EVERWATCH 8620 User manual

Model 8620

EVERWATCH

Room

Pressure

Monitor

User's Guide

Model 8620

EVERWATCH

Room

Pressure

Monitor

User's Guide

July 1994

P/N 1980105

Rev. B

U.S. AND CANADA OTHER COUNTRIES

Sales & Customer Service: Sales & Customer Service:

(800) 777-8356/(651) 490-2711 (001 651) 490-2711

Fax: Fax:

(651) 490-2874 (001 651) 490-2874

SHIP TO: MAIL TO:

TSI Incorporated TSI Incorporated

ATTN: Customer Service P.O. Box 64394

500 Cardigan Road St. Paul, MN 55164

Shoreview, MN 55126 USA

USA

E-MAIL

WEB SITE

www.tsi.com

Copyright TSI Incorporated/July 1994/All rights reserved.

Part number1980105 Rev. B

LIMITATION OF WARRANTY AND LIABILITY

Seller warrants that this product, under normal use and service as described in the operator's manual, shall

be free from defects in workmanship and material for a period of twenty-four (24) months, or the length of

time specified in operator's manual, from the date of shipment to the customer. This limited warranty is

subject to the following exclusions:

1. Batteries, hot wire or hot film sensors and certain other components when indicated in

specifications are warranted for a period of 90 days from the date of shipment to the customer.

2. With respect to any repair services rendered, seller warrants that the parts repaired or replaced will

be free from defects in workmanship and material, under normal use, for a period of 90 days from

the date of shipment to the customer.

3. Seller does not provide any warranty on finished goods manufactured by others. Only the original

manufacturer's warranty applies.

4. Unless specifically authorized in a separate writing by seller, seller makes no warranty with

respect to, and shall have no liability in connection with, any goods which are incorporated into

other products or equipment by the Buyer.

The foregoing is IN LIEU OF all other warranties and is subject to the conditions and LIMITATIONS

stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

THE EXCLUSIVE REMEDY OF THE USER OR PURCHASER, AND THE LIMIT OF THE

LIABILITY OF SELLER FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES IN

CONNECTION WITH THIS PRODUCT (INCLUDING CLAIMS BASED ON CONTRACT,

NEGLIGENCE, STRICT LIABILITY, OTHER TORT, OR OTHERWISE) SHALL BE THE

RETURN OF THE PRODUCT TO THE FACTORY OR DESIGNATED LOCATION AND THE

REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR

REPLACEMENT OF THE PRODUCT. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY

SPECIAL INCIDENTAL OR CONSEQUENTIAL DAMAGES. NO ACTION, REGARDLESS OF

FORM, MAY BE BROUGHT AGAINST THE SELLER MORE THAN ONE YEAR AFTER THE

CAUSE OF ACTION HAS ACCRUED.

The purchaser and all users are deemed to have accepted the terms of this LIMITATION OF

WARRANTY AND LIABILITY, which contains the complete and exclusive limited warranty of seller.

This LIMITATION OF WARRANTY AND LIABILITY may not be amended or modified nor may any of

its terms be waived except by a writing signed by an authorized representative of seller.

SERVICE POLICY

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our customers,

our service policy is designed to give prompt attention to any problems. If any malfunction is discovered,

please contact your nearest sales office or representative, or call TSI's Customer Service department at

(800) 777-8356.

