Evinrude E-tec 2011 Series Technical manual

1

Product Service Update

BRP US Inc.

Technical Publications

300 Sea Horse Drive

Waukegan, Illinois 60085 United States

† AMP is a registered trademark of Tyco International, Ltd.

† Champion is a registered trademark of Federal-Mogul Corporation.

† MicroSoft, MicroSoft Windows XP, Windows Vista and Windows 7 are registered trademarks of MicroSoft Corporation.

† Molex is a registered trademark of Molex Inc.

† NMEA is a registered trademark of the National Marine Electronics Association.

† Oetiker is a registered trademark of Hans Oetiker AG Maschinen

The following trademarks are the property of BRP US Inc. or its affiliates:

Printed in the United States

© 2011 BRP US Inc. All rights reserved.

TM, ® and the BRP logo are registered trademarks of Bombardier Recreational Products Inc. or its affiliates.

Evinrude ® E-TEC ® S.A.F.E. Evinrude ® / Johnson ® XD30™ Outboard Oil

Johnson ® SystemCheck™ Evinrude ® / Johnson ® XD50™ Outboard Oil

FasTrak™ Triple-Guard Evinrude ® / Johnson ® XD100™ Outboard Oil

I-Command™ DealerPort ® TBX™

Evinrude ® ICON™ BossWeb Viper™

2

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CONTACT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

WARRANTY INFORMATION – NORTH AMERICA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WARRANTY INFORMATION – OUTSIDE OF NORTH AMERICA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

FIELD SERVICE AND TRAINING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TECHNICAL PUBLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2011 PRODUCT IMPROVEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

15 – 90 HP INLINE MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

115 – 300 HP 60°/90° V4/V6 MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SERVICE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

15 – 30 HP MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

75 – 90 HP (1.3L) MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

115 – 300 HP 60°/90° V4/V6 MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

200 – 300 HP 90° V6 MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

OILING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

TRIM AND TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

GEARCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

EVINRUDE DIAGNOSTICS SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

IMPROVEMENTS AND CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

EVINRUDE ICON REMOTE CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . .43

ICON KITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ICON RIGGING KIT SELECTION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

ICON INSTALLATION TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ICON SERVICE TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3

CONTENTS

I-COMMAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

I-COMMAND INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

PARTS AND ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

P&A INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

SERVICE TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

NEW SERVICE TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

PAINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

ELECTRICAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

EVINRUDE E-TEC SPARK PLUG SERVICE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

EMM SERVICE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

EVINRUDE E-TEC GEARCASE LINE DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

2011 EVINRUDE E-TEC GEARCASE APPLICATION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

EVINRUDE E-TEC SHIFT ROD CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

EXTERNAL WATER SCREENS AND APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

2011 RPM QUICK REFERENCE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

2011 WATER PRESSURE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

SERVICE LITERATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

BULLETINS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

TOPIC REFERENCE INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

4

5

GENERAL INFORMATION

6

CONTACT INFORMATION

Dealers outside of North America should contact their regional

office. Refer to Dealers – Outside North America (BRP Interna-

tional Offices) on p. 7.

Dealers – North America

North American dealers should use the following contact informa-

tion.

Technical Support

After Sales Support

250 Sea Horse Drive

Waukegan, IL 60085

Ph: 1-800-888-4662 (Authorized Dealers only)

Fax: 1-847-689-6902 (Authorized Dealers only)

Warranty Administration Support

After Sales Support

250 Sea Horse Drive

Waukegan, IL 60085

Ph: 1-800-888-4662 (Authorized Dealers only)

Fax: 1-847-689-7235 (Authorized Dealers only)

Consumer Support

BRP US Inc. Customer Support Services

250 Sea Horse Drive

Waukegan, IL 60085

Ph: 1-847-689-7090 (Non-authorized dealers/consumers)

Fax 1-847-689-6902 (Non-authorized dealers/consumers)

Parts & Accessories Support

North American dealers may call 1-800-888-4662 for technical

assistance with parts and accessories.

•Select option 3 for ordering assistance, pricing, and back order

or returns information.

•Select option 6 for service parts issues, or application and war-

ranty questions.

