EVOCA Brio Touch Owner's manual

INSTALLATION, OPERATION, MAINTENANCE

Translation of original instructions

EN English

Doc. No. H5935EN00

Edition 1 09 - 2021

Brio Touch

DICHIARAZIONE DI CONFORMITA’ - DECLARATION OF CONFORMITY

- DÉCLARATION DE CONFORMITÉ - KONFORMITÄTSERKLÄRUNG -

DECLARACIÓN DE CONFORMIDAD - DECLARAÇÃO DE CONFORMIDADE -

VERKLARING VAN OVEREENSTEMMING - OVERENSSTEMMELSESERKLÆRING

- FÖRSÄKRAN OM ÖVERENSSTÄMMELSE - VAATIMUSTENMUKAISUUSVAKUUTUS

- ERKLÆRING OM OVERENSSTEMMELSE - PROHLÁŠENÍ O G -

DEKLARACJA - șȚȟȠȕȥȕȫȝȴ ȦȣȣȧȗȚȧȦȧȗȝȴ -

IT La presente dichiarazione di conformità è rilasciata sotto l’esclusiva

responsabilità del fabbricante. Si dichiara che l’apparecchiatura, descritta

Ļ·ʷȽ¾»ÊÊ·º¿¿º»ÄÊ¿Ű¹·Ð¿ÅÄ»Ƒò¹ÅļÅÈû·Â»º¿ÉÆÅɿпÅĿ»½¿É·ʿ̻º»Â»

¿È»ÊÊ¿Ì»ËÈÅÆ»»»É˹¹»ÉÉ¿Ì»Ãź¿Ű¹¾»»º¿ÄÊ»½È·Ð¿ÅÄ¿Ɣ

»Ä½ÅÄÅÈ¿ÆÅÈʷʻ»ÄÅÈû·ÈÃÅÄ¿ÐзʻÅ»ÉÆ»¹¿Ű¹¾»Ê»¹Ä¿¹¾»ƺº»É¿½Ä·-

zioni) che sono state applicate in accordo con le regole della buona arte in

materia di sicurezza in vigore nella UE.

EN This declaration of conformity is issued under the manufacturer’s sole

È»ÉÆÅÄÉ¿¸¿Â¿ÊÏƔʿɺ»¹Â·È»ºÊ¾·Êʾ»»ÇË¿ÆûÄʺ»É¹È¿¸»º¸Ïʾ»¿º»ÄÊ¿Ű¹·Ê¿ÅÄ

plate is in compliance with the legal provisions of the European Directives as

well as its subsequent amendments and supplements.

¾»¾·ÈÃÅÄ¿É»ºÉʷĺ·ÈºÉÅÈʾ»Ê»¹¾Ä¿¹·ÂÉÆ»¹¿Ű¹·Ê¿ÅÄÉƺº»É¿½Ä·Ê¿ÅÄÉƻ·Æ-

plied in compliance with the safety rules of good practice in force in the EU are

stated herein.

FR La présente déclaration de conformité est délivrée sous la responsabilité

exclusive du fabricant. On déclare que l’appareillage décrit sur la plaquette

ºƠ¿º»ÄÊ¿Ű¹·Ê¿ÅÄ»ÉʹÅļÅÈû·Ëκ¿ÉÆÅÉ¿Ê¿ÅÄÉÂó½¿É·ʿ̻ɺ»É¿È»¹Ê¿Ì»É

»ËÈÅÆó»ÄĻɻÊ»ËÈÉÃź¿Ű¹·Ê¿ÅÄɻʿÄÊó½È·Ê¿ÅÄÉËÂÊóÈ¿»ËÈ»ÉƔÅÄʿĺ¿ÇËó»É

»ÉÄÅÈûɾ·ÈÃÅÄ¿Éó»ÉÅË»ÉÉÆó¹¿Ű¹·Ê¿ÅÄÉÊ»¹¾Ä¿ÇË»ÉƺºóÉ¿½Ä·Ê¿ÅÄÉƻÇË¿

ont été appliquées conformément aux bonnes règles de l’art en matière de

sécurité en vigueur dans l’UE.

