EverHot BL1 Series User manual

A company that proposes sunny solutions, working with

passion and devotion, for three decades now, to always offer

the best.

A philosophy that leads our steps, and makes us, as

professionals, feel the weight of responsibility and obligation

to offer products and services that are in harmony with the

environment and man. So that we hand over a better world to

our children.

We live in times with great ecological problems. Planet

Earth is sounding the alarm of ecological danger. The

thoughtless use of mineral energy sources is resulting in

increased pollution of the atmosphere, above tolerance

levels.

Ecosystems are either being transformed or destroyed. While

mineral energy reserves are continuously decreasing and

prices continuously rising, we look at the sun and consider that

it radiates over 15.000 times the energy needs of our planet.

So why not direct ourselves to the inexhaustible, free, and

above all clean solar energy?

2

Solar System

•Why should we use a solar system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

•Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Hot water consumption / use

•Calculation of needs / Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

•Forced circulation kit –Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

What a solar system consists of:

(technical characteristics,

specifications)

•Solar collectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

•Boiler EVERHOT type BL1, with one tube heat exchanger . . . . . . . . . . Page 16

•Boiler EVERHOT type BL2, with two tube heat exchangers . . . . . . . . . Page 16

•Hydraulic kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 19

•Differential Thermostat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 22

•Peripheral accessories - Basic Accessories . . . . . . . . . . . . . . . . . . . . . . Page 23

•Peripheral accessories - Optional Accessories. . . . . . . . . . . . . . . . . . . . Page 24

Solar Systems

•Forced circulation systems –Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 25

•Typical installation diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 26

Installation Instructions

•Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 27

•Support base of collectors –installation instructions. . . . . . . . . . . . . . . . Page 28

•Connection of collectors and accessories . . . . . . . . . . . . . . . . . . . . . . . . Page 36

•Hydraulic kit and piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 38

•Electric connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 40

•Lightning protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 40

•Overheating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 40

•Snow and Wind loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 40

•Inspection Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 42

•Instructions to the end user and Installer. . . . . . . . . . . . . . . . . . . . . . . . . Page 43

•Installation sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 44

•Instructions for the Installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 45

3

2

WhyshouldweuseaSolarSystem

a solar system Is Ecologically friendly. Economical, Simple,

aesthetic, Effective and autonomous:

•Ecologically friendly:

With a Everhot 500E system, the emissions of C0 Avoided

Annually are equivalent to the fuel emissions of a car having

run for 10.000 km.

•Economical:

will decrease your cost for energy by 70 -100% because the

burner and electric resistance will not need to operate for at

least 7-12 months of the year, depends on the sun radiation of

each area and the size of the system.

•Simple:

The well-studied selection of materials of Everhot make Its

Installation safe and easy, reducing the time needed for Its

Installation to a minimum.

•Aesthetic:

The excellent exterior design of the Everhot collectors in

combination with their well-studied support base, offer the

possibility of a tangent Installation on tiled roofs matching

aesthetically with every architectural building design.

•Effective and Autonomous:

You have hot water at will 7-12 months per year. During winter

time you secure the pre-heating of the water, and the extra hot

water needed is secured from conventional energy.

4

The forced circulation system EVERHOT consists of

Thank you for choosing to buy a solar system EVERHOT Bl1 or Bl2.

Every system which you acquire consists of:

1. Boiler with one tube heat exchanger (type BL1) or with two tube heat

exchangers (type BL2) on a wooden palette and wrapped with stretch film.

2. One (1), Two (2), or Three (3) collectors which are protected during their

Transport with 4 plastic elbows of hard plastic.

3. Cardboard box with all of the accessories (except pipes and wires) which are

required for the installation of the system like hydraulic kit, expansion vessel,

differential thermostat with plastic case, antifreeze liquid and various

connection accessories in individual plastic packaging. Externally the box

refers to the model of the system for which the accessories are for.

4. Cardboard box with the metal plates of the support base, the screws, moly

plugs, the bolts etc…

5

General Information on needs of hot water

When choosing a solar system for hot water we must first determine our needs for hot

water, in quantity as well as in preferred temperature of consumption. The typical

calculation for the temperature for consumption is 45ºC, but for the calculation of required

quantity you must take into account the daily needs.

Calculation of needs for hot water usage

In family residences, the needs for hot water remain stable during the whole year. An

indication for the needs is given by the number of individuals living in the building (or

apartment). Usually, the per capita daily consumption of hot water at 45ºC is calculated

taking into consideration the following:

Low consumption: 35 liters per capita / day

Medium consumption: 60 liters per capita / day

High consumption: 80 liters per capita / day

In the case where we want to connect to the solar installation the washing machine and the

dishwasher, we would have to increase the calculated daily needs of consumption as

follows:

Washing Machine: 20 liters / day (1 wash per day)

Dishwasher:

20 liters / day (1 wash per day)

Example:

A family of 4 persons needs around 240 liters of hot water daily in order to have a medium

daily consumption. (60 liters per capita x 4 persons). If we include a washing machine and

dishwasher, then we must calculate a consumption of 280 liters per day.

In buildings such as hotels, hostels, etc…, the needs for hot water are related to the amount

of customers. In this case the daily consumption is calculated by the average occupancy

of the rooms, from the period of May up until August. Using this basis, the size of the pro-

posed installation is determined. Here below we indicate the per capita daily need for hot

water at 45ºC

Hostels with rooms with shared bath: 35 liters / person / day

Hostels: 40 liters / person / day

2 Star Hotels: 50 liters / person / day

3 Star Hotels: 80 liters / person / day

4 Star Hotels: 100 liters / person / day

Camping: 60 liters / person / day

6

2)HOTELS-HOSTELS

1) RESIDENCES

General Information

General Information on needs of hot water

Example:

An installation of agro tourism is maintained by a family of 4 persons that live in the

residence. During the period between May and August the average occupancy is 15

clients per day. For the occupants 2 meals are prepared per day and the dishwasher

washes 5 times per day.

Needs of family: 4 x 60 lt = 240 litres / day

Needs of the clients: 15 x 50 lt = 750 litres / day

Kitchen: 30 x 10 lt = 300 litres / day

Dishwasher:

5 x 20 lt = 100 litres / day

Total: 1.390 litres / day

In the next table we present the daily consumption for other applications:

Hospitals and clinics: 80 litres / bed

University residences: 80 litres / bed

Dressing rooms, public showers: 20 litres / person

Schools: 5 litres / student

Restaurants: 8 to 15 litres / meal

Bars: 2 litres / client

Prisons: 30 litres / person

Factories: 20 litres / persona

Offices: 5 litres / employee

Gymnasiums: 30 litres / user

The information of the above table can also be used in combinations so that in every case

the average daily consumption can be properly calculated.

In the case that a recirculation system exists for the hot water usage, you will also have

to take this into account for the needs. The calculation will have to be made every time

individually from the above tables and depends on the dimensions of the circuit and it’s

thermal insulation. Additionally, in the determination of the total needs, the thermal losses

of the total distribution circuit from the point of storage to the points of final consumption

must be taken into consideration.

In every case, the real needs for hot water are related to the personal attitude, the possible

special characteristics and habits of every place and application and also the way each

application functions.

For this reason, a specific calculation can be made by using the information on the gas/

petrol or electric bill. A flow meter installed on the hot water pipes could also be used.

7

REAL NEEDS

FACTORSOFINCREASEDNEEDS

3) OTHER APPLICATIONS

Forced circulation kit

When the difference in temperature between the sensor located in the solar collectors and the

sensor located in the storage tank is greater than the ‘Differential Temperature’, adjusted on the

differential thermostat, the circulator of the closed circuit starts up. This is located in the hydraulic

kit. The circulator functions only for the period of time that the above situation exists and only then

the water in the boiler is being heated from the solar system (BL1 or BL2).

