Everwell FAHC18HA15 User manual

WALL-MOUNT AIR HANDLERS

1.5 to 3 Ton

secondary drain connections.

•Built-in filter rack.

•Wall-hanging brackets.

FAHC18HA15

FAHC24HA15

FAHC30HA15

FAHC36HA15

Installation Manual

Product Features

All phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES.

Important: This Document is customer property and is to remain with this unit.

•Front or bottom return air.

•Blower slides out easily for maintenance.

•Painted finish on galvanized steel.

•Thermoplastic drain pan with bottom primary and

•208/230 VAC operation.

•Direct-drive, multi-speed motor allows air volume

variation for heating/cooling.

•Factory installed R410A orifice.

•Stud or wall mounting installation.

•Fully insulated cabinet.

•3/4'' NPT primary and secondary drains.

•AHRI certified and ETL listed.

•

2.5, 5, 7.5 and 10 kW single phase electric heaters.

The manufacturer has a policy of continuous data improvement and it

reserves the right to change design and specifications without notice.

2

......................................................................................4

Dimension Data.........................................................................................6

Installation Instructions .............................................................................9

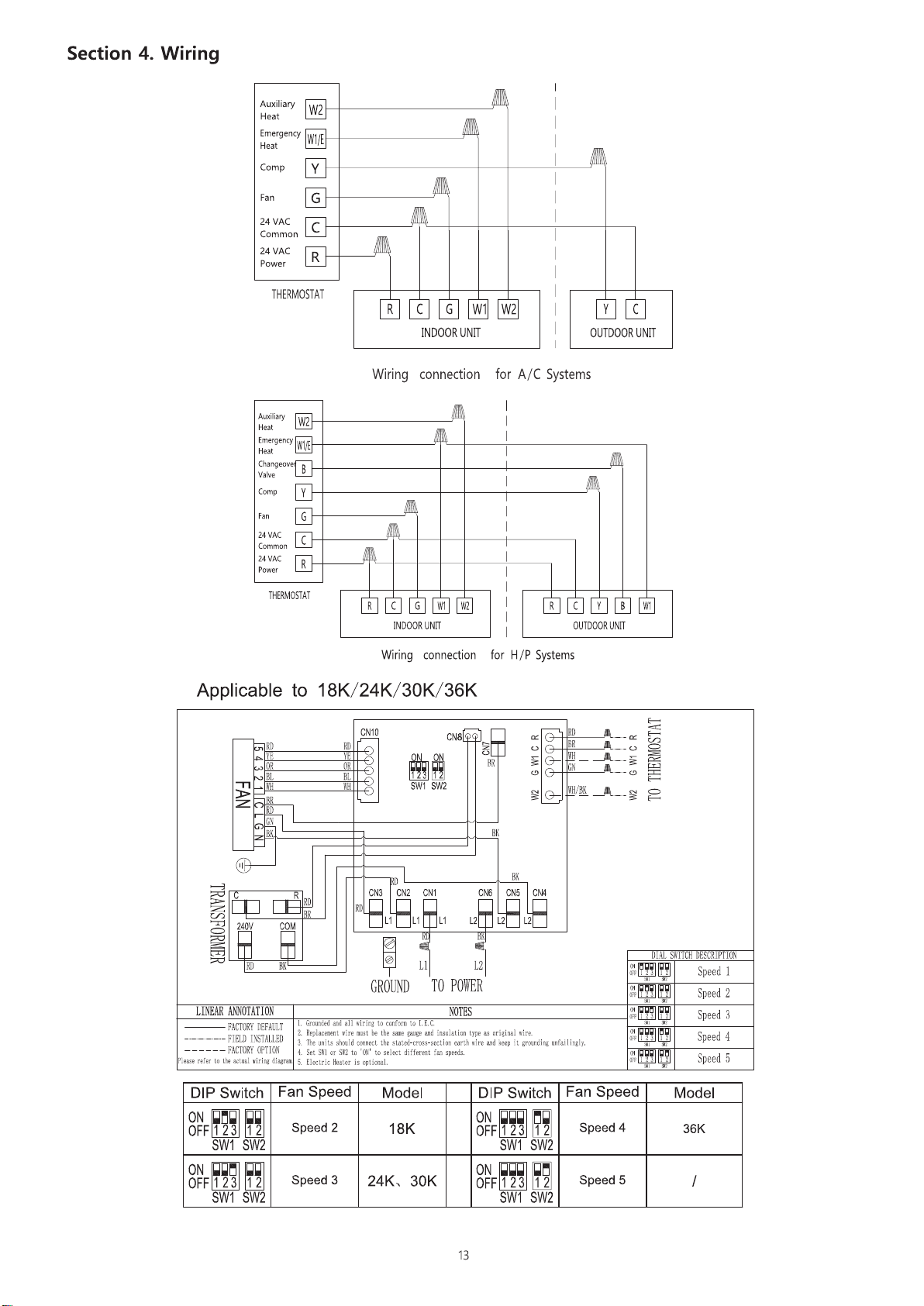

Wiring........................................................................................................13

Safety Precaution

Table of Contents

3

Performance Data....................................................................................15

. ......................................................................14..

Electric Wiring Gauge

Important:

These instructions do not cover all variations in systems

nor provide for every possible contingency to be met in connection

with the installation. Should further information be desired or should

particular problems arise which are not covered sufficiently for the

purchaser’s purposes, the matter should be referred to your

installing dealer or local distributor.

Important:

Installation of this unit shall be made in accordance with

the National Electric Code, NFPA No. 90A and 90B, and any other

local codes or utilities requirements.

Note:

The small air handlers have been evaluated in accordance

with the Code of Federal Regulations, Chapter XX, Part 3280 or the

equivalent. “SUITABLE FOR MOBILE HOME USE.”

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Respirable particles of fiberglass are known to State of California

to cause cancer.

for safety. California Proposition 65 warnings are required for

certain products, which are not covered by the OSHA standards.

California’s Proposition 65 requires warnings for products sold in

California that contain or produce any of over 600 listed

chemicals known to the State of California to cause cancer or

birth defects such as fiberglass insulation, lead in brass, and

combustion products from natural vapor.

All “new equipment” shipped for sale in California will have labels

stating that the product contains and/or produces Proposition

65 chemicals. Although we have not changed our processes,

having the same label on all our products facilitates

manufacturing and shipping. We cannot always know “when, or

if” products will be sold in the California market.

