Evinrude 25 HP Owner's manual

1976

DtunER·s-OPERRTOR·s

~~~~~~~

mRnURL

25

HP

models

~~

25602

25603

25652

25653

EVInRUDEE

first in

outboards

welcomes

you

aboard . . .

Outboard

boating

is

one

of

Amencan's

most

popular

participa-

tion

!>ports.

When

you

selected Evinrude,

you

selected a

product

that

has

gained a

reputation

a!>

the

qualttV leader stnce 1909

And,

there

ts

no

doubt

that

this year's

outboards

are

the

fmest ever

produ~d.

Your new Evinrude

outboard

has all

the

most

wanted

features

in

outboard motors. Some of these features, such as qualtty of

workmanship, engmeering excellence, whisper

qwet

operatton,

and dependability, have long been standards at Evmrude. Your

new Evinrude boasts

many

new features

wh1le

retaining

the

best

features developed

in

preceding years. These features,

the

old and

the

new, are designed

to

enhance

your

boating pleasure and add

to

your satisfaction in selecting Evinrude.

Your

new

Evinrude Motor

is

designed and

constructed

to give

you

the

maximum in service and performance. Please

study

th1s

manual so

that

you

Will

have a complete understanding

of

1ts

operation and

to

be able

to

take

full advantage

of

its many

built-in features. EVERYONE

WHO

USES THIS EQUIPMENT

SHOULD READ THIS MANUAL AND

BE

FAMILIAR WITH

THE SAFETY WARNINGS MARKED A .

This manual

is

dedicated as a mariner's companion to help more

fully

enjoy

the

sport

in

comfort

and safety.

For

quick reference,

keep

it

handY when operatong

your

outboard.

HAPPY BOATING

EVInRUDE

r=

MoToRs

TABLE OF CONTENTS

PAGE PAGE

ADJUSTMENTS

. . . . . . . . .

23

Propeller and

Dr

ive

Prn

Tilt

Fnct1on

Adjustment

. . . . . . . 23 Replacement . . . . . . . .

.....

.

25

Steering

Fnction

Adjustment

. 23

Lubn

c

at10n

. . . . . . . . . . . . . .

26

-27

Idle Speed

Adjustment

. . . . . .

24

Propell

er

Care . . . . .. . .. . . . 28

Carburetor

Adjustment

. . .

...

24

Cleanmg Fuel Pump Filter . .

28

EVINRUDE DEALER SERVICE . . . 34

Cond

itiOn

of

Boat

Bottom

28

20

Hour

Check

. ... . . . . . . 34 External Ftntsh . . . . .. . .. ..

28

Repair Serv1ce . . . . . . . .. . . . . .

34

Off

Season Storage 29-30

t P t 34 After

Stonng

-Before Usmg . . 30

Replacemen ar s . .

..

..

. . . .

FEATURES

..

.

..

· · · · · · ·

....

· · · · 4 6

Starboard

V1ew

. . .. . . . . . . . . . . . . 4 SAFETY · · · · · · · · ·

..

· · · · · ·

Port View .

..

........

. .

.. ..

· . · 5

SPECIFICATIONS

.

........

-. . - 6

FUEL AND

LUBRICANT

. . . . . . . 12

Model

and Senal

Number

..

.

..

6

Recommended

Lubricant

..

...

12 STARTING

AND

OPERATION . .

14

Recommended Gasoline . . .

...

12 Fuel

Tank

14

Fuel

Mixture

. . . . . . . . . . . .

...

13 Manual Starttng . . . . . . . . . . 14-16

Fuel Mtxing Instructions

......

13

Shifting

. . . . .

....

.

........

17

Break-in Procedure . . .

...

. · · 13 Speed

Control

17

INSTALLATION INSTRUCTIONS

..

8

Stopping

(Manual Start) . 17

Transom

Height

. . . . . . . . . . . . . . 8 Electric Starting wtth OMC

Propeller Selectton . . . . . . . . . . 8

Two

Lever Remote

Control

18

Lifting and

Carrying

Motor

. . . . 8

How

to Shift and Control

Installing

Motor

. . ..

......

. 8-9 Speed

with

OMC

Two

Installation

of

Electncal Lever Remote Control 19

Equipment . . .. . . . . . . . . . . .. 9 Stopping (Electric Start) 19

Battery and Battery

Box

Removmg

Motor

Cover

......

19

(not

supplied

with

motor)

...

9 Emergency Starttng

..

. . .

...

20

Replacement Keys . . . . . . . . . . . 9 Trailenng . . .

21

Remote Controls (Accessory) 9-10 Trouble Check Chart . . . . . . .

21

Remote Steenng (Accessory) . 10 Coolmg System . . . . . . . 22

Remote Control Cables Shallow Water Operation . . . . 22

(not supplied wtth motor)

...

10 Fuel Economy . . . . . . . . . . 22

Removing

Motor

from Boat 10 Operating m Weedy Water . . . 22

Reverse Lock . . . . . . 10 Salt Water OperatiOn . . . .. 22

Tiltmg . . . .. . .. 10 Operattng

tn

Freezing

Motor

Angle Adjustment

11

Weather . . . . .. . 22

Boat Trim

11

Antt-Corrosion Protection .. .. .

22

ITEMS OF SPECIAL SUBMERGED MOTOR

..

..

. 30

IMPORTANCE . . . . 7

Motor

Dropped Overboard

Boatmg Responsibtlittes 7 (not runntng) . 30-31

Owner's Regtstratton Card 7

Motor

Dropped Overboard

Changes in Address

and/or

(runmng) . . . . . .

....

. .

31

Ownership 7

Motor

Dropped Overboard

Insurance . . .

...

. .

...

· · · · · 7

(m

salt water)

.......

31

Stolen Motors

..

....

..

...

.· 7 Prolonged Submerston

MAINTENANCE . . . . . . .

25

(fresh

or

salt water) . . . . . . .

31

Spark Plug Inspection WARRANTY . . . . . . . . . . . . .

..

32

and Replacement . .

......

25

WARRANTY SERVICE . . . 33

OUTBOARD MARINE CORPORATION 1975

ALL

RIGHTS RESERVED

3

FEATURES

3----

1 Shift Lever

2

Tilt

Fnct1on Nut

3. Angle AdJuattng Rod

4 Water Pump (Under

Houalng)

5. Water Intake

6. Otl Oratn/FIII Plug

7

Sktg

8

011

Level Plug

9 Stern Brackets

10

Clamp Screwa

ELECTRIC

START

40

31

41

PANEl

UStD

Willi

El rCTr

li

C

MODL t S

ONLY

STARBOARD

VlaW

11 Reverse Lock Lever

12

. Steenng Bracket

(Remote Control)

& Carrying Handle

13

. Electric Cable Plug

(Electric Start)

Stop

Button

Locatton

(Manual Start)

14.

Low

Speed

Adjusting

Knob

1b

Ctwk

Knob

16

Stort r Grip

17

Fuol

ltn

o

18 F

ll

I 1 nk

19

PrulllllQ

Outb

20

Ortlln 'crow

21

1-'11

I G

wg

22

H ndl(

23 Ftllt r C P

24

25

28

.

27

28

29

30

MANUAL

START

PORT

VIEW

.32

• l

~4

35

5

SAFETY

·~

~___...,....,..

l'TO·

-.~-~~

~~:

,':';

·_'

-_·

~

:....:.

0

IIOTa:

AdY

ses

you

of

mformatton

or

instructions

vttal ro the operat,on or

~

enance ot your eqwpment.

SPECIFICATIONS

Mooe 25602,

Ma

al

-25652

Electr

c Sta"ldard Leng

th

Odes

25603.

Manua -25653 Electr c

Lorg

S aft

Powernead Two Cyttnder -

Two

Cycle

Alternate F.r ng

Bore

ar'ld

S roke 2

50

x 2.

25

P on 0 sp acement 22 Cub1c Inch

es

Horsepower 25.0 y Certified Brake Horsepower at 5500

RPM

Fu I Speed

Operattng

Range

---------

5000

to

6000

RPM

lg

tJOn

Low

Tensi

on

Aag

neto

Brea er Gap

~

1

~

_ 020

Sperl( Pfug

lU

(

Ll

~~(

1 a

1

~~J..:......~.!.&'-

Champ1on

J4J

Spark P ug Gap 030"

Sper1t

Plug Torque 17-1/2

to

2Q-1

2 ft.-l

bS

Cooftng System Water Pump -

Pos•t111e

and Centnfugal -Thermostat

Carburetor

----

Frlled High Speed, Adjustable

Low

Speed Jet -Choke

Geer

stUft Forward -Neutral -

Re

erse

Gear

RatiO

12

.

21

Gearcase

lubncant

Capacrty 8.3 ozs. (246 cc

.)

Speed Control Twist

Gnp

Throttle

(Remote

Control

OptiOnal)

Propefler 3 Blade.

9"

d1a

x

10

· P1tch

OptiOnal Propellers

-------

3 Blade, Weedless

9"

d1a

x 10''

P1tch

3 Blade, 9

d1a

x 9

P1tch

Fuel Capacity 6 U.S.

or

5 lmpenal gallon tank

Trantom

He~ght

-Standard Length

---------

14-1/2 to 15-1/2

long

Shaft

---------

19-112

to

2Q-112

"

Weight without fuel tank

Modef

25602

•

85

lba.

------------

Model 25603 -

87

lbs

Model

2.5652

-

95

tbl.

-------------

Model 25653 -

97

tbs.

Fuef

Tank (Empty}

------------------

11

lbs

EVI

RUDE MOTORS reserves the

nght

to

changeweight. constructton,matenals,

specifiCatJOnJ

or

pnce without notice and w1thout obllgat•on

IIODEL AND

II!IUAL

NUMBER

The model and serial number

are stamped

on

a nameplate

attached to the stern bracket

port

Side

Model Number Serial Number

6

ITEMS

OF

SPECIAL

I

POR

TANCE

BOATING

RESPONSIB

ILITI

ES

T e

ope~ator

s

'espo

s

o-e

4

0•

•~e

CO'

e::· o:>era

~

~

.

sa•ety

of

ts occupa"•s

8e

s~·e

·~a

a op::r

a·3·s

.rea~

•

opera

rg

boat S o 1o r

pass~rgers

....

e

xa

o a C

--~

c

~

-;;

';'="

J'

eqlJ·pmel"• Instruct

ore

of

yovr

;::asse"'g<a

s

-0"'~;

·~

a'~

e

