Evil Mad Bulbdial User manual

Kit versions 1.0-1.1

Manual v. 1.1a

Support: http://www.evilmadscientist.com/forum/

Distributed by

Evil Mad Science LLC

http://evilmadscience.com/

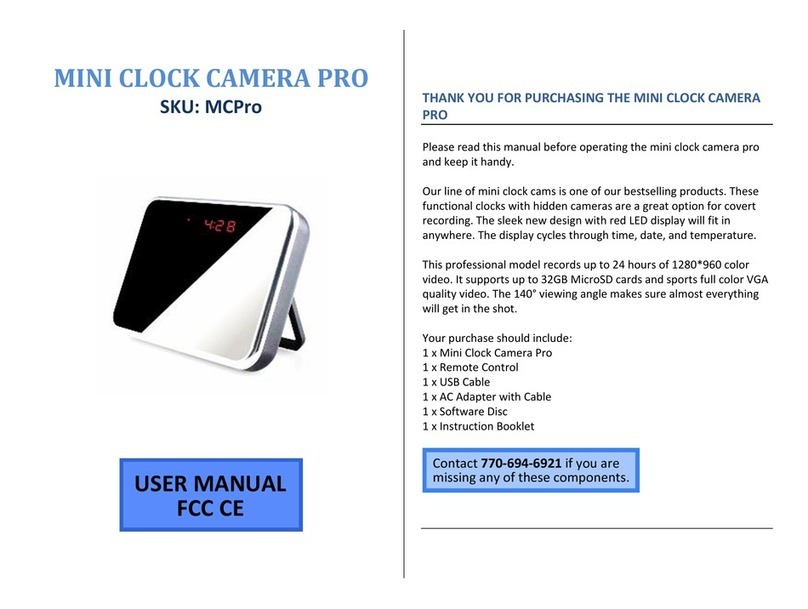

LED Shadow Clock Kit

Assembly Guide

An open-source hardware+software project. For design files, source code, & additional

documentation, please visit: http://wiki.evilmadscience.com/Bulbdial

The Bulbdial Clock kit is based on an original design concept by David

Friedman of IronicSans.com and developed at Evil Mad Scientist Laboratories.

The Bulbdial Clock works like an indoor sundial. Three rings of LEDs cast

shadows of different lengths, forming three moving hands on the clock face.

This guide covers the procedures for assembling the Bulbdial Clock and its

accessories. Please exercise appropriate safety practice while soldering.

STEP 0: Tool Checklist

Essential tools: Needed to build the kit:

1. Soldering iron + solder

Suggested, but not required

Small nippers for for clipping loose wire ends close to

the circuit board.

e.g., Sears Craftsman

A basic soldering iron meant for electronics, with a reasonably

fine point tip. We recommend one of this design-- a "pencil

shape" soldering iron (not gun!) with a base that holds the iron

and a wet sponge. A tip in good condition (a “tinned” tip)

should get shiny when hot-- able to melt and wet to solder.

While you don’t need an expensive one, the iron can make a

big difference in the time needed to build the kit. (Seriously. If

you use one that is old and busted, or a $10 radio shack iron,

or that thing from the dollar store, you should expect to spend

at least twice as long soldering!)

Our recommendation for a low-cost iron:

model WLC100 by Weller, about $40.

[Bulbdial Assembly Guide]

2. Angle flush cutters

3. Electrical power

You’ll also need some solder. Thin rosin-core solder (roughly

.020 - .040” in diameter) is the most common type for

electronic soldering, and is the only choice that is appropriate

for electronic kits. Either standard (lead-bearing) or newer

“lead free” solder types will both work just fine.

And for the adventurous...

1. USB-TTL Cable

FTDI model TTL-232R or equivalent. A “smart” converter

cable with a USB interface chip inside. One end hooks up to

your USB port, the other to the clock. This allows you to

program the Bulbdial Clock through the Arduino development

environment ( http://arduino.cc/ ).

Besides programming, the cable can also be used to set the

time on the Bulbdial clock through a serial sync program.

The 5V version of the cable (TTL-232R-5V) can be used to

provide USB power to the Bulbdial clock.

2. Computer, Internet access, USB port....

All of the software and source code that you’ll need to reprogram

the clock is available online for free. You’ll need a reasonably recent

vintage computer (Mac, Windows, or Linux) and internet access.

Additional information is available at the project page:

http://www.evilmadscientist.com/go/BulbDialKit

2. Resistor lead forming tool

Allows fast, neat bending of resistor leads. Not many

parts like this in the Bulbdial kit, but if you’re obsessive....