i

CONTENTS

Introduction 1

Chapters 1 Getting Started 3

Configuration 3

Calibration 3

2 Operation 5

Front Panel Display 6

Front Panel Controls 7

3 Configuration 9

Description of Configuration Menu Functions 11

Configuration Procedure 14

4 Calibration 19

Calibration Procedure 20

5 Maintenance 23

Velocity Sensor Cleaning 23

Replacement Parts 23

6 Troubleshooting 25

Appendix A Specifications 27

B Theory of Operation 29

C Typical Wiring Diagram 35

D Configuration Menu Flow Chart 37

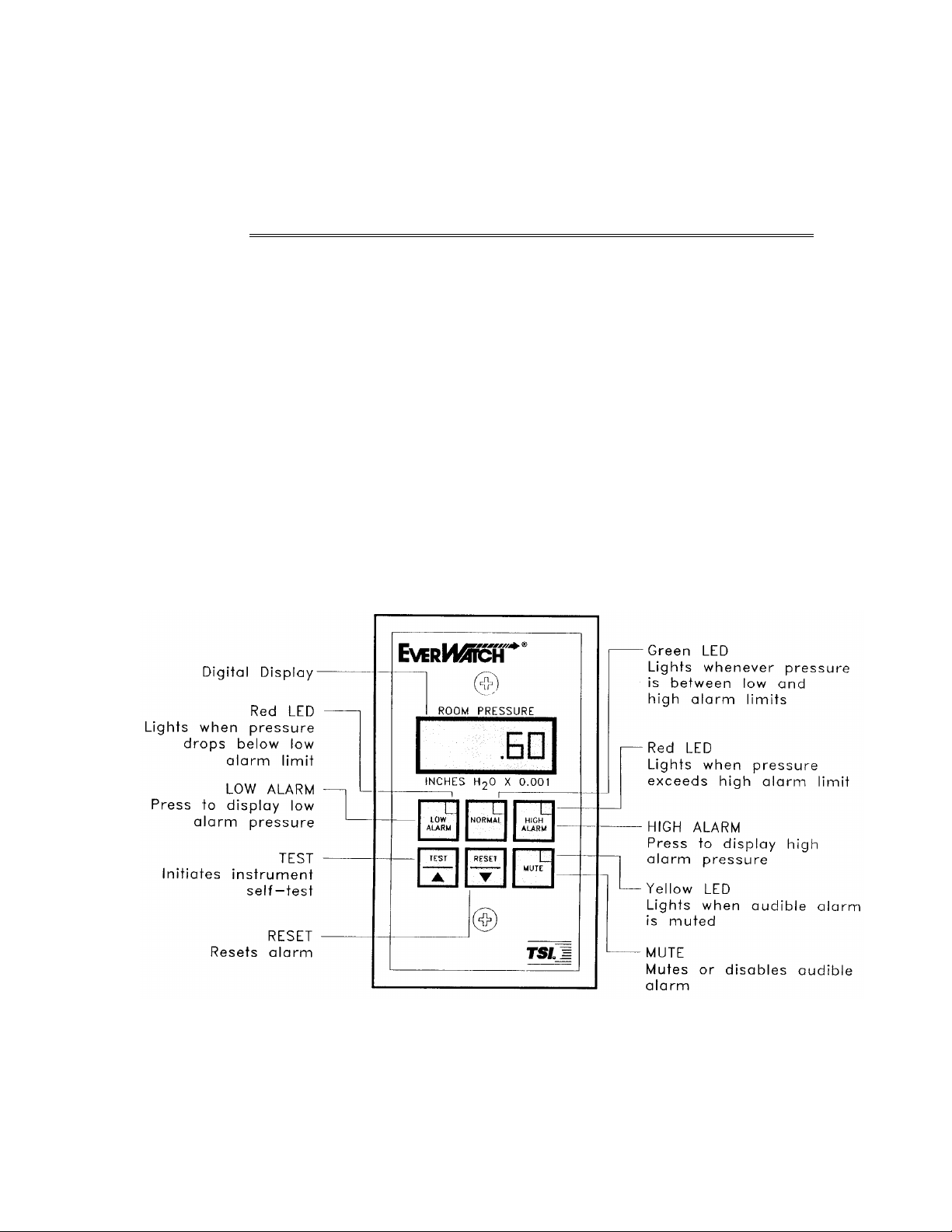

Figures 1. EVERWATCH Front Panel Display and Controls 5

2. EVERWATCH Bridge Circuit 30

3. EVERWATCH Wiring Diagram 35

Tables 1. EVERWATCH Configuration worksheet 9

2. Troubleshooting 25

3. Display Averaging Period Example 31

ii

CONTENTS

1

INTRODUCTION

The EVERWATCH User's Guide describes how to operate, configure, calibrate,

maintain and troubleshoot the Model 8620 EVERWATCH

Room Pressure

Monitor. Please read this guide thoroughly before using the EVERWATCH.