Ow'

......

a•

-case:;

erT'ergePcy 0 S

Coas~

Guard

reQ

...

·e

....

e-•s

•o·

i)ۥsv:

.a

...

depend. g on

-e

1/pe

of

ooat

Be

s~'~

·o

cc~i:o

i •

regu1at

Of'

N

c.

app

es

:o

iO-'

bt)al.

Leam

t>e

Naterway

rues

of

• e oca

t/

;

OJ

bOa

a1•gan e v.atecwc.ys are CO'"''ro e<l ':Ff Feas a

Before ooat

"9

ob

a o : e .,,ez·ner fore::.as·

'o•

,

=--

a

s.a

fa

w1tl'l ttle

-Neat

er o"'reau

~ta•"

"9

s

y

sts~

s

~"a

a

...

-.:

a:e

.....

ay

·cu

fT'a

1on

Contact

yo"r

oca

u"

tee S a•es Ccas· G

...

a•c

......

a,..,

-a,

e

-o

a

•a.ge

:.

t

e1r

seasor~a.

ooat nspect o s arc! sa•e y c asses

OWNER'S

REGISTRATION

CARD

Always carry

yoL>r

Owl"er

s Reg s•rati

O"

Cara

CHANGE

IN

ADDRESS

AND/OR

OW

NERSH

IP

Under t e Federal Boat Safety Act ct\a ges accre:.s a

to

be

reported

to

the manufac rer. A torm s

pro

eo ·

li

• e o :-er-s

ong•nal purchaser Forms for h s p rpose are a so a a ao e • om

oc·

DS

~ER

or

Ev•nrude

Motors

INSURANCE

Insurance

Ofl

your O.Jtboard motor and

or

boats

o Ia be

proc

red

as

soc

"S

pract1cable for protection against

Joss

by

fire

·~e•t

e c.

'r

•e

•o 0 1ooa·c Boat g

Club

of

Amenca,

401

North

M ch1gan Avenue Ch cago l

lli

no1s

606

..

•o~

•

u

~

er

deta•ls.

or

consult

your

local insurance agent

STOLEN

MOTORS

In case of theft report Model and Senal

Number

to

local

a •

or

•res, i s

'&""~

agent and the manufacturer.

7

TRANSOM HEIGHT . .

The proper transom (verttcal) height tor the Standard Length Model

ts

14-1/2

to lS-1/2" The proper transom (vertical) hetght

for

the

L~ng

Shaft

~ode!

is

19-

1/2 to 20-1/2". If the transom is too high. the propeller wtll operate

1~

turbulent

water with lowered effictency. Overheatmg may result.

If

the transom

ts

too

low,

excess1

ve

drag may result and your boat will not perform

properly

.

D

NOTE:

We

recommendusmg an accessory transom plate to

protect

your

boat

and help prevent loss of motor See

your

Dealer.

PROPELLER SELECTION

Your motor is equtpped with a propeller that will perform satisfactorily under

average condttions. However, since some boats have avarying speed potential, it may

be

necessary to install a propeller having

an

increased

or

decreased blade pitch to

achieve maxtmum performance.

When

operating yourmotor

at

full throttle undernormal load

conditions

the engine

RPM

is

the controlling factor 10 determining the correct propeller blade pitch foryour

rig.

To

obtam peak performance. the engme

RPM

under these operating conditions

should

be

tn

the upper half of the FULL SPEED

RPM

OPERATING RANGE. (See

SPECIFICATIONS.) If the engine

RPM

is

on

the low side

of

the recommended range,

install a propeller of reduced pitch and the engine

RPM

will increase.

If

the engine

RPM

ts

above recommended

RPM,

install a propeller

of

an

increased pitch to reduce

engine

RPM.

See

your DEALER.

It

1s

suggested that a tachometer

be

uttlized to accurately check engine

RPM

.

See

your DEALER.

He

will

be

pleased to assist you

in

obtaining maxtmum performance

from your boat and motor.

LiniNG

AND CARRYING MOTOR

A handle. located at the balance

pomt of your motor, is a conventent

grip

to

use

for carrymg. To lift your

motor from boat or motor stand, use

the

carrymg handle and lower motor

co11er

at

the rear.

DO

NOT use the tilt

gnp

on

the

motor cover for lifting or

carrymg

INSTALLING MOTOR

A

1 Carrying

2.

Rear Lower

Motor

Cover

Handle 3.

Tilt

Grip

When

mountmg the mot

th

. .

ttlted

POSltton

bet

If

. or on e boat

tn

shallow water, place stern bracket

tn

f~ll

sand or

Stlt,

ore 1

ttng motoronto transom.Thts will avoid dragging propeller

tn

8

..

0

CLAMP

SCREWS.

Center

motor

on transom before

ttghtening

clamp

screws.

Turn

clamp

screws

ttght

,

tighten

again

after

15

mmutes

of

operation.

Do

not

use

tools

to

tighten

clamp

screws

A

SAFETY

CHAIN

AND

V

TRANSOM

PLATE

.

To

prevent loss

of

motor

over-

board, we

recommend

se-

curing

motor

to

boat

with

a

safety

chain

and

transom

plate

(not

supplied

with

motor).

INSTALLATION

OF

ELECTRICAL

EQUIPMENT

-

(ELECTRIC

START)

We recommend

your

dealer

make

the

electrical

installation

_

for

you.

Should

you desire

to

do

this

yourself,

the

kit

inclu?ed

with

your

motor

IS

complete

With

detailed

instructions

for

installation. These rnstruct1ons

must

be

followed

exactly

in

order

to

insure

proper

operation

of

the

electrical

system

.

The

motor

may be

manually

started

and

operated

without

a

battery

BATTERY

AND

BATTERY

BOX

(Not

supplied

with

motor)

We recommend a 12

volt

battery

with

a

70

ampere

hour

ratmg,

or

better,

and

a

minimum

of

2.0

minutes

cold

starting

capacity

at

300

amperes

discharge,

zero

degrees

fahrenheit

and a 10 second

voltage

rating

of

7.5 volts.

Battery

should

be

installed in a

battery

box

and secured

to

the

boat.

A

aAPaTY

WARNING: BATTERY ELECTROLYTE IS

AN

ACIDIC

~

SOLUTION AND SHOULD BE HANDLED WITH CARE. IF ELECTROLYTE

IS SPILLED OR SPLASHED

ON

ANY

PART

OF

THE

BODY,

IMMEDlATELY FLUSH THE EXPOSED AREA WITH LIBERAL AMOUNTS

OF

WATER

AND OBTAIN MEDICAL AID

AS

SOON

AS

POSSIBL

__

E

.~-

·

·

-~~-----'

~NOTE:

Connecting

the cables to the

battery

should

be

the

last

step

in

your

&l...J

msta/latJon. BE SURE

NEGATIVE

(-)

BATTERY

CABLE,

(BLACK).

IS

SECURELY

ATTACHED

TO

NEGATIVE

TERMINAL

ON

BATTERY

AND

POSITIVE

(+)

BATTERY

CABLE, (REO), IS

SECURELY

A

TTACHEO

TO

POSITIVE TERMINAL

ON

BATTERY

.

All accessories (except as rndicated in

OMC

InstallatiOn

Instructions)

SHOULD

BE PROPERLY FUSED and

connected

DIRECTLY

TO

BATTERY

REPLACEMENT

KEYS

(ELECTRIC

STAAT)

For replacement keys, send key

number. stamped on face

of

ignition

sw1tch, and $1.00 for each key,

mmtmum

two

key order,

to

Stevens

Experimental

Co

, 111

Greenwood

Avenue, P 0 . Box 193, Waukegan,

Illinois 60085

REMOTECONTROLS(ACCESSORY)

KEY

NO

.

Your

motor

is destgned

for

operat1on

with

remote

controls

availabl•~

as an

ac

·

cessory. Properly mstalled and

mamtamed

remoto

controls

will

provtd

smoothly

operating

throttle

and

gearshift

levers

REMOTE CONTROL CABLES

(Not

aupplied

with

motor)

The Control Cables are

an

essential link between the

motor

and the control lever

and should

be

selected wisely.

We

strongly recommend that you

u~e

OMC control

cables or cables of equal quality. OMC cables have annealed core

w1re

ends, sealed

cable ends

and

lifetime lubrication. If you do not use OMC cables make sure the

brand

sele~ted

has

all three of these important features.

A

l1AVE

ANNEALED CORE WIRE ENDS

Ja

1Je$Ul,.T

l,_.

THE

REMOTE CONTROL

REMOVING MOTOR FROM BOAT

Disconnect electric cables from battery and

motor

(ELECTRIC START

MODEL). safety chain and fuel line. Loosen the clamp screws.

Lift

motor vertically

from boat. To lift your motor, use the carrying handle and the lower motor cover

at

the rear.

DO

NOT use the tilt grip on the motor cover

for

lifting or carrying.

See

LIFTING AND CARRYING MOTOR.

~

NOTE: Do not place motor in a position where the

lower

unit

will

be higher

~

than the powerhead.

Any

water remainmg in the exhausttube

may

run into the

cylinder and cause senous damage.

REVERSE

LOCK

During

normal

operation

the

REVERSE

LOCK should

be

in LOCK

position.

The

RELEASE

position

is

used

ONLY

when

tilting the motor. or

operatrng m shallow or obstructed

waters.

The

REVERSE

LOCK,when in LOCK

position, will release when the motor

strikes

an

underwater object while

traveling forward at a moderate speed.

TtLTtiiQ

To tilt motor, move reverse lock to

RELEASE

position, grasp tilt grip at

rear