The Bulbdial Clock kit comes with a regulated universal-input power supply that

accepts worldwide voltages and puts out 5 V at up to 150 mA. If you’re using your

own external power, make sure that it’s regulated, provides 4.5 to 5 V DC, and is

rated for at least 100 mA. (3 “AAA” cells can do the job, for example.) Please be

careful: Inappropriate voltage or polarity can cause permanent damage.

(International users may need to supply a plug adapter to fit the prongs into local

outlets.)

1. Small pliers with smooth jaws

Very helpful for final LED alignment. The jaws should be

smooth so that you don’t scratch the LEDs. Needlenose pliers

with masking tape over the jaws can be a good solution.

[2]

[Bulbdial Assembly Guide] [3]

Your kit came with a bill of materials: an up-to-date list of what’s in your

particular kit. The exact items may differ between versions of the kit,

for example between RGB and monochrome options.

In the instructions, we refer to components by their line

item number on the bill of materials. For example, #14

is the ATmega168 microcontroller.

In some places, the assembly procedure differs

between kit versions.

In particular, watch out for RGB ONLY or MONO ONLY

instructions, which are specific to the 3-color or

monochrome versions of the kit. If you aren’t sure

which you have, please consult your BOM.

STEP 1: It’s the BOM.

STEP 2: The Plan

[Bulbdial Assembly Guide] [4]

In the first part of the build,

we’ll be placing various

electronic components on

the large blue circuit board.

In the second half, we’ll be building up and

aligning the three rings of LEDs. The first ring is

on the main board, and the other two rings

have their own (red and green) circuit boards.

If they are taped together,

pull the tape straight off.

A zerohm jumper looks like a

resistor with one black stripe. Take one and bend it, like so.

Now, find location JP1. Insert the jumper there... ... and press it flush to the board.

(Next... Soldering!)

STEP 3: Placing the first component

[Bulbdial Assembly Guide] [5]

Our first component is a “zerohm” jumper, #4.

It goes in location JP1 on the main circuit board.

(And for this first one, we’ll take it slowly.)

[Bulbdial Assembly Guide] [6]

(3) Solder!

(4) Clip!

(1) Insert! (2) Bend!

45°, max

(0). Pre-form the leads of components if needed.

(For example, like the jumper in step 3.)

(1). Insert each component into the circuit board, from

the top, at its given location. Push it flush to the board

(Note that some components, like the chip and LEDs,

need to be inserted with a particular orientation.)

(2). If your component has flexible leads, gently bend the leads

out, up to 45°, to hold it in place while you solder.

(3). One at a time, from the back side, solder the leads of

the component to the circuit board.

(4). If the component has long and/or or flexible leads, clip off

the extra length, close to the board. (But not so close that

you’re clipping the board itself.)

• Your tip needs to be shiny (tinned). If not, melt some fresh

solder against it and quickly swipe clean on a wet sponge.

• Place the solder against the joint that you wish to connect.

• Touch the iron to the solder and joint for about one second.

Count it out: “one thousand one.”

• The solder should melt to the joint and leave a shiny

wet-looking joint. If not, let it cool and try again.

STEP 4a: Some hints on soldering

Adding components to the circuit board

As the old Heathkit manuals say, “it is interesting to note” that

the vast majority of problems reported with soldering kits turn

out to be due to unreliable solder connections.

Before we go further, here’s a quick refresher, with our

suggested procedures for adding components to the circuit

board. These procedures apply to most components in the kit.

TO BE CONTINUED...

We’ve already inserted the

jumper at location JP1.

Now bend out the leads to hold the

jumper in place while we solder Flip the board over and get ready to solder.

Solder both pins to the board. Inspect the solder joints; make sure

that they look shiny and wet. Clip the excess leads short.

[Bulbdial Assembly Guide] [7]

(Where we perform those

steps that we just described.)

Bend!

STEP 4b: Soldering that first component

Part #5 is a 10k resistor.

It’s the one small resistor, and it has stripes

of color brown-black-orange-gold.

Install it in location R11.

#5

#7 (RGB kit only-- see note above)

If you have the RGB kit:

If you have the monochrome (all white) kit:

[Bulbdial Assembly Guide]

[8]

Now that we’ve stepped through the

basics, we can proceed at a faster pace.

Resistors are added to the board in

the same way as the zerohm jumper,

and are not sensitive to orientation.

