10 DV160 Installation - English

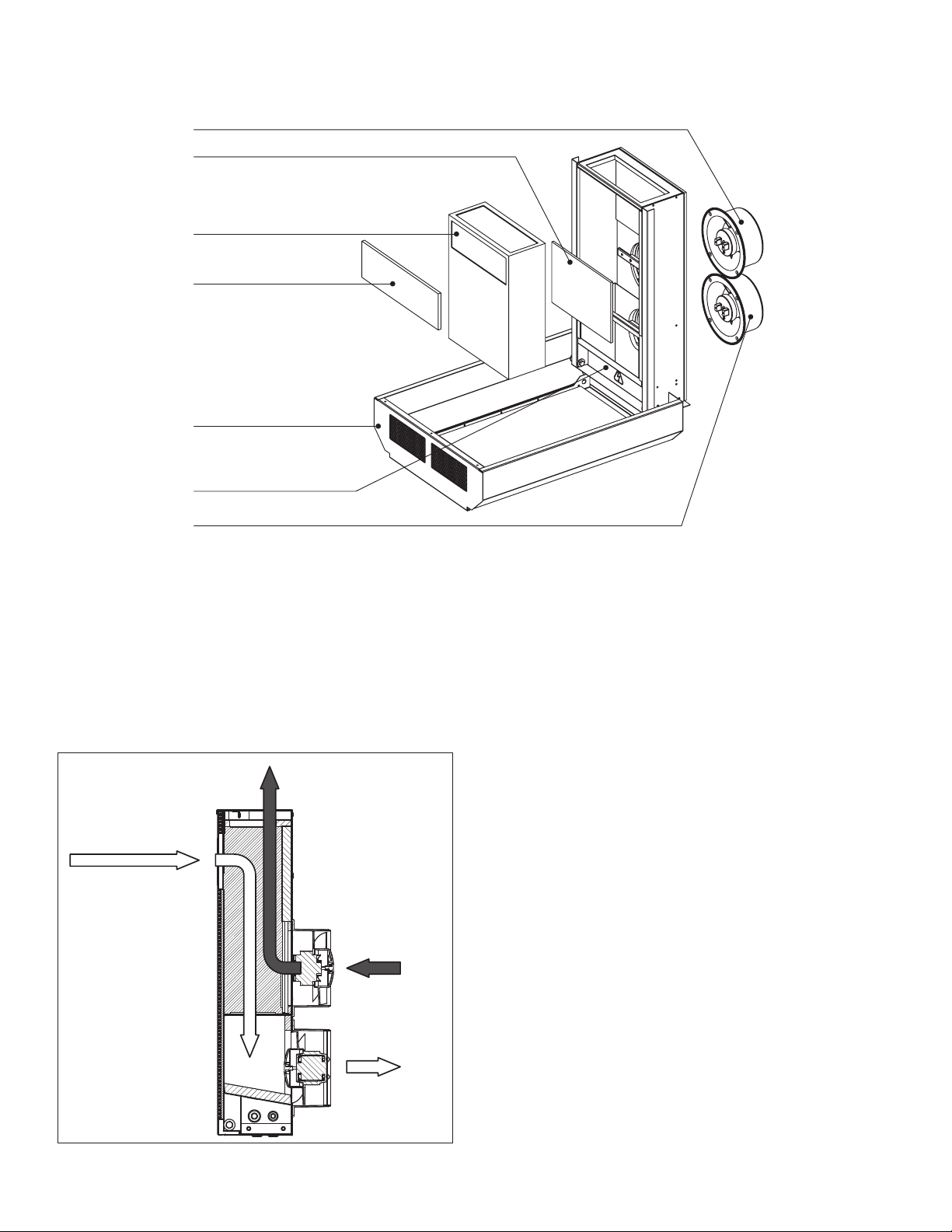

MOUNTING WITH THE MK1 DV160 MOUNTING SET

Wall

Outer ventilation hood

Round air duct

sloped down by 2-3°

Fasteners

DV160 unit

Round air duct sloped

down by 2-3°

The MK1 DV160 mounting set is designed to prepare a mounting

site for installation of the DV160 unit at general construction

stage. The set is not included into the delivery and is available

on separate order. The MK1 DV160 mounting set includes:

• Plastic air duct Ø 125 mm (Ø 5’’), 500 mm (19 11/16’’) long

- 2 items;

• Paper master plate - 2 items. Mounting sequence of the

MK1 DV160

Mounting sequence of the MK1 DV160 set:

1. Fix the rst master plate on the inner wall side with a sealing

tape at a required height.

2. Use the master plate to mark two Ø 130 (5 1/8”) mm holes for

the air ducts and two Ø 8 mm (5/16”) holes for the xing dowels

of the unit.

3. Remove the master plate and drill through holes for the air

ducts and the holes, 60 mm (2 3/8”) deep for the dowels.

4. Re-install the rst master plate with a sealing tape back. Fix

the second master plate on the outer wall side to align the air

ducts with respect to each other. Fix the second master plate

somewhat lower to ensure the minimum slope 3° for the air

ducts. Before installation of the master plate press the marked

perforated opening on the master plate and remove the master plate cut-outs.

5. Install the air ducts into the master plate holes and seal those with a mounting foam through the openings in the master plate. Install the air ducts sloped

down by 2-3° to enable the condensate drainage.

6. After the mounting foam gets hard (see the solidication time in the product specication) remove the master plate and cut the protruding parts of the

air ducts to be ush with the inner wall. On the outer wall side, the air ducts must protrude by 10 mm (3/8’’) to prevent condensate dropping on the wall.

