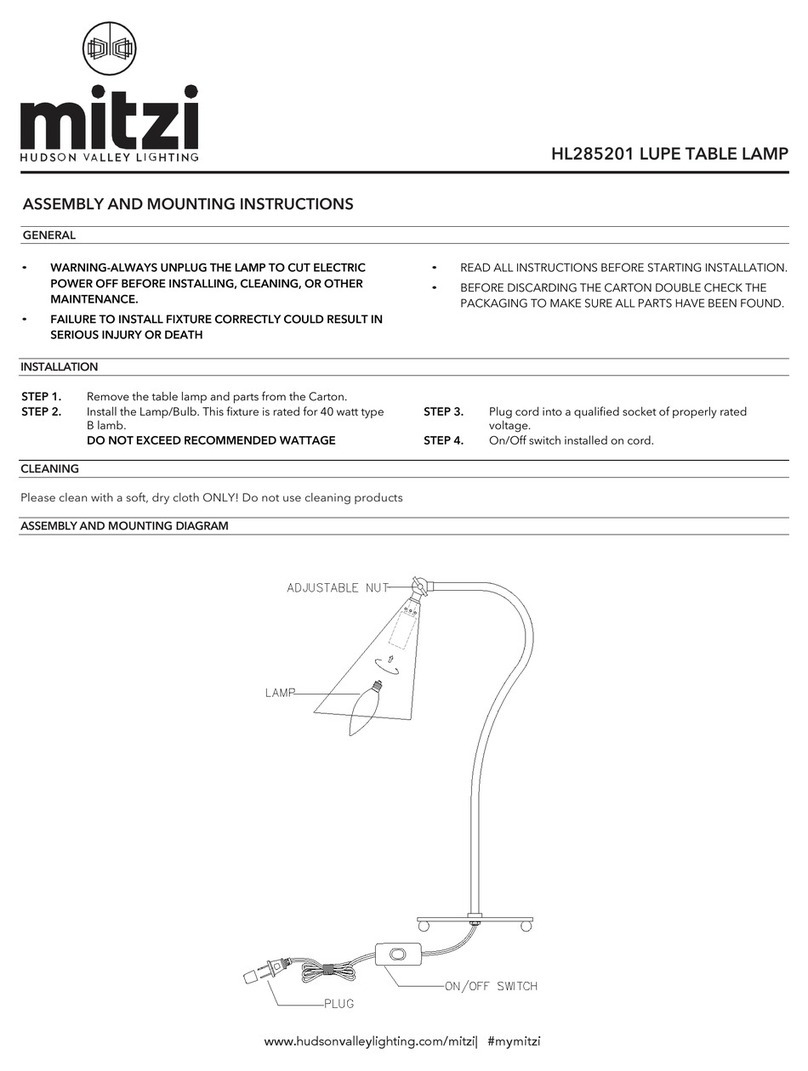

Complete lamp kit includes; orfice,

valve, mixer tube with adjustable

air shutter, burner head, ceramic

tips and two mantles. Specify LP

Or Nat. Gas

IMPORTANT

When ordering parts specify

lamp model, (aluminum or

brass), type of gas (LP or Natu-

MODEL

HK

NOTE: In Canada, the installation shall be in accordance with: the current edition of CAN/CGA-B149.1 Natural

gas installation code or CAN/CGA-B149.2 Propane gas installation code, and all local codes where applicable.

All lamps are available with inverted and upright burner. Replacement parts may be obtained through an authorized MHP dealer,

please visit www.mhpgrills.com for a dealer near you or call 888.647.4745.