This guide assumes that the EVERWATCH has been properly installed. Refer to

the Installation and Checkout Instructions if there is any question as to whether

the EVERWATCH has been installed properly.

The User's Guide has been divided into the following chapters to simplify its

use.

Chapter 1 describes how to program the EVERWATCH.

Chapter 2 describes how to operate the EVERWATCH.

Chapter 3 describes how to configure the EVERWATCH.

Chapter 4 describes how to calibrate the EVERWATCH.

Chapter 5 describes how to maintain the EVERWATCH.

Chapter 6 describes how to troubleshoot the EVERWATCH.

Appendix A lists the EVERWATCH specifications.

Appendix B describes the EVERWATCH theory of operation.

Appendix C describes how the EVERWATCH is wired.

Appendix D contains a flow chart of the configuration menus.

References to the EVERWATCH keypad and digital display are highlighted in this

guide as follows:

Example: Press the LOW ALARM key to display the low alarm set point.

A black four-pointed star is used throughout this guide to call attention to

important notes or comments.

Step-by-step instructions are denoted by numbered circles .

HELP!

Technical assistance and customer service:

Contact TSI Industrial Test Instruments Group at 1-800-777-8356.

2

INTRODUCTION

3

CHAPTER ONE

GETTING STARTED

Configuration The rooms and the environment in which the EVERWATCH operates vary

from facility to facility. There are a variety of ways to display and use

the information gathered by the EVERWATCH. The configuration

procedure is used to program the EVERWATCH to present the

information in the manner desired.

The EVERWATCH has the versatility required to operate in a variety of

configurations. The EVERWATCH comes from the factory configured for

typical operating requirements.

Before beginning to reconfigure the EVERWATCH, take a few minutes to

review the configuration procedures found in Chapter Three. Use the

configuration worksheet to determine how to configure the EVERWATCH

to suit your requirements.

Calibration The EVERWATCH Room Pressure Monitor is a very versatile device

which will work with a variety of rooms. The EVERWATCH is calibrated

at the factory to each sensor. It is imperative that the sensor and

monitor be kept as a matched set. Insure that the serial number on the

monitor matches the number on the sensor.

If the room configuration is unique, "such as 8 ft long tube" the system

should be calibrated to the new setup. The calibration procedure is quite

simple and can be accomplished in a matter of minutes with a little

preparation and practice.

Before beginning to calibrate the EVERWATCH, take a few minutes to

review the calibration procedures found in Chapter Four. A portable air

velocity meter and the calibration instructions are all that are needed to

get started.

4

CHAPTER 1

5

CHAPTER TWO

OPERATION

The EVERWATCH Room Pressure Monitor is easy to use. Its operation is simple

and straightforward. All the information you need to know about the room

pressure is displayed on the monitor's front panel. All calibration and

configuration programming is accessible through the keypad.

From an operations standpoint, the EVERWATCH functions on two levels:

1. The EVERWATCH has a front panel display which provides indication of

the room pressure and alarm conditions via a digital display, indicator

lights and an audible alarm.

2. The EVERWATCH has front panel controls for checking alarm set points,

testing the unit for proper operation, resetting alarms, silencing alarms,

and programming calibration and configuration data.

Specific details about the EVERWATCH front panel display and controls are

described on the following pages.

Figure 1. EVERWATCH Front Panel Display and Controls.

6

CHAPTER 2

Front Panel Digital Display

Display The digital display indicates the room pressure with respect to REFERENCED

CORRIDOR, calibration and configuration menus, and error messages. The

display indicates the room pressure continuously, the error messages when

they occur, and the calibration and configuration menu items when either of

these programming modes is selected.

Low Alarm Light

The red LOW ALARM light indicates low room pressure. The LOW ALARM light

turns on when the magnitude of the room pressure drops below, or is in the

opposite direction of the low room pressure alarm set point. When the lights

are configured for alarm follow operation, the LOW ALARM light remains on until

the room pressure returns to normal. When the lights are configured for alarm

latch operation, the LOW ALARM light remains on until the room pressure returns

to normal and the RESET key has been pressed.