Especially for the system BL2 (with a helping / secondary source of energy - central heating

boiler) in the case where the above mentioned circumstances do not exist, the storage tank can

heat up from secondary source of energy (for example: central heating boiler). This occurs

through the second tube heat exchanger of the boiler. In this case we must use an additional

electric connection / start up order of the burner and the circulator of the central heating boiler.

For both systems - models (BL1 and BL2) an electric resistance as a secondary source of energy

can be used. (upon a special order).

The circulator for recirculation (optional) is used for the re-circulation of the hot water between the

storage tank (boiler) and the usually far off distributors of the hot water.

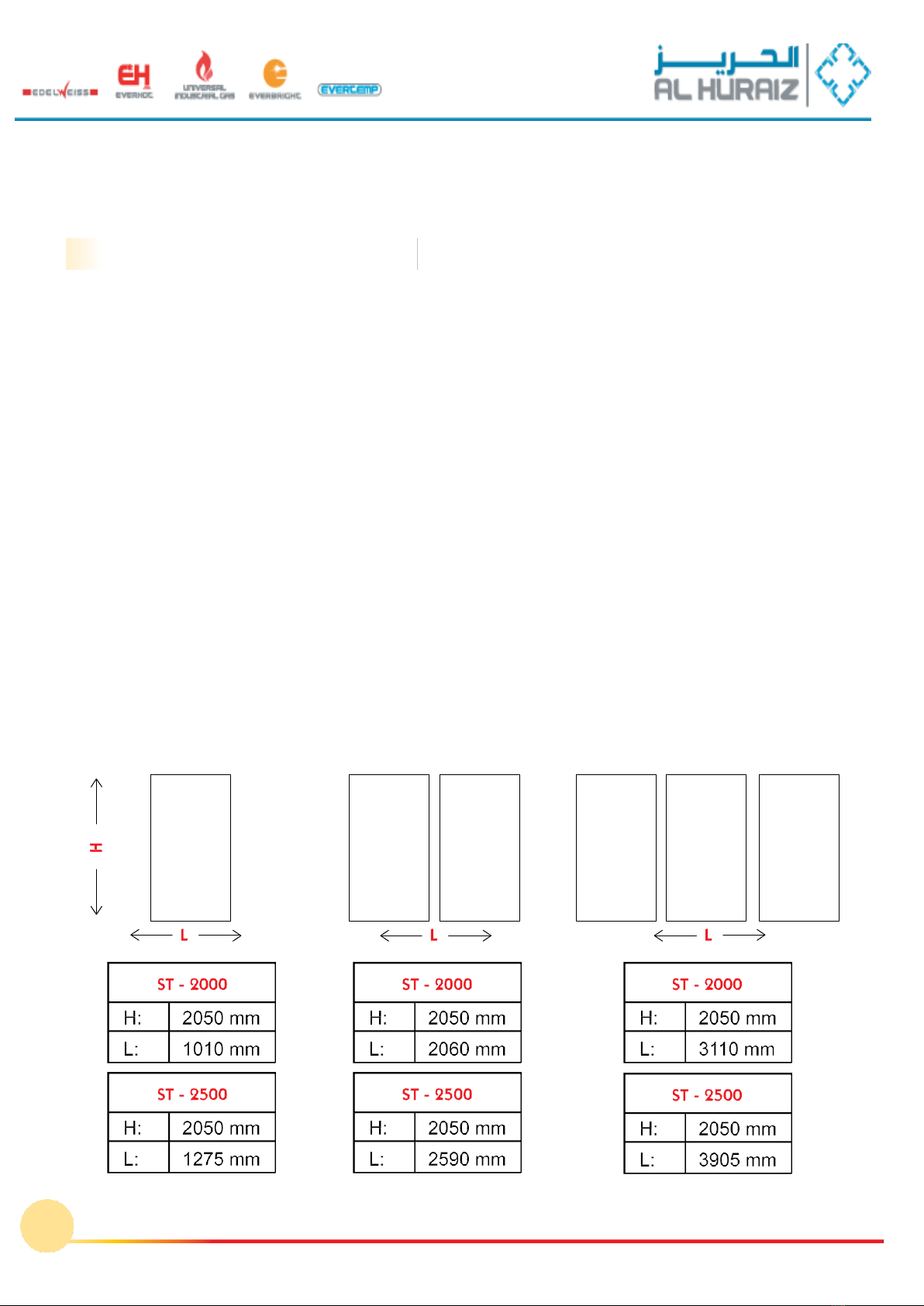

Dimensions of installed collectors

1Collector

2 Collectors

3 Collectors

.

8

Function

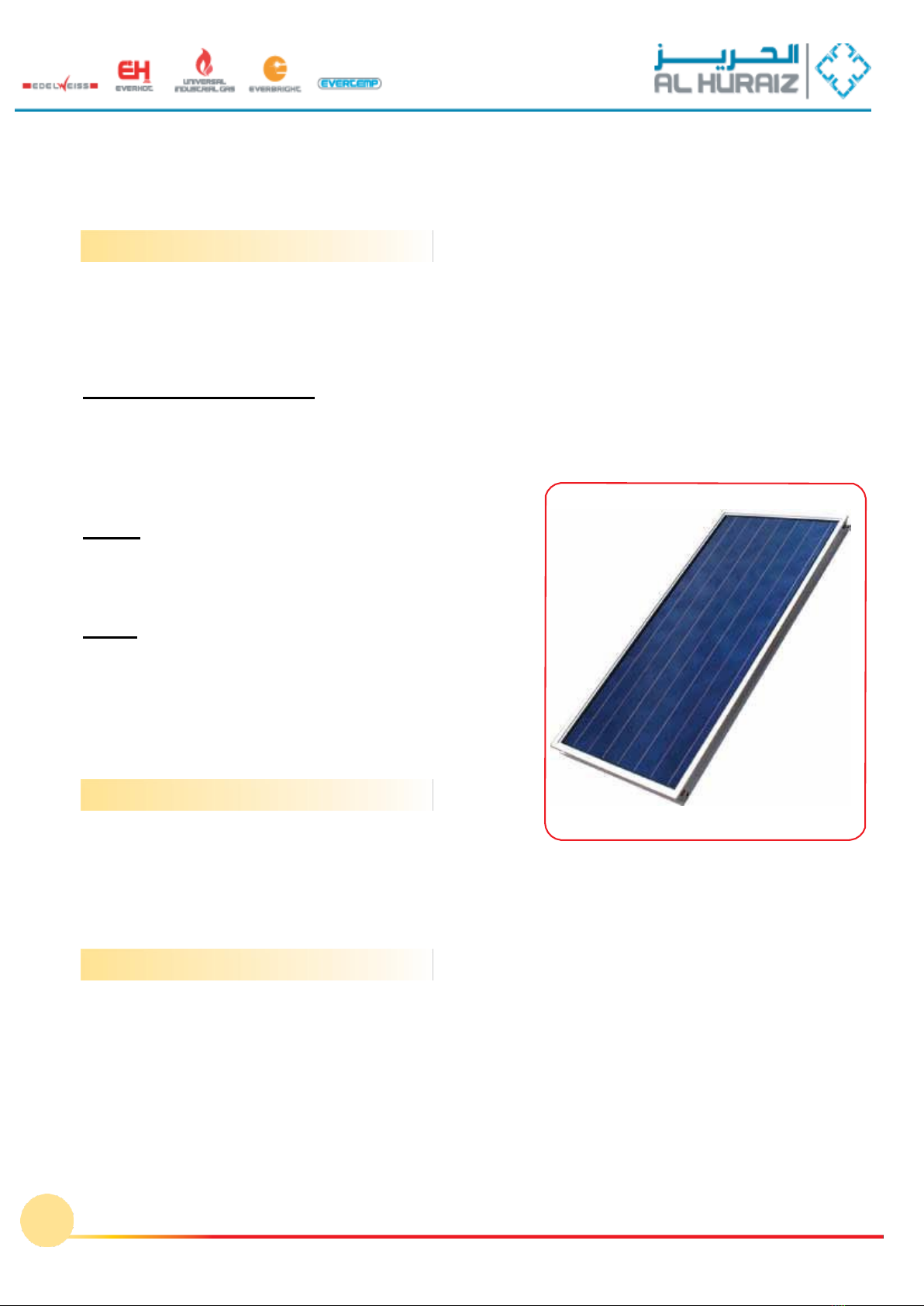

SOLARCOLLECTORSMODELSST-2000ANDST-2500

Collector with

black coating

Description

Flat solar collector, firmly built, of new

technology suitable for all forced circulation

solar systems. The production process and

the raw materials that are used produce a

high thermal energy efficiency even during

periods with insufficient radiation.