9A

10

12

9

2A

HK GG HJ

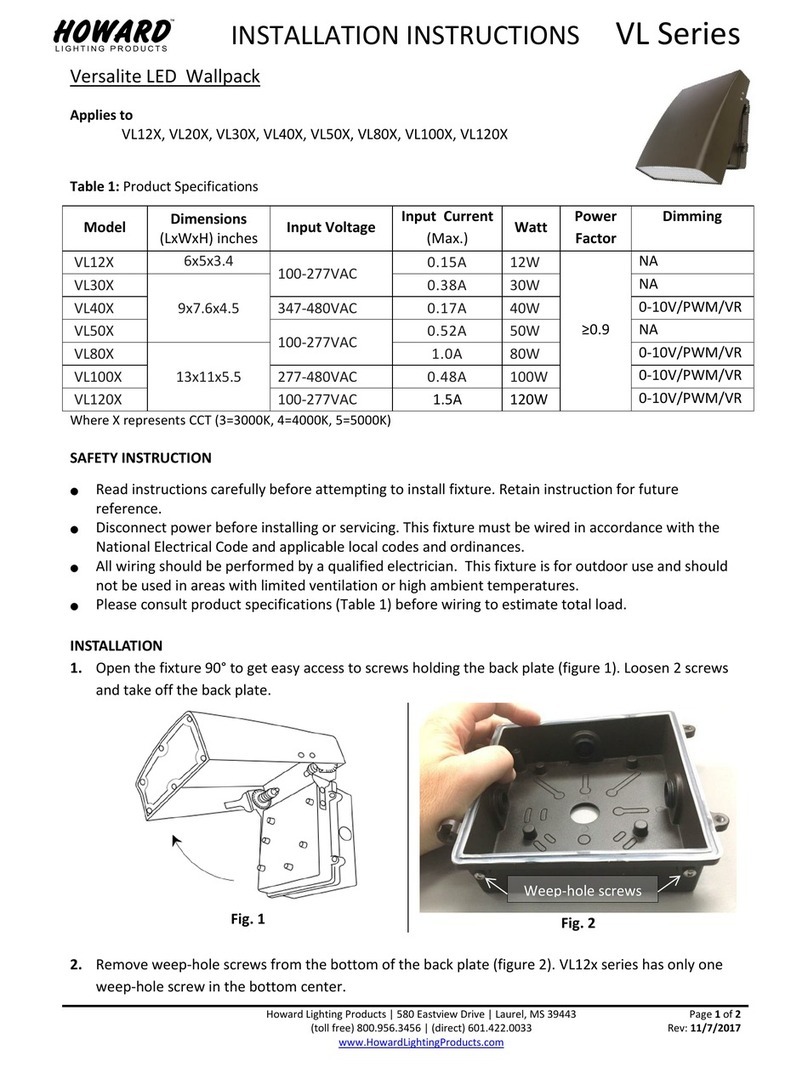

1 LBF LBF LBF Ball Finial

2 HKA2 GGA2 HJA2 Lamp Cap

3 Washer

4 1-3/4 1-3/4 1-3/4 Screw for Cap and Ball 10-24

5 DIB DIB DIB Burner Head

6 BT1 BT1 BT1 Ceramic Burner Tip

7 MTL2 MTL2 MTL2 Soft Mantle– No2 Ring Size

8 ALS ALS ALS Aluminum Lamp Tube

9 ORF ORF ORF Lamp Valve Orifice (Specify LP

or Nat)

10 GLV GLV GLV Lamp Valve

13 CHM CHM CHM Glass Chimney

11 GLS GLS GLS Lamp Glass (4 Needed)

12 DMI DMI DMI Complete Burner Kit

14 MTL3 MTL3 MTL3 Upright Mantle

15 UBA UBA UBA Upright Burner Assembly

2A LSU LSU LSU Stainless Steel Top Screen,

4⅜" dia.

9A LSL LSL LSL Stainless Steel Lower Screen,

3⅝" x 4⅝"

POST AND TUBING INF

Proper post and tubing selection is essential. Your local

gas company or an authorized MHP Dealer can supply

these parts. 1/4"soft copper tubing that has been internally

tinned is recommended. 1/4" flare nuts should be used on

both ends.

NOTE: The lamp is for outdoor installation only and

must be installed at least 12" in any direction from any

combustible materials.

18"

COPPER

TUBE

INLET

POST INSTALLATION

1. Dig a hole in the ground approximately 12" wide

by 24" deep.

2. Set the bottom of the post in the center of the

hole. Brace the post in a plumb position and

pour concrete around the post to just below the

gas line access hole.

INSTALL LAMP ON POST

1. If not already furnished, place tubing in post.

Tubing should have at least two coils at the top

of the post.

2. Connect gas supply line to tubing at the base of

the post and tighten flare nuts clockwise. No

sealants are necessary.

LIGHTING IN

Turn gas supply off and wait for

Broken mantel

IMPORTANT: Gas mantles are very delicate and should not

be handled roughly.

A. Remove new mantle from the container without touching

the cloth portion. Hang the mantle on the burner tip,

rotating it to fit into the slots on the burner tip.

B. Nothing should touch the cloth portion, so when lighting,

do not touch the match to the mantle itself. (Pull down only

on a soft mantle to shape it.

STEP 1

Remove the glass by lifting

from the bottom with fore-

finger, pulling out slightly,

and lowering.

NOTE: Proper combustion

is essential. Do not ob-

struct air inlet or outlet

vents.

STEP 2

WITH GAS TURNED OFF,

Hold a lighted match up to

but not touching the man-

tle. This will burn off the

protective coating (and it

will flash slightly). Do not

touch the mantle with the

match.

STEP 3

After the mantles have

stopped burning, us

screwdriver to slowly turn

the gas ON and hold an-

other match up to

touching, the mantle

light them. When li

the gas on full.

150 South Ram

PH: 888.647.4745 • 847.

FAX: 800.637.2918 • 84

www.mhpgrills.com

MAINTENANCE INSTRUCTIONS

1. Monthly visually inspect the lamps burner flame characteristics. The flame should be contai

and not extend above the ceramic mantle ring (Fig. 2). If flame exte

local gas company or authorized MHP dealer.

2. Proper combustion is essential. Do not obstruct air inlet or outlet

3. Always keep the appliance area clear and free of combustible

4. Turn gas OFF and let lamp cool before performing any maintenan

soapy water or glass cleaner. Lamp may be repainted with a good q

wool or sandpaper.