You may receive inquiries from customers about chemicals found

air-conditioning equipment, or found in natural vapor used with

some of our products. Listed below are those chemicals and

substances commonly associated with similar equipment in our

industry and other manufacturers.

Glass Wool (Fiberglass) Insulation

Carbon Monoxide (CO)

Formaldehyde

Benzene

More details are available at the websites for OSHA

www.osha.gov and the State of California’s OEHHA (Office of

Environmental Health Hazard Assessment), at www.oehha.org.

Consumer education is important since the chemicals and

substances on the list are found in our daily lives. Most

consumers are aware that products present safety and health

risks, when improperly used, handled and maintained.

4

Section 1. Safety Precaution

SAFETY HAZARD!

This information is intended for use by individuals possessing

adequate backgrounds of electrical and mechanical

experience. Any attempt to repair a central air conditioning

product may result in personal injury and/or property

damage. The manufacturer or seller cannot be responsible for

the interpretation of this information, nor can it assume any

liability in connection with its use.

HAZARDOUS VOLTAGE!

Disconnect all electrical power, including remote disconnects

before installing or servicing. Follow proper lockout/tagout

procedures to ensure the power can not be inadvertently

energized. Failure to disconnect power before servicing could

result in death or serious injury.

LIVE ELECTRICAL COMPONENTS!

During installation, testing, servicing, and troubleshooting of

this product, it may be necessar y to work with live electrical

components. Failure to follow all electrical safety precautions

when exposed to live electrical components could result in

death or serious injury.

EXPLOSION HAZARD!

Do not store corrosive or combustible materials, gasoline, or

other flammable vapors or liquids near the unit. Failure to

follow this warning could result in property damage, serious

personal injury, or death.

ELECTRICAL HAZARD!

Grounding Required! Follow proper local and state electrical

code on requirements for grounding. Failure to follow this

warning could result in property damage, serious personal

injury, or death.

HAZARDOUS VAPORS!

Do not install an air handler with a non-ducted return in the

same closet, alcove, or utility room as a fossil fuel device.

Hazardous vapors can be distributed throughout the

conditioned space and equipment damage can result.

WARNING

PROPOSITION 65: This appliance contains fiberglass insulation.

(Occupational Safety and Health Administration), at

All manufacturer products meet current federal OSHA Guidelines

found in, or produced by, some of our heating and

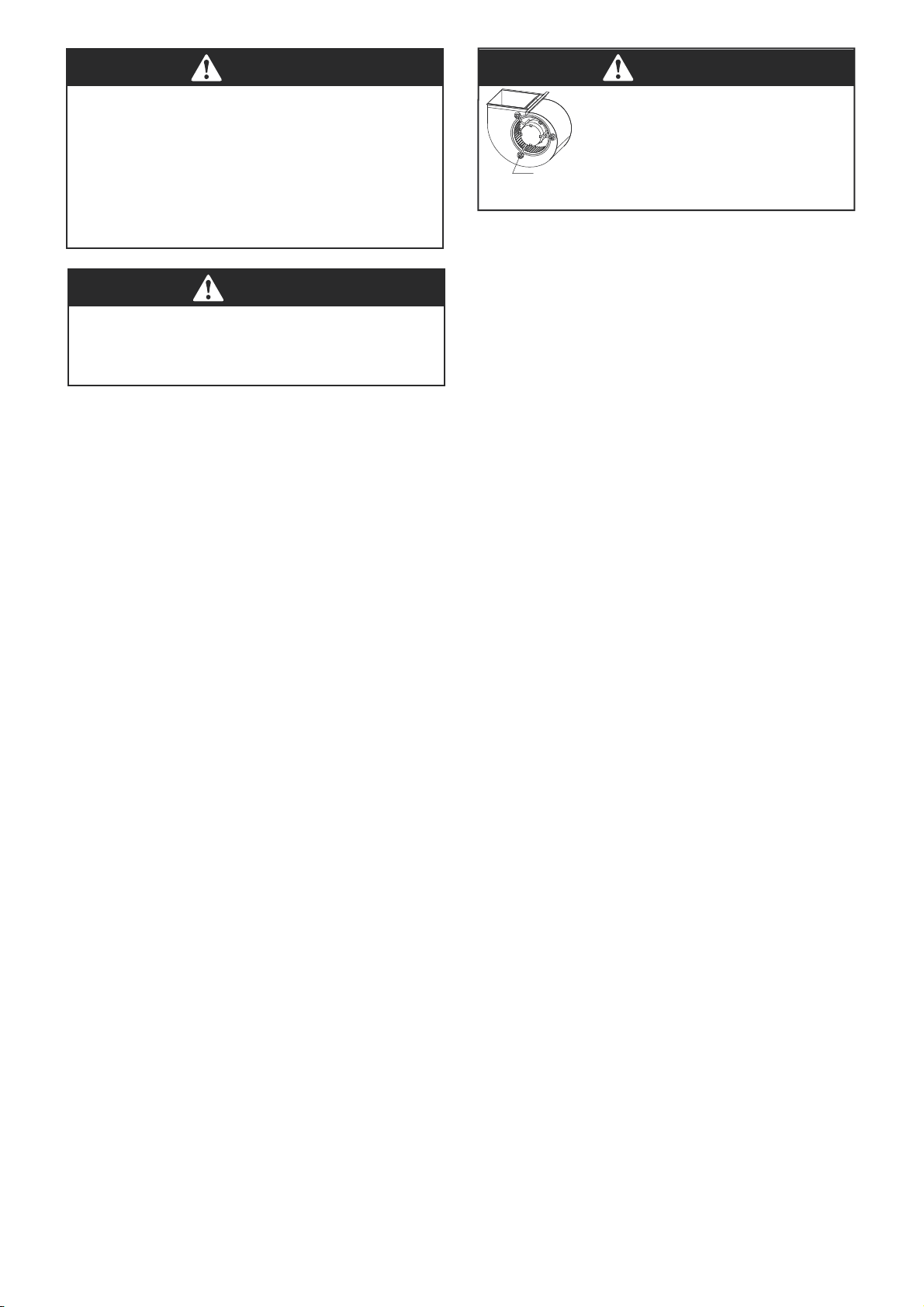

CAUTION

CAUTION

WARNING

Make sure the blower motor support is tight

(3-motor mount bolts) then check to see if

wheel is secured to motor shaft before

operating unit.

BLOWER MOT

OR

SHIPPING BOLT

5

CORROSION HAZARD!

