Evoqua IONPURE IP-POWERDSP-G2 Manual

10 Technology Drive

Lowell, Massachusetts 01851

Tel: (866) 876-3340 Fax: 978-934-9499

www.ionpure.com

IONPURE

®

G2 DISPLAY

BOARD

For use with G2

Power Controllers

Operation

&

Maintenance

Manual

IP-POWERDSP-G2MAN

November 2011

Revision 1

Manual Covers Part #:

IP-POWERDSP-G2

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 2 of 25

Table of Contents

DISCLAIMER STATEMENT .................................................................................................................. 4

PROPRIETARY RIGHTS STATEMENT ................................................................................................ 4

MANUAL REVISION HISTORY............................................................................................................. 4

1INTRODUCTION ............................................................................................................................. 5

1.1 Caution and Warning Messages ................................................................................................ 5

1.2 General Description ................................................................................................................... 5

2INSTALLATION............................................................................................................................... 7

2.1 Requirements............................................................................................................................. 7

2.2 Panel Mount............................................................................................................................... 8

2.3 Connections ............................................................................................................................... 8

2.3.1 Connections to a Single G2 Power Controller....................................................................... 8

2.3.2 Connections to Multiple G2 Power Controllers ..................................................................... 9

2.4 Power Controller Setup ............................................................................................................ 10

2.4.1 DC Output Current Range Selection .................................................................................. 10

2.4.2 Unit ID Selection................................................................................................................. 11

3OPERATION.................................................................................................................................. 12

3.1 Control/Navigation Keys........................................................................................................... 12

3.2 Menu Structure......................................................................................................................... 13

4GETTING STARTED ..................................................................................................................... 23

4.1 Initial Startup ............................................................................................................................ 23

4.2 Output Current Adjustment ...................................................................................................... 23

5TROUBLESHOOTING................................................................................................................... 24

APPENDIX – UL AND CE COMPLIANCE........................................................................................... 25

List of Figures

Figure 1: G2 Display Board.................................................................................................................... 5

Figure 2: G2 Display Dimensions........................................................................................................... 7

Figure 3: Panel Cutout Dimensions ....................................................................................................... 8

Figure 4: Connections to a Single G2 Power Controller......................................................................... 9

Figure 5: Connections to Multiple G2 Power Controllers...................................................................... 10

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 3 of 25

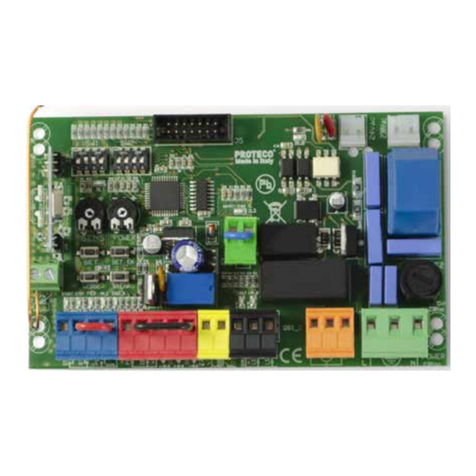

Figure 6: Current Range Selection DIP Switch .................................................................................... 10

Figure 7: Control/Navigation Keys ....................................................................................................... 12

Figure 8: Menu Tree Structure............................................................................................................. 13

Figure 9: OVERVIEW Screen Example ............................................................................................... 14

Figure 10: RUN Screen – Page 1 ........................................................................................................ 14

Figure 11: RUN Screen – Page 2 ........................................................................................................ 15

Figure 12: RUN Screen – Page 3 ........................................................................................................ 15

Figure 13: RUN Screen – Page 4 ........................................................................................................ 16

Figure 14: RUN Screen – Page 5 ........................................................................................................ 16

Figure 15: SETUP Screen – Page 1 .................................................................................................... 17

Figure 16: SETUP Screen – Page 2 .................................................................................................... 18

Figure 17: ALARMS Screen – Page 1 ................................................................................................. 18

Figure 18: ALARMS Screen – Page 2 ................................................................................................. 19

Figure 19: LOGS Screen ..................................................................................................................... 20