CERM

BURN

VENT

TU

FOR YOUR SAFETY

The installation of this gas lamp

must conform with all local codes

or, in the absence of local codes,

with the latest edition of the Na-

tional Fuel Gas Code ANS Z21.42-

1993

line or other

other appliance.

MAINTENANCE

" W.C. pressure for LP gas.

EFT WITH THE CONSUMER.

FOR FUTURE REFERENCE.

the current edition of CAN/CGA-B149.1 Natural

n code, and all local codes where applicable.

y be obtained through an authorized MHP dealer,

5.

HK GG HJ

1 LBF LBF LBF Ball Finial

2 HKA2 GGA2 HJA2 Lamp Cap

3 Washer

4 1-3/4 1-3/4 1-3/4 Screw for Cap and Ball 10-24

5 DIB DIB DIB Burner Head

6 BT1 BT1 BT1 Ceramic Burner Tip

7 MTL2 MTL2 MTL2 Soft Mantle– No2 Ring Size

8 ALS ALS ALS Aluminum Lamp Tube

9 ORF ORF ORF Lamp Valve Orifice (Specify LP

or Nat)

10 GLV GLV GLV Lamp Valve

13 CHM CHM CHM Glass Chimney

11 GLS GLS GLS Lamp Glass (4 Needed)

12 DMI DMI DMI Complete Burner Kit

14 MTL3 MTL3 MTL3 Upright Mantle

15 UBA UBA UBA Upright Burner Assembly

2A LSU LSU LSU Stainless Steel Top Screen,

4⅜" dia.

9A LSL LSL LSL Stainless Steel Lower Screen,

3⅝" x 4⅝"