To prevent shortening its service life, the air handler should

not be used during the finishing phases of construction. The

low return air temperatures can lead to the formation of

condensate. Condensate in the presence of chlorides and

fluorides from paint, varnish, stains, adhesives, cleaning

compounds, and cement creates a corrosive condition which

may cause rapid deterioration of the cabinet and internal

components.

SAFETY HAZARD!

Sharp Edge Hazard. Be careful of sharp edges on equipment

or any cuts made on sheet metal while installing or servicing.

Personal injury may result.

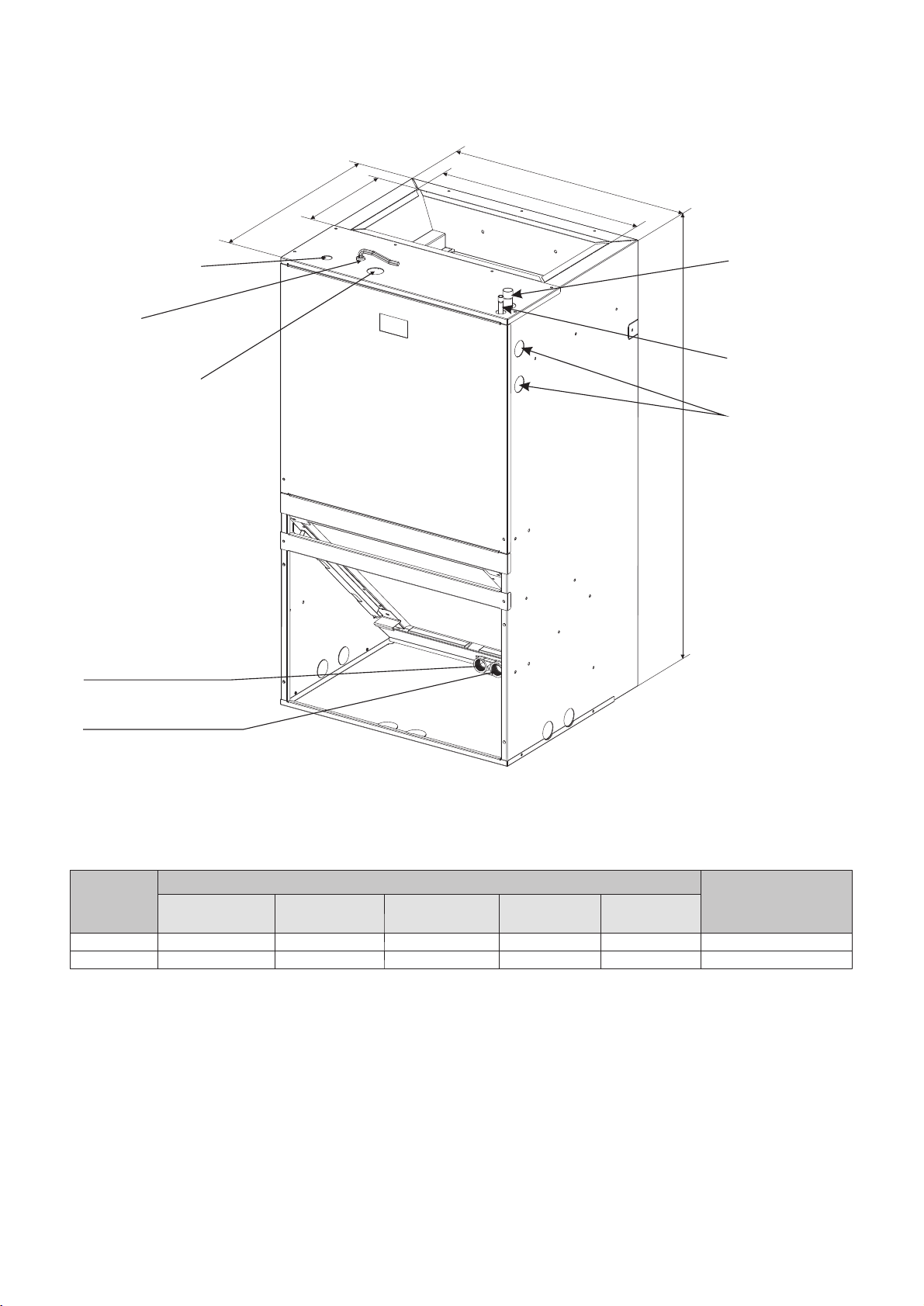

2.1 Unit Dimensions

6

Section 2. Dimension Data

All units are configured for vertical upflow.

Units cannot be installed in any other configuration.

Front return shown. Units may

also be installed as bottom

return. See the applications

section for more details.

1

D

D

H

High voltage connection

7/8" dia knock outs

Liquid line connection

copper (Sweat)(3/8"dia pipe)

Vapor line connection

copper (Sweat)(3/4"dia pipe)

Low voltage

connection

High voltage connection

1-2/25" dia knock outs

High voltage connection

7/8" dia knock outs

Primary drain conncetion 3/4"

female pipe thread (NPT)

Auxiliary drain connection 3/4"

female pipe thread (NPT)

Model

Dimensions- In. (mm) Unit Weight /

Shipping Weight

Lbs. (kg)

Height

H

Width

W

Width

W1

Depth

D

Depth

D1

18K36 (915) 20-1/2 (522)17-2/5 (442) 15 (381) 9-3/5 (244)88 / 99 (40 / 45)

24K36 (915) 20-1/2 (522)17-2/5 (442) 15 (381) 9-3/5 (244)88 / 99 (40 / 45)

