• ConnecttheoutletoftheSR-XFeedertotheicemachinemake-upwater(notcondenserwater)

lineandcoffeebrewingequipment.Proceedtostep4.

3b.ForHighFlowCSRQuadPlusSystem,connectoutlettoequipmentservedpertheinstructionsbe-

low.AlwaysuseaNSFapprovedpipedopeorTeontapeatallconnections.Useabackupwrench

on all fittings while connecting to avoid stress on the system components.

• LocateandmounttheseparateSR-XFeederbetweentheHighFlowCSRsystemandtheice

machine.Make-upwater(notcondenserwater)lineandcoffeebrewingequipment.

• Ateettingislocatedinthesystemheaderbeforethesurgetankisolationandushingvalve.

Usingminimum1/2"I.D.line,connecttheoutletofthisteetothefountainbeverageandremote

SR-XFeederline.Important: Install a tee in this service water line to separate the fountain

water feed from the ice machine/coffee brewer water feed.

In Massachusetts, a backflow preventer is required for this installation.

• Connectonebranchoftheservicewaterteetothefountainbeverageequipment.Connectthe

otherbranchoftheteetotheinletoftheSR-XFeeder.ConnecttheoutletoftheSR-XFeederto

theicemachinemake-upwater(notcondenserwater)lineandcoffeebrewingequipment.

• Thesurgetankisolationandushingvalveislocatedattheendofthesystemheader.Using

ttingsandhoseprovided,connectonebranchofthevalvetothesurge/storagetank.Connect

ahosefromtheother(ushing)branchandruntodrain.Note: Some municipal plumbing codes

and good sanitary practices require an air gap at the drain termination point.

4. Thesurge/storagetankispre-pressurizedto20psi.Checkpressureandadjustasnecessary.

5. Installamanualshut-offvalveleadingtothesystemforservicingandconnectminimum1/2"I.D.

(3/4"forquad)waterlinetothesysteminlet.

6. TheoptionalEverguard™LowPressureAlarm(LPA)consistsofapressureswitch,audible/visual

alarmboxandapoweradapter.Itisdesignedtodetectaxedlowpressure(approx.20psi)

conditionasanindicationoflossofsystemoutletpressureeitherduetoanintentionalshut-down

orexcessfoulingofthewaterlters,thusindicatingtheneedforltercartridgechange-out.Ifthe

systemisequippedwiththeLPA,followthesesteps:

• Determinelocationofaconvenient110VACoutlettoplugintheLPApoweradapter.

• Removetheprotectiverubbercapfromthepressureswitchinstalledinthesystemheader

assembly.InsertthewiresfromtheLPAunitthroughthecapandconnectthemtotheterminals

onthepressureswitch.Eitherwirecanbeconnectedtoeitherterminal.Replacethecap.

• PlugtheLPApoweradapterintoanoutlet.Theaudiblealarmshouldactivate.Pushthereset

switch to silence.

• UnplugtheLPAunit.

