13 2551988C

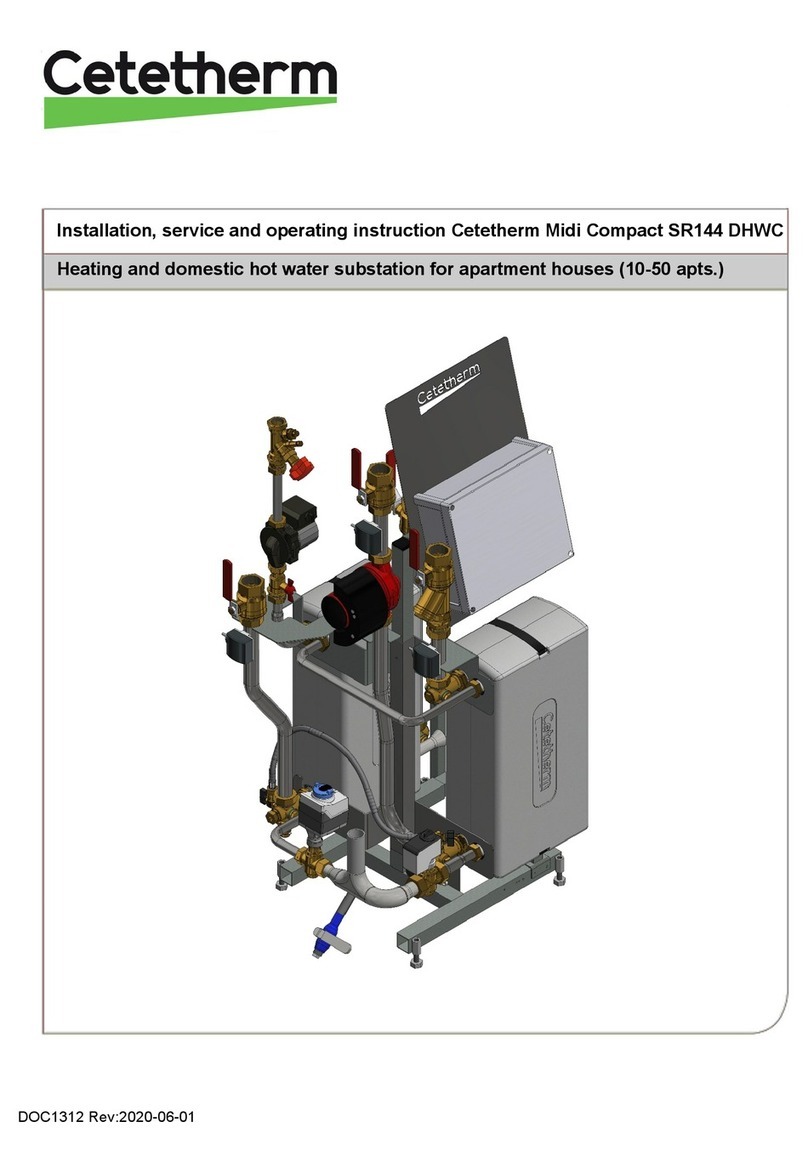

Water treatment

The quality and cleanliness of the water within both the primary and secondary circuits is vitally

important, to prevent damage to the ModuSat components and to ensure that the efficiency and

service life of the unit is maintained.

It is therefore necessary to fully flush and treat both primary and secondary circuits using suitable

water treatment chemicals.

Water treatment in accordance to these instructions.

Please confirm with the water treatment consultants that the chemicals used and

cleaning method statement complies with the requirements set out in this

section.

Water quality may damage the unit.

Poor water quality may damage the components used in the unit and invalidate

the warranty. The manufacturer cannot take responsibility for any damage of the

unit caused by poor water quality.

Chemical cleaning and dosing.

Chemical cleaning and dosing of the system should be in line with the current

regulations, standards and guidelines. Which are, but are not limited to:

BSRIA Application Guide BG29/2012

BS7593:2006

Requirements of Thames Water Utilities

The Water Industry Act 1991, Section 119

HSE The Control of Legionellosis 1991

HSC Approved Code of Practice and Guidance HSG274, Part 2

Water Quality Guidelines

TH - Total hardness is caused by calcium

and magnesium.

pH –this measures the alkalinity of the

water, neutral alkalinity is pH7. Heating

systems require an alkaline pH. Lower

pH will increase the corrosion risk.

TDS –. dissolved solids in the system

and is a measure of the cleanliness of

the water. (satisfactory level should be

within TDS of 10% of the mains water) .

Conductivity –this is the measure of the

ability of water to pass an electrical

current.

Free copper –the level of copper in the

system.

Total Iron and Manganese –this

measures iron concentration in mg/litre.

These are strong oxidants and may

increase the risk for corrosion.

Up to 150 mg/l (as CaCO3)

Free carbon dioxide

(CO2)

Typical Water Quality Guidelines