Part #7 is a 68 ohm resistor (color code blue-gray-

black-gold). It’s the one “normal size” resistor that looks

different from all the others. Install it in location R10.

Go on to Step 6, leaving R10 empty for the moment.

STEP 5: One or two resistors...

[Bulbdial Assembly Guide]

[9]

#6

If you have the mono kit: Install one more 24-ohm

resistor (#6) at location R10.

If you have the RGB kit: There should already be a

68-ohm resistor installed at R10, as shown here.

STEP 6: The rest of the resistors

The last resistor type is part #6, a 24 ohm

resistor (color code red-yellow-black-gold).

Install nine of these in locations R1 - R9.

Those resistors are located in the three

highlighted locations. Don’t forget R8!

[Bulbdial Assembly Guide]

[10]

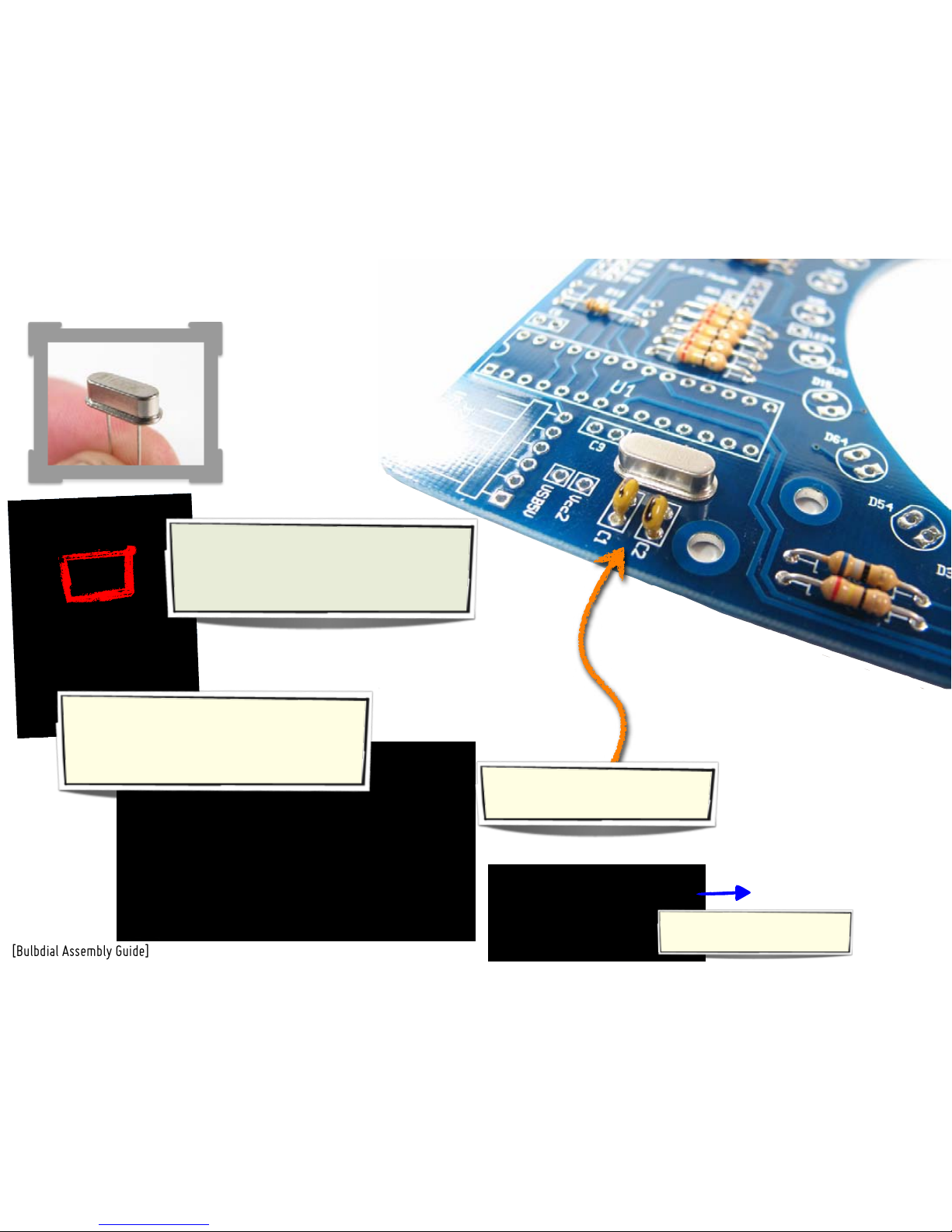

#8

Install part #8, a 16 MHz quartz crystal. Its

two pins go in the outer two holes of the

location marked “Quartz.” Solder both pins

in place, much like a resistor.

