Evinrude E-Tec 40 HP User manual

Printed in the United States.

© 2011 BRP US Inc. All rights reserved.

TM, ® Trademarks and registered trademarks of Bombardier Recreational Products Inc. or its affiliates.

BRP US Inc.

Technical Publications

P.O. Box 597

Sturtevant, Wisconsin 53177 United States

www.evinrude.com or www.johnson.com

† AMP, Superseal 1.5, Super Seal, Power Timer, and Pro-Crimper II

are registered trademarks of Tyco International, Ltd.

† Amphenol is a registered trademark of The Amphenol Corporation.

† BEP is a registered trademark of Actuant Corporation.

† Champion is a registered trademark of Federal-Mogul Corporation.

† Deutsch is a registered trademark of The Deutsch Company.

† Dexron is a registered trademark of The General Motors Corporation.

† Fluke is a registered trademark of The Fluke Corporation

† GE is a registered trademark of The General Electric Company.

† GM is a registered trademark of The General Motors Corporation.

† Locquic and Loctite are registered trademarks of The Henkel Group.

† Lubriplate is a registered trademark of Fiske Brothers Refining Company.

† NMEA is a registered trademark of the National Marine Electronics Association.

† Oetiker is a registered trademark of Hans Oetiker AG Maschinen.

† Packard is a registered trademark of Delphi Automotive Systems.

† Permatex is a registered trademark of Permatex.

† STP is a registered trademark of STP Products Company.

† Snap-on is a registered trademark of Snap-on Technologies, Inc.

The following trademarks are the property of BRP US Inc. or its affiliates:

Evinrude ® Twist Grip™

Johnson ® Nut Lock™

Evinrude ® E-TEC ® Screw Lock™

FasTrak™ Ultra Lock™

S.A.F.E.™ Moly Lube™

SystemCheck™ Triple-Guard ® Grease

I-Command™ DPL™ Lubricant

Evinrude ® ICON™ 2+4 ® Fuel Conditioner

Evinrude ® / Johnson ® XD30™ Outboard Oil Carbon Guard™

Evinrude ® / Johnson ® XD50™ Outboard Oil HPF XR™ Gearcase Lubricant

Evinrude ® / Johnson ® XD100™ Outboard Oil HPF PRO™ Gearcase Lubricant

Gel-Seal II™

2

SERVICE MANUAL

CONTENTS

SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE

1 REFERENCE INFORMATION . . . . . . . . . . . . . . . . . . . . . 3

2 ROUTINE SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 ENGINE COVER SERVICE . . . . . . . . . . . . . . . . . . . . . . 49

4 ENGINE MANAGEMENT MODULE (EMM) . . . . . . . . . . 53

5 SYSTEM ANALYSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6 ELECTRICAL AND IGNITION . . . . . . . . . . . . . . . . . . . . . 87

7 FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8 OILING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

9 COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

10 POWERHEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

11 MIDSECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

12 GEARCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

GEARCASE SERVICE, 40 – 65 HP MODELS . . . . . . . 296

GEARCASE SERVICE, 75 – 90 HP MODELS . . . . . . . 318

13 TRIM AND TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

14 MANUAL STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S–1

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I–1

TROUBLE CHECK CHART . . . . . . . . . . . . . . . . . . . . . . . . T–1

DIAGRAMS

IMPORTANT: For complete outboard rigging and control installation information, refer to the Predeliv-

ery and Installation Guide included with the service manual set.

All special tools referenced in this manual can be found in the Special Tools Guide, P/N 5008526.

REFERENCE INFORMATION

3

1

REFERENCE INFORMATION

TABLE OF CONTENTS

SAFETY NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ABBREVIATIONS USED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

UNITS OF MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

LIST OF ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

EMISSION-RELATED INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

MANUFACTURER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

DEALER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OWNER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

EPA EMISSION REGULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

MODEL DESIGNATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

MODELS COVERED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

STANDARD TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

PRODUCT REFERENCE AND ILLUSTRATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

REFERENCE INFORMATION

SAFETY NOTICE

SAFETY NOTICE

Before working on any part of the outboard, read the SAFETY section at the end of this manual.

This pu blication is written fo r qualified, facto ry-

trained technicia ns who ar e alrea dy familiar with

the use of Evinrude/Johnson Special Tools. The

included in formation is not a substitu te for wo rk

experience. It is an organized guide for reference,

repair, and/or maintenance.