Normal Light

The green NORMAL light indicates that the room pressure is in the normal range.

The NORMAL light is on when the room pressure is between the low room

pressure alarm set point and the high room pressure alarm set point.

High Alarm Light

The red HIGH ALARM light indicates high room pressure. The HIGH ALARM light

turns on when the magnitude of the room pressure exceeds in the same

direction as the high room pressure alarm set point. When the lights are

configured for alarm follow operation, the HIGH ALARM light remains on until

the room pressure returns to normal. When the lights are configured for alarm

latch operation, the HIGH ALARM light remains on until the room pressure returns

to normal and the RESET key has been pressed.

Mute Light

The yellow MUTE light indicates that the audible alarm is disabled. The MUTE

light turns on when the audible alarm has been disabled. The audible alarm

will not sound as long as the MUTE light is on.

Audible Alarm

The audible alarm indicates alarm conditions. The audible alarm sounds when

the room pressure is in an alarm condition. When the audible alarm is

configured for alarm follow operation, the alarm continues to sound until the

MUTE key is pressed or the room pressure returns to normal. When the audible

alarm is configured for alarm latch operation, the audible alarm remains on

until the MUTE key has been pressed, or the room pressure returns to normal

and the RESET key is pressed.

The audible alarm can also be muted by closing the contact closure input (pins

9-10 on back connector). With the contact closure input closed, the mute light

turns on and the audible alarm will not sound.

OPERATION

7

There is a 10 second delay between when the pressure triggers an alarm

and when the monitor shows the alarm condition. This is used so the

alarms don't trigger when someone opens a door to enter or leave the

room.

Front Panel The front panel controls operate as follows when configured

Controls using the standard factory installed default parameters:

LOW ALARM Key

The LOW ALARM key is used to display the low room pressure alarm set point on

the digital display. The low room pressure set point is displayed when the LOW

ALARM key is pressed.

NORMAL Key

The NORMAL key is used to gain access to the calibration and configuration

menus. Refer to Chapters 3 and 4 for configuration and calibration instructions.

HIGH ALARM Key

The HIGH ALARM key is used to display the high room pressure alarm set point on

the digital display. The high room pressure alarm set point is displayed when

the HIGH ALARM key is pressed.

TEST Key

The TEST key is used to initiate an instrument self-test. The monitor display,

indicator lights, audible alarm, and internal electronics are tested when the TEST

key is pressed.

RESET Key

The RESET key is used to reset the low and high room pressure alarm lights and

alarm contacts. Alarm lights and contacts are reset when the room pressure has

returned to normal and the RESET key is pressed. The RESET key is also used to

reset error messages. See the troubleshooting guide in Chapter 6 for details.

MUTE Key

The MUTE key is used to silence and/or disable the audible alarm. An audible

alarm can be silenced at anytime by pressing the MUTE key. The audible alarm

can be disabled by pressing the MUTE key when the audible alarm is not

sounding and the yellow MUTE light is off. The yellow MUTE light turns on when

the audible alarm has been disabled.

The mute light will turn on when the contact closure input is closed.

Pressing the MUTE key has no affect in this configuration.

8

CHAPTER 2

9

CHAPTER THREE

CONFIGURATION

The EVERWATCH is a very versatile device which may be set to operate in a

variety of configurations. This chapter is a guide for configuring the

EVERWATCH.

The configuration menu is used to select the low alarm set point, high alarm set

point, display period, alarm light response, alarm relay response, audible alarm

response, elevation correction and analog output resolution. The items to be

configured are arranged sequentially in the configuration menu. The

configuration data is stored in memory when the configuration menu is exited

and the EVERWATCH is returned to normal operation. A flow chart diagraming

the configuration procedure is included in Appendix D.

The EVERWATCH is shipped with a set of default values already programmed in

memory. These default values are listed on the Configuration Worksheet in

Table 1. Use the Configuration Worksheet to select the desired configuration

parameters for the intended application.