of motor cover and pull motor

toward you.

DO

NOT TILT MOTOR BY

PUSHING DOWN ON STEERING

HANDLE.

10

OAOUTOFWATER.ORIN

~Q.AS

IT

WILL

RESULTIN

I

TOO

HIGH

RPM, AND

MOTOR

ANGLE

ADJUSTMENT

The stern bracket has four

pos1t1ons

for

adjustmg the

motor

to

alto~

for transom

an

le and boat loading.The vert1cal angle of

motor

on boat

must

be

adJUS!ed

for best

pe~ormance

.

In most instances. the ':1otor will be

1n

proper

adJustment

1f

the angle

adjustment rod is m the second

pos1t1on

from the boat

Motor

should

be

perpendicular to water when boat

IS

underway

Th1s

adjustment

can only be determined

by

observing boat operatiOn at

full

sp~ed

Set

an~le

adJust-

ment for your usual load. Angle adjustment

should

be

changed

tf boatloadtng results

in improper

motor

angle.

Adjust motor angle

as

follows

1. Stop motor RELEASED

POSITION

LOCKED

POSITION

2.

Set

reverse

lock

1n

RELEASE

position.

3.

Tilt motor up.

4. Turn tilt adjusting rod up and press

in against spring to release retainer.

Remove rod from stern brackets.

Place rod in desired position. Turn

rod down and press in to allow

retainer to lock. Make sure rod

retainer drops into lock position.

5.

Move motor back against rod and

place reverse lock in LOCK position

so motor is perpendicular to water

when boat is under way.

ROD UP

RETAINER

RELEASED

ROD

DOWN

RETAINER

DOWN

A

UnTY

WARNING:

IF

THE

LOWER

UNIT

IS

TIL

TEO

TOO

FAR

~

FORWARD,

THE

BOW

WILL

DIG,

WHICH

IS

DANGEROUS

WHEN

IN

ROUGH WATER WITH A FOLLOWING SEA OR

IF

TIL

TEO

TOO

FAR

AFT

PORPOISING CREATED MAY

CAUSE

HAZARDOUS

STEERING. SEE

CQRFtECT ANGLE AOJUSTMEN!Jhb..USTRATION.

INCORRECT

CAUSES

BOAT

TO "PLOW"

BOAT

TRIM

....

..

.

INCORRECT

CAUSES

BOAT

TO

"SQUAT"

..

.

CORRECT

GIVES

MAXIMUM

PERFORMANCE

For best boatand

motor

performance, the boat should be driven as

nearly

parallel

to the water

as

possible. Passengers and equipment should be

so

distributed

in

the

boat that it is evenly balanced both

front

to

rear and side to

s1de

.

~

-

::;~;.!=

~

:;::::=s~~

INCORRECT

INCORRECT

OVERLOAD FORWARD OVERLOAD AFT

CAUSES

BOAT

CAUSES

BOAT

TO

"PLOW"

TO

"SQUAT"

11

~

,

......

-

~

·~L~

CORRECT

BALANCED

LOAD

GIVES

MAXIMUM

PERFORMANCE

FUEL AND LUBRICANT

ThiS

isa two cycle engme that requires

lubricant

to

be m1xed

w1th

gasolme Follow

these instructions.

0 NOTE: Recommended lubricant and gasoline

must

be

properly

mixed

or

sarrous damage

wt/1

result to the engme.

RECOMMENDED

LUBRICANT

Use

EVINRUDE LUBRICANT

(m

Canada use

OMC

two

cycle

motor

oil)

wh1ch

is

BIAcert1

fted

for

service TC-W

(Two

Cycle-Water

Cooled)

It

1s

formulated

to

g1ve

best

engme performance with least combustion chamber deposits, least piston varnish,

maximum spark plug

l1fe,

and best lubrication EVINRUDE

LUBRICANT

can

be

purchased from your DEALER in the following packages·

~--------------------------~

Smgle pmt cans (enough for

6 U.S. gallons

(5

Imperial)

of gasoline) .. ... .

..............

.

S1x-Pack of pmt cans

Case of 4 six-packs or

total of

24

pints

.................

.

Always keep

an

ample supply on hand. Do not settle

for

less than the BEST Other

addit1ves

such

as

"tune-ups." "tonics," "friction reducing

compounds,"

etc. are un-

necessaryand should notbe used inyourengine,except

as

described in thismanual.

If

EVINRUDE LUBRICANT

Is

not available, another

BIA

certified TC-W or

rc-2

lubricant (oil) may

be

used.

r;;;l

NOTI!:

Avotd the

use

of

the fo/lowmg,

as

they

wt/1

contnbute

to detenoration

t=l

of

your eng

me

and shorten spark plug Ide:

AVOID USE OF:

• Automotive oils

• Premix fuel of unknown oil

quality

• Premix fuel richer than

50:1

ratio

MCOIIIIDDI!D

GASOLINE

Use

gasoltne with the following minimum octane numbers:

PUMP POSTED OCTANE NUMBER 86

Research Octane

Number

Most

Commonly

Used

an

the Past

91

Automotive

guotines

regular-leaded

or

lead-free meeting these m1mmum

octaAe

numbers may

be

uaed; however, best results will be obtained on 40 hp and

under by ualng lead-free gasoline.

L,AMMABLE AND

ALWAYS STOP

PLAMES

OR

SPARK

fUEL

TANKS.

1101'1&

When

operating in any other

country

than the Umted States. Canada

or

AultraJ;-. any

gao/me

may be used whtch

will

sattsfactonly operate an

eutomobil•

eng~,.

FUEL

MIXTURE

1 part approved

lubncant

to

50

parts

gasoline

(3

Gal Tank) 1/2

pmt

lubncant

to 3

gallons

(2-1

/2

lmpenal)

of

gasoltne

(6

Gal Tank) 1 pmt

lubncant

to 6

qallons

(5 Imperial)

of

gasoline

.

FUEL

MIXING

INSTRUCTIONS

Fuel

mixmg

1nstruct1ons

for

EVINRUDE

LUBRICANT

or

other

BIA

cert1f1ed

TC-W

lubncants

:

A

SAFETY

WARNING:

TO

PREVENT

SPILLING

FUEL

IN

BOAT

REMOVE

~PORTABLE

FUEL

TANK

WHEN

REFUELING.

GASOLINE

IS

HIGHLY

FLAMMABLE

• ALWAYS

MIX

IN

WELL

VENTILATED

AREA

Always use fresh gasoline.

PORTABLE TANK

ABOVE 32°F

FUEL NOZZLE

,..._

__

MUST

CONTACT

METAL FUNNEL

BUILT-IN

TANK

Portable Tank -

Pour

lubricant

into

tank, add

gasoline

Replace f1ller

cap

secure

ly.

To

m1x

fuel,

t1p

tank

on

s1de

as

shown and back

to

upright

posttton

Bu1lt-in Tank -Use large funnel with a fine mesh

stramer

(100 mesh

or

fmer).

Pour

lubncant

slowly with the gasolme

as

tank is filled.

BELOW 32°F

Portable Tank -Pour

approximately

one

gallon

gasolme

tnto tank,

add

reqUired

lubncant. Replace filler cap securely.

Thoroughly

mtx

by

shaking

tan.

Add

balance

of

gasol1ne.

Built-In Tank -In separate

container

m1x

all

lubncant

needed wtth

one

gallon

or

more

of

gasoline Use large funnel with a fine mesh strainer (100

mesh

or

tmeq

Pour

th1s

mixture

slowly

w1th

gasoline as tank tS

filled

.

BREAK-~

PROCEDURE

The

50

:1

mixture

is used

during

break-tn. Use

only

EVINRUDE

LUBRICANT

or

other BlA certified

TC-W

lubncants.

OPERATION (FIRST HOUR). Do

not

operate engine

at

contmuous

full

power

tor

the first

hour

of

operation After

15

mmutes

of

slow

to

half

throttle

operation,

we

recommend a short burst

of

full throttle operatton every 5 to

10

mtnutes. Run at

full

throttle for about 90 seconds, then return

to

half

throttle

or

less

D NOTE: Frequently check operatton

of

coolmg

system

dunng

break-:n A tme

spray

of

water dtscharged from exhaust relief

outlet

tnd

tcates

proper

operatton.

OPERATION (SECOND HOUR).

Bnng

boat

tnto

planmg

attitude

and reduce

power to three-quarter throttle (approximate)

while

mamtaming

planmg

att

iiu

ae At

tntervals

dunng

the second hour. apply full

power

tor

perrods

of

one

to

two

mtnutes

return1ng throttle

to

origmal setttng -three-quarter

throttle

for a

coolmg

penod

'

Avoid continuous full

throttle

operation

tor

extended

penods

durrr g the next

three hours.

L-

----------------------------

~~

----------------------------L-------------------------------

13

STARTING AND OPERATION

FUEL TANK

Place fuel tank in boat so tank

w11l

not

sh1ft

around Be sure fuel line 1

s not

wedged under tank. Allow fuel line slack to permit steenng

MANUAL

STARTING

Q

s11de

fuel lme connectors onto motor and tank couplmgs until locking lever

snaps mto postl•on (PRIMER BULB AT TANK).

To

disconnect fuel line depress, locking lever on fuel lme connector and pull

off

at motor

or

fuel tank.

esqueeze fuel line primer bulb several times until resistance is felt.

8

14

OTurn throttle grip to SHI T pos

1t1on

8 Move shift lever to NEUTRAL position

Motor

can be started ONLY

111

NEUTRAL shift

pOSitiOn

8

EVInRUDEZS

eTurn throttle grip

to

START position.

0 Set reverse lock lever in LOCK

position

.

15

STARTING

AND

OPERATION

MANUAL

STARTING (CONTINUED)

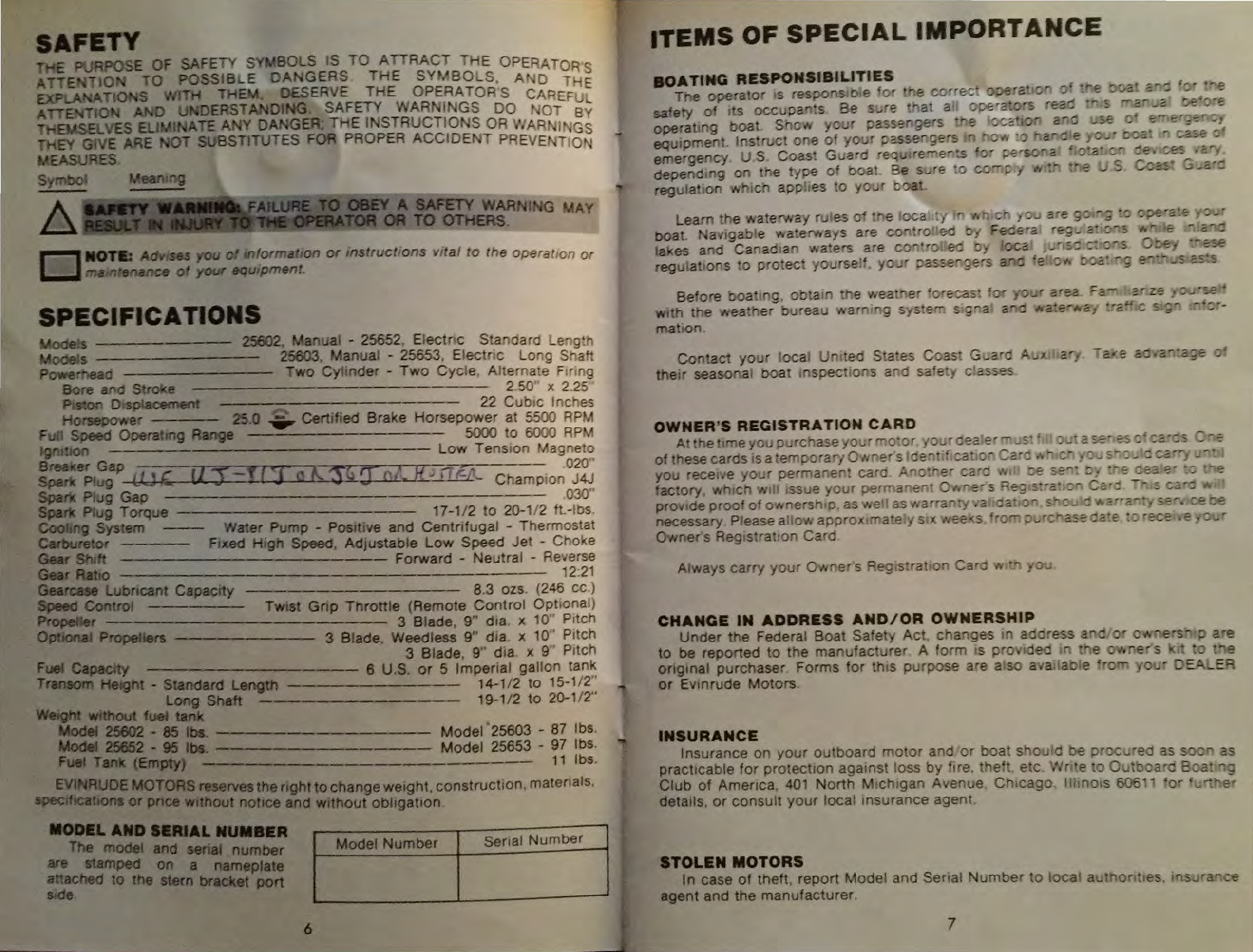

0 Motor -Pull

chOJ..e

knob

all the

way

out