To speed up the process, have your dealer number, the engine

model number, part number and invoice date available.

Technical Training Support

For questions regarding technical training, contact the Technical

Training Center.

Technical Training Center

250 Sea Horse Drive

Waukegan, IL 60085

Ph: 1-847-689-7500

Fax: 1-847-689-7510

7

AFTER SALES SUPPORT

Dealers – Outside North America

(BRP International Offices)

AUSTRALIA

Bombardier Recreational Products Australia Pty Limited

56 Canterbury Road

Bankstown 2200

New South Wales, Australia

Phone: +612 9794 6600

BENELUX

BRP Europe

Skaldenstraat 125

B-9042 Gent Belgium

Phone: +32 9 218 26 00

BRAZIL

Bombardier Recreational Products do Brasil

Rodovia Anhanguera Km 104 - Loteamento Tecno Park

Condominio Empresarial AZTech

Avenida James Clerck Maxwell, 280 Modulo 04

Campinas, SP 13069-380 Brasil

Phone +55 19 3716 8600

CARIBBEAN AND LATIN AMERICA

BRP US Inc.

1600 Sawgrass Corporate Parkway, Suite 150

Sunrise FL 33323

954-846-1442

EUROPE, MIDDLE EAST AND AFRICA

BRP International Division

5-7 CH Chemin du Messidor

Lausanne Switzerland

Phone: +41 21 318 78 00

FRANCE

Bombardier Recreational Products France

Les Jardins de la Duranne Bâtiment C

510 rue René Descartes

F - 13857, Aix en Provence France

Phone: +33 4 42 94 25 00

GERMANY

BRP Germany GmbH

Itterpark 11

D-40724 Hilden

Germany

Phone: +49 2103 960 680

JAPAN

BRP Japan Limited

15/F Parale Mitsui Building

8 Higashadi-Cho, Kawasaki-Ku

Kawasaki 210-0005

Phone: +81 44 200 1431

NEW ZEALAND

BRP New Zealand

7-11 Arwen Place

East Tamaki

Auckland 2130

Phone: +64 9 274 5718

SPAIN

BRP Recreational Products Spain S.L.

c/ Bertrán i Musitu 99-101

Edificio Brasil

08840 Viladecans-Barcelona Spain

Phone: +34 93 636 10 97

UK AND IRELAND

BRP Recreational Products UK Ltd

4 Brunel Close

Ebblake Industrial Estate

Verwood Dorset UK BH31 6BA

Phone: +44 1202 812 100

8

WARRANTY INFORMATION –

NORTH AMERICA

North American dealers should use the following information.

Warranty Allowance Claims

All warranty allowance claims should be entered online when pos-

sible. When a written warranty Allowance Request Form,

P/N 773629, is required it should be mailed to:

BRP US Inc.

After Sales Support

P.O. Box 597

Sturtevant, WI 53177

Warranty parts returned with a Warranty Allowance Request Form,

P/N 773629, should be shipped to:

U.S. dealers ship to:

BRP US Inc.

After Sales Support

300 Sea Horse Drive Dock 5

Waukegan, IL 60085

Canadian dealers ship to:

BRP Warranty Returns – Waukegan

c/o Affiliated Global Logistics

500 Carlingview Drive

Etobicoke, ON M9W 5R3

Prior Authorization Required for Parts and

Accessories Warranty

If a replacement part or a dealer-rebuild fails, contact

Evinrude/Johnson After Sales Support. Dealers are not authorized

to rebuild assemblies without prior authorization.

Have your dealer number, the engine model and serial number,

part number and invoice date available.

Certain parts or assemblies may require additional documentation:

•BRP invoice for the assembly

•installation work order

•previous work order for original repair

•sales receipt (over the counter sales)

Refer to “Parts and Accessories Claims” in the current Warranty

Procedures Manual.

B.E.S.T. Warranty

As outboards enter the service period of a B.E.S.T. contract, there

are several requirements that dealers and customers should be

aware of:

•A 300 hour service (or 3 year inspection) on every outboard

•An inspection report must be provided before any B.E.S.T con-

tract repairs are performed

•Engine must have less than 1000 hours

•There is a $50.00 deductible for each B.E.S.T. contract repair

•Dealers must qualify all engine repairs for outboards with

B.E.S.T. coverage

Refer to Administrative Bulletin 2010-04(A) for complete details

and coverage checklist.