ES La presente declaración de conformidad se entrega bajo la exclusiva respon-

sabilidad del fabricante.Se declara que el aparato, descripto en la etiqueta de

¿º»ÄÊ¿Ű¹·¹¿ĤÄƑ»É¹ÅļÅÈû¹ÅÄ·ɺ¿ÉÆÅÉ¿¹¿ÅĻɻ½¿É·ʿ̷ɺ»Â·É¿È»¹Ê¿Ì·É

ËÈÅÆ»·ÉϹÅÄÉËÉÉ˹»É¿Ì·ÉÃź¿Ű¹·¹¿ÅĻɻ¿ÄÊ»½È·¹¿ÅÄ»ÉƔ

»¿Äº¿¹·Ä·ÉÄÅÈ÷ɷÈÃÅĿзº·ÉÅ·ɻÉÆ»¹¿Ű¹·¹¿ÅÄ»ÉÊó¹Ä¿¹·Éƺº»É¿½Ä·¹¿Å-

nes) que han sido aplicadas de acuerdo con las reglas del buen arte en materia

de seguridad en vigencia en la UE.

DE Diese Konformitätserklärung wurde unter ausschließlicher Verantwor-

tung des Herstellers verfasst. Es wird erklärt, dass das auf dem Typenschild

beschriebene Gerät den gesetzlichen Bestimmungen der Europäischen

Richtlinien und anschließenden Änderungen und Ergänzungen entspricht. Es

ͻȺ»Äº¿»¾·ÈÃÅÄ¿É¿»ÈÊ»ÄÊ»¹¾Ä¿É¹¾»ÄƻпŰÁ·Ê¿ÅÄ»Äƺ»ÉÊ¿ÃÃËĽ»Äƻ·Ë¼-

geführt, die gemäß den Regeln der Kunst hinsichtlich den in der EU geltenden

Sicherheitsnormen angewendet wurden.

PT A presente declaração de conformidade é emitida sob exclusiva respon-

sabilidade do fabricante. Declara-se que o equipamento, descrito na placa

º»¿º»ÄÊ¿Ű¹·îÙÅƑ»ÉÊһùÅļÅÈÿº·º»¹Å÷ɺ¿ÉÆÅÉ¿îī»É»½¿É·ʿ̷ɺ·É

¿È»Ê¿Ì·ÉËÈÅÆ»¿·É»É˹»ÉÉ¿Ì·ÉÃź¿Ű¹·îī»É»¿ÄÊ»½È·îī»ÉƔÙſĺ¿¹·º·É

·ÉÄÅÈ÷ɾ·ÈÃÅĿзº·ÉÅË·É»ÉÆ»¹¿Ű¹·îī»ÉÊó¹Ä¿¹·Éƺº»É¿½Ä·îī»ÉƻÇË»

foram aplicadas de acordo com as regras de boa engenharia em matéria de

segurança, em vigor na UE.

Direttive e regolamenti europei

European directives and regulations

ÅÈû·ÈÃÅÄ¿ÐзʻƭÆ»¹¿Ű¹¾»Ê»¹Ä¿¹¾»