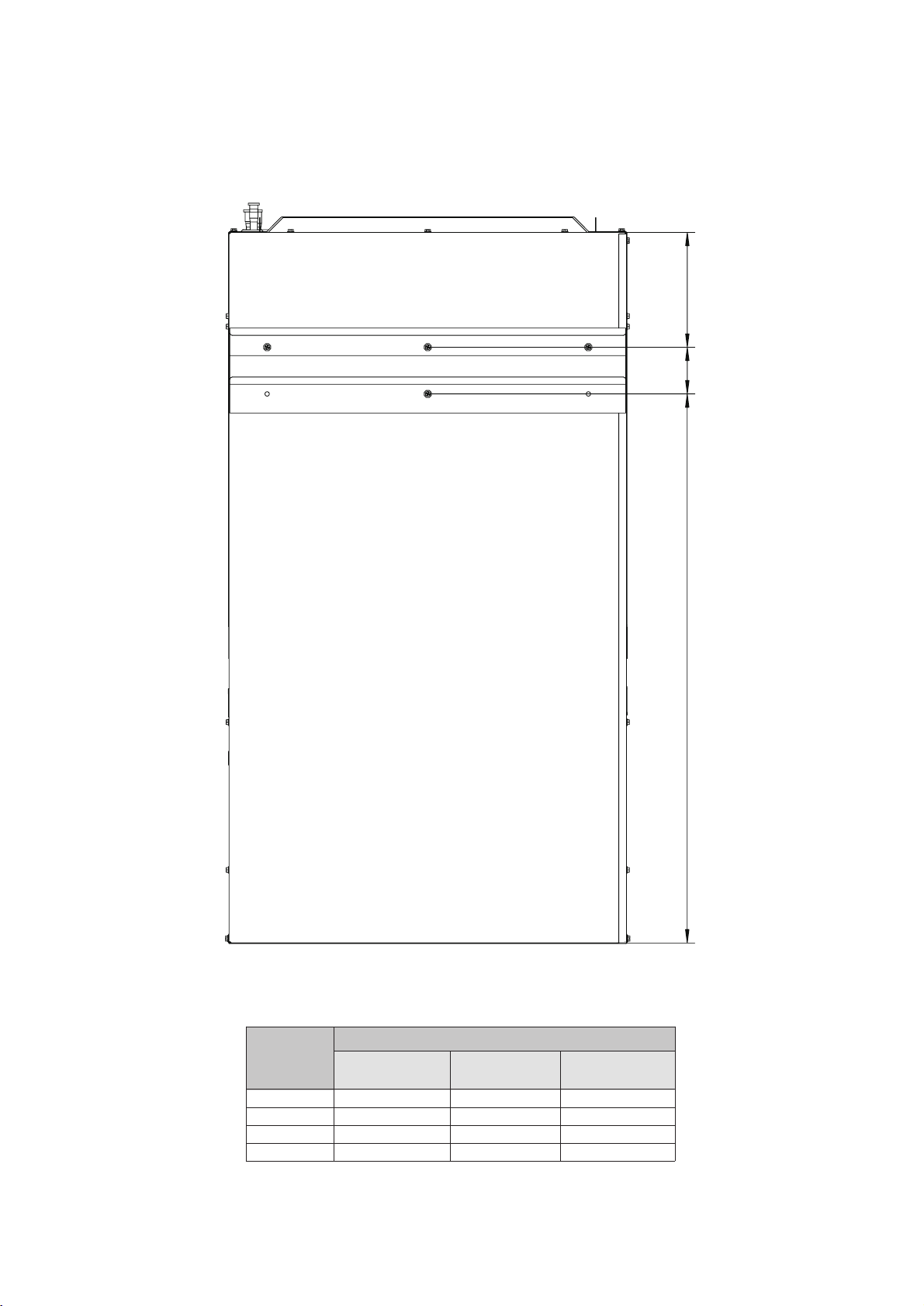

7

Model

Dimensions- In. (mm) Unit Weight /

Shipping Weight

Lbs. (kg)

Height

H

Width

W

Width

W1

Depth

D

Depth

D1

30K39-3/5 (1006) 22 (559) 18-4/5 (477)19 (485)10 (251)110/ 121 (50 / 55)

36K39-3/5 (1006) 22 (559) 18-4/5 (477)19 (485)10 (251)110/ 121 (50 / 55)

Low voltage

connection

All units are configured for vertical upflow.

Units cannot be installed in any other configuration.

Auxiliary drain connection 3/4"

female pipe thread (NPT)

Primary drain conncetion 3/4"

female pipe thread (NPT)

Front return shown. Units may

also be installed as bottom

return. See the applications

section for more details.

D1

D

W

W1

H

High voltage connection

-1 3/8" dia knock outs

Liquid line connection

copper (Sweat)(3/8"dia pipe)

Vapor line connection

copper (Sweat)(3/4"dia pipe)

High voltage connection

7/8" dia knock outs

High voltage connection

-1 3/8" dia knock outs

ABC

2.2 Unit Back Dimensions

Model

Dimensions- In. (mm)

A B C

18K5-3/8 (136)2-2/5 (61) 28-1/4 (718)

24K5-3/8 (136)2-2/5 (61) 28-1/4 (718)

30K6 (151)2-2/5 (61)31-1/4 (794)

36K6 (151)2-2/5 (61)31-1/4 (794)

8

Unpack unit and move to final location. Remove carton, taking care not

to damage unit. Remove protective sheet metal from the base of the

unit, if equipped. Inspect equipment for damage prior to installation.

Locate rating plate on unit. It contains information needed to properly

install unit. Check rating plate to be sure unit matches job specifications.

A front access panel is provided, which permits access to blower assembly

The small air handler should be centrally located and may be

installed in a closet, alcove, utility room, or basement. Minimum

clearances must be met.

The air handler comes standard with two different options for mounting,

wall mount or frame mount. Both mounting options require the unit to

be level from side to side and from front to back in order to allow

condensate to properly drain from the unit. Failure to do this will result

in condensate leaking out from the unit, potentially causing structural

damage to the surrounding support structures, dry wall, carpet, etc.

Also, both mounting structures require the ability to accommodate a

minimum of 150 lb load. Failure to do this will cause damage to the

support structure and potentially damage the unit.

The air handler comes standard with a wall mounting bracket and air

handler mounting bracket. Reference Figure 3-1 for more details.

1. Remove lower wall mounting bracket from the back of the unit by

removing one screw which attaches the bracket to the air handler.

Note: Discard the screw after you have removed the wall mounting

bracket.

2. Install bracket on the wall by using 3 wood screws (not provided).

Make sure the bracket is level in order to provided proper drainage

from the unit. Note: Do not attach the wall mounting bracket into

unsupported dry wall. Make sure that the wood screws are going into a

structure that can suppport a minimum load of 150 lb.

3. Lift the air handler above the wall mounting bracket and attach the

unit to the installed bracket. Reference Figure 3-1.

4. Install the additional bottom plate for extra support for this type

mounting (see figure 3-1).

Note: The additional plate is shipped in the bottom of the shipping

carton.