~~~~

Motor

_ Do not choke If

motor

fails to start

after

a few

pulls

on

the

starter handle, then use the chok.e.

D NOTE: A lock-out prevents starting

motor

in gear.

If

motor

will

not

crank,

reduce throttle to SHIFT positiOn and move shtft lever to NEUTRAL.

A

SAnTY

WARNIIIGt

ATTEMPTING TO MANUALLY START THE

~

JNE

WHILE

fN

GEAR

MAY DAMAGE PARTS OR CAUSE THE START

NSUTRAL

FfAnJRE

TO

BECOME INOPERATIVE. START ENGINE

SHJFT

LEVeR

lN.

NEUTRAL

POSITION.

""

~--

.ull

starter handle slowly until starter engages, then pull

forcibly

. Repeat.

1f

needed, until

motor

starts To prevent damage to starter assembly, allow

starter

cord

to

rewind before releasmg starter handle. When

motor

starts, push

choke m gradually until

motor

IS

runnmg smoothly. If

motor

does

not

start,

see

TROUBLE CHECK CHART.

Qcheck

to

see

that at least a ftne spray

of

water is

coming

out

of

the exhaust

rel1ef

outlets to assure proper water

pump

operat1on. See

COOLING

SYSTEM.

16

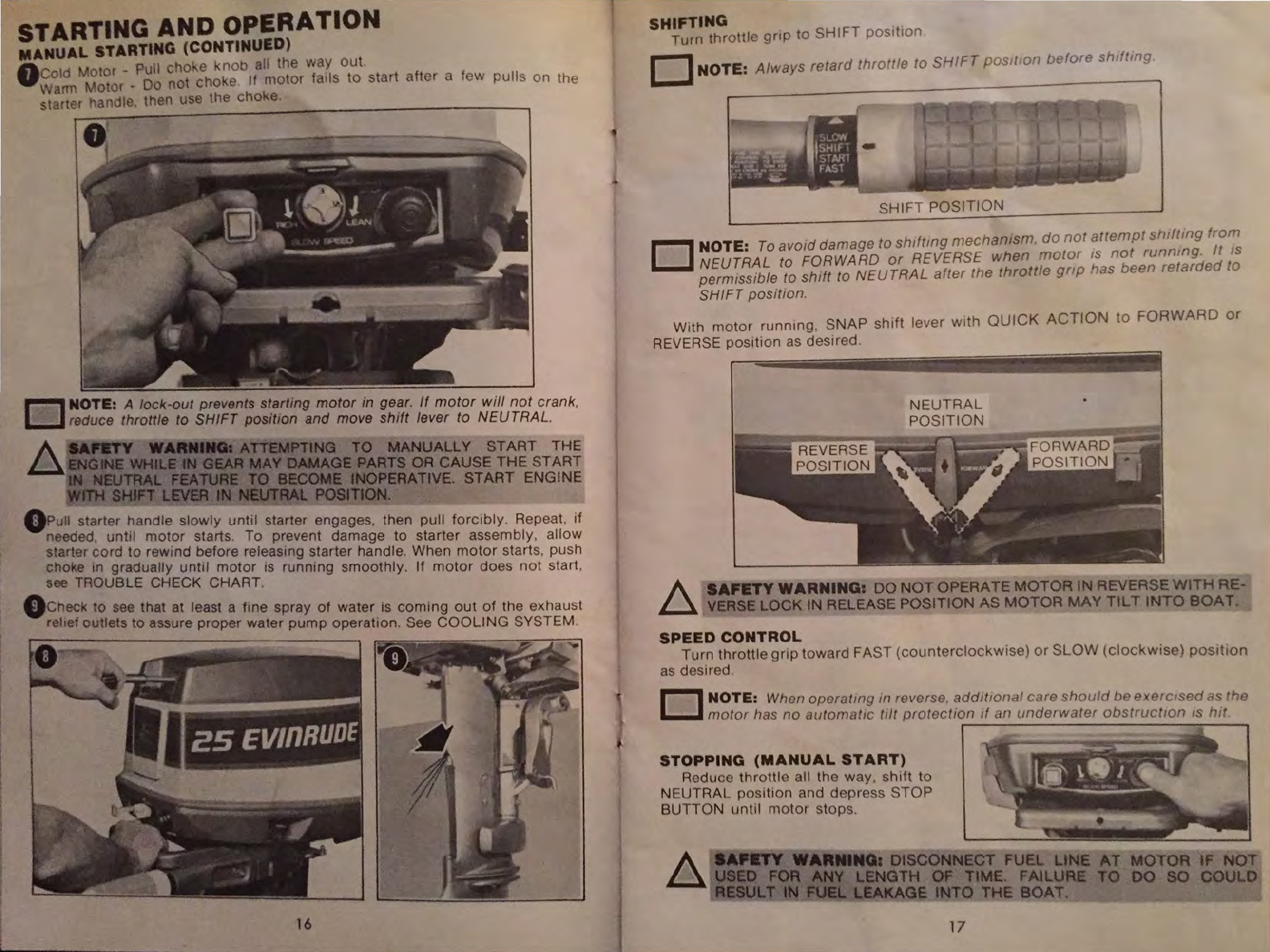

SHIFTING

. .

Turn

throttle

gnp

to

SHIFT

pos1t1on

0 NOTE:

Always

retard

throttle

to

SHIFT

p

osJ

tt

on

befo

re

shtft

in

g.

SHIFT

POSITION

0 NOTE:

To

avo1d damage to

shlftmg

mechan1sm.

do

not

attempt

shifting

from

NEUTRAL to FORWARD

or

REVERSE

when

motor

tS

not

runmng

.

It

IS

permtssible to shtft to NEUTRAL

after

the

throttle

gnp

has been

retarded

to

SHIFT posit1on.

With

motor

runnmg,

SNAP

shift

lever

with

QUICK

ACTION

to

FORWARD

or

REVERSE pOSition

as

des1red.

A

SAFETY

WARNING:

DO

NOTOPERATE MOTOR IN REVERSE WITH RE-

~

VERSE

LOCK IN RELEASE POSITION AS MOTOR

MAY

TILT

INTO

BOAT

.

SPEED

CONTROL

Turn

throttle

gnp

toward

FAST

(coun

t

erclockwise)

or

SLOW

(clockwise)

position

as

des1red

D NOTE: When operattng

tn

reverse. add1t10nal care

should

be

exercrsed

as the

motor

has

no

automattc

tilt

protectiOn tf an

underwater

obstructiOn

ts

l11t.

STOPPING

(MANUAL

START)

Reduce

throttle

all the

way

, sh1ft to

NEUTRAL

position

and depress

STOP

BUTTON

until

motor stops.