The following symbols and/or signal words

may be used in this document:

Indicates an instruction which, if

not followed, could severely damage engine

components or other property.

These safety alert signal words mean:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

IMPORTANT: Identifies information that controls

correct assembly and operation of the product.

DO NOT perform any work unt il yo u have read

and understood these instructions completely.

Torque wre nch tig htening specifications must

strictly be adhered to.

Should removal of any locking fastener (lock tabs,

locknuts, or p atch screws) be requ ired, a lways

replace with a new one.

When repla cement p arts are required, use

Evinrude/Johnson Genuine Parts or parts with

equivalent characteristics, including type, strength

and mate rial. Use of subst andard p arts could

result in injury or product malfunction.

Always wear EYE PROTECTION AND APPRO-

PRIATE GLOVES when using power tools.

Unless otherwise specified, engine must be OFF

when performing this work.

Always be aware of p arts that can move, such as

flywheels, propellers, etc.

Some components may be HOT. Always wait for

engine to cool down before performing work.

If you use procedures or service tools that are not

recommended in th is manual, YOU ALONE must

decide if your actions might injure people or dam-

age the outboard.

This document ma y be tra nslated into othe r la n-

guages. In the event of any discrepancy, the Eng-

lish version shall prevail.

ADANGER

Indicates a hazardous situation which, if

not avoided, will result in death or serious

injury.

AWARNING

Indicates a hazardous situation which, if

not avoided, could result in death or seri-

ous injury

ACAUTION

Indicates a hazardous situation which, if

not avoided, could result in minor or mod-

erate personal injury.

NOTICE

REFERENCE INFORMATION

SAFETY NOTICE

1

ADANGER

Contact with a rotating propeller is likely to result in serious injury or death. Assure the

engine and prop area is clear of people and objects before starting engine or operating boat.

Do not allow anyone near a propeller, even when the engine is off. Blades can be sharp and

the propeller can continue to turn even after the engine is off. Remove propeller before ser-

vicing and when running the outboard on a flushing device.

DO NOT run the engine indoors or without adequate ventilation or permit exhaust fumes to

accumulate in confined areas. Engine exhaust contains carbon monoxide which, if inhaled,

can cause serious brain damage or death.

AWARNING

Wear safety glasses to avoid personal injury, and set compressed air to less than 25 psi (172

kPa).

The motor cover and flywheel cover are machinery guards. Use caution when conducting

tests on running outboards. DO NOT wear jewelry or loose clothing. Keep hair, hands, and

clothing away from rotating parts.

During service, the outboard may drop unexpectedly. Avoid personal injury; always support

the outboard’s weight with a suitable hoist or the tilt support bracket during service.

To prevent accidental starting while servicing, disconnect the battery cables at the battery.

Twist and remove all spark plug leads.

The electrical system presents a serious shock hazard. DO NOT handle primary or secondary

ignition components while outboard is running or flywheel is turning.

Gasoline is extremely flammable and highly explosive under certain conditions. Use caution

when working on any part of the fuel system.

Protect against hazardous fuel spray. Before starting any fuel system service, carefully

relieve fuel system pressure.

Do not smoke, or allow open flames or sparks, or use electrical devices such as cellular

phones in the vicinity of a fuel leak or while fueling.

Keep all electrical connections clean, tight, and insulated to prevent shorting or arcing and

causing an explosion.

Always work in a well ventilated area.

Replace any locking fastener (locknut or patch screw) if its locking feature becomes weak.

Definite resistance to tightening must be felt when reusing a locking fastener. If replacement

is indicated, use only authorized replacement or equivalent.

6

REFERENCE INFORMATION

ABBREVIATIONS USED IN THIS MANUAL

ABBREVIATIONS USED IN THIS MANUAL

Units of Measurement List of Abbreviations

A Amperes

amp-hr Ampere hour

fl. oz. fluid ounce

ft. lbs. foot pounds

HP horsepower

in. inch

in. Hg inches of mercury

in. lbs. inch pounds

kPa kilopascals

ml milliliter

mm millimeter

N·m Newton meter

P/N part number

psi pounds per square inch

RPM revolutions per minute

°C degrees Celsius

°F degrees Fahrenheit

ms milliseconds

µs microseconds

ΩOhms

VVolts

VAC Volts Alternating Current

VDC Volts Direct Current

ABYC American Boat & Yacht Council

ATDC after top dead center

AT air temperature sensor

BPS barometric pressure sensor

BTDC before top dead center

CCA cold cranking amps

CFR Code of Federal Regulations

CPS crankshaft position sensor

EMM Engine Management Module

EPA Environmental Protection Agency

ICOMIA International Council of Marine

Industry Associations

ID Inside dimension

MCA marine cranking amps

MWS modular wiring system

NMEA National Marine Electronics Assoc.