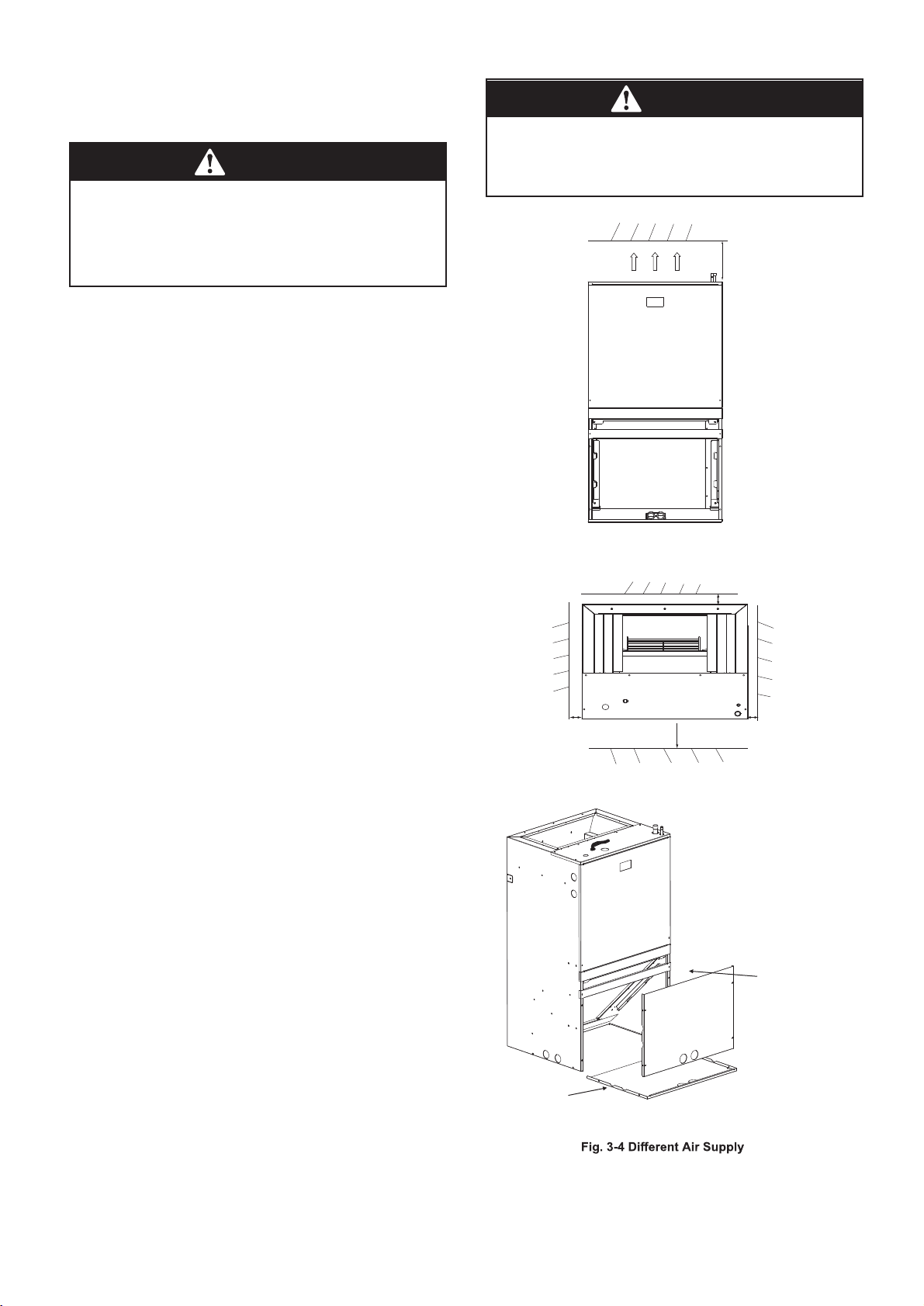

3.2.1 Wall Mount

Fig. 3-2 Frame Mount

3.2.2 Frame Mount

PROVIDED WALL

MOUNT BRACKET

WALLMOUNT BRACKET

WOOD SCREWS

SUPPORTING 2˝X4˝

STRUCTURE

WALL STRUTURE

WOOD SCREWS

WOOD SCREWS

PROVIDED WALL

MOUNT BRACKET

STRUCTURE MUST BE ABLE TO SUPPORT A

MINIMUM OF 150 LBS.

PROVIDED AIR HANDLER

WOOD SCREWS

3.2 Location

NOTE:

IN ORDER TO PREVENT

AIR LEAKAGE,THE TABS

AND SCREW HOLES

NEED TO BE SEALED

UP WHEN THEY ARE

NOT TO BE USED.

OFFSET HANGING

BRACKET

IMPORTANT:

The (8) wood screws are not provided with the unit.

#12 x 1 ½˝ wood screws are recommended. When the unit is installed

on a wood frame, the screws should be used to fix the unit to the

studs. If they are not used, the unit may fall down or cause other

damage. See Figure 3-2 for frame mount installation.

The air handler comes with 8 clearance holes (4 on each side). These

holes are used to mount the air handler inside of a frame structure

(see Figure 3-2). When mounting in this fashion, make sure that the

wood screws are mounted from within the air handler and not from

outside the unit in order to avoid damaging the coil. If the frame does

not provide support in the front of the unit and additional support is

needed, open up the tabs and fix the unit to the frame or other

support structure with screws. Select a solid and level site to ensure

proper installation of the frame mount. Verify that there is sufficient

space for installation and maintenance.(see Figure. 3-3)

WALL STRUCTURE

SUPPORTING

2˝X4˝ STRUCTURE

WOOD SCREWS

SUPPORTING

2˝X4˝ STRUCTURE

STUD ATTACHMENT

HOLES

THE TABS

BRACKET PLACEMENT FOR

HANGING IN A CLOSET

(ONLY FOR 30K/36K)

9

Section 3. Installation Instructions

3.1 Unpacking

Fig. 3-1 Wall Mount

NOTE: MOUNTING WALL AND SUPPORTING

and electrical controls for removal and servicing.

File claim with shipping company if shipment is damaged or incomplete.

MOUNTING BRACKET

Field ductwork must comply with the National Fire Protection

Association NFPA 90A, NFPA 90B and any applicable local

ordinance.

WARNING

Sheet metal ductwork run in unconditioned spaces must be insulated

and covered with a vapor barrier. Fibrous ductwork may be used if

constructed and installed in accordance with SMACNA Construction

Standard on Fibrous Glass Ducts. Ductwork must comply with

National Fire Protection Association as tested by U/L Standard 181

for Class I Air Ducts. Check local codes for requirements on

ductwork and insulation.