·ÈÃÅÄ¿É»ºÉʷĺ·ÈºÉƭ»¹¾Ä¿¹·ÂÉÆ»¹¿Ű¹·Ê¿ÅÄÉ

2014/35/EU* ƺƻ EN 60335-1:2012+A11:2014+A13:2017+A1:2019+A2:2019+A14:2019

EN 60335-2-75:2004+A12:2010+A11:2006+A1:2005+A2:2008

EN 62233:2008

2006/42/EC* ƺƻ EN 60335-1:2012+A11:2014+A13:2017+A1:2019+A2:2019+A14:2019

2014/68/EU ƺƻ EN 60335-1:2012+A11:2014+A13:2017+A1:2019+A2:2019+A14:2019

2014/30/EU ƺƻ EN 55014-1:2017

EN 55014-2:2015

EN 61000-3-2:2019

EN 61000-3-3:2013

2002/72/CE+2008/39/CE

EC 1935/2004 EN 16889:2016 È·¹Ê¿¹·ÂË¿º»ƭƺʹʷʸʺƻˀ

10/2011/EU+amendments

EC 2023/2006 ƺƻ

2011/65/EU+ amendments ƺÅƻ EN 50581:2012

2012/19/EU ƺƻ

2014/53/EU ** ƺƻ EN 62311:2008

EN 60335-1:2012+A11:2014+A13:2017+A1:2019+A2:2019+A14:2019

EN 60335-2-75:2004+A12:2010+A11:2006+A1:2005+A2:2008

ETSI EN 301 489-1 V2.1.1:2016

ETSI EN 301 489-1 V2.2.3:2019

ETSI EN 301 489-17 V3.2.4:2020

ETSI EN 301 489-52 V1.1.0:2016

ETSI EN 301 511 V12.5.1:2017

ETSI EN 301 908-1 V13.1.1:2019

ETSI EN 300 328 V2.2.2:2019

ANDREA ZOCCHI

C.E.O

Il fascicolo tecnico è costituito e disponibile presso:

¾»Ê»¹¾Ä¿¹·ÂŰ»¿É¹ÅÃƿ»º·Äº·Ì·¿Â·¸Â»·ÊƓ Evoca S.p.A.

NL Deze verklaring van overeenstemming wordt uitsluitend onder de

̻ȷÄÊÍÅÅȺ»Â¿ÀÁ¾»¿ºÌ·Äº»¼·¸È¿Á·ÄÊÌ»ÈÉÊÈ»ÁÊƔ»ÄÌ»ÈÁ··Èʺ·Ê¾»Ê·Æ-

Æ·È··ÊƑ¸»É¹¾È»Ì»ÄÅƾ»Ê¿º»ÄÊ¿Ű¹·Ê¿»Æ··ÊÀ»ƑÅ̻Ȼ»ÄÉÊ»ÃÊûʺ»Í»Êʻ¿ÀÁ»

bepalingen van de Europese Richtlijnen en daaropvolgende wijzigingen en

aanvullingen.Hierna worden de geharmoniseerde normen of de technische

ÉÆ»¹¿Ű¹·Ê¿»Éƺ··ÄÍ¿ÀпĽ»Äƻ··Ä½»½»Ì»Äº¿»ÊÅ»½»Æ·ÉÊͻȺ»Ä¿ÄÅ̻Ȼ»Ä-

stemming met de regels van de goede techniek op gebied van veiligheid, die

in de EU van kracht zijn.

DA Denne overensstemmelseserklæring udstedes ene og alene på fabrikan-

tens ansvar. Det erklæres hermed, at apparaturet, der er beskrevet på udsty-

rets typeskilt, opfylder de lovgivningsmæssige i krav i de europæiske direktiver

samt senere ændringer og tilføjelser. De anvendte harmoniserede standarder

»Â»ÈÊ»ÁÄ¿ÉÁ»ÉÆ»¹¿ŰÁ·Ê¿ÅÄ»Èƺ¸»Ê»½Ä»ÂÉ»ÈƻƑÉÅûȷÄ̻ĺʿÅ̻ȻÄÉÉÊ»ÃûÂ-

se med reglerne i de tekniske sikkerhedsforskrifter gældende i EU.

SV Denna försäkran om överensstämmelse utfärdas av tillverkaren på dennes

egna ansvar.Vi försäkrar att utrustningen, som beskrivs på märkskylten,

överensstämmer med lagar och författningar i EU-direktiven och i ändrad och

ÁÅÃÆ»ÊʻȷºÂϺ»ÂÉ»Ɣ·ÈÃÅĿɻȷº»Éʷĺ·Èº»È»Â»ÈÊ»ÁÄ¿ÉÁ·ÉÆ»¹¿ŰÁ·Ê¿ÅÄ»È

ƺ¸»Ê»¹ÁĿĽ·ÈƻâʻȽ»ÉÉÅþ·ÈÊ¿ÂÂÚÃÆ·ÊɻĿ½ÊÉËĺ·Ê»ÁÄ¿ÉÁ·ÆȿĹ¿Æ»È¿¼Èâ-

ga om säkerheten som gäller inom EU och som anges i listan på samma sida.

