Everlast lighting Titan Series User manual

2017 1

Cautions

1. Make sure power is removed or turned off before installing product.

2. This product must be installed in accordance with the applicable

installation code by a person familiar with the construction and

operation of the product and hazards involved.

3. The product must be installed in accordance with the National

Electrical Code and all applicable local codes. Proper grounding is

required for safety.

Titan Series Installation Instructions

1. Veillez à ce que le pouvoir est supprimé ou désactivé avant

d’installer le produit.

2. Ce produit doit être installé conformément au code d’installation

en vigueur par une personne familière avec la construction et

l’exploitation des produits et des risques impliqués.

3. Le produit doit être conforme au Code électrique National et tous

les codes. Raccordée à la terre est nécessaire pour la sécurité.

Précautions

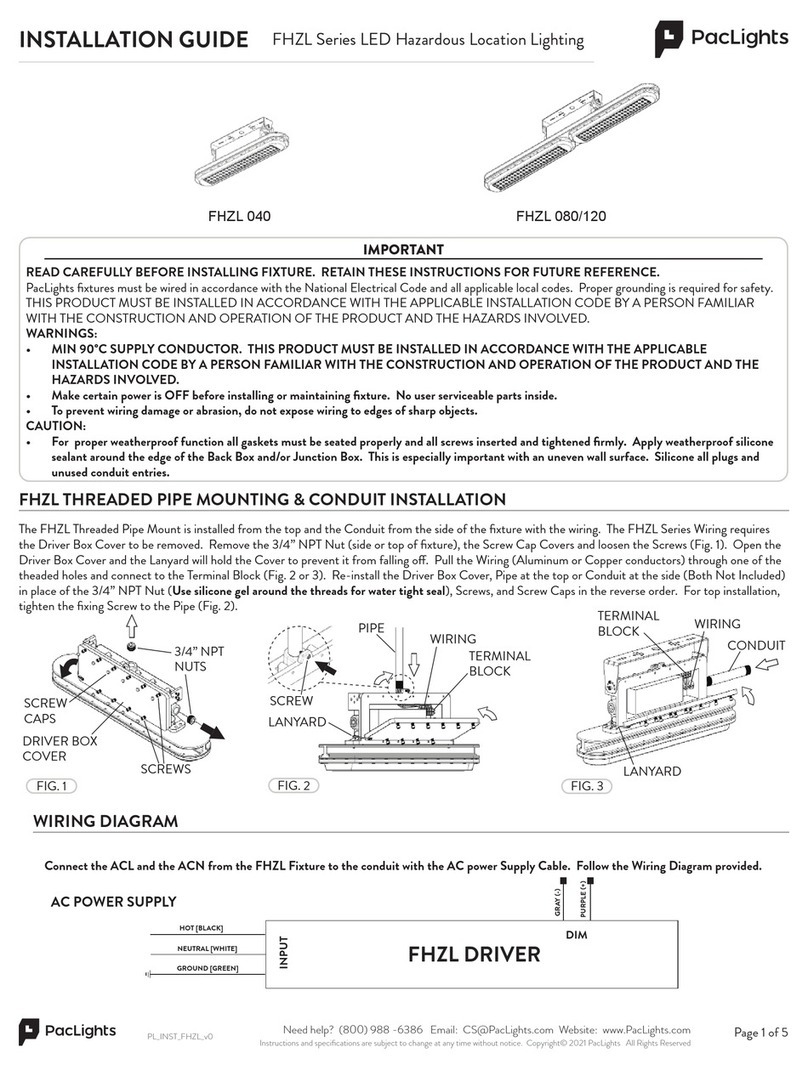

Mounting Instructions

Knuckle Slip Fitter (KSF):

•Make sure pole is suitable for fixture mounting. Place fixture onto pole and secure using properly rated hardware. If applicable, move adjustable brackets to

desired angle and secure.

Surface Square Mount (SSM):

•Use printable dimensions or square mount to mark position on mounting surface. Drill holes for mounting fixture and one for passing power cord through.

•Place power cord through designated hole into mounting surface. Align mounting bracket with corresponding holes, secure bracket to surface using hard-

ware rated for weight of fixture.