• Duct system must be designed within the range of external static

pressure the unit is designed to operate against. It is important that

the system airflow be adequate. Make sure supply and return

ductwork, grilles, special filters, accessories, etc. are accounted for in

total resistance. See airflow performance tables in this manual.

• Design the duct system in accordance with “ACCA” Manual “0”

Design for Residential Winter and Summer Air Conditioning and

Equipment Selection. Latest editions are available from: “ACCA” Air

Conditioning Contractors of America. If duct system incorporates

flexible air duct, be sure pressure drop information (straight length

plus all turns) shown in “ACCA” Manual “D” is accounted for in

system.

• Supply plenum is attached to the 3/4” duct flanges supplied with

the unit.

• IMPORTANT: If an elbow is included in the plenum close to the

unit, it must not be smaller than the dimensions of the supply duct

flange on the unit.

•IMPORTANT: If connected to the blower casing, the front flange

on the return duct must not be screwed into the area where the

power wiring is located. Drilles or sharp screw points can damage

insulation on wires located inside unit.

• Secure the supply and return ductwork to the unit flanges, using

proper fasteners for the type of duct used and tape the duct-to-unit

joint as required to prevent air leaks.

The unit is supplied with primary and auxiliary condensate drains

that have 3/4” NPT connections. Both drains must be trapped outside

the unit and piped in accordance with applicable materials and

building codes. Do not reduce the drain line size less than the

connection size on the drain pan. Condensate should be piped to an

open drain or to the outside. All drains must pitch downward away

from the unit a minimum of 1/4” per foot of line to ensure proper

drainage. Insulate the primary drain line to prevent sweating where

dew point temperatures may be met. (Insulation is optional depending

on climate and application needs.)

Important:

If cleanout Tee is used, standpipe must be sealed/capped.

10

3.3 Duct Work

Do not, under any circumstances, connect return ductwork to

any other heat producing device such as fireplace insert,

stove, etc. Unauthorized use of such devices may result in fire,

carbon monoxide poisoning, explosion, personal injury or

property damage.

3.4 Condensate Drain

Fig.3-3 Space for Frame Mount

Top view of the indoor unit clearance (including air duct).

≥0" ≥0"

≥24"

≥0"

Front of unit

WARNING

Supply duct is intended to handle conditioned air for

circulation through a duct supplying only one room. Room

space may be partitioned into rooms within the same unit,

but supply air is not to be delivered to any other rooms.

AIRFLOW

≥20"

Remove the cross brace when converting cabinet to bottom return.

REMOVE BOTTOM COIL

PANEL OFF PLATE

INSTALL FRONT

COIL PANEL

•Low voltage control connections are made to low voltage pigtails

extending from top of air handler. Connections for control wiring

are made with wire nuts. Control wiring knockouts (7/8˝) are also

provided on the right and left side of the unit for side connection.

•See wiring diagrams attached to indoor and outdoor sections to be

connected.

• Make sure, after installation, separation of control wiring and power

wiring has been maintained.

3.8.3 Grounding

•Grounding may be accomplished when installed in accordance with

electrical codes by bonding the metal conduit to the unit cabinet or by

attaching ground wire(s) to ground lug(s) provided in the unit wiring

compartment.

•Ground lug(s) are located close to wire entrance on left side of unit

(upflow). Lug(s) may be moved to marked locations near wire

entrance on right side of unit (upflow) if alternate location is more

convenient.

•Use of multiple supply circuits require grounding of each circuit to

lug(s) provided in unit.

•If required, install a branch circuit disconnect of adequate size,

located within sight of, and readily accessible to the unit.

•

IMPORTANT: After the Electric Heater is installed, units are equipped

with one 60 amp. circuit breaker. These breaker(s) protect the internal

wiring in the event of a short circuit and serve as a disconnect. Circuit

breakers installed within the unit do not provide over-current protection

of the supply wiring and therefore may be sized larger than the

branch circuit protection.

•Supply circuit power wiring must be 75°C minimum copper

conductors only. See Electrical Data in this section for ampacity, wire

size and circuit protector requirements. Supply circuit protective devices

may be either fuses or “HACR” type circuit breakers.

• Power wiring may be connected to either the right or left side. Two

7/8” dia. concentric knockouts are provided for connection of power

wiring to unit.

•Power wiring is connected to the power cable in unit electric cabinet.

3.8.2 Control Wiring

IMPORTANT: Class 2 low voltage control wiring should not be run in

conduit with main power wiring and must be separated from power

wiring, unless class 1 wire of proper voltage rating is used.

•Low voltage control wiring should be 18 AWG. color-coded. For

lengths longer than 100 ft., 16 AWG. wire should be used.

Field wiring must comply with the National Electric Code (C.E.C. in Canada

) and any applicable local ordinance.

3.8.1 Power Wiring

It is important that proper electrical power is available for connection

to the unit model being installed. See the unit nameplate, wiring diagram

and electrical data in the installation instructions.

WARNING

3.5 Refrigerant Piping

Refrigerant pipe connections are located on the top of the unit.

Refrigerant piping external to the unit shall be sized in accordance

with the instructions of the outdoor equipment. When units are

recessed mounted in the wall, make certain that piping connections

are pressure tested prior to the wall being closed. While brazing, be

sure to protect the cabinet and grommets from heat damage.

All units are shipped and installed with an orifice designed for air

conditioning or heat pump operation. Pressures equalize after

shut down. Some outdoor models may require a start assist kit.

See outdoor unit for more information.

3.8 Wiring

This unit is supplied with a multi-speed motor with a direct drive

blower wheel which can obtain various air flows. The unit is shipped

with factory set cooling and heating speed taps. Airflow performance

tables are available for additional speed taps. Disconnect all power to

the unit before making any adjustments to the motor speed taps. Be

sure to check the air flow and the temperature drop across the

11

3.6 Metering Device

3.7 Blower

Disconnect all power to unit before installing or servicing.

More than one disconnect switch may be required to de-

energize the equipment. Hazardous voltage can cause severe

personal injury or death.

evaporator coil to ensure sufficient air flow.

The unit must be permanently grounded. Failure to do so can

result in electrical shock causing personal injury or death.

WARNING

Select a thermostat that is commonly used with HP or AC single

stage heating/cooling with electric heat. The thermostat will energize

the fan on a demand for heating or cooling.

Install the thermostat on an inside wall, away from drafts, lights or

other heat sources in a location that has sufficient air circulation from

other rooms being controlled by the thermostat. The thermostat

should be mounted 4 to 5 feet above the floor.