Table 1. EVERWATCH Configuration Worksheet.

Default User

Function Display Range/Options Value Value

Low Alarm L AL OFF, -195.00 to 195.00 OFF

inches H20 X 0.001 in 0.05,

0.50, 5.00 increments

depending on the magnitude of

the alarm.

High Alarm H AL OFF, -195.00 to 195.00 OFF

inches H2O X 0.001 in 0.05,

0.50, 5.00 increments

depending on the magnitude

of the alarm.

Display dSPL 2 to 10 seconds 5

Averaging Period (in 1 second increments)

Alarm light LEdS Latch (LA) or Follow (UnLA) LA

Alarm Relay rLYS Latch (LA) or Follow (UnLA) LA

Audible Alarm AUD Latch (LA) or Follow (UnLA) LA

Alarm Disable dSbL On or OFF On

Elevation ELEV 0 - 10,000 feet in 1000 0

feet increments

Analog Output AOUT 1, 10 and 100. 1 is maximum, 1

100 is minimum range

Access Code PASS On or OFF OFF

10

CHAPTER 3

The magnitude of the alarm increments changes with the

magnitude of the set point. ①When the magnitude of the

setpoint is less than 10.00 inches H20 X 0.001, the increments

equal 0.05 inches H20 X 0.001. ②When the magnitude of the

setpoint is between 10.00 and 100.00 inches H20 X 0.001, the

increments equal 0.50 inches H20 X 0.001. ③When the

magnitude of the setpoint is greater than 100.00 inches H20 X

0.001, the increments equal 5.00 inches H20 X 0.001.

Description of Display Function Description

Configuration

Menu

Functions COnF Configuration Menu The configuration menu

function indicates the

configuration menu is about to

be entered.

COdE Access Code The access code function

prevents unauthorized access to

the configuration menu. This

function is not enabled and is

not indicated on the display on

initial start-up. The access code

function is enabled by turning

the access code enable function

on (See PASS Below).

L AL Low Alarm The low alarm function is used

to set the low alarm set point.

The low alarm set point may be

set to OFF, or it may be set

between -195.00 and 195.00

inches H2O X 0.001. A low

room pressure alarm condition

is initiated when the magnitude

of the room pressure falls

below, or is in the opposite

direction of, the low alarm set

point.

H AL High Alarm The high alarm function is used

to set the high alarm set point.

The high alarm set point may

be set to OFF, or it may be set

between -195.00 and 195.00

inches H2O x 0.001. A high

room pressure alarm condition

is initiated when the magnitude

of the room pressure rises above

the high alarm set point.

There is a 0.50 inches H2O x 0.001 dead band between the low

alarm set point and high alarm set point which prevents the

alarm set points from overlapping. For example, when the low

alarm set point is set at .50 inches H2O x 0.001 the lowest the

CONFIGURATION

11

high alarm set point can be set is 1.00 inches H2O x 0.001. If the

magnitude of the alarms is greater than 100.00, the deadband

increases to 5.00 inches H20 x 0.001.

The alarm set points must have the same sign. Normal room

pressure should lie between the high and low alarm set points.

For example, if the low alarm is -0.50 inches H20 X 0.001, the

lowest high alarm set point is -1.00 inches H20 X 0.001.

dSPL Display Averaging The display averaging period

Period function is used to set the

display averaging period. The

display averaging period may

be set between 2 and 10

seconds. The display averaging

period is the period of time over

which the room pressure

readings are averaged before

being displayed. The longer the

display averaging period, the

more stable the display.

See Appendix B for an in-depth

description.

LEdS Alarm Light The alarm light function is used

to select whether the low and

high alarm lights latch in an

alarm condition(LA) or follow

an alarm condition(UnLA).

When alarm latch is selected,

the alarm light turns on in an

alarm condition and remains on

until the room pressure returns

to normal and the RESET key is

pressed. When alarm follow is

selected, the alarm light turns

on in an alarm condition and off

when the room pressure returns

to normal.

rLYS Alarm Relay The alarm relay function is used

to select whether the low and

high alarm relay latch in an

alarm condition(LA) or follow

an alarm condition(UnLA).

