STEAMER DE-LIMING

• These instructions apply to the Everpure SR-X Feeder as well as to

the previous AR-X Feeder.

• Use only Everpure ScaleKleen™ scale remover product. Other harsh

acids may damage bowl material and clog system orifices.

• Use a one kilogram (2.2 lb) package to de-lime most countertop

steamers.

• Use four kilogram (2.2 lb) packages to de-lime most boiler-based

steamers.

1. Turn off the power switch on the steamer.

2. Blow down the steamer. Blow-down is done automatically on

some steamers when power is turned off. Manually blow down the

steamer if this is not done automatically.

3. Turn off inlet water to the SR-X system.

4. Depress the red button on the head to relieve system pressure.

5. Unscrew the clear bowl and remove the used cartridge. Dispose of

the exhausted cartridge in normal trash and empty any remaining

water from the bowl.

6. Locate the SR-X dip tube and insert the tube, O-ring first, into the

center port of the head as far as it will go.

7. Open a one kilogram (2.2lb) package of ScaleKleen and empty it

into the bowl. Wipe off any excess ScaleKleen material which may

be on the bowl threads or O-ring.

8. Thread the bowl back into the SR-X head - hand tight only! NOTE:

The dip tube end may become packed with ScaleKleen. This is

normal and will not affect the de-liming procedure.

9. Turn on the inlet water to the SR-X system.

10. Turn on the power to the steamer. NOTE: This action will quickly

introduce the ScaleKleen material directly into the boiler chamber.

If you are de-liming a countertop steamer, proceed to step 11.

If you are de-liming a boiler-base unit, monitor the ScaleKleen

level in bowl. When the level drops to 1”, quickly turn off the inlet

water. Now relieve pressure and unscrew the bowl from the head.

Add another kilogram of ScaleKleen to the bowl and reintroduce

the material into the boiler. Repeat this procedure until four (4)

kilograms of ScaleKleen have been introduced into the boiler

chamber. Proceed to step 11.

11. With ScaleKleen material introduced into the boiler chamber and

the inlet water turned on, allow the steamer (countertop or boiler-

base) to come up to operating temperature and pressure, and hold

for one hour.

12. Thirty minutes into the de-liming procedure, turn on steam

to cooking chamber(s) for one minute. This will de-lime the

distribution lines, small orifices, and steam solenoid valves.

13. After one hour of de-liming the steamer at operating temperature

and pressure, turn the steamer power switch off.

14. Manually blow down the steamer if it is not done automatically

when the power is turned off.

15. Fill the boiler with fresh, clean water and repeat blow down a

second time to void the boiler chamber of any un-dis-solved loose

scale. Thoroughly rinse the cooking compartment(s) with cold

water and wipe dry with a clean, soft towel.

16. After the second blow-down, turn the steamer power switch off,

and turn off the water to the SR-X Feeder.

17. Relieve system pressure by depressing the red button on the SR-X

head until all air is purged and water begins to escape.

18. Unscrew the bowl and remove the dip tube from the head. BE

SURE TO PLACE THE DIP TUBE IN A CONVENIENT LOCATION.

19. Install a new SS-10 cartridge into the head and thread the bowl

back onto the head. Snug the bowl with the sump wrench (EV3112-

41).

20. Turn on the inlet water. Relieve any trapped air in the bow by

depressing the red button on the SR-X head until all air is purged

and water starts escaping.

21. Turn the steamer power switch on. The steamer is now ready to

be placed back into service.

22. Be sure to order additional SS-10 replacement cartridges,

ScaleKleen and carbon filter cartridges to maintain future worry-

free operation of your steamer.

REPLACEMENT PARTS

Contact your local Everpure dealer for filter cartridges or system

replacement parts.

Description Part Number

Head EV3112-37

O-ring EV3112-40

10" bowl, clear EV3112-39

Sump wrench EV3112-41

SS-IMF 7" ScaleStick (12-pack) for SR-X EV9799-32

SS-IMF spacer EV3114-69

SS-10 ScaleStick (12-pack) for SR-X w/Deliming Kit EV9799-02

Dip tube for SR-X Deliming Kit EV3080-40

3/4" outlet check valve for SR-X w/Deliming Kit EV3114-50

SPECIFICATIONS

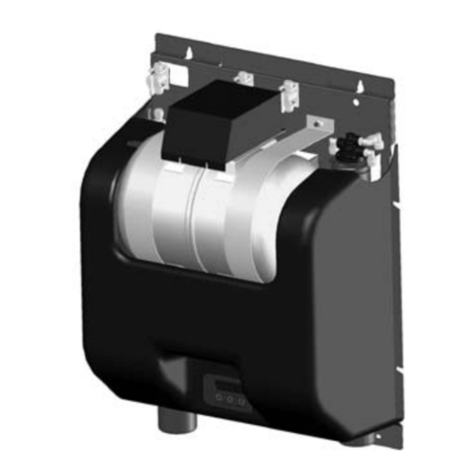

Overall Dimensions: 12.44”H x 5.16”D

Shipping Weights: 2 lbs. (SR-X); 4.5 lbs. (SR-X w/ Deliming Kit)

Inlet/outlet Connections: 3/4” FNPT

Materials of construction:

- Head: polypropylene

- Clear bowl: transparent plastic

Service Flow Rate: 0.5-6.0 gpm (1.9-22.5 lpm)

Pressure Limit: 125 psi (8.6 bar)

Temperature Limits: 35°F -100°F (2-38°C)