3.10 Thermostat

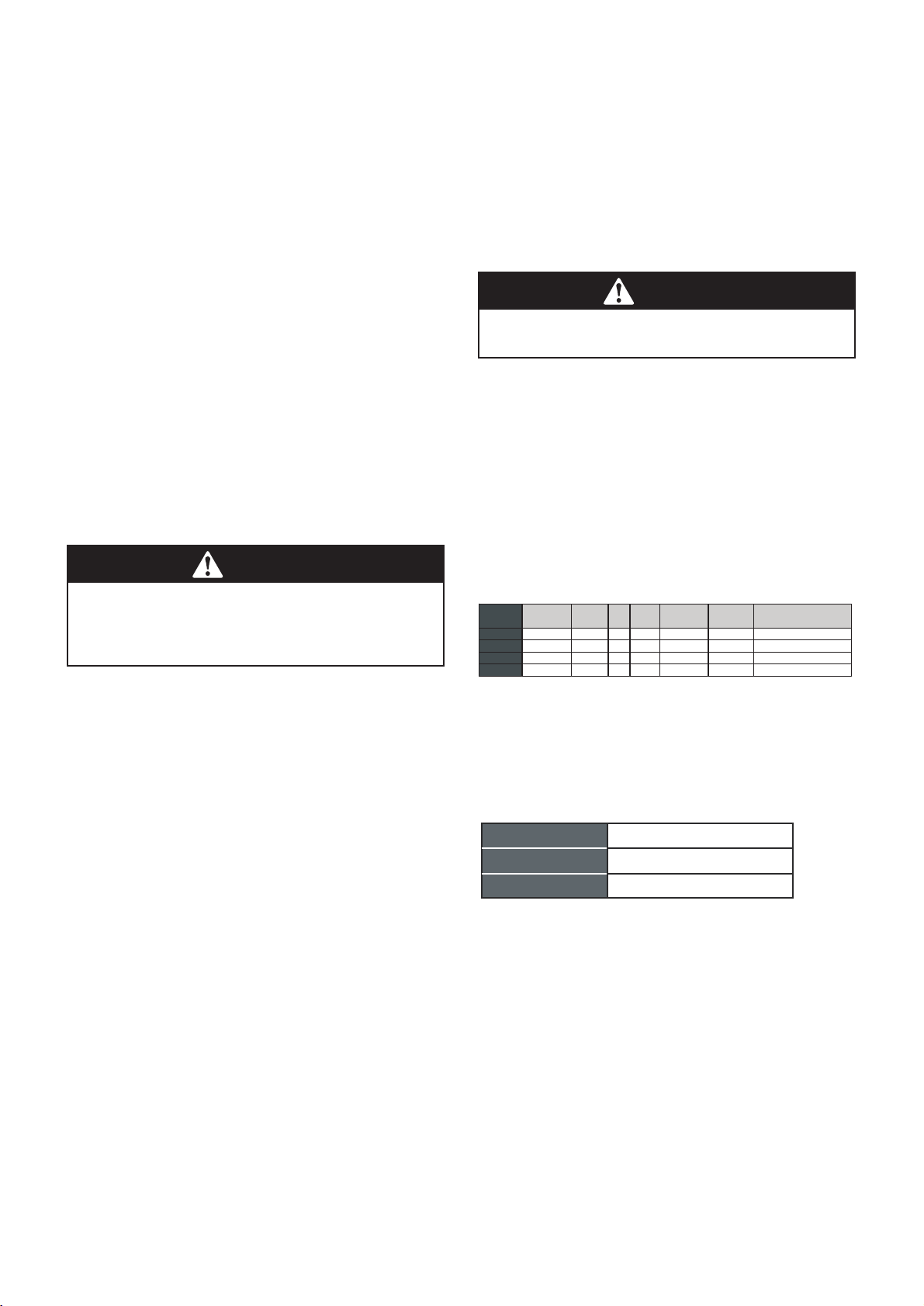

An air filter must be installed before air enters the evaporator coil in

order to protect the coil, blower, and other internal parts from

excessive dirt and dust . A filter must be installed. Consult the filter

manufacturer for proper sizing and maximum velocity requirements.

3.9 Air Filter

Filter Sizes

18K/24K15*19 [381*483]

Model Filter Sizes in. [mm]

30K/36K20*20 [508*508]

MODEL

VOLTAGE HERTS HP RPM SPEEDS CIRCUIT

AMPS.

MAXIMUM CIRCUIT

PROTECTOR

18K 208/230 60 1/3 960 5 1.9 3(A)

24K 208/230 60 1/3 1010 5 2.2 3(A)

30K 208/230 60 1/2 960 5 2.6 3(A)

36K 208/230 60 1/2 1000 5 3.2 6(A)

3.8.4 Electrical Data

12

3.12 Operational And Checkout Procedures

To obtain proper performance, all units must be operated and charge

adjustments made in accordance with procedures found in the Service

Facts document of the outdoor unit.

After installation has been completed, it is recommended that the entire

system be checked against the following list:

1. Be sure unit suspension (if used) is secure and there are no tools or

loose debris in, around or on top of the unit.

2. Properly insulate suction lines and fittings.

3. Properly secure and isolate all refrigerant lines.

4. Verify that all electrical connections are tight.

5. Check all duct outlets; they must be open and unrestricted.

6. Check drain lines and be sure all joints are tight.

7. Be sure the return air filter is installed.

8. Operate complete system in each mode to verify proper

performance. Verify operation of supplementary electric heater.

The system air filter(s) should be inspected, cleaned or replaced at least

monthly. Make certain that the access panels are replaced and secured

properly before placing the unit back in operation. This product is

designed for dependable service; however, periodic maintenance should

be scheduled and conducted by trained professional service personeel.

This service should be conducted at least annually, and should include

testing and inspection of electrical and refrigerant components. The heat

transfer surface should be cleaned. The blower motor is permanently

lubricated for normal operating conditions.

3.13 Maintenance

Cooling (heat pump)

Constant torque version – When the thermostat calls for cooling, the

circuit from R to G is completed. The blower motor is energized

directly by the 24VAC signal from the thermostat.

The circuit from R to Y is also completed, energizing the compressor

contactor of the outdoor unit. The contactor will close and start the

compressor and condenser fan motor.

Circuit R to B energizes the reversing valve to the heating position.