Figure 20: MAX VALUES Screen......................................................................................................... 20

Figure 21: MIN VALUES Screen.......................................................................................................... 21

Figure 22: MODULE OHMS&S Screen ........................................................................................ 22

Figure 23: DIAGNOSTICS Screen....................................................................................................... 22

List of Tables

Table 1: Unit ID Selection .................................................................................................................... 11

Table 2: Troubleshooting ..................................................................................................................... 24

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 4 of 25

Disclaimer Statement

The operation and maintenance manual should provide complete and accurate information to meet

your operating and/or service requirements based on the information available at the time of

publication. The information in this manual may not cover all operating details or variations or provide

for all conditions in connection with installation, operation and maintenance. Should questions arise

which are not answered specifically in this manual, contact your equipment supplier.

Siemens reserves the right to make engineering refinements that may not be reflected in this manual.

The material in this manual is for informational purposes and is subject to change without notice.

Proprietary Rights Statement

This manual discloses information in which Siemens has proprietary rights. Neither receipt nor

possession of this manual confers or transfers any right to the client, and by its retention hereof, the

client acknowledges that it will not reproduce or cause to be reproduced, in whole or in part, any such

information except by written permission from SIEMENS. The client shall have the right to use and

disclose to its employees the information contained herein for the purpose of operating and maintaining

the SIEMENS equipment, and for no other purpose.

In the event the content of this manual is altered or section/items are omitted during reproduction, in

whole or in part, and instructions or definitions within the reproduction result in personal injury to those

who follow the altered instructions, the burden of responsibility for personal injury falls solely on the

party who effects the reproduction.

Manual Revision History

Event Date Description

Original Publication

Rev 0

September 2011 Original publication

Rev 1 November 2011 Updated remarks on firmware in sections 3.2 and 5

Updated Figure 23

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 5 of 25

1 Introduction

1.1 Caution and Warning Messages

WARNING and CAUTION labels are used to attract attention to essential or critical information in

this manual. The labels are located to the left of the associated messages. Caution and Warning

messages will be located immediately before related text.

Warnings indicate condition, practices, or procedures that must be

observed to avoid personal injury or fatalities.

Cautions indicate a situation that may cause damage or destruction of

equipment or may pose a long-term health hazard.

Notes are also used to draw attention to information. Notes may be located before or after the

related text.

NOTE: Notes are used to add information, state exceptions, and point out areas that may be of

greater interest or importance.

1.2 General Description

Figure 1: G2 Display Board

The Ionpure® G2 Display Board IP-POWERDSP-G2 is a digital controller designed specifically to

function as the human interface that allows an operator to control and monitor the Ionpure

G2 DC

Power Controller IP-POWER600-G2.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 6 of 25

The display board employs a 20 X 4 LCD backlit display for a clear view of data under most lighting

conditions. Parameters can be adjusted and screens can be navigated using the four membrane

switches on the front panel. Once the parameters have been configured, the setup menu may be

locked out to require a four-digit password for further modifications.

One of the two RJ-45 ports available on the back of the unit is used for connection with the G2

power controller utilizing a Cat 6 cable, Ionpure

part numbers IP-CABLE50CM-G2 or IP-

CABLE2M-G2. One display board can independently operate up to sixteen G2 power controllers

when they are linked together in a daisy chain. No external power supply is required with the

G2 display board.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 7 of 25

2 Installation

2.1 Requirements

The G2 Display Board meets NEMA 4/IP65 requirements when properly installed. The unit is

intended to be mounted into an enclosed panel with the supplied gasket to provide a seal at the

panel cutout and it is secured from the back with the provided nuts.

The environmental limits for operation are 0 to 50 °C at up to 95% relative humidity

(non-condensing).

Consider the display’s dimensions shown in Figure 2 to select the proper size for the panel.

Figure 2: G2 Display Dimensions

All connections and settings in this section should be made without

energizing the power controller(s). Review other safety procedures prior to

working in the panel.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 8 of 25

2.2 Panel Mount

To mount the G2 display into a panel:

a. Prepare a cutout and four mounting holes in the door of the panel as shown in Figure 3. All

cutouts should be clean and free of burrs.