Models

The solar collectors EVERHOT are produced

in two types, ST-2000 (2,10 m2) and ST-2500

(2,61 m2), with blue titanium selective absorber

or black selective coating which either in solo

or in combinations cover all of the

requirements of solar systems.

•Frame made from anodized aluminum, which is extremely durable to adverse climatic

conditions (high humidity - coastal areas).

•Strong side and back insulation (20mm glass wool and 40mm rock wool), minimize

Thermal losses in areas with low seasonal temperatures.

•Special prismatic glass, resistant to hale (solar tempered glass).

•Absorber made from one unique sheet absorber with blue colour titanium selective

coating or with black selective coating. The absorber with titanium coating is ideal for

regions with high diffused radiation and low temperatures, absorbing up to 16% more

solar radiation in winter months compared to simple black chrome absorbers. This

method of coating is non toxic and does not pollute the environment, while keeping

stable its mechanical and optical properties during high and low temperatures.

TyPE

SElECTIVE

Dimensions

(m2)

Gross

Surface

(m2)

Net

Surface

(m2)

weight

(kg)

Capacity

(l)

Test

Pressure

(bar)

max. working

Pressure

(bar)

absorber

a

e

ST-2000

2050x1010x90

2,10

1,80

43

1,67

10

7

95%±2%

5%±3%

ST-2500

2050x1275x90

2,61

2,31

51

2,09

10

7

9

DIMENSIONS OF THE SOLAR COLLECTORS

Basic Technical Characteristics

SOLAR COLLECTORS MODELS ST-2000 AND ST-2500 SELECTIVES

Absorber: a unique sheet

Thermal Absorption: 95%

Thermal loss: 5%

Thickness: 0,2mm

Coating: selective titanium

Characteristics of the tubes:

Diameter of the horizontal tubes: (22mm)

Diameter of the vertical tubes: (10mm ou 8mm)

Material: copper

Test Pressure: 10 bars

Maximum functional pressure: 7 bars

Frame:

Material: anodized aluminum profile

Back insulation: 35-40 mm insulation

Side insulation: 20 mm glass wool

Cover:

Material: solar tempered glass

Thickness: 4mm

Water tightness: joint EPDM and transparent silicone

Total thermal efficiency: 95% ± 2%

Total thermal losses: 5% ± 3%

Antifreeze:

glycol

appropriate for

solar systems

The characteristics of the support base for the collector(s) with the ways of installation on the various

types of roofs, are described analytically on page 28 Installation Instructions.

.

10

Support base:

General Characteristics:

Technical C h a r a c t e r i s t i c s :

Collector

with titanium

selective treatment

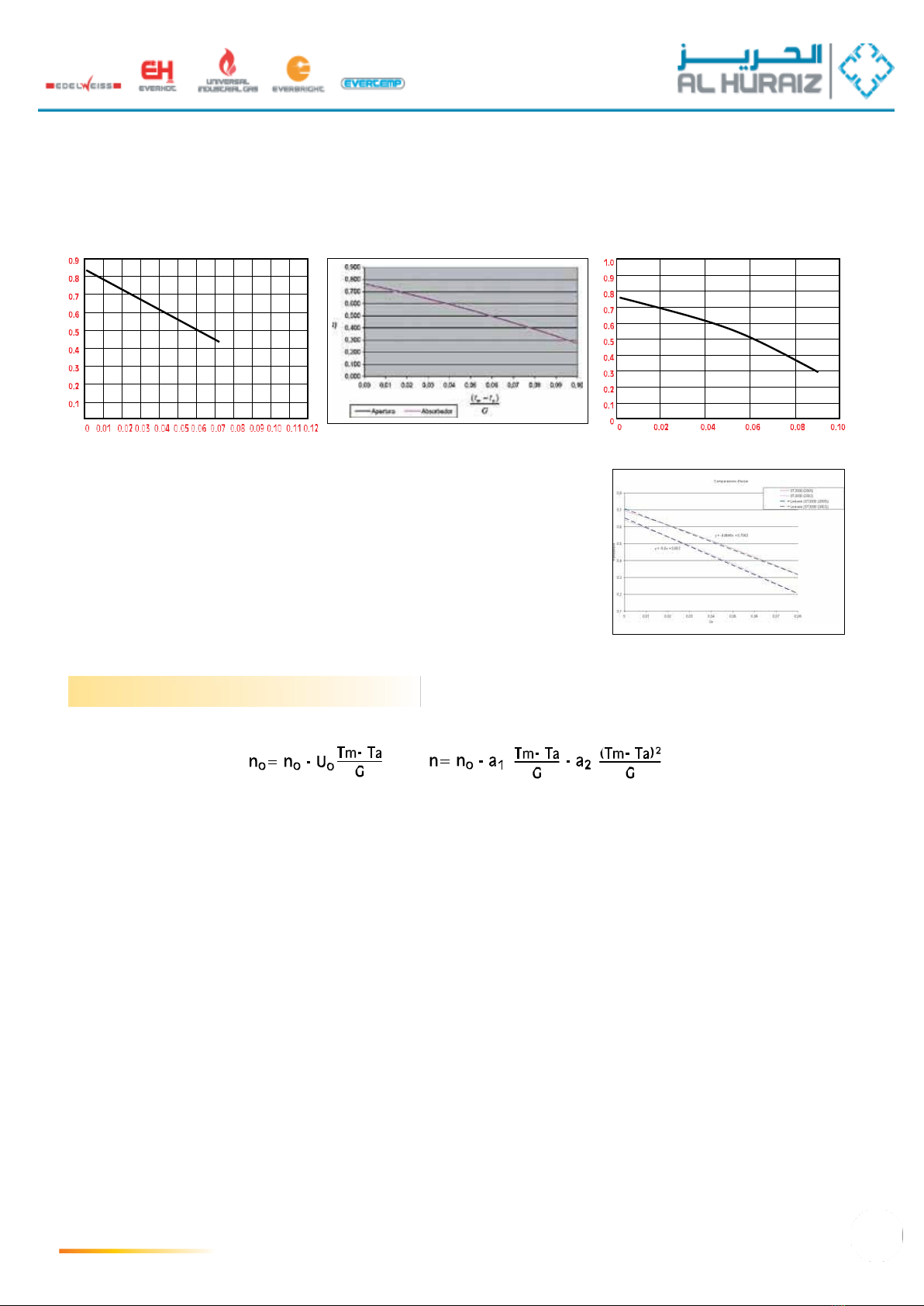

Efficiency curves of MEGASUN solar collectors

ST 2000 Selective (2,10m2

, 24 C)

ST2500Selective

SUN-POWER Selective

a.TestNr:1021 b.TestNr:30.0012.0-3 c.Test Nr28601068

•Curve a:

Test by DEMOKRITOS (Greece) n= 0,85 - 5,44 T*

•Curve b:

Test by CENER (Spain) n= 0,767-0,37 (tm - ta)/G

•Curve c:

Test by TÜV Bayern (Germany) n=0,794-3.907 T*- 0,0157 (m-L)T*

•Curve d:

Calculus CST Bat (France) y = -4,8648x + 0,7063

d.