ROM read only memory

S.A.F.E. speed adjusting failsafe electronics

SAC start assist circuit

SAE Society of Automotive Engineers

SYNC synchronization

TDC top dead center

TPS throttle position sensor

USCG United States Coast Guard

WOT wide open throttle

WTS water temperature sensor

7

REFERENCE INFORMATION

EMISSION-RELATED INSTALLATION INSTRUCTIONS

1

EMISSION-RELATED

INSTALLATION

INSTRUCTIONS

Failing to follow these instructions when

installing a certified engine in a vessel violates

federal law (40 CFR 1068.105 (b)), subject to

fines or other penalties as described in the

Clean Air Act.

Maintenance, replacement, or rep air of the emis-

sion control de vices and systems ma y be per-

formed by any ma rine SI (sp ark ig nition) engine

repair establishment or individual.

Manufacturer’s Responsibility

Beginning with 1 999 model year o utboards, man-

ufacturers o f ma rine outboards must de termine

the exha ust emissio n levels for each outbo ard

horsepower family and certif y the se o utboards

with the Unite d States of America Environmental

Protection Age ncy (EP A). An emissions control

information labe l, showing emission leve ls a nd

outboard specifications, mu st be placed o n each

outboard at the time of manufacture.

Dealer’s Responsibility

When pe rforming service on all 1 999 a nd more

recent Evinrude/Johnson outboards that carry an

emissions control information la bel, adjustments

must be kept with in pub lished factory specifica-

tions.

Replacement or repair of any emission rela ted

component must b e exe cuted in a manne r that

maintains emission levels within the prescrib ed

certification standards.

Dealers are not to mo dify the outbo ard in an y

manner that would alter the horsepower or allow

emission levels to excee d their predete rmined

factory specifications.

Exceptions include manu facturer’s prescrib ed

changes, such as altitude ad justments, for exa m-

ple.

Owner’s Responsibility

The owner/operator is required to have outboa rd

maintenance performed to maintain emission lev-

els within prescribed certification standards.

The owner/operator is not to, and should not allow

anyone to, modify the outboard in any manner

that wo uld a lter th e horsepower or a llow e mis-

sions levels to exceed their predetermined factory

specifications.

Tampering with the fuel system to change horse-

power or mo dify emission levels beyond fa ctory

settings or specifications will void the product war-

ranty.

EPA Emission Regulations

All new 19 99 and more recent Evinrude/Johnson

outboards are certified to the EPA as confo rming

to the requirements of the regulations for the con-

trol of air pollutio n from new watercraf t marine

spark ignition outboards. This certification is con-

tingent on certain adjustments being set to factory

standards. For this reason, the factory procedure

for servicing the product must be strictly followe d

and, whe never pra ctical, ret urned to the original

intent of the design. The responsibilities liste d

above are gen eral and in no way a comple te list-

ing of the r ules and reg ulations pertaining to th e

EPA re quirements on e xhaust emissions for

marine products. For more detailed information on

this subject, you may cont act th e fo llowing loca-

tions:

VIA U.S. POSTAL SERVICE:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

401 M St. NW

Washington, DC 20460

VIA EXPRESS or COURIER MAIL:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

501 3rd St. NW

Washington, DC 20001

EPA INTERNET WEB SITE:

www.epa.gov

8

REFERENCE INFORMATION

MODEL DESIGNATION

MODEL DESIGNATION

Model and serial numbers are located on the swivel bracket and on the powerhead.

BE 200 DP X IN E

STYLE:

J = Johnson

E = Evinrude

HORSEPOWER

LENGTH:

= 15” Std.