9

AFTER SALES SUPPORT

WARRANTY INFORMATION –

OUTSIDE OF NORTH AMERICA

Dealers outside of North America should contact their regional

office for processing of warranty allowance claims, or returning

parts. Refer to Dealers – Outside North America (BRP Interna-

tional Offices) on p. 7.

Predelivery Checklist Included in Shipping

Crate

A Predelivery Checklist is now included in the shipping crate

(owner’s package) of all Evinrude E-TEC outboards. A pack of ten

(10) predelivery checklist forms, P/N 5008381, is available through

Evinrude/Johnson Genuine Parts.

Dealers are REQUIRED to perform a complete predelivery inspec-

tion on each outboard. Dealers MUST keep predelivery checklists

on file for a minimum of seven years.

Refer to Predelivery Bulletin 2010-01(D) for complete details.

10

FIELD SERVICE AND TRAINING

Dealers outside of North America should contact their regional

office. Refer to Dealers – Outside North America (BRP Interna-

tional Offices) on p. 7.

Dealers – North America

Technical Service Representatives –

Applications Engineers (TSR-AE’s)

TSR–AE's support both Dealer and OEM Partners. TSR–AE tech-

nical support visits are coordinated through the After Sales Support

Call Center. Dealer and OEM Technicians should first contact the

After Sales Support Center Team to resolve technical issues. Con-

tact them at 1-800-888-4662 and follow the prompts.

TSR-AE's provide the following dealer support:

•Service department development assistance (Service Evalua-

tions and goal setting)

•Feedback reports for product and business trends

•Technical support of BRP Outboard Engine products

•Customer Relations

•Serve as instructors at Dallas, Tacoma and Laval Training Cen-

ters

TSR's provide the following OEM partner support:

•All aspects of rigging, technical training to ensure safety and

maximum performance for BRP powered boats

•Feedback reports for product and business trends

•Preparation and distribution of Performance Reports

Training

Schedule training online (www.DealerPort.com). For questions

contact the Technical Training Center.

Training courses are offered at the following locations:

•Waukegan, Illinois

•Morrow, Georgia

•Tacoma, Washington

•Laval, Quebec

•Dallas, Texas

Technician Certification

Technicians who achieved "Certified" status between June 2005

and June 2006 must attend the Outboard Certification Course by

May 30, 2011. Certified status WILL EXPIRE soon for technicians

who fall into this category.

Technicians who achieved "Certified" status prior to June 2005

were required to return in prior training seasons. Certified status is

EXPIRED for technicians who fall into this category. They should

return as soon as possible to recertify.

11

AFTER SALES SUPPORT

Master Technician Program

Technicians desiring Master Technician status MUST:

1. Maintain Certified status for at least 4 years (no lapses).

2. Successfully complete all updates by the due date.

3. Complete Outboard Certification Course in 4.5 days or less.

4. Upon successful completion of the Outboard Certification

Course, technicians who meet the qualifications, and who are

approved by their instructor(s) will be given the opportunity to

take the Master Technician exam.

5. Complete the 50 question exam with a minimum score of 90%.

The exam may include questions on ANY outboards sold or mar-

keted by BRP.

To maintain Master Technician status, technicians MUST:

•Complete all distance learning updates by the due date.

•Return for hands-on training when required. See Technician

Certification on p. 10.

•When returning to the Outboard Certification Course, technicians

must complete the course and pass Master Technician exam as

outlined in steps 3 through 5 above.

If a technician allows their Certification to lapse, Master Technician

status is lost.

A technician can take a missed exam at any time to have Certified

status reinstated. However, Master Technician status can only be

reinstated by again meeting the qualifications listed in steps 1

through 5 above.

TECHNICAL PUBLICATIONS

Changes to Service Manual Set

Please note the following changes to the 2011 Service Manuals

and Service Manual Sets:

•The Installation and Predelivery section has been removed from

individual service manuals.

•The Special Tools section has been removed from individual ser-

vice manuals.