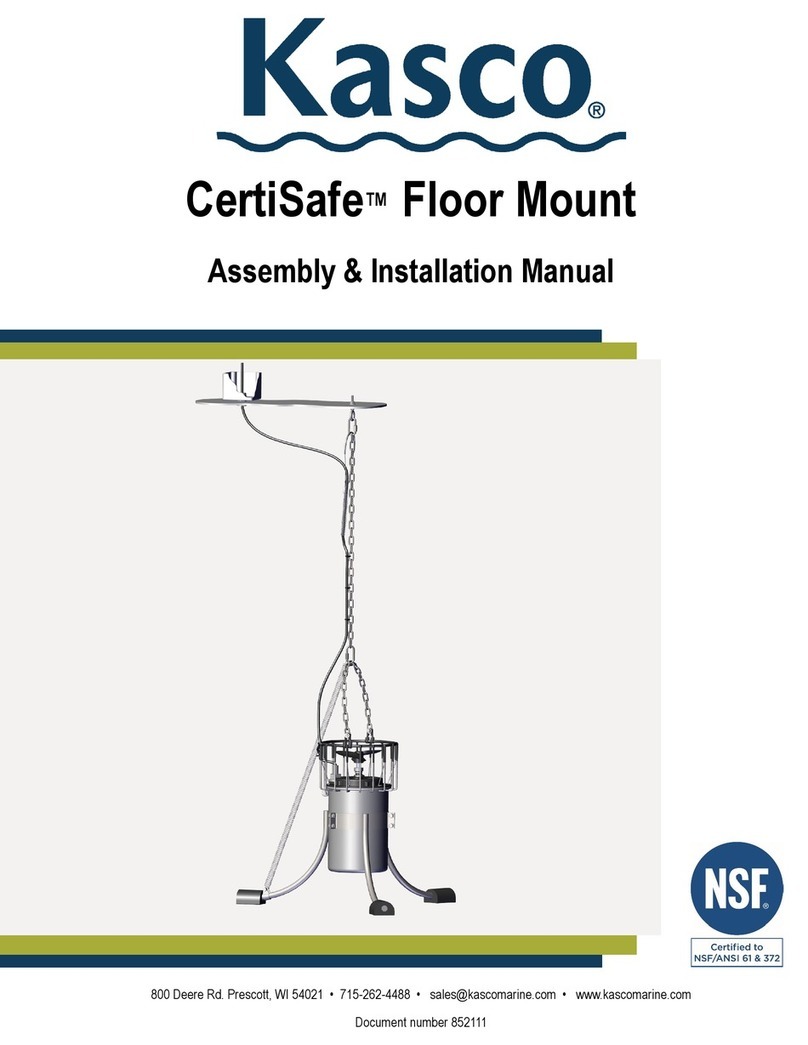

7. Shutoffthesysteminletvalvelocatedontheinletoftheprelterhead.

8. Checktobesuretheo-ringontheprelterhousingissufcientlylubricated.Useagoodgradeof

siliconelubricant,ifneeded.PositiontheEC210preltercartridgeonguideseatinthebottomof

thebowl.Thenthreadthebowlintotheheadbyhand.Useasumpwrenchtosnugthebowlonto

the head.

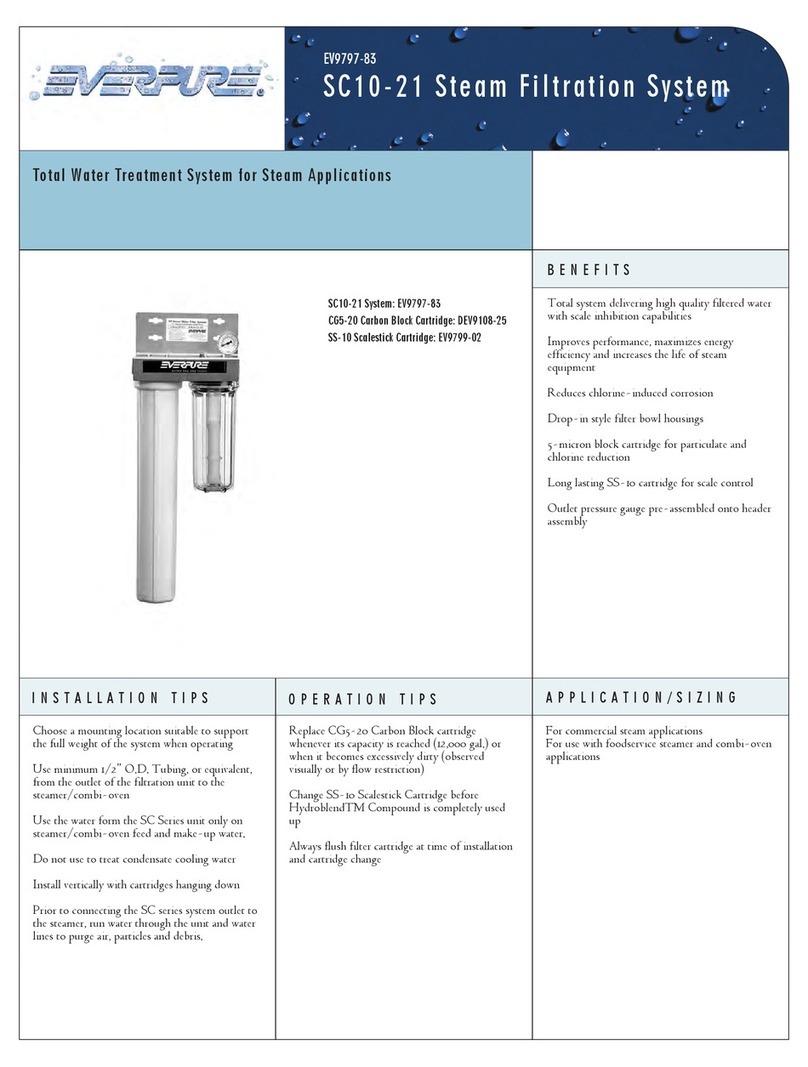

9. InstallonlygenuineEverpure™carbonltercartridge(s)intothelterhead(s)followingdirections

onthecartridgelabelorasshownintheCartridgeChangeillustrations.InstalltheSS-10Scale

InhibitorcartridgeintotheSR-Xhousing.