L = 20” Long

Y = 22.5” Special

X = 25” X-long

Z = 30” XX-long

MODEL YR:

I= 1

N= 2

T= 3

R= 4

O= 5

D= 6

U= 7

C= 8

E= 9

S= 0

Ex: IN = 2012

MODEL RUN

or SUFFIX

DESIGN FEATURES:

B = Blue Paint

C = Counter Rotation

D = Evinrude E-TEC®

E = Electric Start w/Remote Steering

F = Direct-Injection

G = Graphite Paint

H = High Output

J = Jet Drive

M = Military

P = Power Trim and Tilt

R = Rope Start w/Tiller Steering

S = Saltwater Approved

T = Tiller Steering

TE = Tiller Electric

V = White Paint

W = Commercial Model

PREFIX:

B = Bodensee model

D = ICON model

1. Model and serial number 002224

1

1. Serial number 002225

1

REFERENCE INFORMATION

MODELS COVERED IN THIS MANUAL

9

1

MODELS COVERED IN THIS MANUAL

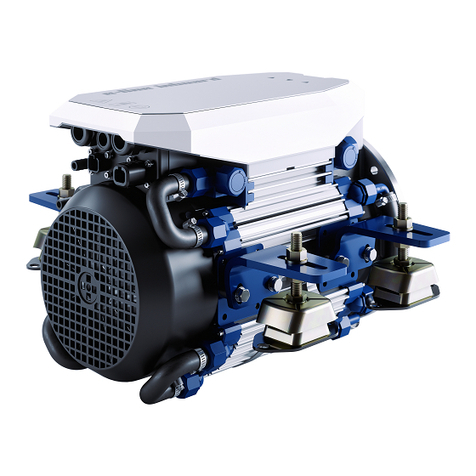

This manual covers service information on all 52.7 cubic inch (.86 L), 2-Cylinder; and 79 cubic inch (1.29

L), 3-Cylinder Evinrude E-TEC models.

Model Displacement Gearcase Height Color

Description

E40DRLINC .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Manual Tilt, Tiller Steering, Rope Start

E40DTLINM .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Power Tilt, Tiller Steering, Electric Start

E40DPLINC .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Power Tilt, Remote Steering, Electric Start

E40DSLINM .86 L, 52.7 ci 12:32 / 0.375 F 20" White Power Tilt, Remote Steering, Electric Start

E40DHLINS .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Power Tilt, Remote Steering, Electric Start, H.O. Stylin

g

E40DHSLINS .86 L, 52.7 ci 12:32 / 0.375 F 20" White Power Tilt, Remote Steering, Electric Start, H.O. Stylin

g

E50DTLINM .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Power Tilt, Tiller Steering, Electric Start

E50DPLINC .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Power Tilt, Remote Steering, Electric Start

E50DSLINM .86 L, 52.7 ci 12:32 / 0.375 F 20" White Power Tilt, Remote Steering, Electric Start

E60DTLINM .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Power Tilt, Tiller Steering, Electric Start

E60DPLINC .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Power Tilt, Remote Steering, Electric Start

E60DSLINM .86 L, 52.7 ci 12:32 / 0.375 F 20" White Power Tilt, Remote Steering, Electric Start

E65WDRLINM .86 L, 52.7 ci 12:32 / 0.375 F 20" Blue Manual Tilt, Tiller Steering, Rope Start

E65WDRYINM .86 L, 52.7 ci 12:32 / 0.375 F 22.5" Blue Manual Tilt, Tiller Steering, Rope Start

E75DPLINC 1.29 L, 79.0 ci 13:26 / 0.50 S 20" Blue Power Tilt, Steel Steering Arm

E75DSLINM 1.29 L, 79.0 ci 13:26 / 0.50 S 20" White Power Tilt, Stainless Steering Arm

E90DPLINC 1.29 L, 79.0 ci 13:26 / 0.50 S 20" Blue Power Tilt, Steel Steering Arm

E90DSLINS 1.29 L, 79.0 ci 13:26 / 0.50 S 20" White Power Tilt, Stainless Steering Arm

E90DPXINC 1.29 L, 79.0 ci 12:27 / 0.444 O 25" White Power Tilt, Stainless Steering Arm

E90WDELINM 1.29 L, 79.0 ci 13:26 / 0.50 S 20" Blue Manual Tilt, Steel Steering Arm, Commercial Model

E90WDEXINM 1.29 L, 79.0 ci 12:27 / 0.444 O 25" White Manual Tilt, Steel Steering Arm, Commercial Model