A

SAnTY

WARMING~

OISC.

ONNECT

FUEL LINE AT MOTOR IF NOT

~USED

FOR

ANV

LENGTH

OF

TIME. FAILURE

TO

00

SO

COULD

RESULT

IN

FUEL

LEAKAGE

INTO

THE

BOAT

.

17

- - '

·~.

. .

~

(

-#,

.'

...

-:.i~·

'

~

1;,

i..

~-,.>

't

'

.....

...,

ff

........

..,.,-

t.-

,..,_,..

moto1 covet'.

S..

REMOVING MOTOR COVER

U..

•

aJr

w...c::ft

to remowe.,..,..

ICtewt

attechmg

liNter.

Ute

a

518"

wrench to

~

~

~

....,.,...

loctwut

LeYer

Aaembly,

CautiOn -Lever

t&

........

MotOr

lhQll

d

be

toll

wj

c

nor

a ope•a+ g

Y.;t

~

A-::!1

• ';"..a!

rtJa1

~

eara!":~

can

be obt8 ned

by

p.ac

ng

an~

e alj, 1;9 roo

,:;

er

e•r.;

b·ac:t'~

pcx,

~#"

1

fl..,

constructu>n s

lJ

does

om

proYld€

811~

ate

c:

earar;-;e

~

'10~(

DEA\.£R

tor

()MC

acceHOrY

tr&

• g braclte1

' •

·,

..

~·{

• • ! ' •

,'".

...

/

' "

...

-:~~

. ' .

. .

.

.,.

;

·~

,.

' ' '

. . .

MOTOA

WILL

NOT

START, check for:

1,

Thfott..

grip

in

START

posit1on

and

thift

lever

in

NEUTRAL

position

2.

Fuel

in

tank

3.

Fuel

line

connector

property

attached

4. Fuel line

primer

bulb

at tank end

5 Carburetor primed (squeeze

pnmer

bulb)

8.

Fuel tank resttng

on

fuel lme

7.

Fuel hne clear and

not

kinked

8.

Cold

motor: Eng1ne

not

choked

sufficiently

8.

Warm motor: Engme over-choked

or

flooded (correct

by

pushing

in

choke knob, disconnect fuel hne at

motor, and cranking

until

cleared)

10. Fuel

pump

f1tter obstructed

11.

War

in fuel system

12.LooM

tpark

plug

leads

13.

Spark

plugs

carbooed, burned or

Wet

14

Incorrect

span

pfug

gap

(correct

gap IS

O.ooo")

15.

LOOM

sperk plugs, causing poor

compresston

(recommended

torque 17-112

to

20-1/2 ft.-lbs.}

18.

Recheck &tarting inetructtOM

MOTOR

WILL

NOT tOt.E PROPEALY

check

for:

1.

Carburetor

adjultment

tmpropetfy

set

2 Defective spatlt.

plugs

3

Improper

fue

m.xture

MOTOR

LOSES POWER

check

for.

1

Defectve

<Spark

p gs

2.

Fuel

pump

f

er

part1a 'I restriCted

or

fue

contam

'"'ated

3

Obs

ruct

on

at

wa~er

entake.

Coohng

system

not

operat

ng

properly

MOTOR VIBRATES EXCESSIVELY.

check

for

t Damaged

prope

'er

21

2

Carburetor

Improperly

adtusted

3 Loose

steer

og

fr

ct

on

screw

4 WeedS

on

prope

fer

MOTOR

RUNS, BUT MAKES

ITTLE

OR

0 PROGRESS

check

for.

1 Damaged

prope

er

2 Weeds

on

prope

ter

3 Sheared

dr

e

pm

If

th

1s

does

not

sofve prohterrl hen

contact

your

DEALER

STARTING AND OPERATION

COOLING SYSTEM

Water or cooling

1S

supplied by a water pump located above the gearcase. The

pump op rates

as

a diSplacement pump

at

low speeds

and

as

a centnfugal pump

at

h1gh

speeds.The thermostat maintatns consistent operating temperatures through-

out the entire range

of

motor operation. tncreasmg motor life and eftlc1ency.

~

NOTE:

For

contmuous

operatiOn m waters

contammg

excessive

amounts

of

&:.....I

:;nit,

sand

or

stlt, we

recommend

an

OMC

accessory

chrome

plated

water

pump

J(lt.

See

your

DEALER.

SHALLOW WATER OPERATION

Avoid operating in shallow waters. If necessary, proceed at slow speeds until

deeper water is reached.

The reverse lock is designed

to

release automatically from the LOCK position

if

an

obstruct1on

is

hit

wh1le

going forward at normal running speeds. The reverse

lock may not release from the LOCK pos1tion when runnmg

at

slow speed.

When

running

1n

shallow water, place the reverse lock in RELEASE position which

allows the motor to ''kick-up" more easily if

an

obstruction

is

hit. If

an

obstruction

is hit, retard the throttle immediately and stop motor. Check lower unit for

possible damage.

If motor vibrates excessively after striking

an

underwater obstruction, it may

ind1cate a damaged propeller. Operate

at

slow speed. Replace damaged propeller.

See

PROPELLER AND DRIVE

PIN

REPLACEMENT.

D NOTE:

Operating

motor

with

lower

unit

dragging

on

bottom

will

result in

propeller

wear,

and

cause

sand

to

be

forced

into

water

pump

and

may

cause

damage

to

the

pump.

FUEL ECONOMY

The

economy throttle pos1tion

can

effect fuel savmgs depending

on

boat load

and hull

des1gn.

When

boat reaches top speed, slightly back off on throttle from

FULL

SPEED

position. This

w1ll

result in a fuel saving without noticeable loss in

speed

.

OPERATING IN WEEDY WATER

Weeds

on the propeller will cause motor to vibrate. Run at reduced speed

when

weeds are thick. Stop motor, clear propeller and water intake completely of

weeds

as

often

as

necessary before resuming speed in clear water.

SALT WATER OPERATION

Your motor

IS

built for operation in either fresh

or

salt water. If motor

is

to re-

mam

on boat during long periods of inoperation, tilt gearcase out of the water

(except during freezing temperatures). When removing motor from water, allow

cooling system

to

drain thoroughly. by placing motor in upright position. Internal

flushing

is

unnecessary.

We

recomrT1'end

that motor exterior

be

rinsed with fresh

water

and

wiped

off

with a lightly oiled rag.

OPIRATINO

IN

FREEZING WEATHER

. In freezing temperatures. keep the lower unit submerged in the water at all

ttmes

Th1s

will avoid freezing and possible damage to the water pump

or

other

parts

o_f

the motor. When removing the motor from the water, keep the motor in

an

upnght pOsition until water is completely drained from the cooling system.

ANTI..CORROSION PROTECTION

It

is.

importantespecially in salt water areas to protect the lower

unit

from galvanic

corros1on. Your dealer has accessory kits ava1lable which provide additional pro-

tection under adverse conditions

22

ADJUSTMENTS

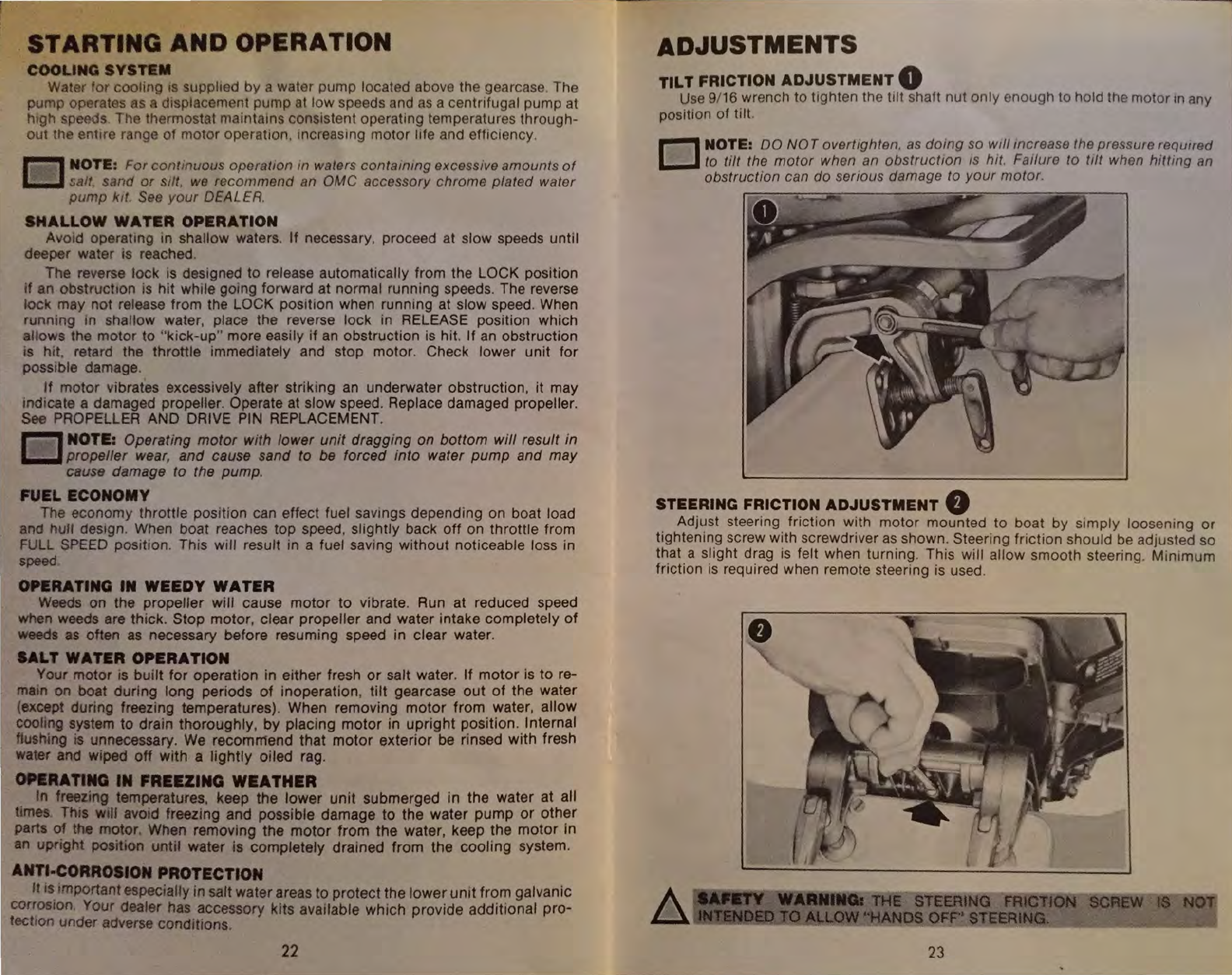

TILT FRICTION ADJUSTMENT 0

Use

9/16 wrench to tighten the tilt shaft nut only enough to hold the motor

rn

any

positiOn of tilt

D NOTE:

DO

NOT

overtighten.

as

domg

so

wt/1

tncrease the pressure required

to

tilt

the

motor

when an

obstructton

ts

hit

. Failure

to

tilt

when

hitting

an

obstruction

can

do

serious

damage

to

your

motor

.