10.Turnoninletwatertotheltersystemandcheckforleaks.

11.Opentheushingvalveandushthecartridge(s)byrunningwaterthroughatfullforceforve

minutes.Thiswillsetthelteringmediaandpurgeanyairandnes,insuringmaximumlterlife.

See illustrations.

12.Afterushing,closetheushingvalve,turnonpowertoequipmentandplugtheLPA(ifso

equipped)intotheelectricaloutlet.Thesystemisreadyforoperation.

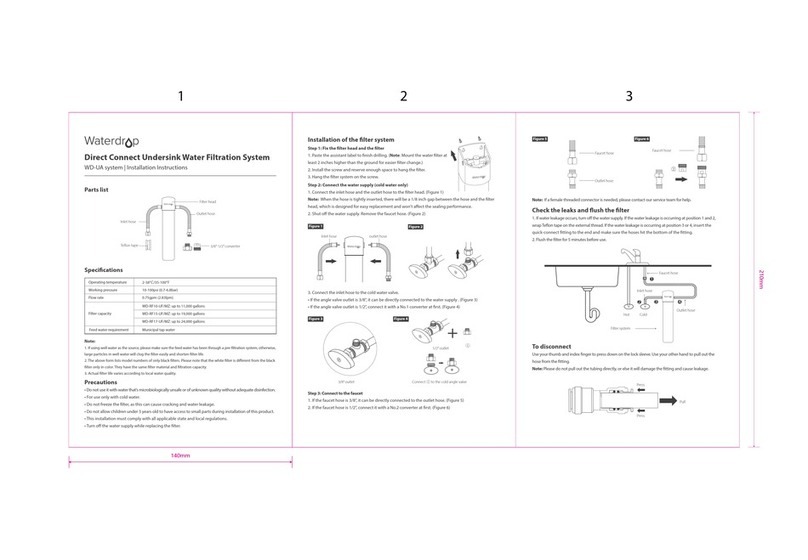

Figure5–HighFlowCSRTwin

25.80"

ICE MACHINE/

COFFEE

OUTLET

3/4" FNPT

INLET

3/4" FNPT

FOUNTAIN

OUTLET

3/4" FNPT

25.59"

Figure6–HighFlowCSRTriple

25.59"

30"

INLET

3/4" FNPT

ICE MACHINE/

COFFEE

OUTLET

3/4" FNPT

FOUNTAIN

OUTLET

3/4" FNPT

Figure8–HighFlowCSRQuadPlus

29.69"

OUTLET

3/4" FNPT

INLET

3/4" FNPT

ICE MACHINE/

COFFEE

OUTLET

3/4" FNPT

INLET

3/4" FNPT

INSERT TEE FITTING.

ONE OUTLET TO FOUNTAIN,

ONE OUTLET TO SRX.

31.38"

Figure7–HighFlowCSRQuad

34"

INLET

3/4" FNPT

ICE MACHINE/

COFFEE

OUTLET

3/4" FNPT

FOUNTAIN

OUTLET

3/4" FNPT

25.69"

Checkforcompliancewithstateandlocallawsand

regulations.TheCommonwealthofMassachusetts

PlumbingCode248CMRshallbeadheredto.Consultyour

locallicensedplumberforinstallationofthissystem.Do

notusewithwaterthatismicrobiologicallyunsafeorof

unknownqualitywithoutadequatedisinfectionbeforeor

after the system. Systems certified for cyst reduction may

beusedondisinfectedwatersthatmaycontainlterable

cysts.

FLUSHING

For maximum life, all carbon filter cartridges must be flushed for five minutes at full flow before use. ALL

NEW CARTRIDGES MUST BE FLUSHED AFTER EACH CARTRIDGE CHANGE BEFORE BEING PUT INTO SERVICE!

Ifthecartridgesarenew,havebeenproperlyushedandbothneedleandfollowerregisterinadequatepressure,or

theLPAissounding,youmaybeexperiencinginadequatewaterpressureorsomerestrictionmayexistintheinlet

waterline.Ineithercase,theincomingwaterpressuremustbeimprovedtoreceiveoptimumlterlife.

COMPLETECARTRIDGECHANGEINSTRUCTIONSCANBEFOUNDONTHEFILTERCARTRIDGELABEL.

Not for residential use. For food service applications only.