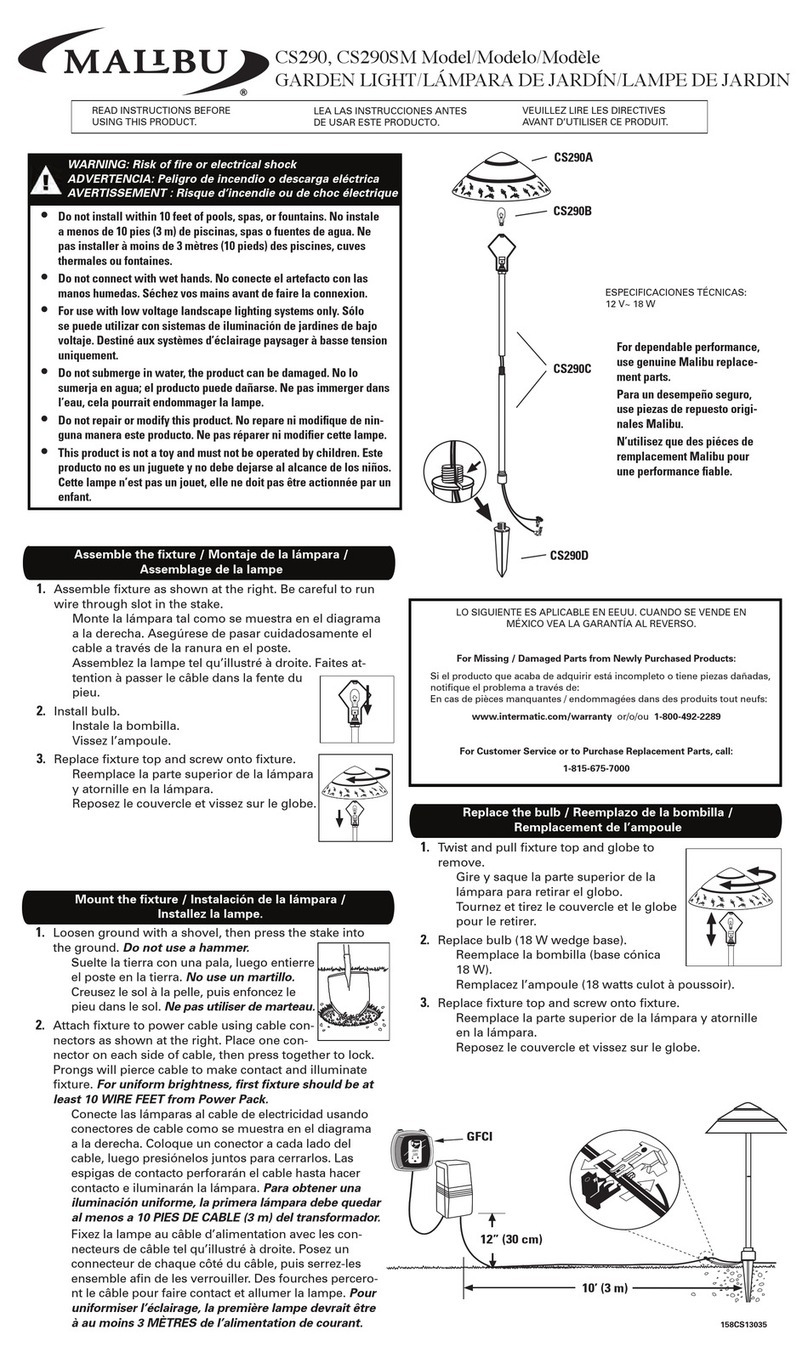

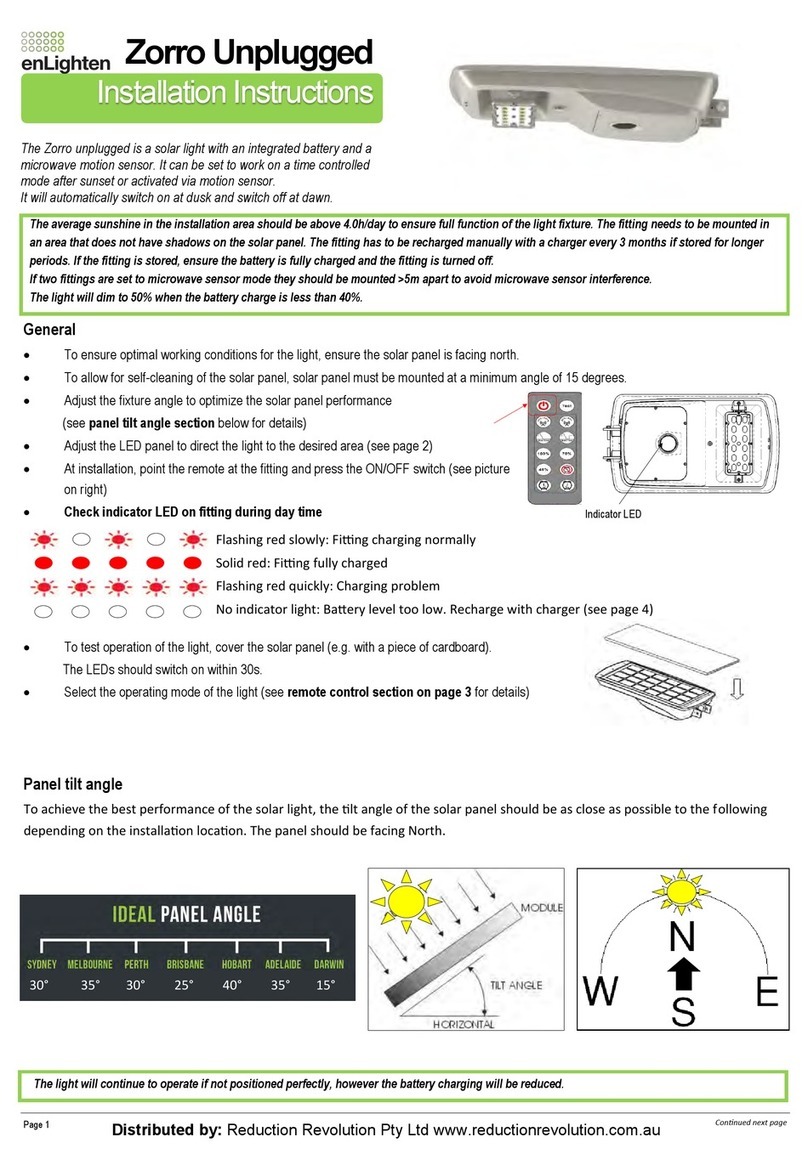

POST AND TUBING INFORMATION

Proper post and tubing selection is essential. Your local

gas company or an authorized MHP Dealer can supply

these parts. 1/4" soft copper tubing that has been internally

tinned is recommended. 1/4" flare nuts should be used on

both ends.

NOTE: The lamp is for outdoor installation only and

must be installed at least 12" in any direction from any

combustible materials.

LADDER

REST

COPPER

INTERNALS

1/4" Tubing

with

Flare Ends

HOLE 24"

DEEP

12" DIA.

16"

CONCRETE

18"

COPPER

TUBE

INLET

3. Perform any remaining assembly to the lamp but

do not install glass.

•Remove contents from burner kit box.

•Install finial to rain cap.

•Attach valve to gas supply tubing and tighten

flare nuts clockwise. Be sure the fittings are tight.

4. Slowly lower the lamp onto the post, guiding the

valve up through the center hole in the bottom of

the lamp. Take care not to bend or crimp the

tubing.

5. Align slot in the top of the post with the access

hole in the collar. Align valve stem with the access

hole and tighten the lock screw in the collar of the

lamp to secure the lamp to the pos.

6. Thread the burner tube onto the valve. Keep the

valve from turning by inserting a screwdriver

through the access hole.

7. Be certain the lamp valve is in the off position

turning on the gas supply.

8. Leaving lamp valve in off position, turn on main

gas supply and check all connections for leaks

using a soapy solution. Tighten any leaky joints

and recheck for leaks.