10

REFERENCE INFORMATION

SERVICE SPECIFICATIONS

SERVICE SPECIFICATIONS

40 – 65 HP E-TEC Models

ENGINE

Full Throttle

Operating Range RPM

40 HP – 5000 to 6000 RPM

50 HP – 5500 to 6000 RPM

60 HP – 5500 to 6000 RPM

65 HP – 5500 to 6000 RPM

Power

40 HP (29.4 kw) @ 5500 RPM

50 HP (36.8 kw) @ 5750 RPM

60 HP (44.1 kw) @ 5750 RPM

65 HP (47.8 kw) @ 5750 RPM

Idle RPM in Gear 800 ± 50 EMM Controlled

Idle RPM in Neutral 750 ± 50 EMM Controlled

Test Propeller P/N 382861

Weight

(may vary depending

on model)

(RL) Models: 232 lbs. (105 kg)

(HL, PL, SL, TL) Models: 240 lbs. (109 kg)

Lubrication Evinrude/Johnson XD100, XD50, XD30; or

NMMA TC-W3 certified

Engine Type In-line, 2 Cylinder, Two-Cycle

Displacement 52.7 cu. in. (864 cc)

Bore 3.601 in (91.47 mm)

Stroke 2.588 in. (65.74 mm)

Standard Bore 3.6005 to 3.6015 in. (91.45 to 91.48 mm)

To bore oversize, add piston oversize dimension to standard bore

Top Crankshaft Journal 2.1870 to 2.1875 in. (55.55 to 55.56 mm)

Center Crankshaft Journal 2.1870 to 2.1875 in. (55.55 to 55.56 mm)

Bottom Crankshaft Journal 1.5747 to 1.5752 in. (40.0 to 40.01 mm)

Rod Crankpin 1.3757 to 1.3762 in. (34.94 to 34.96 mm)

Piston Ring End Gap, Both 0.011 to 0.023 in. (0.28 to 0.58 mm)

FUEL

Fuel/Oil Control EMM Controlled

Starting Enrichment EMM Controlled

Minimum (High) Fuel Pressure 24 to 28 psi (165 to 193 kPa)

Minimum Fuel Lift

Pump Pressure 3 psi (21 kPa)

Maximum Fuel Inlet Vacuum 4 in. Hg.

Minimum Octane 87 AKI (R+M)/2 or 90 RON

Additives

2+4 ®Fuel Conditioner, Fuel System Cleaner

Use of other additives may result in engine damage.

See Fuel Requirements on p. 131 for additional information

REFERENCE INFORMATION

SERVICE SPECIFICATIONS

11

1

40 – 65 HP E-TEC Models

ELECTRICAL

Minimum Battery

Requirements 640 CCA (800 MCA) or 800 CCA (1000 MCA) below 32° F (0° C)

Alternator 25-Amp fully regulated. Refer to Predelivery and Installation Guide for multiple battery

applications.

Tachometer Setting 6 pulse (12 pole)

Engine Fuse P/N 967545 – 10 A

COOLING

Thermostat 14 3°F (62°C)

Maximum Temperature 212°F (100°C)

Water pressure 12 to 14 psi @ 5000 RPM

IGNITION

Type Capacitor Discharge

Firing Order 1-2

Ignition Timing EMM Controlled

RPM Limit in Gear 6250

RPM Limit in Neutral 1800

Crankshaft Position Sensor Air

Gap Fixed

Spark Plug Refer to Emission Control Information Label

Champion† QC10WEP @ 0.028 ± 0.003 in. (0.71 mm)

GEARCASE

Gear Ratio 12:32 (.375)

Lubricant HPF XR Gearcase Lube

HPF Pro in high performance or commercial applications

Capacity 22 fl. oz. (650 ml)

Shift Rod Height 20 in. (L) Models: 21.38 (543 mm) ± one-half turn

Shift Cable Stroke 1.125 to 1.330 in. (28.6 to 33.8 mm) measured between NEUTRAL and FORWARD

POWER TRIM/TILT

Lubrication Evinrude/Johnson Biodegradable TNT Fluid

Fluid Capacity 15.2 fl. oz. (450 ml)

Trim Range 0° to 15°

Tilt Range 16° to 65°

12

REFERENCE INFORMATION

SERVICE SPECIFICATIONS

75 – 90 HP E-TEC Models

ENGINE

Full Throttle

Operating Range RPM 4500 to 5500 RPM

Power 75 HP (56 kw) @ 5000 RPM

90 HP (67.1 kw) @ 5000 RPM

Idle RPM in Gear 700 ± 50 EMM Controlled

Idle RPM in Neutral 600 ± 50 EMM Controlled

Test Propeller (L) Models: P/N 386246

(X) Models: P/N 387388

Weight

(may vary depending

on model)

(L) Models: 320 lbs. (145 kg)