STEERING FRICTION ADJUSTMENT 8

.

Adj~st

steering. friction w!th motor mounted to boat by simply loosenmg or

t1ghtenmg

screw

w1th

screwdnver

as

shown. Steering friction should

be

adjusted so

t~at.

a s!ight

d~ag

is

felt when turning. This will allow smooth steering. Min1mum

fnct1on

IS

reqUired when remote steering

is

used.

WARIIIIIGi

THE

STEERJNO

FRlCT.JON

SCREW

Del)

TO

ALLOW

''HANDS

OFF''

STE

=

ER

;..;:.;

l

:.:..;:

N=G

::....

·

-~----_..,;

23

ADJUSTMENTS

IDLE SPEEO ADJUSTMENT

Turnmg clockwt on thn knob

mer

a. es

tdl

speed,

turntng

toltnterclock

wi~e

deere

ses

''11

,

d

Mnk

orttun that throttl

Is

in

slow p sttion nd th motor 1 at

normal ·) rattng tamp raltH< b fort

m,

king th tdlo sp d AdJUStmont.

CARBURETOR ADJUSTMENT

HIGH SPEED

Hrgll so d fu I ratio calibration 1 mainturn d through use of fixed htgh speed

jl

t No adtustm nt is reqwr

d.

LOW

SP

·ED

iho

car

bur tor low

sp

ed

adrustment

ts

pr

set t th factorywith provisions made

t r normaladju tmcnt to cornpensat for changes in fuel.

nltitu<Je

and chmato

Whe-n

runnmg t slow sp d with warm nglne.

dJust

th

"low

speoo·· knob unttl motor

tdle rnoothly. Turnmg th

adJliStrn=-nt

tmobclockwis (nght hand rotnttonl will I an

out the tu

.I

mtxtur . Turning th adjustment knob count rclockwts< (left hand

rotation)

wtll ennch th

lu

I mtxture. Should dditton I r AdJustment b r qutrod,

proc d

as

follows:

1.

Stop motor.

2 R move

motor

cover. s AE·

MOVING MOTOR COVER

3

Pun

off

low sp

ed

lever and

dtsconnect from linK. Be car lui

not to b nd lmkage.

<t

Us

low spa d lever to turn ne .dl

valve cloci<Wis unttl

1t

g ntly

se.ats.

DO

NOl

FORCE

5

Turn

ne

dle

valve

counterclockwise

3/~

turn.

6 Start

motor

on boat

or

in t st

tMk

(U&tng

t t

wh

el)

and

run

unttl

warm, approximately 2 minutes

7.

Retard throttto to normal tdle

speed

and

adJUSt

n edle valv unttl

best performance tS obtamed

8 Replace low

spe(KI

lever and link.

(Do not

dt

turn

positton

of

neodt

Whll tnstalling lever.)

9.

ReadJust

1dlo

sp d screw.

10.

top motor

&ncs

replace motor

cover

Aft

r th Carburetor

ha

b

r;

dju

~ot.

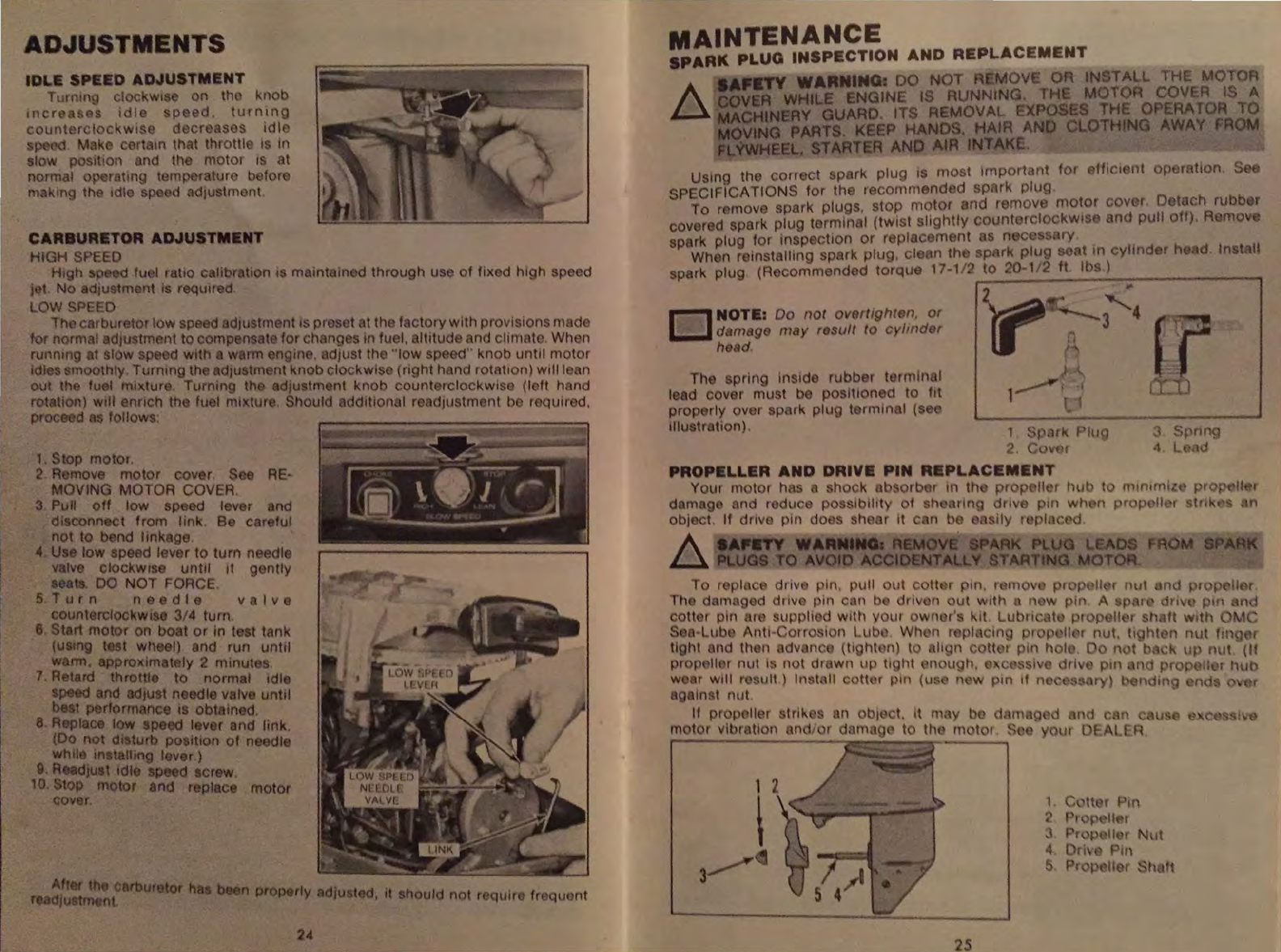

MAINTENANCE

SPARK PLUG INSPECTION AND

REPLACEMENT

SAFIITY WARNING:

DO

NOT

EMOV

OR

INSTALL THE MOTO

A COVER WHILE ENGINE IS RUNNING. TH MOTOR COVER IS A

~

MACHINERY GUARD. ITS REMOVAl.. EXPOSES THE OPERA

TOR

TO

MOVING PART . KEEP HAND ,

HAIR

AND CLOTHING AWAY

fROM

FLVWHEEL. STARTER AND AIR INTAKE.

0 NOTE: Do

not

overtighten,

or

damago may rosutt to

cylmd

r

he

d.

Tl1e

spring in id rubber torrmnnl

lead

cov~

r must b poslt1oned to ftt

prop rly over spMk plug t rmtnal ( e

tllu tr tton).

4

5

ffic:•

nt

op ·r tton. S

r h d tn tall

Spnng

L d

24

~------------------------------------------------------

--

----------------------------__£

25

MAINTENANCE

LU8RICA

TIOM

TYPES

OF

LUBRICANT Contact your

DEALER

for

OMC

Lubricants

OMC

SEA·!.UBE'

ANTI-CORROSION

LUBE

J

TUBE

GREASE

GUN

•

OUTBOARD

LUBRICANT

(OIL)

OMC

SEA-LUBE'

LUBAIPLATE

PREMIUM

BLEND

777

GEARCASE

LUBE

0

LUBRICATION

PICTURE

SYMBOLS

GEARCASE

LUBRICATION

A

Remove

oil drain/fill and oil level plugs from side

of

gearcase. With motor

in

normal running position, allow oil to drain completely.

To

refill, place tube of OMC SEA-LUBE' Premium Blend Gearcase Lube in

dramlfill hole. With motor in normal running position, fill until lubricant appears at

oil

level

hole.

See

SPECIFICATIONS for gearcase capacity

~

NOTR:

Recommended lubricants which have been formulated to protect

J::U

against damage to bearings and gears must

be

used,

as

extensive damage

can

result from improper lubrication.