Avis Technique 14/05-947

Procedure for the calculation of estimated energy output of collector

The collector instantaneous efficiency curve is expressed by the following relation in linear or second-order form:

where n is the collector instantaneous efficiency, Tm is the mean temperature of water inside the collector, in ºC, Ta is the

ambient air temperature, in ºC and G is the total solar radiation that falls in the collector, in W/m2. The parameters of the

above equations of the instantaneous efficiency curve n0 and U0 are determined by testing according to the standards EN

12975-2 and ISO 9806-1.

The estimated energy output of the collector is calculated using the values of parameters n0 and U0, as these have been

Determined by testing from several accredited laboratories of Europe, for a number of cities and under the following conditions:

- solar radiation, ambient air temperature and temperature of cold water (average monthly values as given in the tables of

the following page)

- Temperature of hot water delivered by the collector to the user equal to 45ºC and 40ºC.

For every day of the month the efficiency of the collector is calculated, where the maximum efficiency and the heat losses of

the collector are taken into account depending on the existing climatic conditions of the day and the desired temperature of

hot water delivered by the collector to the user. Also, the latitude of the area of installation and the slope of the collector are

taken into account. Following this, the mean monthly output of the collector is calculated using the climatic data of the month.

Finally, the sum of the mean monthly outputs of the collector gives the total annual output. It is noted that the values of the

estimated energy output of the collector that are calculated and given in the next tables are the maximum estimated and

therefore they are achieved only by the optimum design and installation of the solar collector and the solar system. This

means that that there must not be any shading of the collector during the hours of sunshine and operation of the system, any

water penetration inside the collector from the rain, any accumulation of water in the inside part of the collector cover, any

accumulation of dust or other substances on the outside part of the collector cover, any deformation of any part or area or

material of the collector and system, any leakage in the hydraulic connections in any part of the collector or system, bad or

no insulation of the piping of the solar system, bad operation of the valves of the solar system, non proper maintenance of

the collector and the system and problems caused by deposition of salts within the tubes of the collector by the usage water.