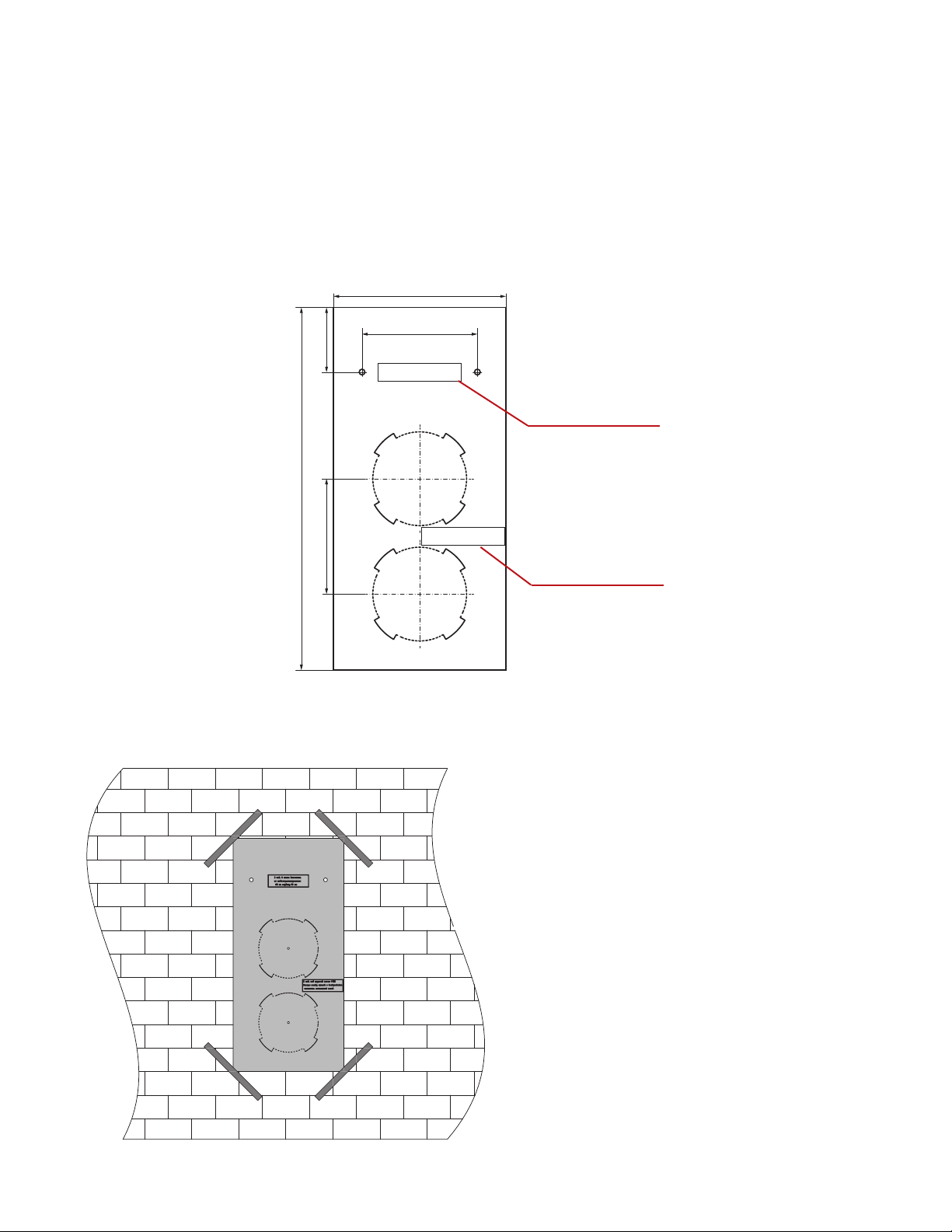

MOUNTING WITH THE MK2 DV160 MOUNTING SET

The MK2 DV160 mounting set is designed for the DV160 unit mounting and is available upon separate order. The MK2 DV160 mounting set includes:

• Plastic air duct Ø 125 mm (Ø 5’’), 500 mm (19 11/16’’) long - 2 items;

• Paper master plate - 1 item;

• NB DV160 outer ventilation hood - 1 item;

• 8x40 screw and dowel - 4 items.

Mounting sequence of the MK2 DV160 set:

1. Fix the master plate from the delivery set on the inner wall side with a sealing tape at the required height.

2. Use a master plate to mark two Ø 130 (5 1/8”) mm holes for the air ducts and two Ø 8 mm (5/16”) holes for the xing dowels of the unit.

3. Remove the master plate and drill through holes for the air ducts and the holes, 60 mm (2 3/8”) deep for the dowels.

4. Re-install the master plate with a sealing tape back. Fix the master plate from the mounting set on the outer wall side to align the air ducts with respect

to each other. Before installation of the master plate press the marked perforated opening on the master plate and remove the master plate cut-out.

5. Install the air ducts into the master plate holes and seal those with a mounting foam through the openings in the master plate. Install the air ducts sloped

down by 2-3° to enable the condensate drainage.

6. After the mounting foam gets hard (see the solidication time in the product specication) remove the master plate and cut off the protruding parts of the

air ducts to be ush with the inner wall. On the outer wall side, the air ducts must protrude by 10 mm (3/8’’) to prevent condensate dropping on the wall.

7. Install the outer ventilation hood NB DV160 on the outer wall side to prevent ingress of large foreign objects into the air ducts. Installation of the NB

DV160 outer hood is carried out with four 8x40 screws and dowels and is carries out as follows:

• Lean the NB DV160 outer ventilation hood against the wall;

• Mark fastening holes;

• Drill four Ø 8 mm (Ø 5/16”) holes, 40 mm (1 9/16’’) deep;

• Install 8x40 dowels;

• Install the NB DV160 ventilation outer hood;

• Fix the NB DV160 outer hood with screws.