Install oil level plug before removing lubricant tube from oil drain/fill hole.

Ora

nlfill

plug

can

then

be

securely installed without oil loss.

If

the

proper tube or filler type can

is

not available, install drain/fill plug.

Slowly

fill

gearcase through oil level hole allowing trapped air to escape. Install

plug.

LUBRICATION POINTS

OShifter Starter Lockout

QCarburetor, Choke

linkage

and

Cam

8 Shift lever Shaft,

Reverse

Lock

and

Swrvel

Bracket

8 Clamp

Screws

0 Motor Cover Latch and Starter

Neutral Lockout

0 Throttle Shaft Bushings and Gears

E)Throttle

and Shaft

Linkage,

Electric Starter

Frequency of Lubncation •

Fresh

Water-60 Days • Salt Water-30 Days (Some

areas

may

require more frequent lubrication)

C)Gearcue

Change

after first

20

hours of operation and check after 50 hours

of

operation.

Add

lubncant

if

necessary.

Drain

and

refill every 100 hours

of

operation

or

once each season whichever

occurs

farst.

·rrademark

26

STARBOARD

VIEW

PORT

VIEW

27

MAINTENANCE

OFt=

SEASON

STORAGE (CONT)

9 Remove and check spark plugs. Clean

or

replace

1f

necessary Torque to 17-

112

to

20-1/2

ft. lbs. Refer

to

S~ARK

PLUG INSPECTION

AND

REPLACE-

MENT. Leave spark plug leads disconnected.

10

Touch

up

pamt. See

your

DEALER.

11. Apply a coat

of

automotive wave on external fintsh

of

the motor.

12

..

G1

ve

motor

thorough visual check

for

loose screws

or

damaged and worn

parts.

13.

Store

motor

In an upright position in a

dry

and well ventilated room.

An'aR

STORING • BEFORE USING

If

you have .properly stored

your

motor

proceed

as

follows:

1.

Connect

spat1(

plug

leads.

2.

Check lower

unit

lubrication. If leakage is evident,

lower

umt

seals

may

need

attention. See

your

DEALER.

3. Electric Start Models -Check battery water level and charge. Install and

connect battery. See INSTALLATION OF ELECTRICAL EQUIPMENT.

4. After startrng,

check

to

see that a least a fine spray

of

water is

comi~g

out

of

the exhaust relief outlets. This indicates

proper

water

pump

operation.

SUBMERGED MOTOR

IIOTOR

DROPPED

OVERBOARD

(NOT

RUNNING)

If

motor

is recovered

from

water immediately,

it

must

be serviced

within

3

hOUrJ

after recovery. See

your

DEALER. (See PROLONGED SUBMERSION.)

Since thiS

motor

is provided

with

needle bearings.

it

must

be serviced

within

3

hours after reccwery to avoid

costly

repairs.

Both

fresh

and

salt

water

characterlstlcalfy will start

etching

the

highly

machined

bearing surfaces

of

the

crankthaft and

connecting

rods

as

well

as

the

bear:'lgs

once

exposed

to

the

surrounding atmosphere.

If

eervice

Is

not

readily available, proceed as follows:

1

Remove

motor

cover

and

rinse

motor

with

fresh water.

2.

OlSCONNECT SPARK PLUG LEADS

and

remove spark plugs. Reattach leads

and

ground

plug•

on

motor

block.

r=l_,..,

To

remove

or attach

leads,

pull

off

or push

on

with a slight

IW

counterclockwiH

tw11t.

30

Place

motor

in

horizontal

position

(spark

plug

openings

do~n)

and

wo~k

out

3· all

of

the water

by

rotating flywheel

w1th

starter

cord

approxtmately

25

t1mes.

Place

motor

in

upright

pos1t1on.

Remove

h1gh

speed screw and washer to

4. drain carburetor.

Starters and electrical

equipment

on

motors

that have been subm.erged should

5· be completely disassembled. cleaned, flushed w1th fresh water

tf

exposed to

salt, and

thoroughly

dried before assembly.

Reassemble parts

you

removed and

follow

starting

ms~ructions.

After

s~arting.

6· permit

motor

to

run

112

hour

or

longer

on

boat

or

tn

a test tank

w1th

test

wheel.

If

motor

fails

to

start, remove spark

plugs

again

to

see

if

water

is

p~esent

7· between electrodes.

Blow

out

any

water

from

between

electrodes

and

remstall

or

replace

with

new spark plugs.

If

the

motor

still

fails

to

start. HAVE IT

SERVICED IMMEDIATELY.

Motors

which

have been su.

bmerged

mu~t

be

started

or

disassembled as

soon

as

possible

or

expenstve repa1rs

Wll!

~e

necessary.

To

minimize

damage,

motor

must

be

started

or

serv1ced w1thm

approximately 3 HOURS

after

recovery.

~

NOTE:

If

motor

cannot be started

and

if

semce

is

not

read1/y

availabf~.

t....J the

motor

should

be re-submerged tmmediate/y in fresh _water to

avo_td

exposure to the atmosphere. Make arrangements

to

have tt servtced wtth

the least possible delay.

MOTOR

DROPPED

OVERBOARD

(RUNNING)

Follow the same

procedure

as

MOTOR

DROPPED

OVERBOARD

(NOT

RUNNING) However,

if

there is

any

bmding

when

flywheel

IS rotated

11

indicates

a

bent

connecting

rod and

no

attempt

should

be made

to

start

the

motor

HAVE

IT

SERVICED IMMEDIATELY.

MOTOR

DROPPED

OVERBOARD

(IN

SALT

WATER)

Follow same

procedure

as

MOTOR

DROPPED

OVERBOARD

(NOT

RUNNING}

and (RUNNING}

but

take the

motor

to

your

DEALER as

soon

as

possible

even

ifit

can

be started, as salt water

can

causeexcess1ve

corrosion

of

1gn1tion

system

and

internal

parts.

PROLONGED

SUBMERSION

(FRESH

OR

SALT

WATER)

If

motor

has been

dropped

overboard

and

not

recovered

immediately,

then

motor

must be serviced

within

3

hours

after

recovery

See

your

DEALER.

If sand has entered

the

motor.

no

attempt

at

startmg

should

be

made

.

Return

1t

to

your

DEALER

for

disassembly

and

cleanmg.

31

;,I

0~vvvov~~~~

WARRANTY

SERVICE

t

the

autnonzed

E,·,nrude d 1 r I

rom

'

i<l

nom

tne

out-

To mak a claim under \1\arranty.

conta~e

nearest

authonzed

Ev1nr:.soe

deal

r R m moer.

your

t>Oard

motor

WB$

Ollg,na~

p~r/;~~a~o

~·n°!u'thor

zed E

mruoe

dealar

Wliit'1•n

th

wa

ranty

period, and

outbOard motOr must

r'be

rrformed

by

an authonzed E

nrvde

deal Proot

of

purcrut Will

be

re-

a

II

w rranty

....

orEk

musd

dpeealer

to

substanhate any warranty

claim

U e

your

Ev•nrude

own

a

q lr d by the

VIOrU

e

r~•stratlon

card to establish

proof

of

purchase

EXAMPLES

Of

ITEMS

NOT

COVERED BY WARRANTY

Prov•s•ons

of

the Warranty1W8

•1

1

1

s~gt

~~ft~g

tfhe

warranty

oe

.

nod

such

carburetor

or

•gmuon

Normal

serv1ce

reqwremen s '

,.

1

mp

ad1

ustment or

repa1r,

~;

:ve:rr

8

~fd

•ag~~~~~~n~op~~;m~J·

~~~~:~

~

~tu

of

u !

11

pans

~~~~~~d·~~~~,:~ub)ect

to m1 use. neglect.

neE~~?~r;.ce,

cc•~

0

nt(;

or,

u lyd

'g'

~~

~::'e~r

~~

''"'"·

OutbOard motors that hav been alter··d

or

mvu•

'""'

so

performance or duraolltty or

to

change

thear

Intend~

llSe

tes

"""

h

ar

tth r tn

om~t·i>l•

With

R

a•rs

made necessary by the use

of

p11n

or

ac"

or

•

the

o~tboard

motor

or

adversely affect

_rts

operation.

pedrfor_!ll•"ft~

~e

~~r~,~~~rrons

rn

it\o E nru

Outboard motors not operated or m tnt

m<'d

m acoor an..e w

Owner's·Operator's Manual

Twenty-hour check-up. servtce check-up. tune-up,

or

cllagnosts

Notmal cleantng,

adJUSting

or

replacing

ol

:.p rk

ptug

m

the_

oo.tti'>O

rd

m tor

Per~od1c

checktng or addtng

of

oil

to the g arc se

of

u-,

oumoard

motor

Expense of returmng lhe

outbollrd

motor

to the d aler

nd

exp

n

o!

returntng

tne outbo

r.d

motor back to the own r removal

of

the

outbol!rd

motor

from

a poat nd r tn:.t

llauon.

rne

nlc

travel umo, and tn-and-out

..

of.l

....

aler charg s

Tho

wammty

applies

only

to the OrtQtnal retatl

purchA~

r.

OWNER'I 08LIGATION AND

RISPONIIBILITV

Normal matntenanco servtce and rcplac

ment

ot

servtce It m

lit<

th r

spon

ol)lhtr' 01 tit

o-....n

as

such

11re

not con tder d daf ct

on

maten I or wo1km n

h•O

w•thtn

tt

t

rms

01

tn

wan

nty

Individual op rating habits and us

g11

contnbute

trJ

tn n d tor

rn11111t

nan

•

tn

obtaining maxtmum ervtre and

satt:~tacuon

from

your

n w

[vtnrut1

prtnctpal servtce and rttpl .em nt Items

re

dtl:IC!Ihed

a follows

PROPEA

MAINTfNANCI'

AND

CARf

See your F.vtnrude

!1

al r tor

pll

1 matntenanc nu

'-

re

Of

your outbo

rd

muwr

PrOJlllr

111

tnt naoce

t~nd

,,

til

w111

as

111

111

t..

eplno

your

ovu•

II

Qpe•llllng

osl

at

a mtotnHIIn

1111

toll

dllli1!J

s

ill

lhol<

a

lihtHil•l

HtJtll

,

...