Parts #9 are 18 pF ceramic capacitors-- little

yellow beads with two pins. There are two

similar types of ceramic capacitors in the kit,

so these ones are marked with a black stripe.

If they are taped together, pull

them straight out of the tape.

Solder these two capacitors on

the board at locations C1 and C2.

STEP 7: Crystal & Caps

Install two of them, at locations C3 and C6.

[Bulbdial Assembly Guide]

[11]

STEP 8: Two more caps

Parts #13 are 0.1 µF ceramic capacitors that

look almost the same as the 18 pF caps.

(These ones don’t have the black stripe.)

(C6)

Part #11 is a 6-pin header

that goes at location J2.

Set the circuit board atop the other two,

to raise it a bit above your work surface.

Place the header in its location;

it should sit flat as shown.

If you do not plan to connect to a computer, you can skip this step.

From the top, solder one pin of

the header to tack it in place.

Here’s how it looks with

one pin tacked in place.

Solder the other five pins on the bottom,

and then finish up the first one. The leads

do not need trimming.

[Bulbdial Assembly Guide] [12]

STEP 9: The USB-TTL connector In this step, we add a header that allows the Bulbdial clock to

be connected to a computer through an FTDI USB-TTL cable.

[Bulbdial Assembly Guide] [13]

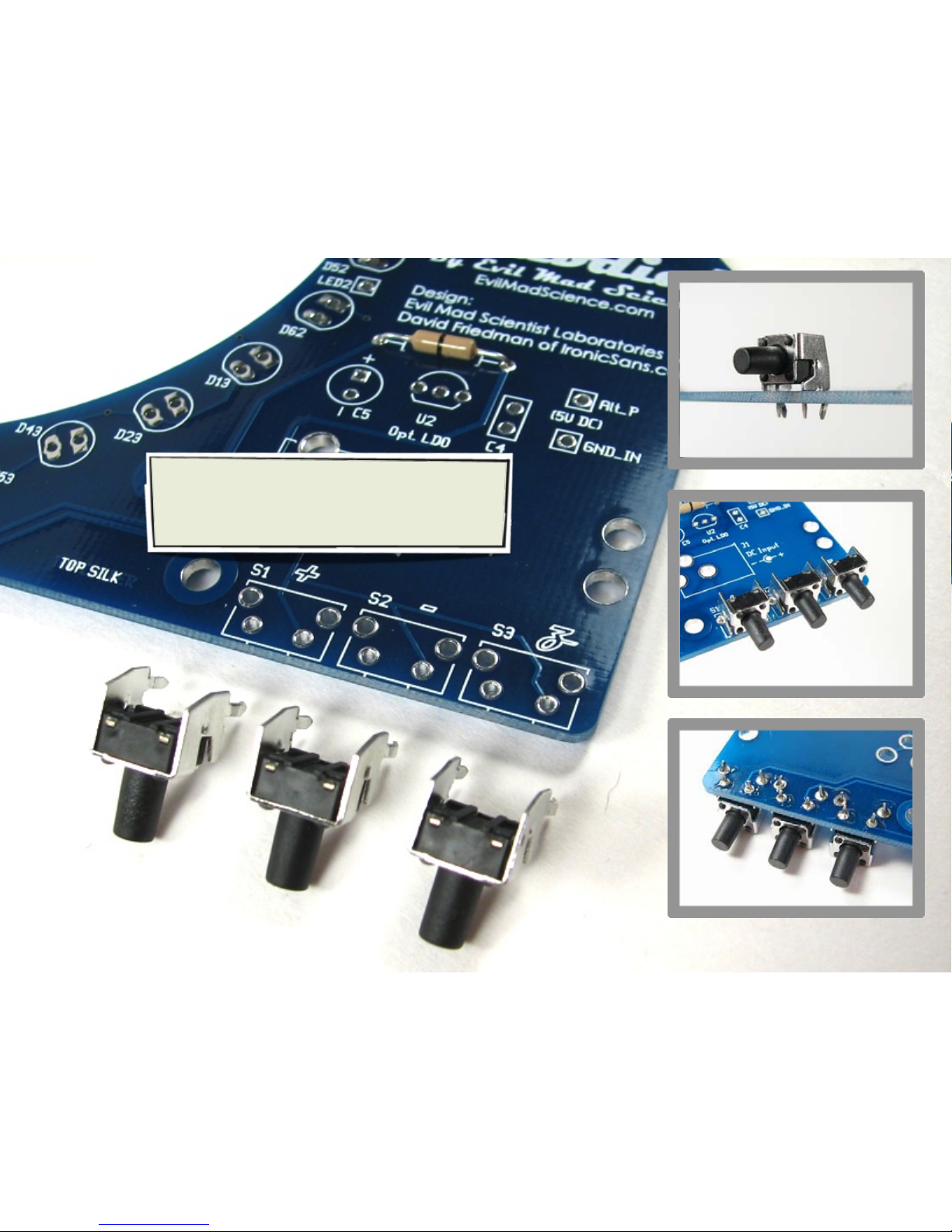

STEP 10: Buttons!

Parts #10 are right-angle tactile button switches.

“Snap” them into locations S1, S2 and S3, and make

sure that they sit flat on the board. Solder all four

pins of each switch.

[Bulbdial Assembly Guide] [14]

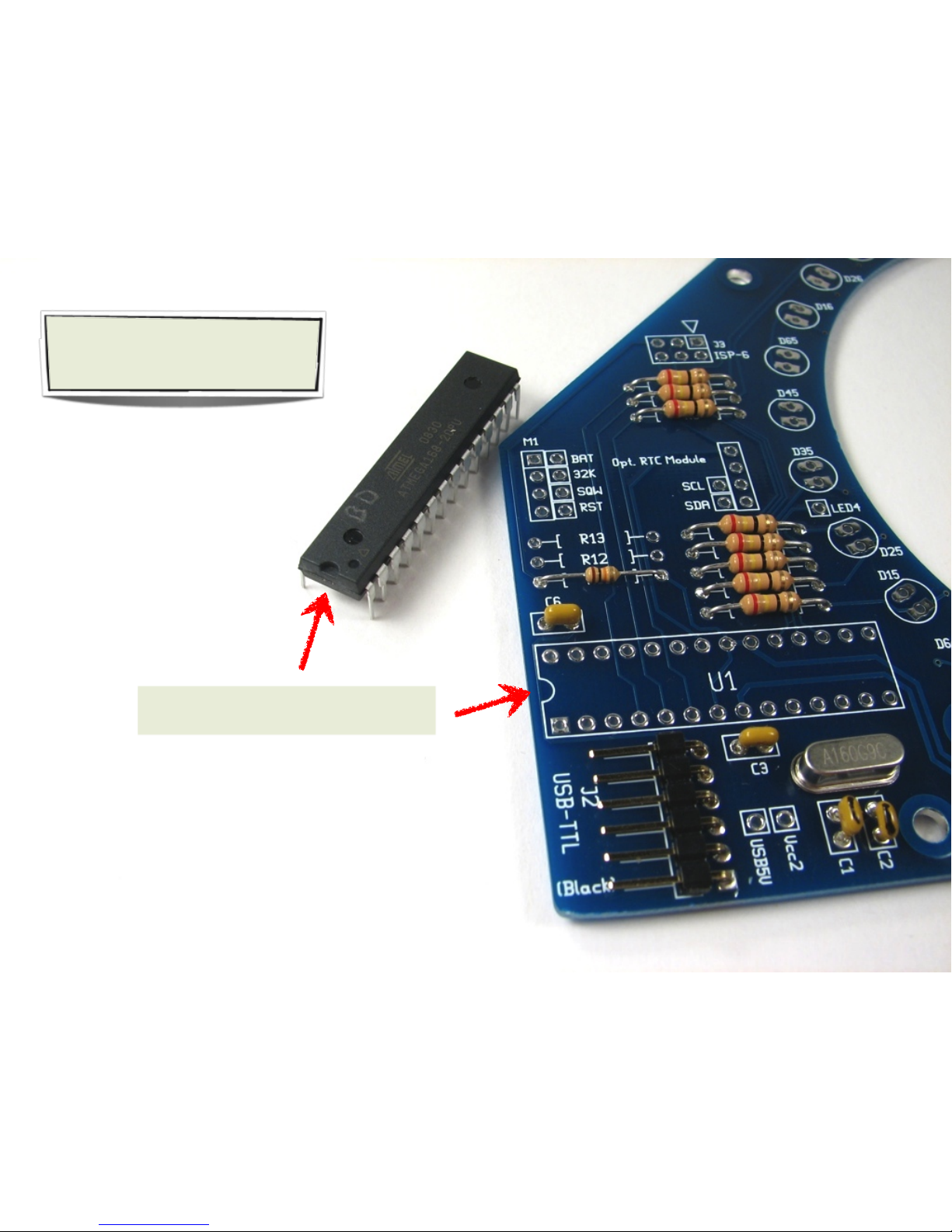

STEP 11a: AVR Microcontroller

Part #14 is an ATmega168, a type of

AVR microcontroller. It goes in location

U1, and must be oriented correctly.