•The 2011 Installation and Predelivery Guide has been added to

the Service Manual Set. Additional Installation and Predelivery

Guides may be ordered using P/N 5008506.

•The 2011 Special Tool Guide has been added to the Service

Manual Set.

IMPORTANT: The 2011 Special Tool Guide, P/N 5008526, con-

tains tools for current Evinrude E-TEC product only. Dealers should

retain a copy of the 2010 Special Tools Guide, P/N 5007858, or a

prior Special Tools Guide as a reference of tools for older outboard

products.

12

NOTES – GENERAL INFORMATION

13

2011 PRODUCT IMPROVEMENTS

14

1. Engine management software version and revision

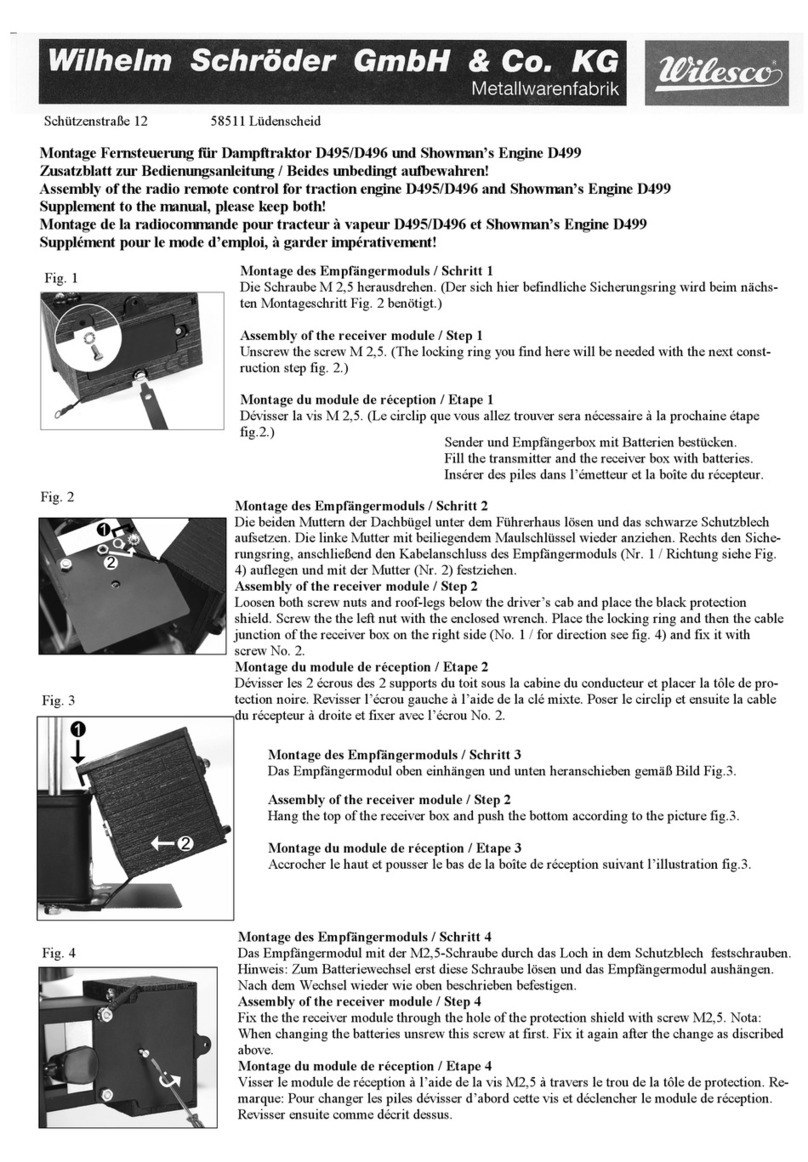

1. 6-pin AMP connector (tiller harness)

2. 2-pin AMP connector (neutral switch)

1

2

1

15 – 90 HP INLINE MODELS

Engine Management Software 15 – 30 HP Models

Engine management software has been developed to improve emissions and

reduce fuel consumption on 15 – 30 HP models.

Update engine management software on engines with serial numbers 5283875

to 5289986.

Refer to Warranty Bulletin 2010-09(W).