Figure 3: Panel Cutout Dimensions

b. Install the display board on the door of the enclosure using the supplied hardware and

gasket.

2.3 Connections

2.3.1 Connections to a Single G2 Power Controller

To connect the G2 display to a single G2 power controller:

a. Connect one end of a standard Cat 6 cable to one of the two RJ45 ports on the back

of the display.

b. Connect the other end of the cable to one of the two RJ45 ports on the G2 power

controller.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 9 of 25

c. Once the power controller is turned on, the display should power on.

Figure 4 illustrates the connections described above:

Figure 4: Connections to a Single G2 Power Controller

2.3.2 Connections to Multiple G2 Power Controllers

To connect the G2 display to multiple G2 power controllers:

a. Connect one end of a standard Cat 6 cable to one of the two RJ45 ports on the back

of the display.

b. Connect the other end of the cable to one of the two RJ45 ports on the first G2

power controller.

c. Use additional standard Cat 6 cables to daisy-chain other power controllers, as

shown in Figure 5.

d. Once any of the power controllers is turned on, the display should power on.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 10 of 25

Figure 5: Connections to Multiple G2 Power Controllers

2.4 Power Controller Setup

2.4.1 DC Output Current Range Selection

To limit the possibility of applying excessive current to a CEDI module, it is recommended to

select an appropriate output current range with DIP switch SW1 of the G2 Power Controller as

described in Figure 6. Select the current range that can limit the current closest to the

maximum value that could be required by the module. Table 3 of the G2 Power Controller

manual lists the maximum DC currents required by each module.

Figure 6: Current Range Selection DIP Switch

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 11 of 25

The G2 display will detect the selected current range upon startup and will limit the DC output

current setpoint (A DC out) to this range.

2.4.2 Unit ID Selection

A unique identification number/letter needs to be assigned to each power controller that is

connected to a G2 display so they can be recognized without conflicts. This is done via rotary

switch SW2 of the G2 Power Controller. Each SW2 position corresponds to a channel or

module (MD) identification number on the display board, as shown in Table 1.

Table 1: Unit ID Selection

SW2 Position G2 Display Channel

0 1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

A 11

B 12

C 13

D 14

E 15

F 16

If two or more power controllers are mistakenly set to the same SW2 position, the G2 display

will show “ADDRESS CONFLICT” for that channel.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 12 of 25

3 Operation

3.1 Control/Navigation Keys

Figure 7: Control/Navigation Keys

ESC:press to exit a submenu, deactivate the cursor or discard setpoint changes.

UP: press to see the previous page of information or select between submenus or

configurable setpoints. When adjusting a setpoint, press to increase the value. Hold to

increase the value at a higher speed.

DOWN:press to see the previous page of information or select between submenus or

configurable setpoints. When adjusting a setpoint, press to decrease the value. Hold to

decrease the value at a higher speed.

ENTER: press to activate the cursor to select submenus or configurable setpoints. Press

again to enter the selected submenu or to accept setpoint changes.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 13 of 25

3.2 Menu Structure

Figure 8: Menu Tree Structure

OVERVIEW: this is the startup screen. It displays 3 channels at a time and shows the CEDI

module’s identification number (selected on the G2 Power Controller via switch SW2), DC

output volts, DC output current and module resistance in ohms. Unused channels are

represented with a line of asterisks (*). Resistance values above 999.9 are represented with

“***HI”. When the DC output current is zero, resistance will be represented with “----“ to

indicate that resistance can not be measured.

Channels 1, 2 and 3 are displayed upon startup of the unit. Pressing the UP or DOWN arrows

will scroll through all 16 channels.

A blinking module number indicates where the cursor is. Pressing the ENTER key will access

the RUN submenu of the CEDI module selected with the cursor.

A blinking row indicates and alarm condition for a specific power controller. The alarm type

can be identified under the ALARMS submenu.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 14 of 25

Figure 9: OVERVIEW Screen Example

RUN: this submenu provides operational data and access to adjust the DC output current of

the selected power controller, as well as access to submenus SETUP, ALARMS, LOGS and

DIAGNOSTICS.

