*Not Performance Tested or Certified by NSF

5. Hold (do not attach) mounting bracket onto head and position head

at wall location that will provide most convenient installation. Orient

elbow fitting as required. Plan carefully before cutting tubing. Cut

tubing so that ends are “square.” If tubing ends cannot be joined

directly to installed head fittings, a coupling and 3 feet of plastic

tubing are provided.

6. Using mounting bracket as a template, mark location and drill, or

start, holes for mounting head to wall. Install mounting bracket onto

head in appropriate position.

7. Remove straight and elbow fittings. Apply Teflon tape to threads that

install into head and reinstall fittings tightly. Final orientation of elbow

fitting should be achieved while it is being tightened. Do not back

off fittings into final position.

8. Slide compression nut onto cold water faucet tubing with threads

facing cut end. Slide clamping ring (taper facing cut end) onto tubing

and then slide cone (taper facing cut end) onto tubing. Wet tubing

end for lubrication and then insert tubing fully into straight fitting.

Slide down cone and clamping right and secure in position by fully

tightening compression nut. Repeat this procedure securing water

supply line to elbow fitting. If water supply line is too short to be

directly connected, cut supplied tubing to proper length and use

supplied coupling, compression nuts, clamping rings and cones to

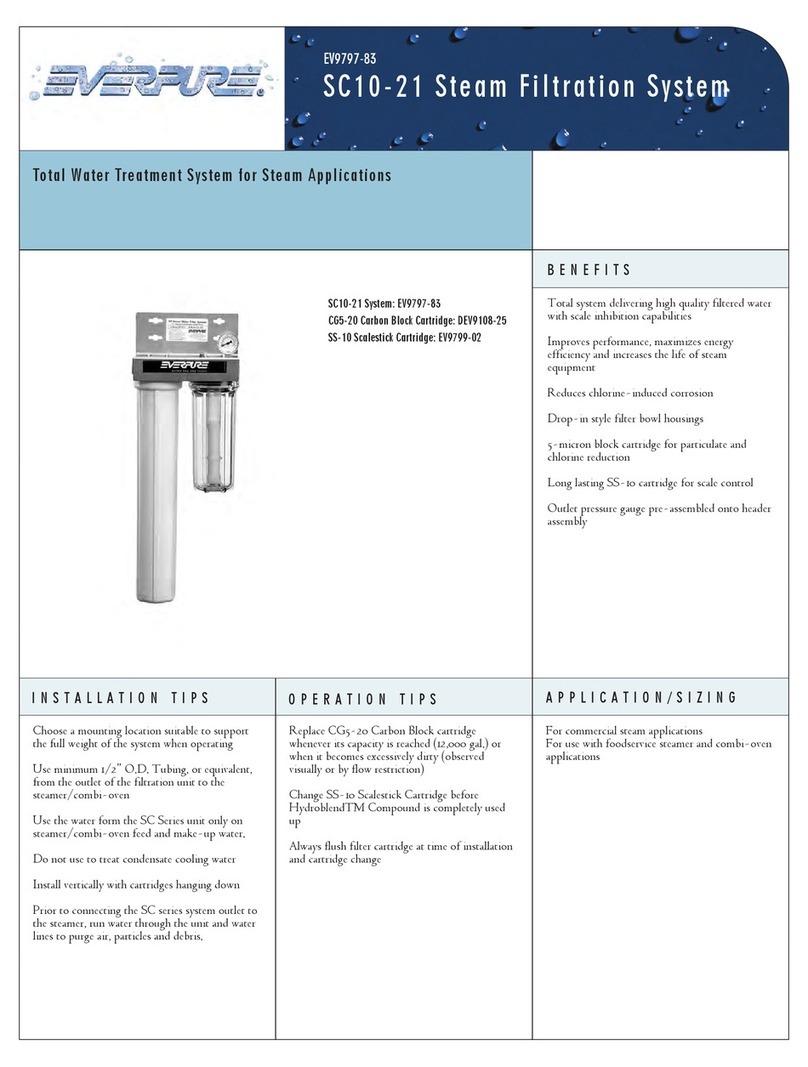

make final connection. (Figure 3)

9. Tighten all connections to insure leakproof installation. Double

check that incoming water supply line is connected to head inlet.