11

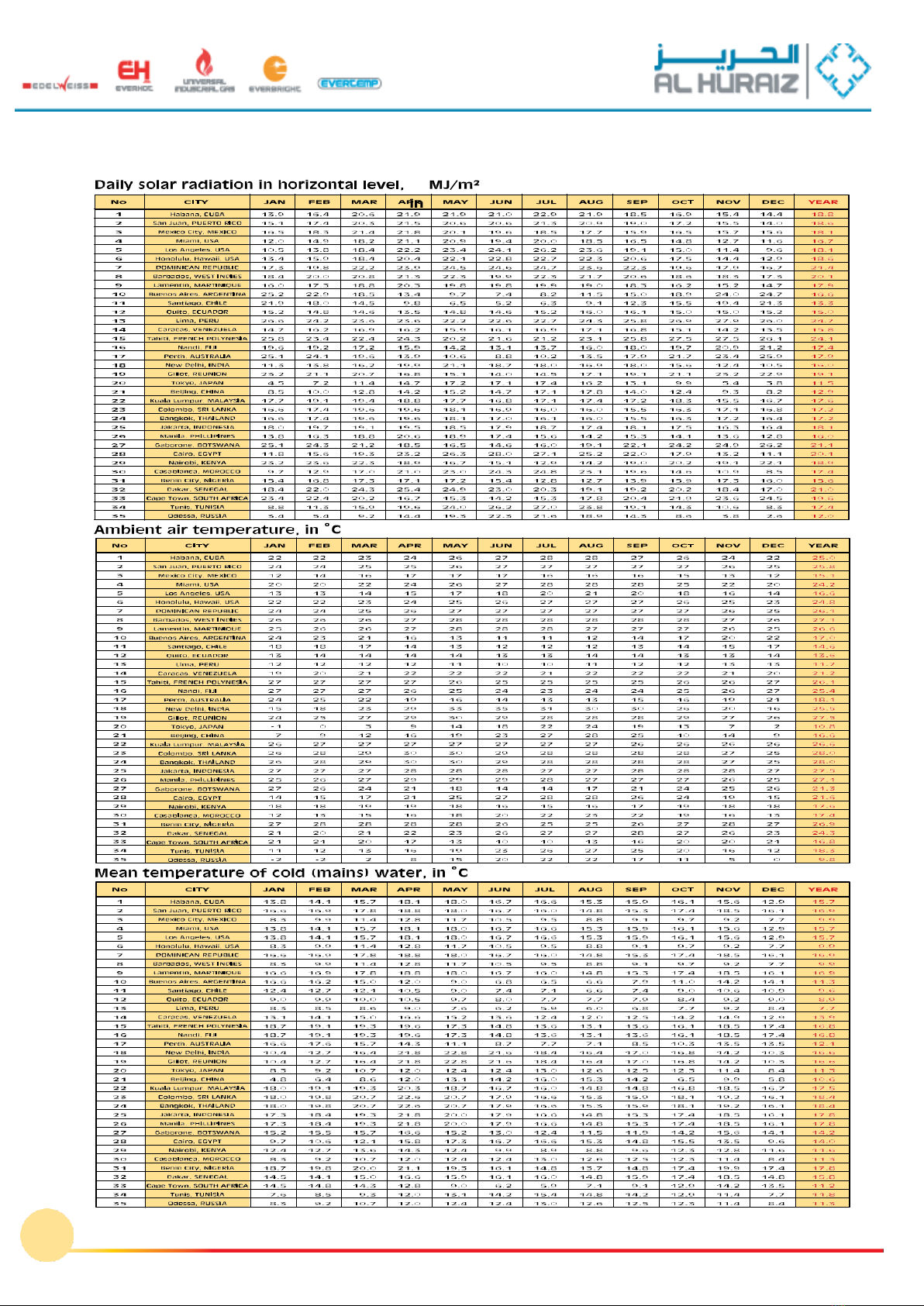

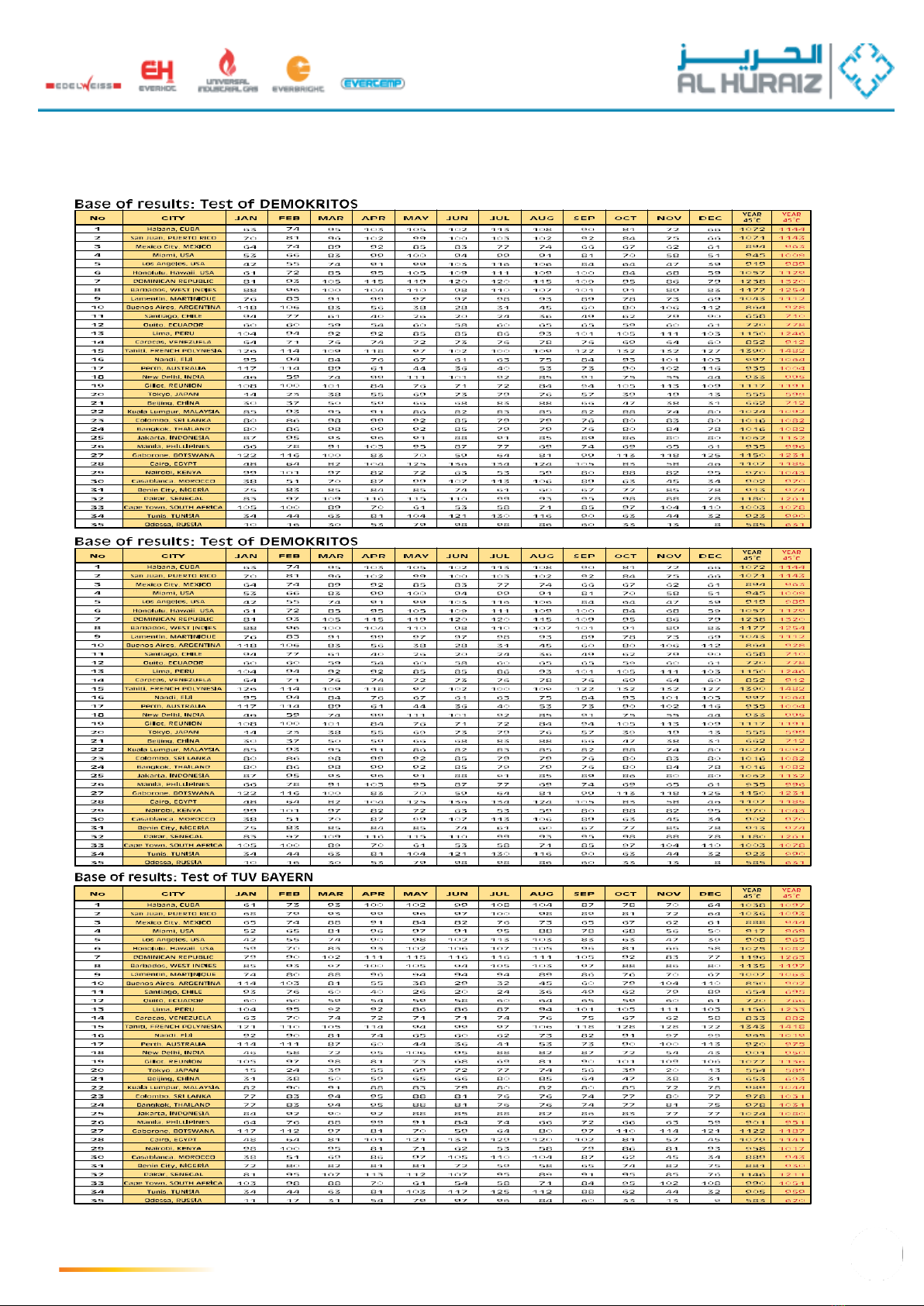

CLIMATIC DATA OF SELECTED WORLD CITIES

12

Energyoutputofthecollectorinseveralcitiesoftheworld(inkWh/m2)

13

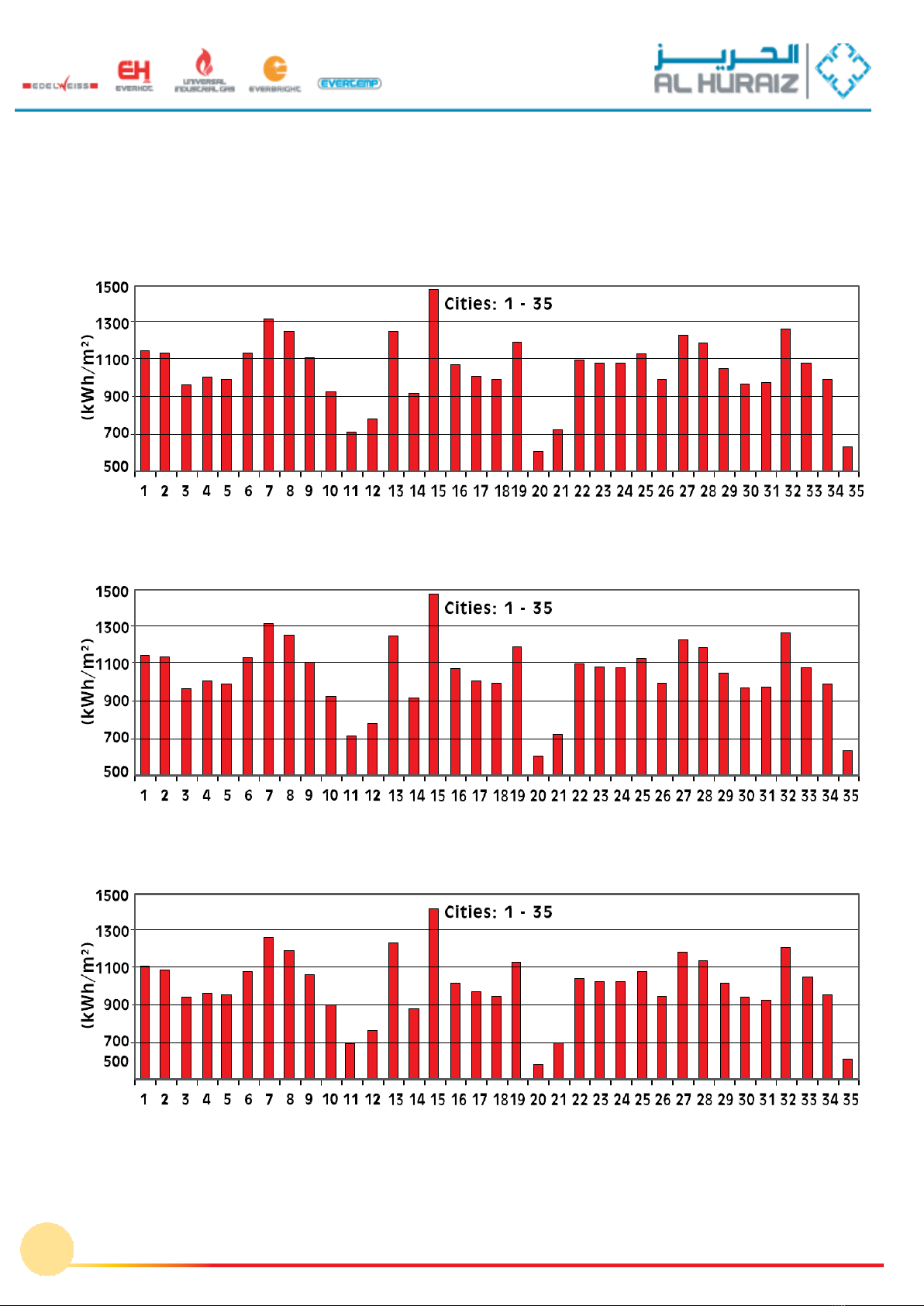

GRAPHICAL REPRESENTATION OF ENERGY OUTPUT OF COLLECTORS IN

SELECTED CITIES OFTHE WORLD (in KWh/m

2

), in temperature 40°C

Collector: ST 2000 selective- Base of results: Test of DEMOKRITOS, GREECE

Collector: ST 2000 selective- Base of results: Test of DEMOKRITOS, GREECE

Collector: ST 2000 selective (SUN-POWER) - Base of results: Test of TÜV BAYERN, GERMANY