There are 5 pages in this submenu. Data is grouped as follows:

PAGE 1:

Figure 10: RUN Screen – Page 1

V DC out: actual DC output voltage from the power controller to the selected

CEDI module.

A DC out: setpoint for the DC output current from the power controller to the

selected CEDI module. Press the ENTER key to adjust this value using the UP

or DOWN keys. Press ENTER again once the desired value has been set. This

setpoint can not be set to a value outside the current range selected in the power

controller via DIP switch SW1.

Ohms pres: actual resistance in ohms of the selected CEDI module. Resistance

values above 999.9 are represented with “***HI”. When the DC output current is

zero, resistance will be represented with “----“ to indicate that resistance can not

be measured.

Ohms init: initial resistance in ohms of the selected CEDI module. This value is

captured when the power controller has operated continuously for 2 hours after

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 15 of 25

48 hours of cumulative operation from the initial startup. Resistance values

above 999.9 are represented as “***HI”.

PAGE 2:

Figure 11: RUN Screen – Page 2

Ohms chg%: percentage of change in CEDI module resistance from initial

(Ohms init) to present (Ohms pres). Positive values represent an increase in

resistance and negative values represent a decrease in resistance, in reference

to the initial value.

V AC in: actual AC input voltage to the selected power controller. If this value is

higher than 726 VAC, a high AC input alarm will trigger.

A AC in: actual AC input current drawn by the selected power controller.

Power(kW): actual power consumption (Volts DC x Amps DC) in kilowatts of the

selected CEDI module.

PAGE 3:

Figure 12: RUN Screen – Page 3

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 16 of 25

Op.hours: hours in operation since the initial startup. Time is accrued only while

the Remote ON/OFF input of the power controller is closed.

Ic (VDC): estimated value of analog signal between terminals Ic+/Ic- of the

selected power controller.

Vm (VDC): estimated value of analog signal between terminals Vm+/Vm- of the

selected power controller.

Im (VDC): estimated value of analog signal between terminals Im+/Im- of the

selected power controller.

PAGE 4:

Figure 13: RUN Screen – Page 4

Board temp: temperature in degrees Celsius of the selected power controller’s

heatsink. If this value is higher than 64±4

o

C, a high temperature alarm will

trigger.

Press ENTER to activate the cursor and use the UP or DOWN arrows to select

any of the following submenus: SETUP, ALARMS or LOGS. Press ENTER

again to access the selected option.

PAGE 5:

Figure 14: RUN Screen – Page 5

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 17 of 25

DIAGNOSTICS: press ENTER to access the DIAGNOSTICS submenu.

SETUP:this submenu provides access to adjust the following settings: Ohms limit, VDC limit,

Ext control, Change password? and Change module?

This submenu is protected by a 4-digit password. The factory default password is 0000 and it

can be changed by the user.

The setting options are grouped in 2 pages:

PAGE 1:

Figure 15: SETUP Screen – Page 1

Ohms limit: the default and maximum setpoint is 996 ohms. When set correctly,

this value will alert the operator of a possible issue with the CEDI module due to

scaling, fouling or any other issue that could cause an abnormal increase in the

resistance of the module. This value should be adjusted to match a module’s

high resistance limit as follows: once the module has come to steady state

(typically after about 48 hours of actual operating time), set the Ohms limit to 1.5

times the steady-state electrical resistance. This is higher than the

recommendation in the EDI manual (25%) for resistance change to allow for

temperature fluctuations.

VDC limit: the default and maximum setpoint is 600 Volts. This voltage setting

will limit the actual DC output voltage of the power controller. It is recommended

that this number be set at the “Maximum Required DC Volts” value for the

specific CEDI module, as described in Table 3 of the G2 Power Controller

manual. If the actual DC voltage reaches the setpoint, a high DC voltage alarm

will trigger.

Ext control: the default setting is “No”. Changing this setting to “Yes” disables

the DC output current control capabilities of the display board so an analog

device can be used to control the DC output current of the power controller with

a 0-5 VDC signal at terminals Ic+/Ic-.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 18 of 25

Change password?: press ENTER and use the UP/DOWN keys to change the

password of the SETUP submenu.