FI Tämä vaatimustenmukaisuusvakuutus annetaan valmistajan yksinomaisen

vastuun alla.Vakuutamme, että arvokilvessä kuvattu laite vastaa neuvoston

direktiivejä sekä niihin liittyviä muutoksia ja täydennyksiä. Lisäksi annetaan

Ͼº»ÄÃËÁ·¿ÉÊ»ÊËÊÉʷĺ·Èº¿ÊÊ·¿Ê»ÁĿɻʻȿÊÊ»ÂÏÊƺÁÚÏÊÊĬÊ·ÈÁÅ¿ÊËÁÉ»ÊƻƑÀÅ¿Ê·ÅÄ

sovellettu EU-maissa, voimassa olevien turvallisuutta koskevien valmistukseen

liittyvien määräysten ohella.

NO Denne samsvarserklæringen er utferdiget under eneansvar av produ-

senten. Det erklæres at apparatet, beskrevet på typeskiltet, er i samsvar med

gjeldende europeiske direktiver og senere endringer og tillegg. Harmoniserte

Éʷĺ·Èº»È»Â»ÈÊ»ÁÄ¿ÉÁ»ÉƻɿŰÁ·ÉÀÅÄ»Èƺ¸»Ê»½Ä»ÂÉ»Èƻ·Ä̻ĺʿɷÃÉÌ·Èûº

EUs gjeldende sikkerhetsregler er angitt.

CZ TÅÊÅÆÈžÂÒŀ»ÄċÅɾźúÀ»ÌϺÒÄÅÌÆÂÄóÐźÆÅÌúºÄÅÉʿ̚ȟ¹»Ɣ

Èž·ŀËÀ»É»ƑŨ»Ð·ļċлÄċÆÅÆÉ·ÄóÄ·¿º»ÄÊ¿ŰÁ·ìÄċÃÊÏÆÅÌóÃÂċÉÊÁËźÆÅÌċºÒ

»½¿É·ʿÌÄċÃÄ·ļċлÄċÃÌÈÅÆÉÁš¹¾ÉÃúÈÄ¿¹Ì»ÐÄúÄċÆÅкúÀŀċ¹¾ÐÃúÄ·ºÅ-

ÆÂğÁőƔ·ÈÃÅÄ¿ÐÅÌ·ÄóÉʷĺ·ÈºÏÄ»¸ÅÊ»¹¾Ä¿¹ÁóÉÆ»¹¿ŰÁ·¹»ƺÅÐÄ·ì»ÄċƻÀÉÅË

·Æ¿ÁÅÌÒÄÏÌÉÅË·ºËÉ»ÉÆÈÒÌÄÅËÆÈ·ÎċÆ·ÊÄÅËÌËÌ»º»ÄÅËÄċŨ»Ɣ

džË·ÂËÄÇ˻ɿ··ÆÆ¿¹·¸¿Â»ƭ¾¿¹¾»Ì»È·ÆÆ¿¹·¸Â»

**Solo con moduli radio di Evoca S.p.A. / Only with radio modules of Evoca S.p.A.

Ed. 10 20

EVOCA S.p.A.

ad unico socio

Sede amministrativa e operativa: Via Roma 24

24030 Valbrembo (BG) Italia

Tel +39 035 606111

Fax +39 035 606463

www.evocagroup.com

Sede legale: Via Tommaso Grossi 2

20121 Milano (MI) Italia

Cap. Soc. € 41.138.297,00 i.v.