14

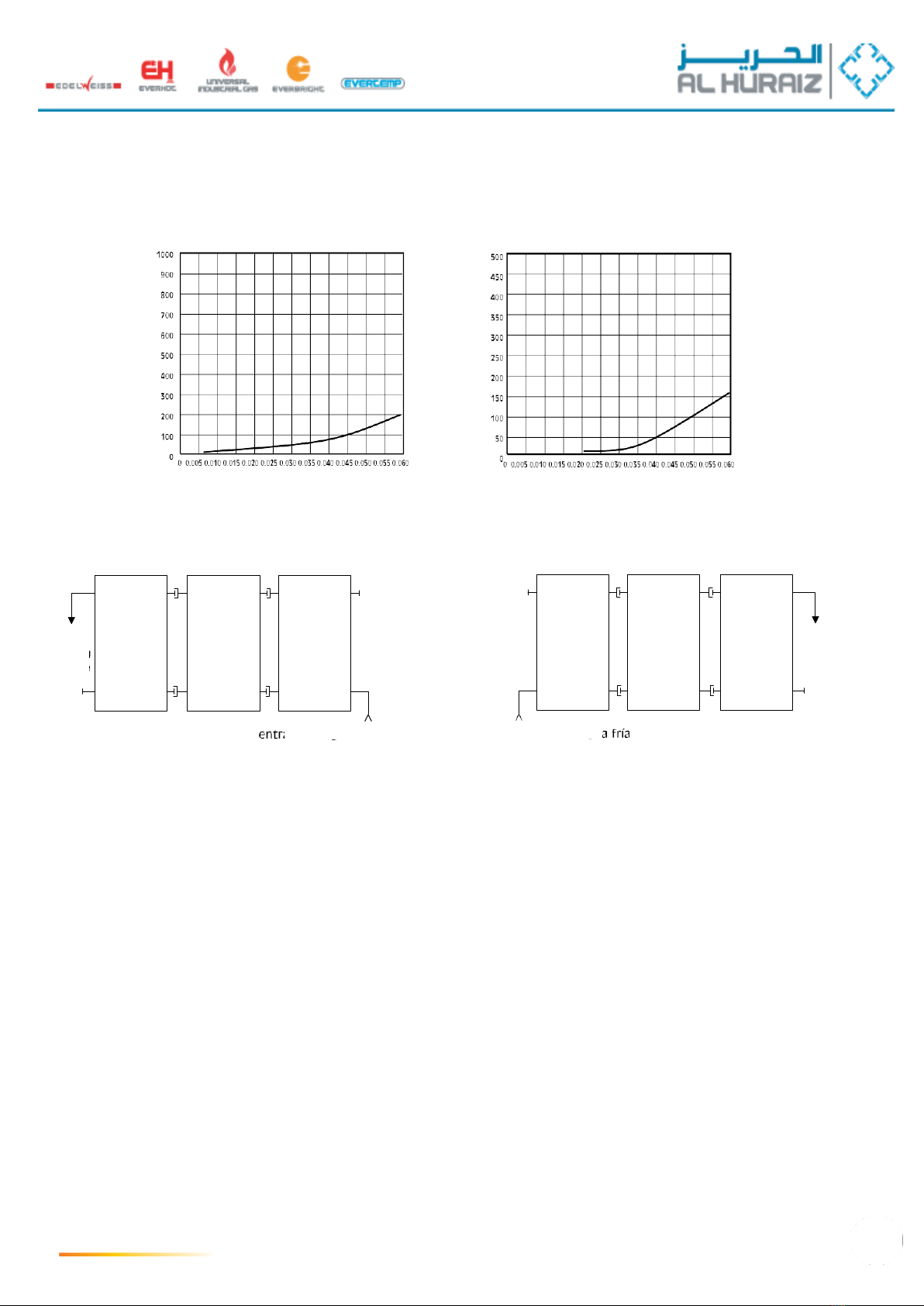

Pressuredropincollectors–Calculationsof DemokritosInstitute

Collector: ST 2000 selective (2,10 m2

,26 C)

Collector: ST 2500 selective (2,61 m2

, 24 C)

For the systems 150 –500, BL1 or BL2, the parallel connection of the solar

Collectors is recommended

In this case the pressure drop in one collector is about equal to the pressure

drop in the whole row of collectors for the supply that is equivalent to the total

of installed square meters.

The required flow of the pump for the forced circulation is approximately 40 - 80

liters / h for each installed square meter and depends on the design of each

installation.

Example:

For one system 300 E/BL1 with 3 collectors ST-2000 in a parallel connection,

total surface area 6,30m2, we can choose a medium flow rate of 60lt/h

per square meter of installed collectors. This means that the necessary flow

rate of the pump must be 60lt/hm2x6,30m2=378lt/h approximately. When

dividing by 3 (number of collectors), we obtain 126lt/h. When transforming to

liters/second (by dividing by 3.600) we will have 0,035 liters/second. From the

above graph of pressure drop of the collector St 2000, we estimate that

the flow rate of 0,035 liters/second corresponds to a pressure drop of

approximately 100 Pa.

15

hot

water

outlet

cold water inlet

or

hot

water

outlet

cold water inlet

Mass flowrate (Kg/s)

Mass flowrate (Kg/s)

Pressore

Drop

(PA)

Pressore

Drop

(PA)

Models

Models Bl1

(With1tubeheatexchanger)

Models Bl2

(With2tubeheatexchangers)

BoilerEVERHOT typeBL1andBL2with oneortwotubeheatexchangers

Technical C ha rac t er is t ic s

The EVERHOT boilers are manufactured according to European and German standards in the new

state of the art solar boilers manufacturing facility and offer absolute safety in operation, great

savings and a long lifespan. These tanks are for indoor use.

•Manufactured from extra thick and high quality USD 37.2 steel plate.

•Double tested for water tightness.

•The internal cleaning of the cylinder is not done chemically but in the most modern sand blasting

facility, resulting in the perfect addiction of the enameling on the steel surface.

•The enameling is made with double ‘direct’ enamel process and it is heated at a temperature of

850ºC.

•Supplied with a big magnesium rod DN 32mm for additional anti-

Corrosive protection.

•Side flange DN 115 mm. for easy cleaning (except for models 150).

•Top flange DN 115 mm for easy replacement of the magnesium rod.

•Optional electric resistance (2 - 9 KW).

•Available with one or two tube heat exchangers, suitable for every

Application

•Upon a special order, buffers can be delivered (150lt -1000lt models BL0) without a tube heat

exchanger.

model Insulation

Capacity

exterior

(litres)

model Insulation

Capacity

exterior

(litres)

150BL1

Yes

150

150BL2

Yes

150

200BL1

Yes

200

200BL2

Yes

200

300BL1

Yes

300

300BL2

Yes

300

420BL1

Yes

420

420BL2

Yes

420

500BL1

Yes

500

500BL2

Yes

500

800BL1

Yes

800

800BL2

Yes

800

1000BL1

Yes

1000

1000BL2

Yes

1000

Material: Steel plate USD37.2 quality

Welding: Robotically welded in inert gas

environment

Cleaning: 6 point metal blasting

Internal treatment: Glass enameling heated at 850°C

Function Pmax: 6 bar

Testing Pmax: 15 bar for 5 minutes

Function Tmax: +95° C

PVC in various colors

Material: Polyurethane CFC & FCKW Free

Density: 40 kg/m3

Thickness: 65 mm

(For storage tanks BL800 –BL1000 for all the models, the

insulation is made from flexible polyurethane 75 mm and is

detachable for easier passage during installation)

2 to 4 KW (230 V) with thermostat or 6KW or 9KW (400

V) without thermostat

Coil heat exchanger made of heavy duty steel tube 33mm

(tube)

.

16

Heat Exchanger Type:

Electrical Backup (upon request):

Insulation:

Tank:

Description

Outer Cover Material:

DESCRIPTION OF STORAGE TANKS

1.

Hotwateroutlet

2. Magnesium rod

3.

TopflangeΦ115

4.Sensorinlet

5. Recirculation connation

6.Electricback-upinlet

7.Collectorinlet

8.Sensorinlet

9.

Side flange Φ115

10. Collector outlet

11.

Coldwaterinlet

BL1

BL2

1.

Toplange Φ115

2. Magnesium rod

3. Hot water outlet

4. Back-up heat exchanger inlet

5. Sensor inlet

6. Recirculation connexion

7. Sensor inlet

8. Back-up heat exchanger outlet

9. Electric back-up inlet

10. Collector inlet

11. Sensor inlet

12. Collector outlet

13. Cold water inlet

14.

Side lange Φ115

Outer Cover material:

Color PVC jacket

Storage tanks weight empty (kg)

/External dimensions (mm):

* DIMENSIONS WITHOUT INSULATION

Thermal Insulation:

Polyurethane Foam CFC & FCKW free

Density: 40 kg/m3

Thickness: 65 mm.

Thermal Conductivity: 0,023 W/mk

Fire Class: Β3, auto extinguishable.

Hydraulic Connections Bl:

Corrosion Protection

Inner cleaning of the tank with automated sand

blasting (not chemically) resulting in a perfect

adherence of the enamel.

Food grade enamel quality applied with a

“double direct” method and baked at 850°C

(BUFFER tanks are excluded).

Extra corrosion protection is offered by

magnesium rods that must be checked and

replaced if necessary every 2 to 5 years,

depending on the quality of the water.