Flood Mount (FLM):

•Use printable dimensions or flood mount to mark position on mounting surface. Drill holes for mounting fixture and one for passing power cord through.

•Place power cord through designated hole into mounting surface. Align mounting bracket with corresponding holes, secure bracket to surface using hard-

ware rated for weight of fixture.

•If applicable, move adjustable brackets to desired angle and secure.

150W fixture &

Knuckle Slip Fitter 300W fixture &

Flood Mount

200W fixture &

Square Surface Mount

2017 2

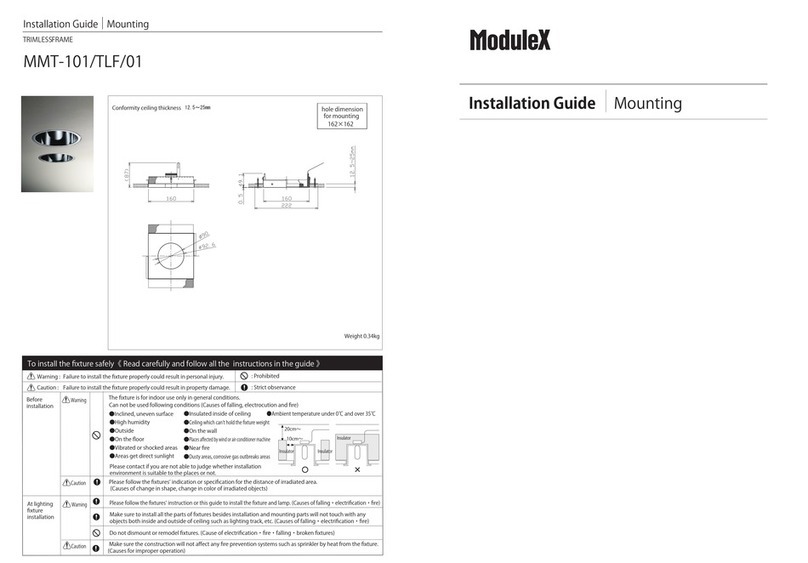

Photocell Orientation Instructions

• After fixture installation, make sure eye of photocell is orientated properly.

• If reorientation is needed, locate North position on photocell receptacle.

• Loosen both screws securing receptacle to fixture, rotate receptacle 180o,

tighten screws to secure receptacle to fixture.

• Place photocell into receptacle and turn to lock into position.

Photocell

Photocell

Receptacle

• Make sure power is of or removed before making any electrical connections.

• Make sure all connections are completed within properly rated junction box or a location suitable for making electrical

connections. All electrical connections must be in-line with standards set by the National Electrical Code and all applicable

local codes.

• If applicable, all cords must be appropriately secured to corresponding receptacle.

• See Wiring Diagrams on following pages.

Fixture Wiring

2017 3

LINE

NEUTRAL

GROUND

120-277V AC

L1-LINE

L2-NEUTRAL

GROUND -

Driver

(Factory Installed Leads)

Standard 120-277 V

Photocell

or

Blank Photocell

LINE

NEUTRAL

LOAD

Wiring Diagrams

LINE

NEUTRAL

GROUND

120-277V AC

L1-LINE

L2-NEUTRAL

GROUND -

Driver

(Factory Installed Leads)

Occupancy Sensor

White (-)

Blue (+)

Gray (-)

Violet (+)

LINE

NEUTRAL

LOAD

LOAD

NEUTRAL

LINE

Photocell

On/Off

2017 4

Bi-Level

LINE

NEUTRAL

GROUND

120-277V AC

L1-LINE

L2-NEUTRAL

GROUND -

Driver

(Factory Installed Leads)

Occupancy Sensor

White (-)

Blue (+)

Gray (-)

Violet (+)

LINE

NEUTRAL

LOAD

LOAD

NEUTRAL

LINE

Photocell

120-277V AC

L1-LINE

L2-NEUTRAL

GROUND -

(Factory Installed Leads)

BLACK/NEUTRAL (Primary)

LINE

NEUTRAL

GROUND

Driver

Photocell

or

Blank Photocell

RED/LINE - (Primary)

BLUE/LINE - (Secondary)

BLACK/NEUTRAL (Secondary)

480v Transformer

LINE

NEUTRAL

LOAD

347-480 V

2017 5

Maintenance

*Review EverLast Lighting Inc. warranty for a list of components covered under warranty.*

NOTE: For employee safety, all power connections shall be turned off or removed before performing any maintenance on lighting fixtures.