Engine Wiring Harness Change 15 – 30 HP Models

Evinrude E-TEC 15 – 30 HP (C, H, R, and S-suffix) model outboards have a new

engine wiring harness to support changes to the Touch Troll and neutral

switches.

The Touch Troll switch connector has been eliminated. Wiring for the Touch Troll

switch has been relocated to a new 6-pin AMP connector of the tiller harness.

The neutral switch has a dedicated 2-pin AMP connector, similar to other

Evinrude E-TEC models.

15

2011 PRODUCT IMPROVEMENTS

New Flywheel Torque Specification 15 – 30 HP Models

When servicing flywheels on Evinrude E-TEC 15 – 30 HP outboards, torque the

flywheel nut to 66 to 70 ft. lbs (90 to 95 N·m).

IMPORTANT: Torque the flywheel using the correct flywheel holder. To prevent

damage to the crankcase or the cylinder block, DO NOT allow the flywheel

holder to rest against the mounting boss for the recoil starter.

Also refer to Service Bulletin 2010-08(S), or the 2011 Service Manual.

Lower Mount 15 – 30 HP Models

A bump stop washer, P/N 353674, was added to the lower mount on 15 – 30 HP

models. This change to improves impact protection, and provides common ser-

vice parts and procedures for all 15 – 30 HP models.

Refer to the correct Service Manual for lower mount service procedures.

1. Bump stop washer

1

16

1. Vent

1. Nut

2. Spring

1

1

2

Oil Cap Assembly, 15 – 90 HP Models

The oil cap used on 15 – 90 HP models has changed.

The oil cap has a redesigned vent valve, to help prevent oil from leaking out of

the vent while the engine is tilted.

Oil cap assembly, P/N 5008406, replaces oil cap assembly, P/N 5007256, and

services 2009 and newer 15 – 30 HP models and 2010 and newer 40 – 90 HP

(F-suffix) models.

Electric Starter Motor Change 40 – 65 HP Models

The electric starter motor used on Evinrude E-TEC 40 – 65 HP models has been

changed.

The starter features a new nut and spring to retain the drive gear. Previously, the

drive gear was retained with a clip, spring and spacers. This change improves

the durability of the starter and provides common service for all 15 – 65 HP mod-

els.

The electric starter motor, P/N 587045, services all 2004 and newer 15 – 65 HP

models.

17

2011 PRODUCT IMPROVEMENTS

Throttle Body Assembly 40 – 65 HP Models

A new throttle body assembly is used on all 40 – 65 HP models.

The throttle body assembly features a nickel-plated throttle valve, which

improves corrosion resistance and durability. The new throttle valve is silver in

color, while the previous throttle valve was gold in color.

The new throttle body assembly, P/N 5008407, services all 2004 and newer 40 –

65 HP models.

Exhaust Housings 40 – 65 HP Models

A change was made to the exhaust housing for 40 – 65 HP models.

Retainer tabs have been added to the exhaust housing to better secure the

engine wiring harness. Tie straps are now used to secure the engine wiring har-

ness, rather than the previous “J-clamps.”

This change also makes it easier to reinstall and secure the engine wiring har-

ness when servicing the engine.

Exhaust housing, P/N 5008275, services 2006 and newer 40 – 50 HP models.

Exhaust housing, P/N 5008274, services 2006 and newer 60 – 65 HP models.

1. Throttle valve

Exhaust Housing

1. Tie straps

1

1

18

1. Clamp, oil sensor to housing, P/N 982115

1

115 – 300 HP 60°/90° V4/V6 MODELS

Lower Engine Covers 115 – 200 HP 60° Models

Lower engine covers for 115 – 200 HP 60° models have been changed. The

lower engine covers feature a new fastener insert that reduces the risk of crack-

ing the lower engine covers during removal and installation.

Service parts for older product will supersede to new part numbers. Refer to the

correct Parts Catalog for parts ordering information.

Note: Do not use power/impact tools to tighten lower engine cover screws.

Oil Pressure Sensor 115 – 300 HPModels

Clamp, P/N 982115, is now used to retain the oil pressure sensor to the oil pump

housing on all V4 and V6 models.

This change improves the retention of the oil pressure sensor and provides com-

mon service parts for these models.

Table of contents

Other Evinrude Engine manuals