Backup Heating Source Using the Second,

Upper Heat Exchanger

Coil type heat exchanger, from heavy duty

steel (type Tube) integrated in the upper part

of the tank, in order for the secondary heating

source to heat only the upper part of the tank.

Further technical data concerning the upper

heat exchanger refer to the table concerning

BL2 tanks.

Volume

150 l

200 l

300 l

420 l

500 l

800 l

1000 l

Sensor

1/2"

1/2"

1/2"

1/2"

1/2"

1/2"

1/2"

Heat exchangers

1"

1"

1"

1 "

1 "

1 "

1 "

Hot-Cold inlets

1"

1"

1"

1 "

1 "

1 "

1 "

Electric Element

1 ½"

1½"

1½"

1½"

1½"

1½"

1½"

Recirculation

1"

1"

1"

1"

1"

1"

1"

ATTENTION:Tankshaveamaximumservicepressureof6bar.Itishighlyrecommendedtoinstalla6barTPValveandanexpansionvesselinthecoldinlet.

17

litter/

model

Bl1

Bl2

DIamETER

HEIGHT

150

64

69

603

1050

200

85

93

603

1400

300

108

128

603

1930

420

146

156

730

1730

500

165

182

730

1970

800

176

210

805*

945

1735*

1800

1000

201

235

805*

945

1985*

2050

Technical Specifications

model

Bl 150

Bl 200

Heat Exchangers

Solar (lower) Heat Exchanger

(Bl1 models)

Back-up Heat Exchanger

(Bl2 models)

Solar (lower) Heat Exchanger

(Bl1 models)

Back-up Heat Exchanger

(Bl2 models)

Heat Exchanger Capacity

lt

3.45

2.7

5.7

2.7

Heat Exchanger surface area

m2

0.6

0.5

1

0.5

lower Heat Exch. Flow Rate

m3/h

3

3

3

3

Pressure drop

mbar

65

52

120

60

Inlet temperature

° C

55

70

80

90

55

70

80

90

55

70

80

90

55

70

80

90

HeatExchangerPower*

Kw

7.8

15.6

20.4

25.5

4.7

9.4

12.3

15.4

10

20.5

26.5

33.7

4.7

9.4

12.3

15.4

Hot water continuous

supply

lt/h

190

385

500

625

115

232

303

380

250

500

650

830

115

232

303

380

Thermal losses **

Kwh/24H

1.2

1.65

model

Bl 300

Bl 420

Heat Exchangers

Solar (lower) Heat Exchanger

(Bl1 models)

Back-up Heat Exchanger

(Bl2 models)

Solar (lower) Heat Exchanger

(Bl1 models)

Back-up Heat Exchanger

(Bl2 models)

Heat Exchanger Capacity

lt

7.4

5.7

7.6

6

Heat Exchanger surface area

m2

1.4

1.2

1.5

1.3

lower Heat Exch. Flow Rate

m3/h

3

3

3

3

Pressure drop

mbar

150

130

155

140

Inlet temperature

° C

55

70

80

90

55

70

80

90

55

70

80

90

55

70

80

90

HeatExchangerPower*

Kw

12.3

25

32.6

41

11.8

23

30.5

38.3

14.2

27.5

36.6

46.4

12.8

23

34.5

37.5

Hot water continuous

supply

lt/h

300

620

800

1000

290

565

750

940

350

675

900

1150

315

567

850

982

Thermal losses **

Kwh/24H

2.24

2.68

model

Bl 500

Bl 800

Heat Exchangers

Solar (lower) Heat Exchanger

(Bl1 models)

Back-up Heat Exchanger

(Bl2 models)

Solar (lower) Heat Exchanger

(Bl1 models)

Back-upHeatExchanger

(Bl2 models)

Heat Exchanger Capacity

lt

11.5

6

11.5

6.3

Heat Exchanger surface area

m2

2.2

1.3

2.2

1.4

lower Heat Exch. Flow Rate

m3/h

3

3

3

3

Pressure drop

mbar

220

140

220

130

Inlet temperature

° C

55

70

80

90

55

70

80

90

55

70

80

90

55

70

80

90

HeatExchangerPower*

Kw

16.7

32.2

42.8

54.2

12.8

23

34.5

37.5

17

32

43

54

11.4

21

30.5

32.3

Hot water continuous

supply

lt/h

410

790

1050

1330

315

567

850

925

440

820

1100

1390

560

660

950

1010

Thermal losses **

Kwh/24H

2.91

3.22

model

Bl 1000

Heat Exchangers

Solar (lower) Heat Exchanger

(Bl1 models)

Back-up Heat Exchanger

(Bl2 models)

Heat Exchanger Capacity

lt

13.3

7.5

Heat Exchanger surface area

m2

2.5

1.4

lower Heat Exch. Flow Rate

m3/h

3

3

Pressure drop

mbar

250

145

Inlet temperature

° C

55

70

80

90

55

70

80

90

HeatExchangerPower*

Kw

20.5

40

53

65.5

12.3

25

32.6

41

Hot water continuous

supply

lt/h

500

980

1300

1600

415

845

1100

1390

Thermal losses **

Kwh/24H

3.6

*Cold water temperature 10°C. Hot water outlet temperature 45°C. Storage temperature 60°C.

** Water storage temperature 65°C –ambient temperature 20°C.

ATTENTION:Tankshaveamaximumservicepressureof6bar.It ishighlyrecommendedtoinstalla6barTPValveandanexpansionvesselinthecoldinlet.