Persons performing maintenance shall be familiar with construction and operation of product, plus the hazards involved.

Cleaning Schedule

To maintain proper efficiency of luminaire, a regular cleaning schedule needs to be established in regards to the placement, location and

conditions of product installation. Frequency of cleaning shall be to the discretion of the end user, but should be no less than every 90 days. If

conditions mandate, a more frequent cleaning schedule must be implemented. Improper cleaning may result in component malfunctions, product

failure and voidance of warranty.

Fixture Cleaning

If applicable –use air to blow dust and debris from lens, hood, heatsinks and drivers before wiping with a cleaning solution.

Use only mild, nonabrasive cleaners. Spray cleaner onto

soft

cloth and wipe surface of lens before wiping down other surfaces of lighting fixture.

If needed –use a very

soft

brush or duster to remove excess particles from between heatsinks, drivers or other difficult to reach areas.

Note any damage (cracking, splitting, peeling, breaks). Contact local sales representative, distributor or EverLast Lighting Inc. if damage

replacement is necessary.

Hardware

Fixture hardware shall be inspected before each cleaning.

Check to make sure all hardware connections are secure. Make sure to tighten any loose screws, bolts, nuts, liquid tight connectors, strain reliefs or

electrical connections.

Note any instances of damaged hardware. If any hardware is found to be consistently loose, damaged or questionable in any manner; contact local

sales representative, distributor or EverLast Lighting Inc.

Electrical Connections

Check electrical connections each time maintenance is performed.

Check to make sure all components (drivers, sensors, transformers, etc.) are properly connected and secured.

Proper wiring connections and ground are imperative for fixture performance and customer safety.

Safety Cables (if applicable)

Safety cables shall be regularly inspected during cleaning cycles.

Check to make sure cables and connectors show no signs of damage. If damage is found contact local sales representative, distributor or EverLast

Lighting Inc. for replacements cables right away.