»½ƔÃÆÈƔƑźƔ¿É¹Ɣ»ƔƓʷʼʷʺʼʽʷʷˀʽʺ

»½ƔÈźËÊÊÅÈ¿ƔƔƔƓʷʿʷʹʷʷʷʷʷʷʸʷʼʻ

źƔ¿º»ÄÊ¿Ű¹·Ê¿ÌÅƓʷʼʷʺʼʽʷʷˀʽʺ

12/10/2020

ДЕКЛАРАЦИЯ СООТВЕТСТВИЯ - DECLARAȚIE DE CONFORMITATE

RU Настоящая декларация соответствия выдается только под экс-

клюзивной ответственностью изготовителя. Свидетельствуется, что

оборудование, описанное в идентификационной табличке, соответствует

законодательным положениям Европейских Директив, а также после-

дующим изменениям и дополнениям. Приводятся гармонизированные

нормы или технические спецификации (указания), которые были при-

менены в соответствии с правилами качественного

RO Această declarație de conformitate este eliberată pe răspunderea

exclusivă a producătorului. Declarăm că aparatura descrisă pe eticheta de

identicare este conformă cu dispozițiile legale ale Directivelor Europene, cu

modicările și completările ulterioare.

Sunt indicate standardele armonizate sau specicațiile tehnice (descrierile)

care au fost aplicate în acord cu regulile de bună practică în materie de securi-

tate în vigoare în UE.

Declaration of conformity

The declaration of conformity is

issued under the manufacturer’s

sole responsibility.

The declaration of conformity with

the European Directives and Standards

provided for by the laws in force is supplied

by the rst page of this manual, which is an

integral part of the machine.

-The legal provisions of the European

Directives in force (with the subsequent

amendments and integrations thereof)

-The harmonised standards in force

-The technical specifications (designa-

tions) applied in compliance with the

safety rules of good practice enforced in

the EU and listed on the same page.

integration of radio modules

In compliance with Article 17 of Direc-

tive 2014/53/EU (RED), the manufacturer

checks whether the radio equipment is in

compliance with the essential requirements

of article 3 of the Directive.

The procedure used to check compliance

is at the manufacturer’s discretion.

If a radio module is built in a “non-radio”

equipment, the subject integrating the

module will become the manufacturer of

the end product and it must therefore check

the compliance of the end product with the

essential requirements of the 2014/53/EU

(RED) Directive.

As a matter of fact, the integration of radio

modules in other products can inuence

the compliance of the end product with the

essential requirements of the Directive.

definitions according to the law

The manufacturer is a natural person who

or a public body which manufactures radio

equipment and/or electric material or has it

engineered, manufactured or marketed by

putting its own trademark or name on it.

An importer or distributor who places

radio equipment or electric material on the

market by putting its own name or trade-

mark becomes the manufacturer.

An importer or distributor who makes any

change to radio equipment or electric mate-

rial already placed on the market to such an

extent that the said change may condition

the compliance with the listed directives

is held to be the manufacturer and it must

therefore assume the relative obligations

according to the said directives.