If in doubt, check flow direction arrow, molded into top of head.

10. Insert filter cartridge following instructions on the cartridge

label. Refill water tank with superchlorinated water (follow

superchlorination instructions provided in the following

paragraphs) and run water from cold water faucet checking

all new connections for leaks. (Figure 2)

USE OF SUPERCHLORINATION FOR MAXIMUM PROTECTION

Chlorine is the world’s most accepted and widely used disinfectant.

A chlorine excess, called a residual, is recognized as an indication of

water safety.

Superchlorination is a disinfection method which provides a chlorine

residual of 3.0 to 5.0 ppm.** It will make all the water (from every

outlet) in your RV microbiologically safe. Although the chlorine will

impart a somewhat offensive taste and odor, this will be reduced

from your cooking and drinking water by the Everpure water filter.

The Everpure Water Treatment System provides all that is needed

except chlorine, which must be purchased fresh locally. Simply

proceed with the following instructions:

TO SUPERCHLORINATE YOUR WATER

Superchlorinate with household laundry bleach (sodium hypochlorite).

You may not have thought of this familiar product (Clorox®, Purex®,

Sun-Brite®, etc.) as a water disinfectant, but it is a common form of

sodium hypochlorite (chlorine). Fill the Everpure chlorine disinfectant

dispenser with fresh liquid bleach and add 1/6 ounce (5 ml) or 1

teaspoonful to each 10 gallons (38 l) of water held in your tank. This

doses the water with 6.7 ppm (parts per million) chlorine for killing

harmful bacteria and slime-forming organisms. The most effective

method for putting chlorine into the water system is to first connect

your hose to your vehicle and then put the bleach into the other end of

the hose just before connecting it to the park faucet or other hydrant.

Use chlorine every time you connect to a water source to keep the

hose sanitary and to protect your water system from becoming

contaminated via the water source.*

The chlorine color test (described in the following section) tells you

whether or not you have added enough chlorine to your water to

provide a safety-indicating excess.

YOU MUST TEST FOR SAFETY-INDICATING CHLORINE

RESIDUAL

A residual of 3.0 to 5.0 ppm chlorine,** after as little as 7 minutes

standing time, insures that your water is microbiologically safe – and

chlorine water disinfection lets you test for safety with a quick, simple

feature.

The Everpure RV Water Treatment System provides easy to use test

strips for determining the chlorine residual in your system’s water.

Take one strip and place under running water from any cold water

outlet not served by your Everpure water filter. Leave the strip in the

stream for approximately 10 seconds. Remove strip and compare the

color of the free chlorine square with the color blocks on the side of

the bottle labeled free chlorine. For maximum results your water color

should be deeper than the 4 ppm color block. If it is not, add more

chlorine to the water.

If you are not able to get a minimum 3.0 ppm residual reading by adding

small amounts of chlorine to your water, most likely your water system

is very badly contaminated. This can be remedied by dosing the system

with a higher concentration of chlorine.

(IMPORTANT NOTE: RV manufacturers suggest sanitizing the water

systems in new recreational vehicles. The following procedure may

also be used for this purpose.)

Add 6 oz. (0.2 liter or 2/3 cup) of a 5¼% liquid household bleach to

each 10 gallons (38 liters) of water held in your tank. To make sure of

a thorough mixing, fill half of the tank, add bleach, then finish filling.

Now open each faucet not serviced by the Everpure water filter until

the water coming from it smells of chlorine; then shut it off. In this

way, you draw chlorinated water from all parts of the system. Don’t

forget the hot water faucets. Repeat this at one hour intervals until the

chlorine smell is immediately noticeable when you open a faucet. Now

drain the water system and follow the directions under the heading “To

superchlorinate your water”.

** The NSF claim for Chlorine reduction is based on a 2.0 ppm influent

challenge.

Figure 3