2.76

2.01

0.37 THRU

0.67 THRU

5.04

3.94 0.43 THRU

SSM

FLM

Titan Series Bracket Diagrams

Table of contents

Popular Light Fixture manuals by other brands

LIGHTS 4 Europe

LIGHTS 4 Europe Lucid nova eos Operation, installation and service instructions

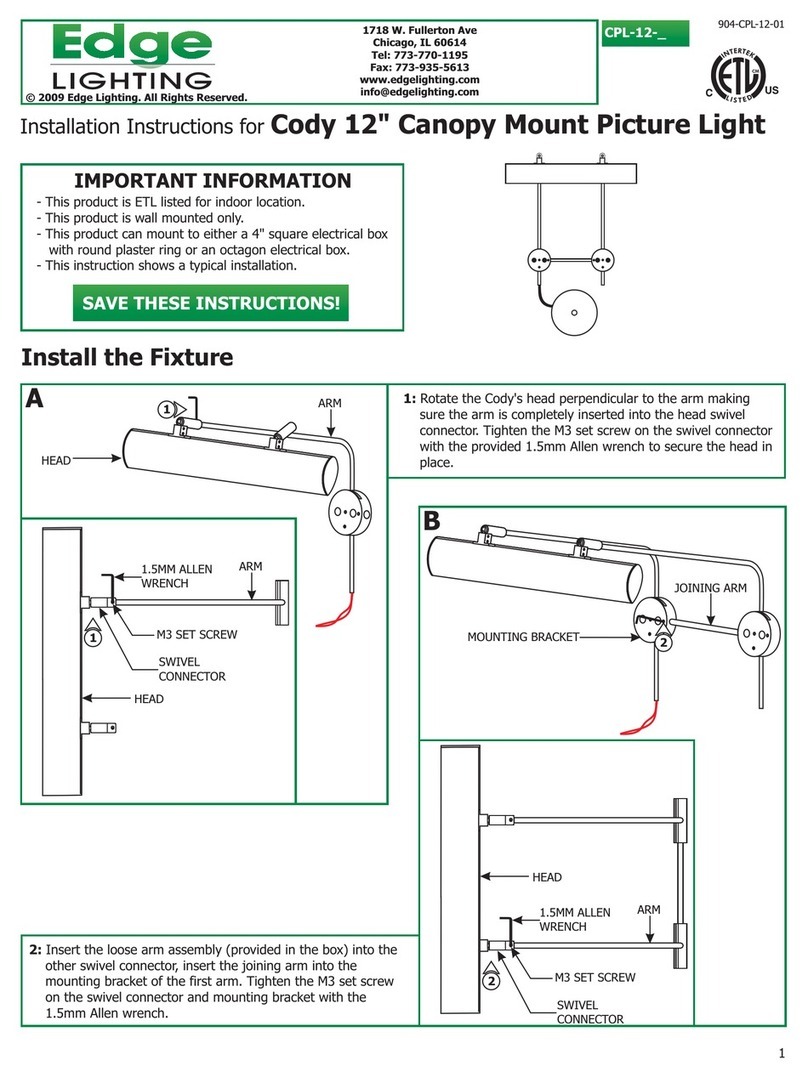

Modulex

Modulex MMT-101/TLF/01 installation guide

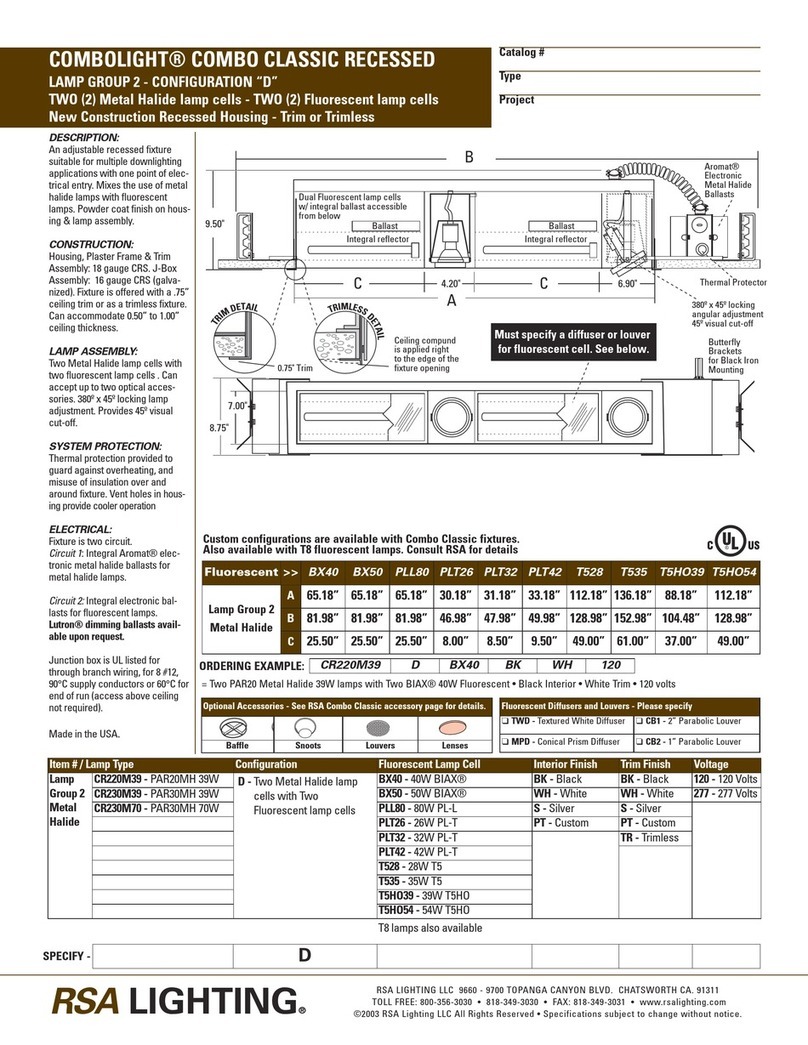

Cooper Lighting

Cooper Lighting Combo Classic CR230M39 Specification sheet

Philips

Philips SpotOn Ultra 69141/14/PH brochure

Quasar Science

Quasar Science Q-Lion quick start guide

PR

PR AQUA Laser 260 BWS manual