Heating (heat pump)

Constant torque version – When the thermostat calls for heating, the

circuit from R to G is completed and the blower motor is energized

directly by the 24VAC signal from the thermostat.

The circuit from R to Y is also completed, energizing the compressor

contactor of the outdoor unit. The contactor will close and start the

compressor and condenser fan motor.

If the indoor temperature continues to fall, the R to W2 circuit is

completed, energizing the electric heat contactor(s).

Heating (electric heat only)

Note: The thermostat must be setup to bring the blower on when the

electric heat is energized.

Constant torque version - When the thermostat calls for heating, the

circuit from R to G is completed and the blower motor is energized

directly by the 24VAC signal from the thermostat. The circuit from R

to W1 is completed energizing the heating contactor(s).

Defrost

Supplemental heat during defrost can be provided by connecting the

W1 (white) wire from the outdoor unit to W1 at the indoor unit. This will

prevent cold air from being discharged from the indoor unit during

defrost.

Low voltage control wiring should be 18 AWG, color coded (105 degree

C minimum). For lengths longer than 100ft., 16 AWG wire should be

used. Make certain that separation of control wiring and power wiring

has been maintained.

If the indoor temperature continues to fall, the R to W2 circuit is

completed, energizing the electric heat contactor(s).

contactor of the outdoor unit. The contactor will close and start the

compressor and condenser fan motor.

3.11 Sequence of Operation

Constant torque version – When the thermostat calls for cooling, the

circuit from R to G is completed. The blower motor is energized directly

by the 24VAC signal from the thermostat.

Cooling (cooling only)

The circuit from R to Y is also completed, energizing the compressor

14

Section 5. Electric Wiring Gauge

Note:

The cross-section areas of wires or lines should not be less than the corresponding ones listed in the table below;

Besides, if the power wires is quite long from the unit, please choose the windings with larger cross-section area

to guarantee the normal power supply.

Model ( )cooling only type

18K

24K

30K

36K

Line

Gauge

Indoor Unit

Power Line

Line Quantity

3

3

3

3

Line Diameter(AWG)

16

16

16

16

Outdoor

Unit Power

Line

3

3

3

3

14

14

12

12

Indoor-

Thermostat

Singal Line

5

5

5

5

18

18

18

18

Outdoor-

Thermostat

Singal Line

2

2

2

2

18

18

18

18

Line Quantity

Line Diameter(AWG)

Line Quantity

Line Diameter(AWG)

Line Quantity

Line Diameter(AWG)

Model ( ) cooling & heating type

18K

24K

30K

36K

Line

Gauge

Indoor Unit

Power Line

Line Quantity

3

3

3

3

Line Diameter(AWG)

16

16

16

16

Outdoor

Unit Power

Line

3

3

3

3

14

14

12

12

Indoor-

Thermostat

Singal Line

5

5

5

5

18

18

18

18

Outdoor-

Thermostat

Singal Line

5

5

5

5

18

18

18

18

Line Quantity

Line Diameter(AWG)

Line Quantity

Line Diameter(AWG)

Line Quantity

Line Diameter(AWG)

15

Section 6. Performance Data

Airflow performance data is based on cooling performance with a coil and no filter in place. Select performance table for appropriate unit size

external static applied to unit allows operation within the minimum and maximum limits shown in table below for both cooling and electric heat

operation.

Airflow Performance (Standard CFM)

The air distribution system has the greatest effect on airflow. The duct system is totally controlled by the contractor. For this reason, the contractor

should use only industry-recognized procedures.

Heat pump systems require a specified airflow. Each ton of cooling requires between 350 and 450 cubic feet of air per minute (CFM), or 400 CFM

nominally.

Duct design and construction should be carefully done. System performance can be lowered dramatically through bad planning or workmanship.

Air supply diffusers must be selected and located carefully. They must be sized and positioned to deliver air along the perimerter of the space. If

they are too small for their intended airflow, they become noisy. If they are not located properly, they cause drafts. Air grilles must be properly sized

to carry air back to the blower.If they are too small, they also cause noise.

The installers should balance the air distribution system to ensure proper quiet airflow to all rooms in the home. This ensures a comfortable living

space.

1. Airflow based upon dry coil at 230V with no electric heat and no filter. For 18, 24, 30 and 36 sizes, airflow at 208V is approximately the same

as 230V because the mult-tap ECM motor is a constant torque motor. The torque doesn’t drop off at the speeds in which the motor operates.

2. Airflow is equivalent for front or bottom return configurations.

NOTES:

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

1 812 783 741 698 669 619 586 525 474

2-Factory Default 916 875 851 812 786 746 717 673 634

3 1005 978 941 917 882 856 819 792 752

4

5

1 812 783 741 698 669 619 586 525 474

2 916 875 851 812 786 746 717 673 634

3-Factory Default 1005 978 941 917 882 856 819 792 752

4

5

1 1059 1009 960 921 871 829 751 692 616

2 1150 1116 1069 1036 988 953 912 850 779

3-Factory Default 1282 1235 1203 1158 1131 1076 1050 1015 953

4 1404 1374 1335 1306 1265 1231 1195 1150 1115

5 1575 1534 1492 1446 1401 1331 1239 1132 1025

1 1059 1009 960 921 871 829 751 692 616

2 1150 1116 1069 1036 988 953 912 850 779

3 1282 1235 1203 1158 1131 1076 1050 1015 953

4-Factory Default 1404 1374 1335 1306 1265 1231 1195 1150 1115

5 1575 1534 1492 1446 1401 1331 1239 1132 1025

Model

Blower Speeds

36K

18K

24K

30K

External Static Pressure(in.w.c)

This manual suits for next models

3

Table of contents

Popular Air Handler manuals by other brands

S&P

S&P UTV-2 ECOWATT manual

Stealth

Stealth SC-24CD-UM owner's manual

CyClone

CyClone DV160 Installation and operation instructions

Maytag

Maytag Amana AMVT P1400 Series Installation & operating instructions

Trane

Trane CeilAir CW Installation, operation and maintenance

Vents

Vents VUT 2000 PBE EC user manual

Trox Technik

Trox Technik X-CUBE operating instructions

Vents

Vents VUE 300 PBE EC user manual

Vision

Vision CAC 003G - 090G Installation and maintenance manual

Trane

Trane Hyperion AM8A0A24V21CA Series Field Reference Data

TCF

TCF ZAE Series Installation, operation and maintenance manual

Salda

Salda Veka INT 3000-15 L1 EKO Technical manual