POST INSTALLATION

1. Dig a hole in the ground approximately 12" wide

by 24" deep.

2. Set the bottom of the post in the center of the

hole. Brace the post in a plumb position and

pour concrete around the post to just below the

gas line access hole.

INSTALL LAMP ON POST

1. If not already furnished, place tubing in post.

Tubing should have at least two coils at the top

of the post.

2. Connect gas supply line to tubing at the base of

the post and tighten flare nuts clockwise. No

sealants are necessary.

LIGHTING INSTRUCTIONS INVERTED BURNER

- CAUTION -

Turn gas supply off and wait for lamp to cool before starting any repairs. Remove and clean glass when necessary. Replace

Broken mantels. Refer to steps 1-6 of instructions.

BURNER

HEAD

IMPORTANT: Gas mantles are very delicate and should not

be handled roughly.

A. Remove new mantle from the container without touching

the cloth portion. Hang the mantle on the burner tip,

rotating it to fit into the slots on the burner tip.

B. Nothing should touch the cloth portion, so when lighting,

do not touch the match to the mantle itself. (Pull down only

on a soft mantle to shape it.

If a mantle should become damaged, additional mantles may

be obtained through your local gas company, gas appliance

dealer or hardware store. Always replace both mantles at the

same time. Mantles are Modern Home Products Part No.

MTL-2, No. 2 ring size. These are soft mantles requiring

shaping.

Refer to steps 1-6 for proper lighting procedure.

To clean the glass panels of your lamp, turn the gas off with

a screwdriver through the access hole in the lower collar of

the lamp head.

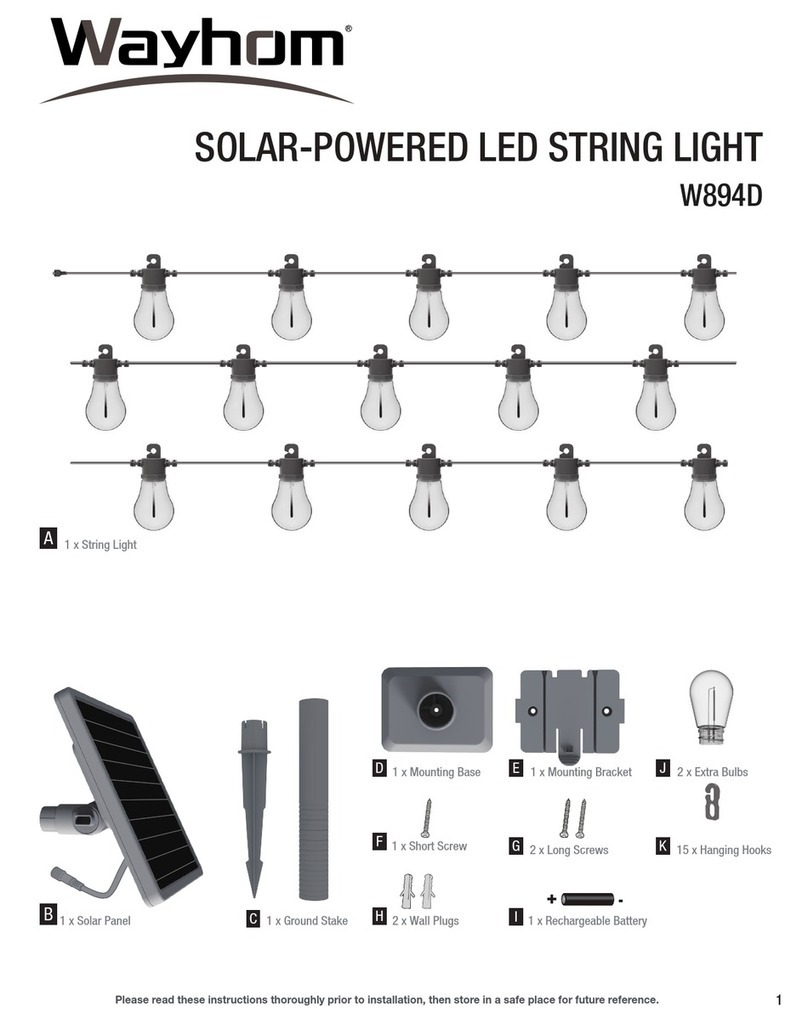

STEP 1

Remove the glass by lifting

from the bottom with fore-

finger, pulling out slightly,

and lowering.

NOTE: Proper combustion

is essential. Do not ob-

struct air inlet or outlet

vents.

STEP 2

WITH GAS TURNED OFF,

Hold a lighted match up to

but not touching the man-

tle. This will burn off the

protective coating (and it

will flash slightly). Do not

touch the mantle with the

match.

STEP 3

After the mantles have

stopped burning, use a

screwdriver to slowly turn

the gas ON and hold an-

other match up to, but not

touching, the mantles to

light them. When lit, turn

the gas on full.

STEP 4

Your MHP lamp is factory

set to burn at its most

efficient point. However,

this adjustment may be

changed during shipment.