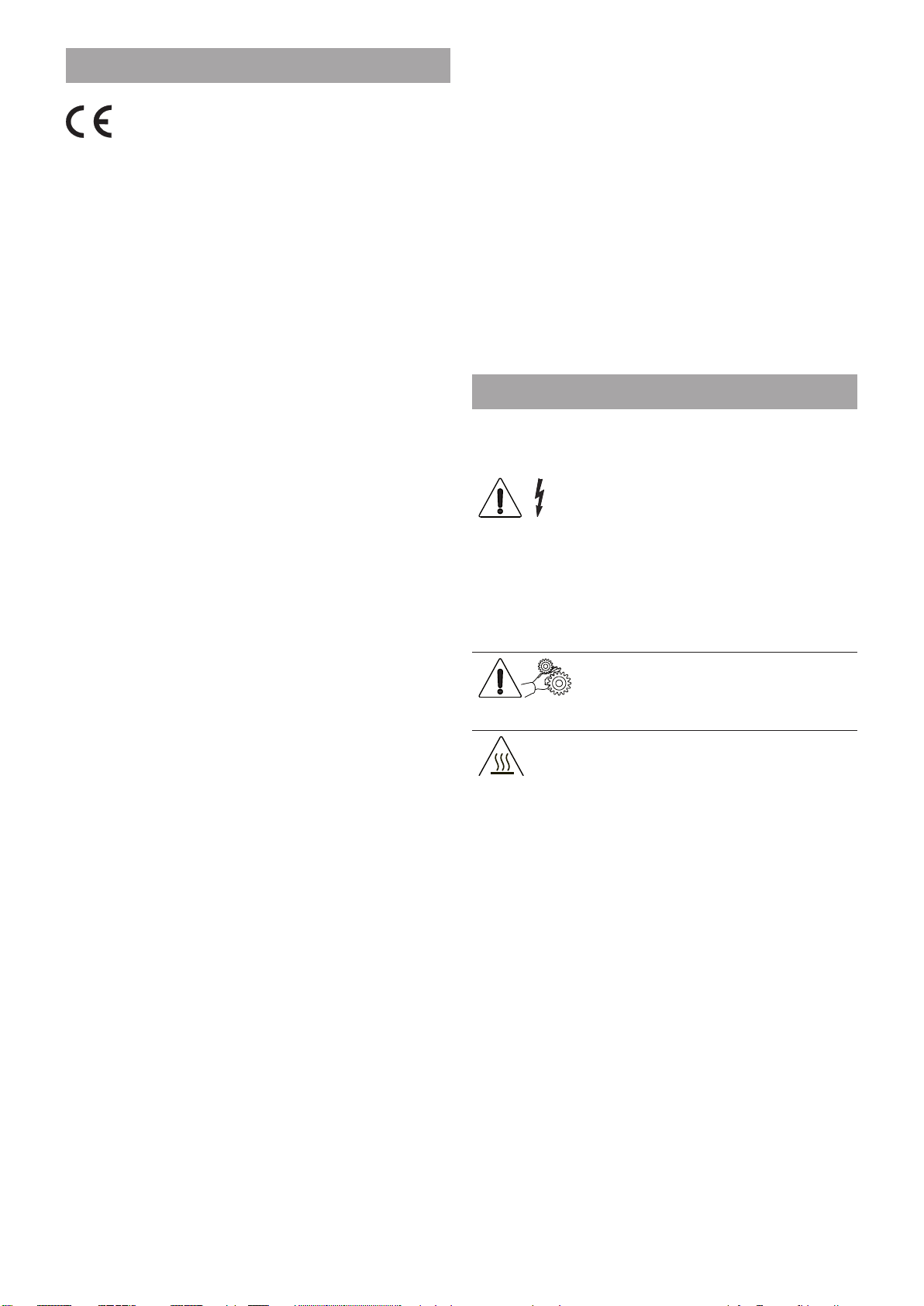

Symbology

The following symbols may be present

inside the machines, according to models

(signs of danger)

Attention: dangerous voltage

Power o before removing the

cover

To reduce the risk of re or

electric shock, don’t remove

the cover. No user-servicea-

ble part inside.

Repairs should be done by

authorized service personel

only.

Attention

Danger of crushing your han-

ds

Attention

Hot surface

The signs of danger must be readable

and visible; they shall be neither hidden

nor removed. Damaged or unreadable

labels must be replaced.

Table of contents

Other EVOCA Coffee Maker manuals

Popular Coffee Maker manuals by other brands

Bunn

Bunn LCA-1 Installation & operating guide

Chris Coffee Service

Chris Coffee Service Silvano owner's manual

Black & Decker

Black & Decker BLACK DECKER HOME DE790 Use and care book

Saeco

Saeco Vienna Plus Sup 018M operating instructions

INCAPTO

INCAPTO BXCO1470E Instructions for use

Bosch

Bosch TASSIMO finesse TAS16B Series user manual