(X) Models: 335 lbs. (152 kg)

Lubrication Evinrude/Johnson XD100, XD50, XD30; or

NMMA TC-W3 certified

Engine Type In-line, 3 Cylinder, Two-Cycle

Displacement 79.1 cu. in. (1296 cc)

Bore 3.601 in (91.47 mm)

Stroke 2.588 in. (65.74 mm)

Standard Bore 3.6005 to 3.6015 in. (91.45 to 91.48 mm)

To bore oversize, add piston oversize dimension to standard bore

Top Crankshaft Journal 2.1870 to 2.1875 in. (55.55 to 55.56 mm)

Center Crankshaft Journals 2.1870 to 2.1875 in. (55.55 to 55.56 mm)

Bottom Crankshaft Journal 1.5747 to 1.5752 in. (40.0 to 40.01 mm)

Rod Crankpin 1.3757 to 1.3762 in. (34.94 to 34.96 mm)

Piston Ring End Gap, Both 0.011 to 0.023 in. (0.28 to 0.58 mm)

FUEL

Fuel/Oil Control EMM Controlled

Starting Enrichment EMM Controlled

Minimum (High) Fuel Pressure 24 to 28 psi (165 to 193 kPa)

Minimum Fuel Lift

Pump Pressure 3 psi (21 kPa)

Maximum Fuel Inlet Vacuum 4 in. Hg.

Minimum Octane 87 AKI (R+M)/2 or 90 RON

Additives

2+4 ®Fuel Conditioner, Fuel System Cleaner

Use of other additives may result in engine damage.

See Fuel Requirements on p. 131 for additional information

13

REFERENCE INFORMATION

SERVICE SPECIFICATIONS

1

75 – 90 HP E-TEC Models

ELECTRICAL

Minimum Battery

Requirements 640 CCA (800 MCA) or 800 CCA (1000 MCA) below 32° F (0° C)

Alternator 25-Amp fully regulated. Refer to Predelivery and Installation Guide for multiple battery

applications.

Tachometer Setting 6 pulse (12 pole)

Engine Fuse P/N 967545 – 10 A

COOLING

Maximum Temperature 212°F (100°C)

Thermostat 143°F (62°C)

Water pressure 19 to 21 psi @ 5000 RPM

IGNITION

Type Capacitor Discharge

Firing Order 1-2-3

Ignition Timing EMM Controlled

RPM Limit in Gear 6250

RPM Limit in Neutral 1800

Crankshaft Position Sensor Air

Gap Fixed

Spark Plug Refer to Emission Control Information Label

Champion† QC10WEP @ 0.028 ±.003 in. (0.71 mm)

GEARCASE

Gear Ratio 20 in. (L) Models: 13:26 (.500)

25 in. (X) Models: 12:27 (.444)

2:1

2.25:1

Lubricant HPF XR Gearcase Lube

Capacity 20 in. (L) Models: 31.6 fl. oz. (935 ml)

25 in. (X) Models: 32.8 fl. oz. (970 ml)

Shift Rod Height 20 in. (L) Models: 21.25 (539.75 mm) ± one-half turn

25 in. (X) Models: 26.25 (666.75 mm) ± one-half turn

Shift Cable Stroke 1.125 to 1.330 in. (28.6 to 33.8 mm) measured between NEUTRAL and FORWARD

POWER TRIM/TILT

Lubrication Single Piston System–Evinrude/Johnson Biodegradable TNT Fluid

Fluid Capacity 21 fl. oz. (620 ml)

Trim Range 0° to 15°

Tilt Range 16° to 65°

14

REFERENCE INFORMATION

STANDARD TORQUE SPECIFICATIONS

STANDARD TORQUE

SPECIFICATIONS PRODUCT REFERENCE

AND ILLUSTRATIONS

BRP US Inc. reserves the right to make changes

at a ny time, wit hout no tice, in specificatio ns a nd

models and also to discon tinue models. The rig ht

is also reserve d to change any specifications or

parts, at any time, without incurring any obligation

to equ ip same on mode ls manufactured prior to

date of such ch ange. Specifications used are

based on the late st product information a vailable

at the time of publication.

The continuing accuracy of this manual cannot be

guaranteed.

All photographs and illustrations used in this man-

ual may no t de pict a ctual models or equipment,

but are intended as representative views for refer-

ence only.

Certain features or systems discussed in this

manual mig ht not be found o n all mod els in all

marketing areas.