To adjust this, raise or

lower the air shutter until

the mantles are burning

their brightest.

STEP 6

Replace the glass by fitting

the top edge into the frame

top, holding the glass

against the tabs inside the

frame. Allow the glass to

slide into frame bottom.

STEP 5

If flame extends above

the ceramic mantle ring,

turn off lamp valve and

contact your local gas

company or authorized

MHP dealer.

NOTE: Proper combus-

tion is essential. Do not

obstruct air inlet or

outlet vents.

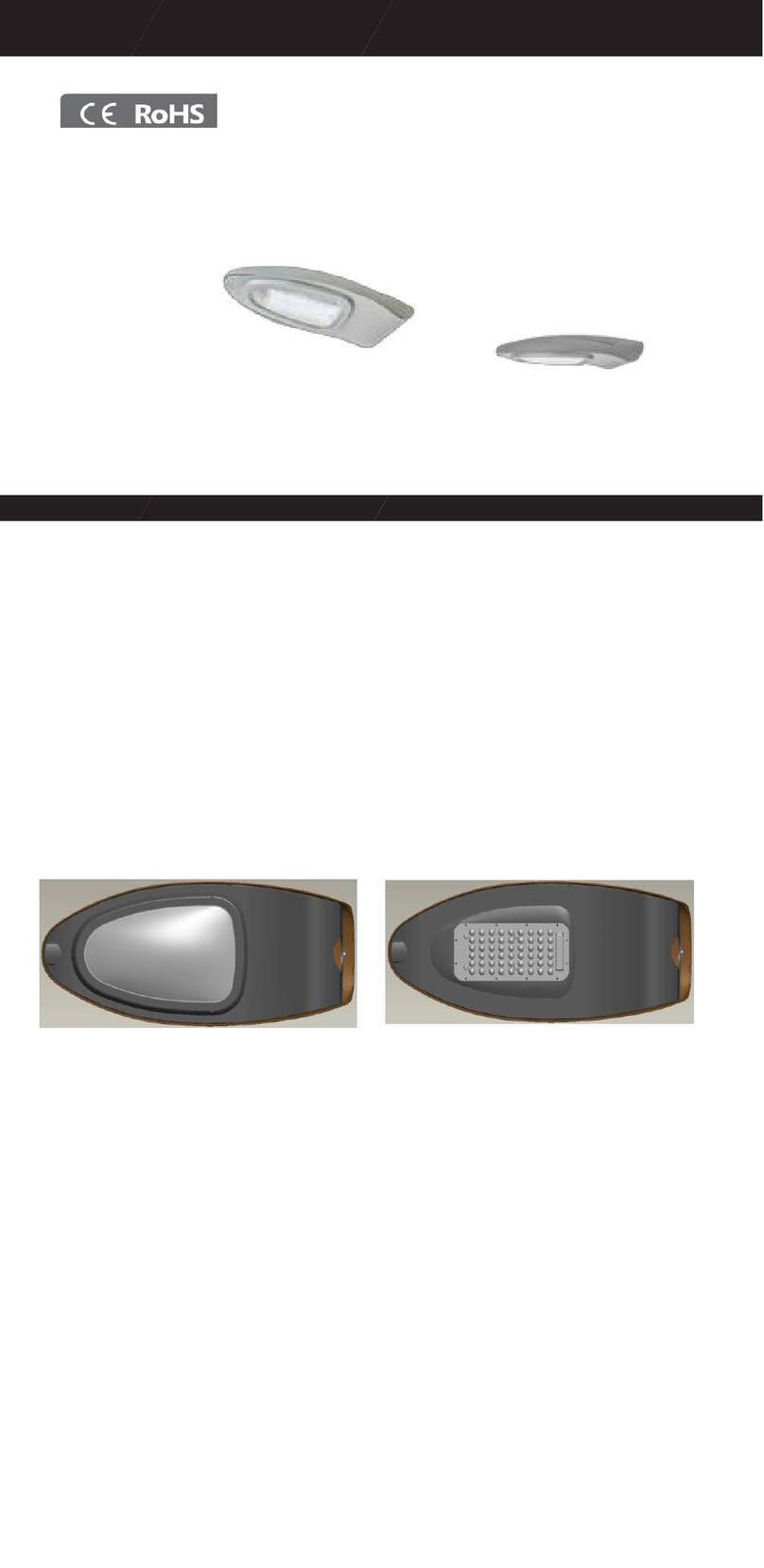

Fig. 1 Fig. 2

150 South Ram Road • Antioch, Illinois 60002

PH: 888.647.4745 • 847.395.6556

FAX: 800.637.2918 • 847.395.9121

Email: [email protected]

www.mhpgrills.com

FOR REPLACEMENT PARTS VISIT, WWW.MHPONLINESTORE.COM

1. Monthly visually inspect the lamps burner flame characteristics. The flame should be contained inside the mantle sack, (FIG. 1)

and not extend above the ceramic mantle ring (Fig. 2). If flame extends above the mantle ring, turn lamp OFF and contact your

local gas company or authorized MHP dealer.