First, identify the end of both the chip and of

location U1 that have the half-moon shape.

TO BE CONTINUED...

The chip should easily slip into the board. If

necessary, bend the pins of the chip to straight

up and down before inserting the chip. Do not

bend them by hand; bend all pins on one side at a

time by pushing them against a hard flat surface.

From end of chip:

YES!

no.

[Bulbdial Assembly Guide] [15]

STEP 11b: AVR Microcontroller, continued

Now place the chip in its location, matching

the marks on the chip and circuit board.

To hold the chip in place while you solder

it, you can bend out the corner pins, again

by up to 45°.

Solder every pin of the chip. Remember

to keep the soldering time per pin brief.

The pins do not need to be clipped.

The DC power jack, #15, goes in location

J1, matching the outline on the board.

Set the circuit board atop the other two,

to raise it a bit above your work surface,

as in step 9. Place the jack in its location.

From around back, it is possible to solder

one pin of the jack to tack it in place.

Solder one pin of the connector to tack

it in place. The larger metal here takes

a while to heat, up to about 8 s.

Here’s the view from the bottom side

after tacking the jack in place. Solder

the other two holes as well.

[Bulbdial Assembly Guide] [16]

STEP 12: Power jack

All three holes are now soldered. It is

not necessary to completely fill the

holes with solder.

Parts #12 are 4-pin

female headers that

go at location M1.

There are actually two locations at M1,

the headers go in the outer positions.

Put the headers in their places. Turn the board upside down to

rest flat on the headers. To verify that they are sitting flat, it may

be helpful to rest it on top of a pedestal, such as the kit box.

If you do not plan to use an RTC module, you can skip this step.

Solder one pin of each header

to tack them in place.

[Bulbdial Assembly Guide] [17]

STEP 13: RTC Sockets In this step, we add the sockets that allows the Bulbdial clock

to be connected to a real-time clock module (e.g., Chronodot)

With only one pin soldered, the headers are somewhat

“hinged”-- do your best to straighten both of them. Finally, solder the remaining

three pins of each header.

Straighten!

This completes the first part

of the build. We now move

on to putting the LEDs on

board. This is a 3D, multi-

board circuit, and we’ll test

each part individually as we

go, just to make sure that

everything works in the end.

[Bulbdial Assembly Guide] [18]

The LED bending jig is part #17.

To follow along, grab an LED from

your bag of blue LEDs, #16A. *

Use your thumb to hold

the LED body in place.

[Bulbdial Assembly Guide]

Each LED has a long and short lead. Place

an LED in the jig, being careful to put the

short lead on the side labeled “SHORT.”

Use your other thumb, or a firm surface, to

bend the leads firmly around the corner.

The LED, bent with the guide, with its 90°

turn intact. Your LEDs should look like this.

Executed properly, the LED should have a

sharp, right-angle bend and not spring out.

[19]

STEP 14: The LED bending guide Properly aligning the LEDs to make good shadows is an

important part of the assembly process. We use several

tools, including this LED guide, to ease this process along.

long lead

short lead

(*For monochrome kits, just grab any one of your LEDs, #16.)

[If you do not have an LED guide,

bend the LEDs 5.4 mm from their

base, in the direction shown.]

[Bulbdial Assembly Guide] [20]

STEP 15: Get ready to build the “blue” ring.

The circuit board we’ve

built up thus far

7/8” hex standoffs, #19

Hex wrench, #23

Long 4-40 screws, #24

3/8” hex standoffs, #18

“Red” circuit board, #3

Before starting to put the first ring of LEDs together,

gather up the necessary materials and have them at

the ready. You’ll also need to bend the first 30 LEDs

to shape. We’ll be using this setup to locate the LEDs

in place before soldering them.

30 Blue LEDs #16A*,

pre-formed, as in step 14.

(*Again, for monochrome kits, just grab 30 LEDs, #16.)

Table of contents