PAGE 2:

Figure 16: SETUP Screen – Page 2

Change module?: it is recommended to use this option to reset all historic data

after a module replacement. Pressing ENTER will reset the following:

- Op.hours value in RUN submenu

- Ohms init value in RUN submenu

- Resistance alarm in ALARMS submenu

- All logs in the LOGS submenu

ALARMS:this submenu displays the status of alarms and provides the option to clear them.

There are 2 pages in this submenu. Data is grouped as follows:

PAGE 1:

Figure 17: ALARMS Screen – Page 1

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 19 of 25

Clear alarms?: if any alarms are active, pressing ENTER on this page will

activate the cursor to change the “N” to “Y” using the UP or DOWN arrows.

Pressing ENTER once “Y” is selected will clear all alarms that are active (not

“ok”).

Input VAC: reports the level status of the actual AC input voltage to the power

controller. The alarm will be “ok” if the input voltage is lower than 726 VAC; it will

be “hi” if it exceeds this value.

Output VDC: reports the level status of the actual DC output voltage from the

power controller. The alarm will be “ok” if the output voltage is lower than the

value set for VDC limit in the SETUP submenu; it will be “hi” if it exceeds this

value.

Resistance: reports the level status of the actual resistance of the CEDI module.

The alarm will be “ok” if the resistance is lower than the value set for Ohms limit

in the SETUP submenu; it will be “hi” if it exceeds this value.

PAGE 2:

Figure 18: ALARMS Screen – Page 2

Board temp: reports the level status of the actual temperature of the power

controller’s heatsink. The alarm will be “ok” if the temperature is lower than

64±4

o

C, and it will be “hi” if it exceeds this value.

Unit status: reports the status of the power controller’s power stage and

temperature sensor. The alarm will be “ok” if no issues are found, and it will be

“fail” otherwise.

LOGS: this submenu provides access to historical data recorded in the power controller. Data

is grouped in three logs: MAX VALUES, MIN VALUES and MODULE OHMS&S.

Press ENTER to activate the cursor and use the UP or DOWN arrows to select any of the

data logs. Press ENTER again to access the selected log.

IONPURE ®

G2 DISPLAY BOARD – IP-POWERDSP-G2

IP-POWERDSP-G2MAN Rev 1 Page 20 of 25

Figure 19: LOGS Screen

MAX VALUES: displays maximum values of important parameters to help with

performance analysis and troubleshooting. These values are monitored continuously

while the DC output of the power controller is enabled (closed remote ON/OFF input).

Figure 20: MAX VALUES Screen

VAC: maximum registered AC input voltage to the selected power controller.

AAC: maximum registered AC current drawn by the selected power controller.

VDC: maximum registered DC output volts from the selected power controller to

the CEDI module.

ADC:maximum registered DC amps from the selected power controller to the

CEDI module.

Ohms: maximum registered CEDI module resistance, in ohms. Resistance

values above 996 ohms are represented with “***HI”.

Board temp:maximum registered heatsink temperature in degrees Celsius of

the selected power controller.

This manual suits for next models

1

Table of contents

Popular Control Panel manuals by other brands

Telemotive

Telemotive Remote Control Touch Startup guide

Kontron

Kontron 2-DH47-0010 user guide

SJE Rhombus

SJE Rhombus 123 Installation Instructions and Operation/Troubleshooting Manual

IntelliSense

IntelliSense ST900C User manual addendum

Panasonic

Panasonic AK-HRP1010G operating instructions

SANJIANG

SANJIANG JB-QGL-9100E user manual

Microm

Microm MIX-4000 Series Installation and operation manual

GRASS VALLEY

GRASS VALLEY JUPITER CONTROL PANEL S25 - datasheet

Honeywell

Honeywell Notifier ID50 installation, commissioning & configuration manual

CAME

CAME ZLB24SA installation manual

Symetrix

Symetrix ARC-3 quick start guide

Bosch

Bosch Solution 2000 user guide