All service technicians must be familiar with nauti-

cal orient ation. This manual of ten identifies p arts

and procedures using these terms.

Size In. Lbs. Ft. Lbs. N·m

No. 6 7–10 0.58–0.83 0.8–1.1

No. 8 15–22 1.25–1.83 1.7–2.5

No. 10 24–36 2–3 2.7–4.0

No. 12 36–48 3–4 4.0–5.4

1/4 in. 60–84 5–7 7-9.5

5/16 in. 120–144 10–12 13.5–16.5

3/8 in. 216–240 18–20 24.5–27

7/16 in. 336–384 28–32 38–43.5

M3 15–22 1.25–1.83 1.7–2.5

M4 24–35 2–2.9 2.7–4.0

M5 35–60 2.9–5 4.0–6.8

M6 84–106 7–8.8 9.5–12

M8 177–204 14.7–17 20–23

M10 310–336 25.8–28 35–38

IMPORTANT: These values apply only when a

specific torque for a specific fastener is not listed

in the appropriate section. When tightening two

or mo re screws on the same p art, DO NOT

tighten screws completely, one at a time.

AWARNING

Torque wrench tightening specifications

must be strictly adhered to. Replace any

locking fastener (locknut or patch screw)

if its locking feature becomes weak. Defi-

nite resistance to turning must be felt

when reusing a locking fastener.

If replacement is specified or required

because the locking fastener has become

weak, use only authorized Evinrude/John-

son Genuine Parts.

Nautical Orientation 006411

ROUTINE SERVICE

15

2

ROUTINE SERVICE

TABLE OF CONTENTS

INSPECTION AND MAINTENANCE SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

LIFTING THE OUTBOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

OUTBOARD RIGGING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

CONTROL CABLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

SYSTEMCHECK HARNESS CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

I-COMMAND NETWORK CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

WATER PRESSURE GAUGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

BATTERY AND BATTERY CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

OETIKER CLAMP SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

STEERING FRICTION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

THROTTLE FRICTION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

TILT LIMIT SWITCH ADJUSTMENT (75 – 90 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

TRIM SENDING UNIT ADJUSTMENT (40 – 60 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

TRIM SENDING UNIT ADJUSTMENT (75 – 90 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

TRIM TAB ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

DUAL-OUTBOARD ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

OPERATIONAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

ENGINE FLUSHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

RUNNING THE OUTBOARD USING A HOSE AND FLUSHING ADAPTER . . . . . . . . . . . . . . . . . . . . . . . . . . .36

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

STEERING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

TILLER HANDLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

SWIVEL BRACKET AND TRAILERING BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

TILT TUBE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

THROTTLE AND SHIFT LINKAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

PROPELLER SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

GEARCASE LUBRICANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

TRIM AND TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

SPARK PLUGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

INDEXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

FUEL AND OIL SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

OIL FILTERS AND OIL RESERVOIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

AIR SILENCER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

HOSES AND CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

ANTI-CORROSION PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

FUEL SYSTEM TREATMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

INTERNAL ENGINE TREATMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

ADDITIONAL RECOMMENDATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

PRE-SEASON SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

SUBMERGED ENGINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

16

ROUTINE SERVICE

INSPECTION AND MAINTENANCE SCHEDULE

INSPECTION AND MAINTENANCE SCHEDULE

Routine inspection and maintenance is necessary to prolong outboard life. The following chart provides

guidelines for inspection and maintenance to be performed by an authorized Dealer.

IMPORTANT: Outboards used in rental, commercial, or other high hour applications require more fre-

quent inspections and maintenance. Adjust schedule for operating and environmental conditions.

Description

Engine

Care

Product Routine

Inspection

Every 300 hours

or every three

years (1)

(1) Average recreational use. Commercial use, heavy use, or use in salt or polluted water requires more frequent inspection and maintenance.

Engine Monitor self-test and warning horn, check

Emergency stop circuit and lanyard, check operation

Controls, steering and tilting; check operation

Engine mounting hardware, re-tighten (40 ft. lbs.)

