The encoding module has a xed electronic component that is installed below the mechanical

area. This also comes with a read/write head for magnetic stripes, a contact station for smart

cards and a housing for contactless encoders with or without a remote antenna.

In its factory conguration, the module comes with the following:

l An ISO 7811 encoding unit, a 3-track HiCo/LoCo

l An ISO 7816-2 contact station for smart cards

l An antenna bracket

l 2 x internal USB ports to connect a contact smart card encoder and a contactless smart card

encoder

l 1 x MAX232 dual I/O to connect a contact smart card encoder and a contactless smart card

encoder

l Internal power supply connectors to power the encoders

l 2 x female DB9 plugs on the external connecting panel to directly link the encoders or smart

coupler to the PC

l A connector that links the motherboard to the reversible encoding unit

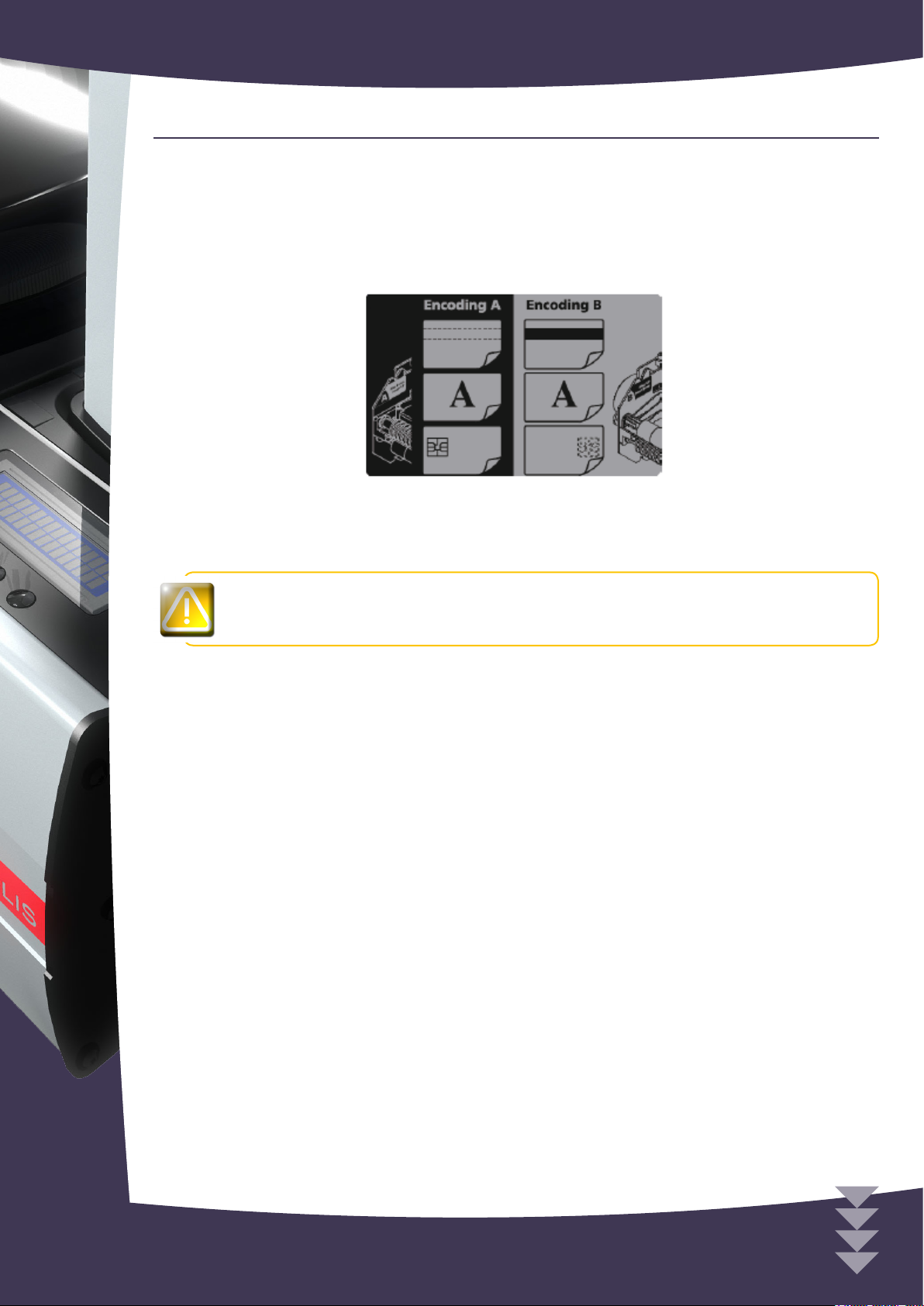

l A system to ip the encoding unit over and enable the following:

l Magnetic encoding on the reverse side and chip encoding on the front side (factory settings),

with the encoder in A position

l Or, magnetic encoding on the front side and chip encoding on the reverse side, with the

encoder in B position

On demand, this encoding module can be tted with the following features:

l JIS2 (Japan) encoding unit in replacement of the ISO encoder

l Smart card encoder (contact or contactless). The list of supported encoders is available upon

request

For maximized exibility, the encoding module can be recongured within minutes and by the

users themselves.

Integration can be easily achieved, thanks to the information and advice provided in this

document, and to the available extension kits and the connectors from Evolis.

In compliance with the safety, quality, assembly and connections guidelines, users can customize

the Quantum to their specic needs, when, for example, switching from a Mifare encoder to a

device that manages HID Prox cards.

You must strictly comply with the instructions and guidelines on assembling

and disassembling an encoder to ensure user safety and prevent your

Quantum from being compromised.

3