18

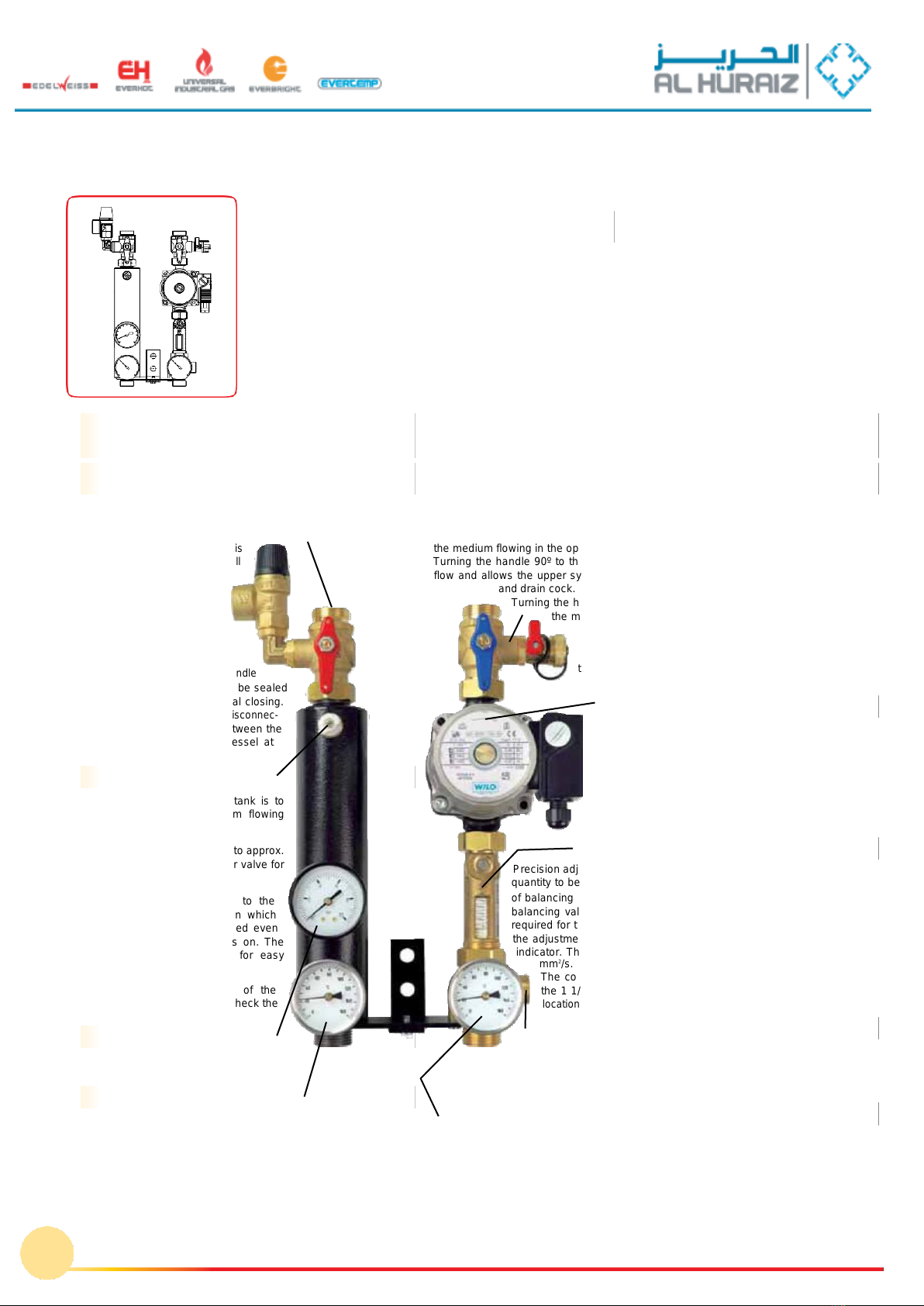

Hydraulic kit

As a pump, regulator and air venting valve in solar heating systems.

With the hydraulic kit, hydraulic balancing, flow measurement and venting can be performed directly in

the station.

The built-in SETTER Inline UN allows the required quantity of fluid in the primary circuit to be exactly

and simply set and checked. The continuous venting system meets the most

demanding requirements and keeps the system free of air.

Systems which are correctly balanced hydraulically and air-free guarantee

optimal energy extraction, and are thus more cost-effective in the sense of the

energy-saving directives laid down by law.

Using the scale, which is pre-calibrated for glycol, the technician can set and

check the exact flow-rate values on-site. Neither training courses nor expen-

sive measuring devices are required. Installation and venting can be carried

out by one person working unaided.

The solar station must be mounted vertically to ensure problem-free function-

ing of the venting unit.

•Rugged

design

•Cost-effective installation and filling

•Multi-functional ball valve, which greatly simplifies the filling and draining of

the system

•Collector and reservoir sections can be separated for installation work

•Straightforward pump replacement (suction and pressure side can be shut off)

•Precise and rapid regulation adjustments, requiring no diagrams, tables or

expensive measuring devices

•Function checking using the direct flow rate indicator in theSETTER Inline UN

•Visual scale in l/min pre-calibrated for glycol mixes u=2.3 mm2/s

•Constant air release while system is running

•Straightforward venting directly in the station

•Can be connected to any readily-available controller

•Reliable operation, and maintenance-free

The flow-rate measurement is based on the proven principle of a baffle float.

The basis for the air venting are special flow technology measures which accumulate the air in the top

of the venting space, from where it can be released from time to time. At the same time, acts as a check

on whether air is building up in the system. There are no

Mechanical parts, so the design ensures a long service life.

19

Operation

Advantages

Installation position

Application

is

the medium flowing in the opp

all

Turning the handle 90º to the

flow and allows the upper sys

and drain cock.

Turning the ha

the me

b

handle the

can be sealed

u

nal closing.

disconnec-

etween the

vessel at

bleeder valve

tank is to

um flowing

to approx.

er valve for Precision adju

quantity to be

routed to the of balancing v

ion which balancing valv

ssed even required for th

is on. The the adjustmen

for easy indicator. The

mm

2

/s. T

The con

quantity of the the 1 1/2

check the

locations

Conne

Hydraulic kit

1) Circulation pump

2) SETTER Inline UN

balancing valve

3) Venting tank with

bleeder valve

4) Bleeder valve

5) Pressure gage

6) Thermometer

7) Stop ball valve with

Safety valve

8) Stop ball valve with fill

and drain cock and

integrated check valve

9) Safety valve

10) Connector ADG for the

expansion vessel

11) Wall fixing

12) Packaging box

The ball valve allows the flow circuit line to be divided between the

collector and the heat accumulator. As required by safety

regulations, the connection between

the collector and safety valve

not interrupted in any of the b

valve positions.

The safety valve thus

protects the system

components a g a i n s t

excessive over-pressure in

all operating phases.

Holes are provided in the

of the ball valve so that it

to protect against un intentio

This prevents unintentional

tion of the connecting line b

collector and the expansion

this point.

Venting tank with

The purpose of the venting

remove air from the medi

through the tank.

The venting tank can hold up

2.5 dl of air and has a bleed

releasing the air.

The bleeder valve is

outside through the insulat

means that it can be acce

when the insulating casing

outlet has a suitable fitting

attachment of a hose.

The frequency and

collected air can be used to

leak tightness of the system

Pressuregage

The pressure gage with a range from 0 to

10 bar indicates the system pressure.

Thermometer

The thermometer with a range from 0 to 160ºC constantly indi-

cates the medium temperature in the flow circuit. The temperature

is recorded directly in the medium to minimize the reaction time.

The sensor is inserted in a protective pipe so that it can be

exchanged without having to empty the system.

The ball valve allows the return line to be split between the collector and the heat accu-

mulator. The special ball cock design provides various functions. If the handle is pointing

in the direction of flow the system medium can circulate. An integrated check valve stops

osite direction and also acts as a gravity brake.

right closes the ball cock in the direction of the medium

tem part (collector) to be filled and emptied using the fill

ndle 90º to the left closes the ball cock in the direction of

dium flow and allows the lower system part (reservoir) to

e filled using the fill and drain cock.

A male thread G 3/4” is provided on the fill and drain cock

for connecting a hose. Holes are provided in the handle of

ball valve so that it can be sealed to protect against

nintentional closing.

WILOST25/6-3circulationpump,solarversion

This circulation pump, included as standard in the scope

of delivery and integrated in the hydraulic kit, covers a

large delivery range.

The required operating point can be preselected using

one of the three levels.

A defective pump can be replaced without having to

empty the system using the stop cocks on the suction

side (Setter Inline UN) and the pressure side (ball valve).

SETTERInlineUNbalancingvalve

stment at the balancing valve allows the required delivery

adapted to system requirements. The proven combination

alve and flow indicator in one housing in the hydraulic kit

es means that no additional measuring components are

e SETTER Inline UN. Flow rate indication is constant, i.e.

t can be immediately verified by means via the flow rate

indicator is pre-calibrated for a medium viscosity of 2.3

his does away with the need for correction curves.

nection flange on the outlet side is directly screwed onto

”pump connector fittings which means there are no seal

for further adapter components.

ctorADG

The connector fitting with G 3/4” connecting thread for the expansion

vessel is connected in series with the circulation pump. This arrangement

prevents negative working pressure conditions in even critical systems and avoids reduc-

tions in the working pressure, one of the main causes of early evaporation of the medium.

Thermometer

The thermometer with a range from 0 to 160ºC constantly indicates the medium tempera-

ture of the flow circuit. The temperature is recorded directly in the medium to minimize

the reaction time.

The sensor is inserted in a protective pipe so that it can be exchanged without having to

empty the system.

20

Stopball valvewithfill and draincock

andintegratedcheckvalve

Stopballvalvewithsafetyvalve

(responsepressure 6bar)

Return circuit components

(pump side)

Flow circuit components

(venting side)

HYDRAULICKIT

This manual suits for next models

33

Table of contents

Popular Heating System manuals by other brands

Salda

Salda RIRS 400VE EKO 3.0 Technical manual

NuAire

NuAire XBOXER XBC Series Installation, operating and maintenance instructions

DEVI

DEVI Devifoil Mirror installation instructions

System air

System air VTR 100/B LITE user manual

OSTBERG

OSTBERG HERU 400 Series Installation

Etherma

Etherma 9120054178607 Installation and operating instructions