Fasteners, tighten any loosened components

Water intake screens, check condition

Cooling system; check water pump indicator / water pressure

Anticorrosion anodes, check condition

Gearcase, check condition

Propeller, check condition

Fuel and oil systems, inspect and repair leaks (2)

(2) Emission-related component

Check battery connections and condition

Access EMM information, resolve any service codes

Electrical and ignition wires, inspect for wear or chafing

Fuel filter, replace

Oil filters, replace

Gearcase lubricant, replace A

Spark plugs, inspect or replace (2)

Thermostats, inspect and check operation (2)

Grease fittings, lubricate (3)

(3) Annually in salt water applications

C

Power trim/tilt and fluid level, inspect B

Propeller shaft splines, inspect and lubricate (3) C

Starter pinion shaft, inspect and lubricate (3) D

Control cables, inspect and adjust

Steering cable, inspect and lubricate C

Water pump, inspect / replace (more often if water pressure loss or overheating occurs)

AHPF Pro Gearcase Lubricant

B Power Trim/Tilt Fluid (Three ram hydraulic systems)

Biodegradeable TNT Fluid (Single ram hydraulic systems)

CTriple-Guard Grease

D Starter Bendix Lube Only

17

ROUTINE SERVICE

LIFTING THE OUTBOARD

2

LIFTING THE

OUTBOARD

Use correct Lifting Fixture to lift outboard:

With re coil st arter re moved, Place lif ting t ool on

flywheel and se at the three screws completely.

Refer to RECOIL STARTER REMOVAL on

p. 363.

Use only the 1 1/8 in. (short)

screws, P/N 398067, included with the tool to

avoid damage to electronic components under

the flywheel.

Fasten appropriate chain hoo k to eye of too l.

Carefully hoist outboard with chain and unbolt out-

board mounting brackets from frame.

OUTBOARD RIGGING

CONNECTIONS

IMPORTANT: For complete outboard riggin g

and remote control installation information, refer to

the Predelivery and Installation Guide included

with the service manual set.

Common Practices – All Models

Control Cable Identification

IMPORTANT: Identify con trol ca ble fun ction

before rigging outboard.

Identify each control cable:

•Put the co ntrol handle into NEUTRAL positio n.

The throttle cable casing guide will retract com-

pletely and the shift cable casing guide will go to

the midpoint of its travel.

Extend the control cables and lubricate them with

Triple-Guard grease.

AWARNING

To avoid personal injury, make sure the lift-

ing capacity of the hoist is at least twice

the weight of the outboard.

DO NOT allow the lift hook or chain from

the hoist to come in contact with any part

of the engine during lifting.

Model Lifting Fixture

40–90 HP P/N 396748 with

1 1/8 in. screws

1. Lifting fixture

2. 1 1/8 in. screws 002098

2

1

NOTICE

1. Shift cable casing guide extended to midpoint

2. Throttle cable casing guide retracted DP0811

30501

1

2

18

ROUTINE SERVICE

OUTBOARD RIGGING CONNECTIONS

Cable Retainer Clip Installation

When installing retainer clips on control arm lin k-

age pins, clips should be locked and must not be

bent or deformed.

For proper installation, review the following steps:

•Place washer on pin.

•Position retainer clip with straight section on the

bottom and angled section on the top.

•Use long nose pliers to insert straight section of

clip into linkage pin hole.

•Push th e clip toward s t he h ole while li fting on

the curved end with the pliers.

•Be sure retainer clip fully engages the pin.

•Lock the retainer by moving the an gled section

behind the straight section.

Cable, Hose, and Wire Routing

Refer to Control Cable Identification on p. 17.

Apply soapy water to the inside surfaces of grom-

met and install cables and fuel line as shown:

Place the g rommet int o position in the lower

engine cover.

When g rommet is in p lace and all cables have

been installed, tighten a tie strap around the out-

side of the gromme t to form a watertight sea l

around the cables.

1. Straight section

2. Angled section DP0818

DP0817

Locked Retainer Clip

1. Angled section behind straight section DP0817a

1

2

1

ACAUTION

To prevent accidental starting while servic-

ing, disconnect the battery cables at the

battery. Twist and remove all spark plug

leads.

1. Throttle cable

2. Shift cable

3. Main wiring harness

4. Battery cable

5. Fuel line

001998

002104

3

4

5

1

2

This manual suits for next models

5

Table of contents

Other Evinrude Engine manuals

Popular Engine manuals by other brands

Nice

Nice RMKIT AXS 3017 Instructions and warnings for installation and use

WÜRGES

WÜRGES HV operating instructions

Beckhoff

Beckhoff AL2009 Operation manual

Lister Petter

Lister Petter ALPHA LPW2 Operator's handbook

Hägglunds

Hägglunds Compact CBP Series Installation and maintenance manual

Graco

Graco SaniForce A Series Instructions - parts