EVIHRUDE DEALER SERVICE

20

MOUR CMI.CK

1'h1s

is

important. After the first

20

hours of operat1on, we

reco~mend

.that you

return your Evinrude outboard to your DEALER for mmor mspect1on and

adjustment (if necessary).

20 Hour Check Includes:

Dram, flush & refill gearcase using OMC Sea-Lube· Premium Blend Gearcase

lube

2. Torque cylinder head and spark plugs

3 Adjust carburetor

4. Check propeller

5. Check timing and ignition

6.

AdJust

remote control and linkage (where applicable)

This

is

an

opportune time to discuss with your DEALER any questions on your

outboard motor which have arisen in the first

20

hours of operation, and establish

a routine preventative maintenance schedule.

The

20 hour check will

be

performed at local DEALER rates and paid for

by

the owner.

REPAIR

SERVICE

Should you

be

in need of service

an

Evmrude dealer

is

not far. He usually carri

es

a

complete stock of spare parts. Always take your motor to

an

authori

zed

Ev

inrude

dealer, he has the knowledge, experience and special tools to take care of any

problem that may ari

se

.

If

you

are

away from your home waters, take your motor to

the nearest authorized

Ev

inrude dealer. Names and addresses can be found m

your

Evinrude Dealer

Serv1ce

Directory or your telephone directory under "Outboard

Motors." If you are in your home waters, take your motor back to the selling dealer

-he knows you and your equipment.

FIND YOUR

NEAREST

EYINRUDE

DEALER

IN THE

YELLOW

PAGES

r)l

~

·t

,.

~-

'-""

_____

.....,

REPLACEMENT PARTS

DEALER

PHONE NO.

IN

ORDER

TO

ASSURE RECEIVING

PROPER

SERVICE PARTS ALWA

YS

PROVIDE THE FULL MODEL & SERIAL

NUMBERS

OF

YOUR

MOT

OR

Be

sure

that only factory approv

ed

parts de

s1

gned for your motor are used

as

rep

l

acements

Your authonzed

Ev

inrude dealer c

an

be

re

lied on as a source of

genume

parts Replacement parts not of our manufactu

re

ha

ve

notbeen approved for

use

on

Evmrude motors

EVInRUDE

SERVICE

34

OF

THE

ROAD

FOR

OUTBOARDING

•

Keep

clear

of

saolmg

craft

and

rowboats.

Yoeld

right

of

way

to

slower

boats

.

e

Always

keep

to

the

r1ght

•

•

Do

not

use

your

motor

near

sw1mmers

or

skin

divers.

•

Learn

the

11

gn

language

of

the

variOUS

buoys

and

warning

signals.

These

are

yo

ur

nauttc•l

traffic

stgns,

posted

for

your

saf•tY

l!lnd

conven1ence.

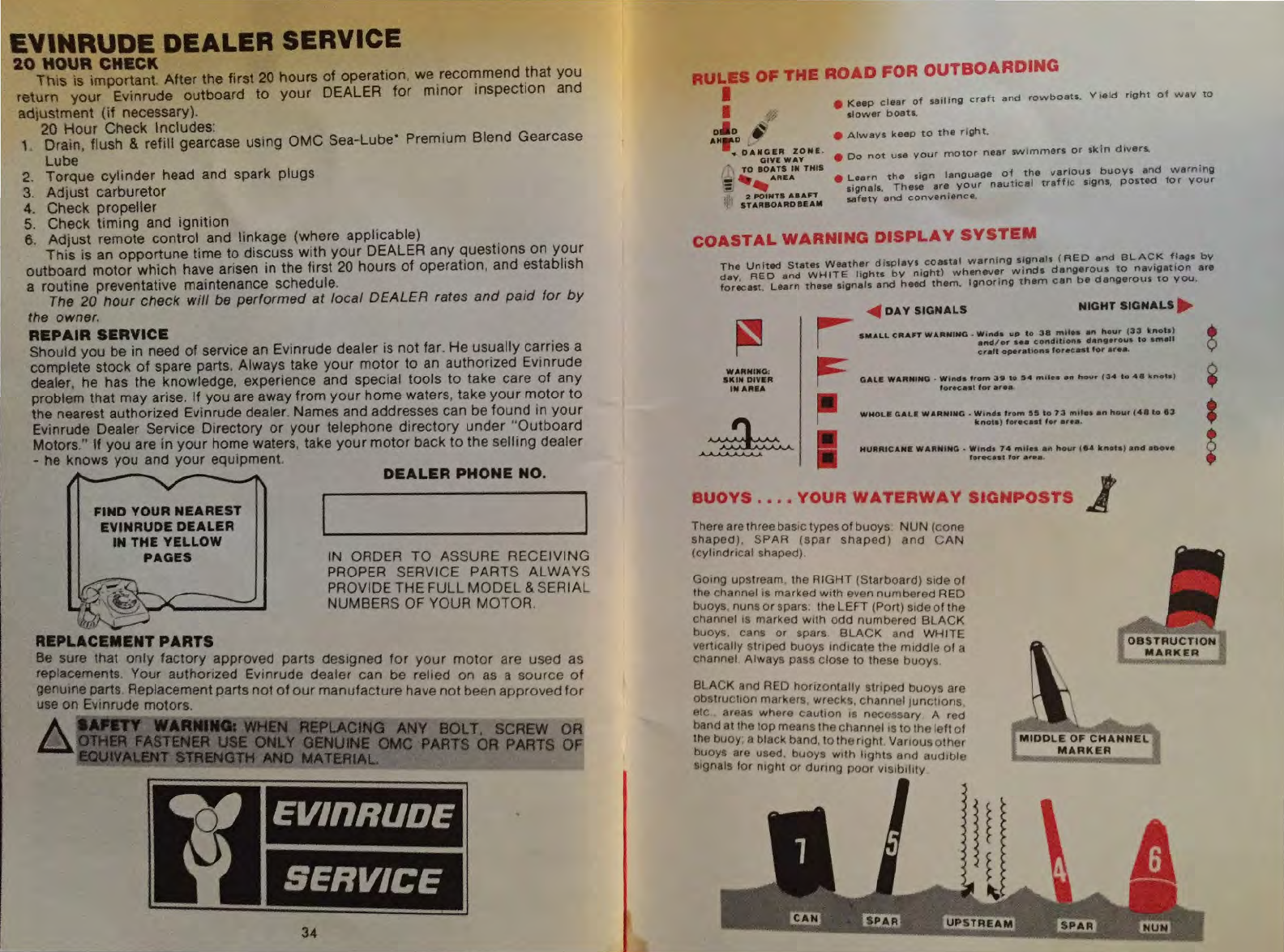

COASTAL

WARNING

DISPLAY

SYSTEM

T

ha

Un

it

ed

S

ta

tes

Weat

her

displays

coastal

warning

si

g

nals

(RED

and

BLACK

flags

bY

day,

RE

D and

WH

I

TE

lights

by

night)

w h

enever

w

&n

d t

dangerous

to

navogatoon

are

fo recas

t.

Learn

these

signals

and

heed

them.

l g

nonn

g

them

can

ba

dangerous

to

you.

~

DAY

SIGNALS

NIGHT

SIGNALS

.

,.........

SMALL

CIIAn

WAfii:NUfG

~

W•n

4 a " " to 3 a

m•l

• • a " hour

(33

Ill

not

e)

I

.....

,.,.

au

c.ond lttofta 4

•rt•ero

ua

to

aM

all

cf

afl

op

er

a u

ona

fo

roc:"t

t

or

ar

ea

.

WAIItNINO:

SIC

IN

DIYIIIt

IN

AlltiA

F

GAU

WAIININO . W

l""'

o

,,..,.

3e

to

54

"'''••

an

,...,,

(3

4 t o 4 8

kno

t• I

t

oroc•

at

f

or

ar

ea

·~

WHOLI:

GALl

WARNING

. Wtn4a f

ro

m

aS

to

13

l'l'ltlol

•n

hou

r (4 8 to e

-3

kn

ot

s ) f

orocaat

,

.,

o

r•

•·

..............

"'

HU

..

IIU

C

ANI

WA"M

INQ • W t

nd

a

74

mtl

ea

aft

h

4Kir

~._.

tu

•ataf

an

d

aoo

v e

t

er.-c

aa

t for a

rea

BUOYS

••••

YOUR

WATERWAY

SIGNPOSTS

1

There arethree

basoc

types

of

buoys

NUN

(cone

shaped)

. SPAR

(spar

shaped)

and

CAN

(cyltndrocal shaped)

Goong upstream. the

RIGHT

(Starboard)

sode

of

the channel is marked

w1th

even

numbered

RED

buoys nuns

or

spars the LEFT (Port)

sode

of

the

channel

os

marked

woth

odd

numbered

BLACK

buoys cans

or

spars

BLACK

and

WHITE

vcrtocally

~tnped

buoys tnd1cate the moddle

of

a

channel Always pass

clo'Se

to

the e

buoys

.

BlACK

and RED

honzontally

stnped

buoys

are

obSiructlon markers, wreck'!, channel 1

unchons

,

<>tc

areas

whP.re

caut1on

IS

nec~sary

A red

band at tho top means thP channet1s

to

thP.Ieft

of

the buoy, a black band, to the

nght

Vanous

other

buoys arc used. buoys

woth

hghts

and

audobleo

sognals f

or

ntght

or

dunng

poor

vosobohty

OBSTRU

C

TION

MARKER

MIDDLE

OF

CHANN

EL

MARKER

EVInRUDE

firstin

outboards

EVINRUDE MOTORS

4143

N

27TH

STREET

Mil

\VAUKEE WIS

53216

DIVISION

OF

OUTBOARD

MARINE

CORPORATION

ITEM

NO.

5167 PART NO. 207547 5/75

EVInRUDE

SERVICE

*

X

LITHO

U.S.A

This manual suits for next models

4

Table of contents

Other Evinrude Engine manuals