When alarm latch is selected,

the alarm relay contacts close in

an alarm condition and remain

closed until the room pressure

returns to normal and the RESET

key is pressed. When alarm

follow is selected, the alarm

12

CHAPTER 3

relay contacts close in an alarm

condition and open when the

room pressure returns to

normal.

Aud Audible Alarm The audible alarm function is

used to select whether the

audible alarm latches in an

alarm condition(LA) or follows

an alarm condition(UnLA).

When alarm latch is selected the

audible alarm turns on in an

alarm condition and remains on

until the room pressure returns

to normal and the RESET key is

pressed. When alarm follow is

selected the audible alarm turns

on in an alarm condition and off

when the room pressure returns

to normal.

dSbL Alarm Disable The alarm disable function is

used to select whether the

audible alarm can (On) or

cannot (OFF) be disabled from

the keypad.

ELEV Elevation Correction The elevation correction

function is used to correct

the pressure readings to

changes in air density that

occur at different elevations.

AOUt Analog Output This enables the user to select

Resolution the range of the analog output.

This value can be set to 1, 10, or

100. 1 represents a range from

-0.1 to 0.1 inches H20. 10

represents a range of -0.01 to

0.01 inches H20 and 100

represents a range from -0.001

to 0.001 inches H20.

PASS Access Code The access code enable function

is used to select whether an

access code is required (ON) or

not required (OFF) to enter the

configuration menu.

End End Configuration Identifies the end of the

configuration menu.

CONFIGURATION

13

SAVE Save The save function confirms that

any new values entered have

been saved to memory. Save is

displayed only when new

values have been entered.

Configuration The EVERWATCH is configured as follows:

Procedure

Enter the Configuration Menu

Press and hold the NORMAL key until CONF is indicated on the

display, then release the NORMAL key.

Press and release the NORMAL key to select the configuration

menu.

If L AL is indicated on the display, the access code enable

function is set to off and an access code is not required to enter

the configuration menu. Skip to the next page for instructions

descriping how to set the low alarm set point.

If COdE is indicated on the display, the password enable function

is set to on and an access code is required to gain access to the

configuration menu. Enter the configuration menu access code

as follows:.

Enter Configuration Menu Access Code

Press and release the LOW ALARM key.

Press and release the TEST key.

Press and release the RESET ALARM key.

Press and release the HIGH ALARM key.

Press and release the LOW ALARM key.

If the access code is entered correctly, the configuration menu is entered

and L AL is indicated on the display.

The configuration and the calibration access codes are not the

same. The configuration access code allows access to the

configuration menu only.

The access code must be entered within 40 seconds

(approximately eight seconds per keystroke). COdE flashes on

and off five times between keystrokes. If the next access code

key is not pressed within this time period, the configuration

menu is exited. The audible alarm sounds briefly each time a

keystroke has been entered. If an incorrect code is entered, an

error message (ERR) flashes on the display, the audible alarm

sounds and the configuration menu is exited.

14

CHAPTER 3

Set the Low Alarm Set Point

Confirm that L AL is indicated on the display.

Press and release the NORMAL key to display the current low

alarm set point.

Use the or keys to change the low alarm set point value.

Press and release the NORMAL key to save the displayed value.

L AL is indicated on the display.

Press and release the key to step to the next menu item.

Set the High Alarm Set Point

Confirm that H AL is indicated on the display.

Press and release the NORMAL key to display the current high

alarm set point.

Use the or keys to change the high alarm set point.

Press and release the NORMAL key to save the displayed value.

H AL is indicated on the display.

Press and release the key to step to the next menu item, or the

key to return to the previous menu item.

Set the Display Averaging Period

Confirm that dSPL is indicated on the display.

Press and release the NORMAL key to display the current display

averaging period.

Use the or keys to change the value of the display

averaging period.

Press and release the NORMAL key to save the displayed value.

dSPL is indicated on the display.

Press and release the key to step to the next menu item, or the

key to return to the previous menu item.

Table of contents