2. Proper combustion is essential. Do not obstruct air inlet or outlet vents.

3. Always keep the appliance area clear and free of combustible material, gasoline and other flammable liquids.

4. Turn gas OFF and let lamp cool before performing any maintenance. Periodically remove glass panels and clean with hot

soapy water or glass cleaner. Lamp may be repainted with a good quality heat resistant paint after roughing surface with steel

wool or sandpaper.

MANTLES

HANG ON

TIPS

CERMAMIC

BURNER

VENTURI

TUBE

AIRFLOW

ADJUSTMENT

RING

IMPORTANT

Shutter opening

should be approx.

1/16"

0419

This manual suits for next models

2

Popular Outdoor Light manuals by other brands

Suneco

Suneco ECO5326LD Series manual

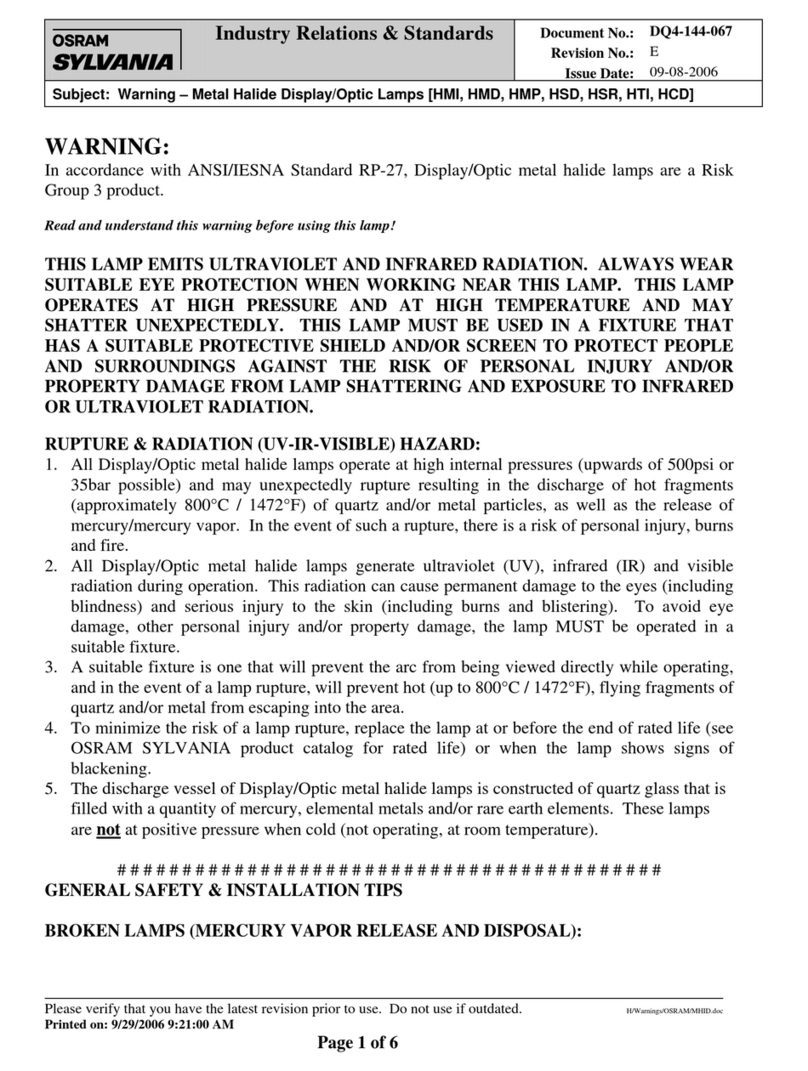

Osram

Osram SYLVANIA Series Installation and operation manual

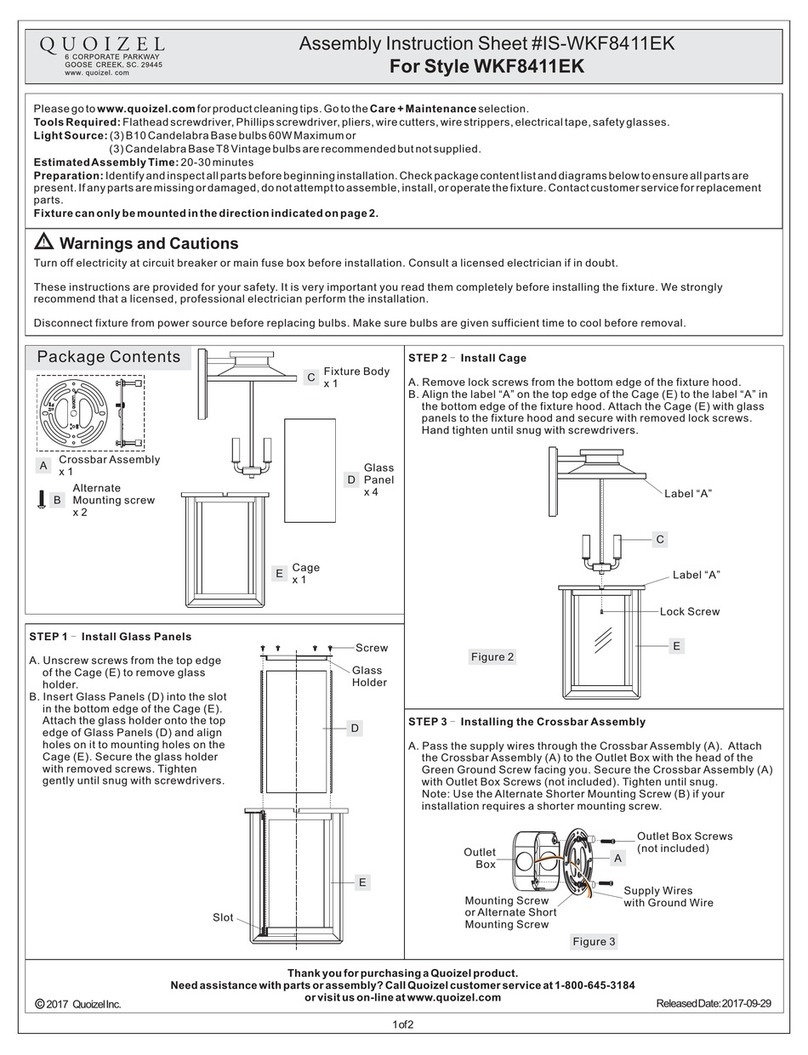

Quoizel

Quoizel WKF8411EK Assembly instruction sheet

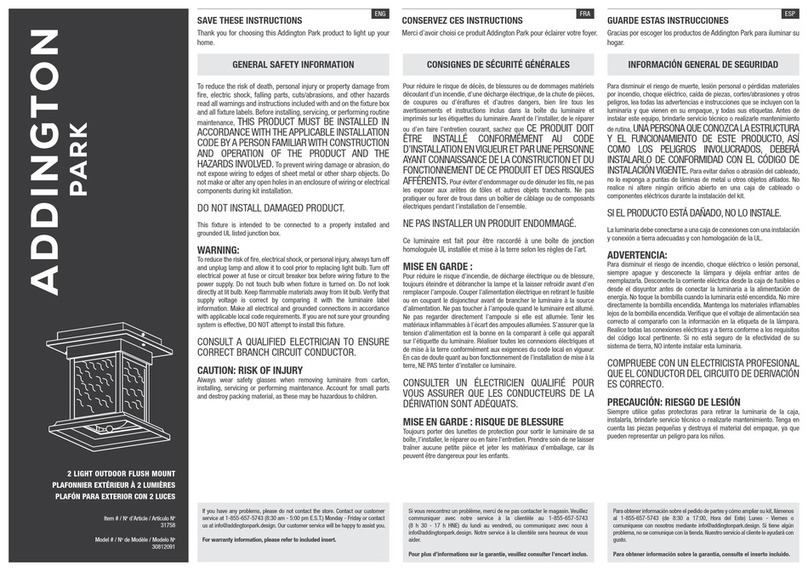

Addington Park

Addington Park 30812091 quick guide

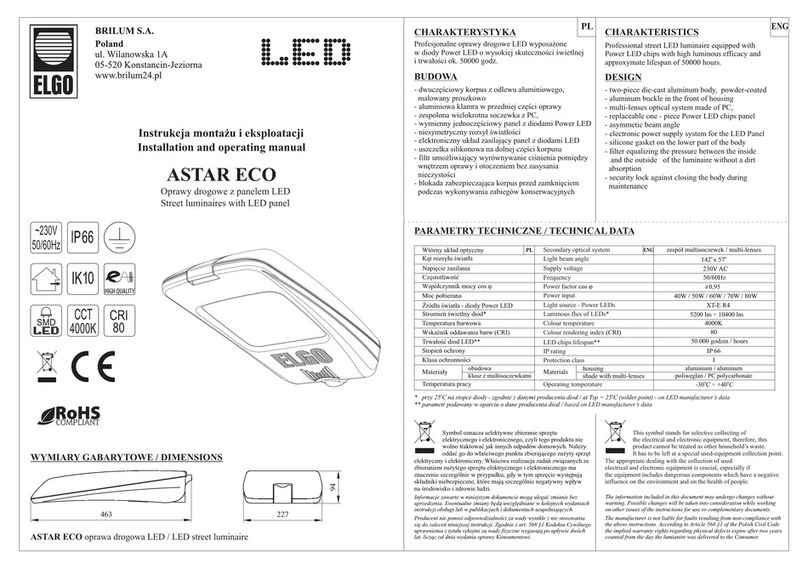

Elgo

Elgo ASTAR ECO Installation and operating manual

Kenroy Home

Kenroy Home Simplicity 30110WHWH-1 Use and care guide