Chapter Outline

Please read the safety notice in this manual carefully, if not, it may cause serious

injury or death.

safety instruction

It mainly explains the safety instruction when install and operate the inverter.

Symbols and signs

It mainly explains the safety symbols on EVVO 20000TLG23P~EVVO 33000TLG23P.

1.1

Safety instructions

The inverter must beinstalled according tothe national andlocal grid standard and law. Read

and understand the instruction of this manual andbe familiar with relevant safety symbols in

the paragraph, then start to install and debug the equipment. According to the national

and state requirements, before connecting the grid, you must get power department

permission, and perform the operation only by qualified electrical engineer. Before

installing and maintaining the equipment, you should cut off the high voltage application

of PV array. You can also open the switch of Solar Array Combiner to cut off the high

voltage. Otherwise, serious injury may becaused.

Body sign and protection

There are warning signs on the body of the inverter,whichhas important safety operation

information, it is forbidden to damage these signs.

Thereisnameplateonsidebodyoftheinverter,whichhasimportantinformationofproduct

parameters,it isforbidden to damagethese signs.

Qualified persons

The customer must make sure the operator has the necessary skill and training to do his/her

job. Staff in charge of using and maintaining the equipment must be skilled, awareand

mature for the described tasks and must have the reliability to correctly interpret what is

described inthemanual.Forsafetyreasononlya qualified electrician,who has received

trainingand

/

orhasdemonstratedskillsandknowledgeinconstructionandinoperationof

thisunit,caninstallthisinverter. EVOLVEENERGY GROUP CO.,LIMITED doesnottakeany

responsibilityforthepropertydestructionandpersonalinjurybecauseofanyincorrectuse.

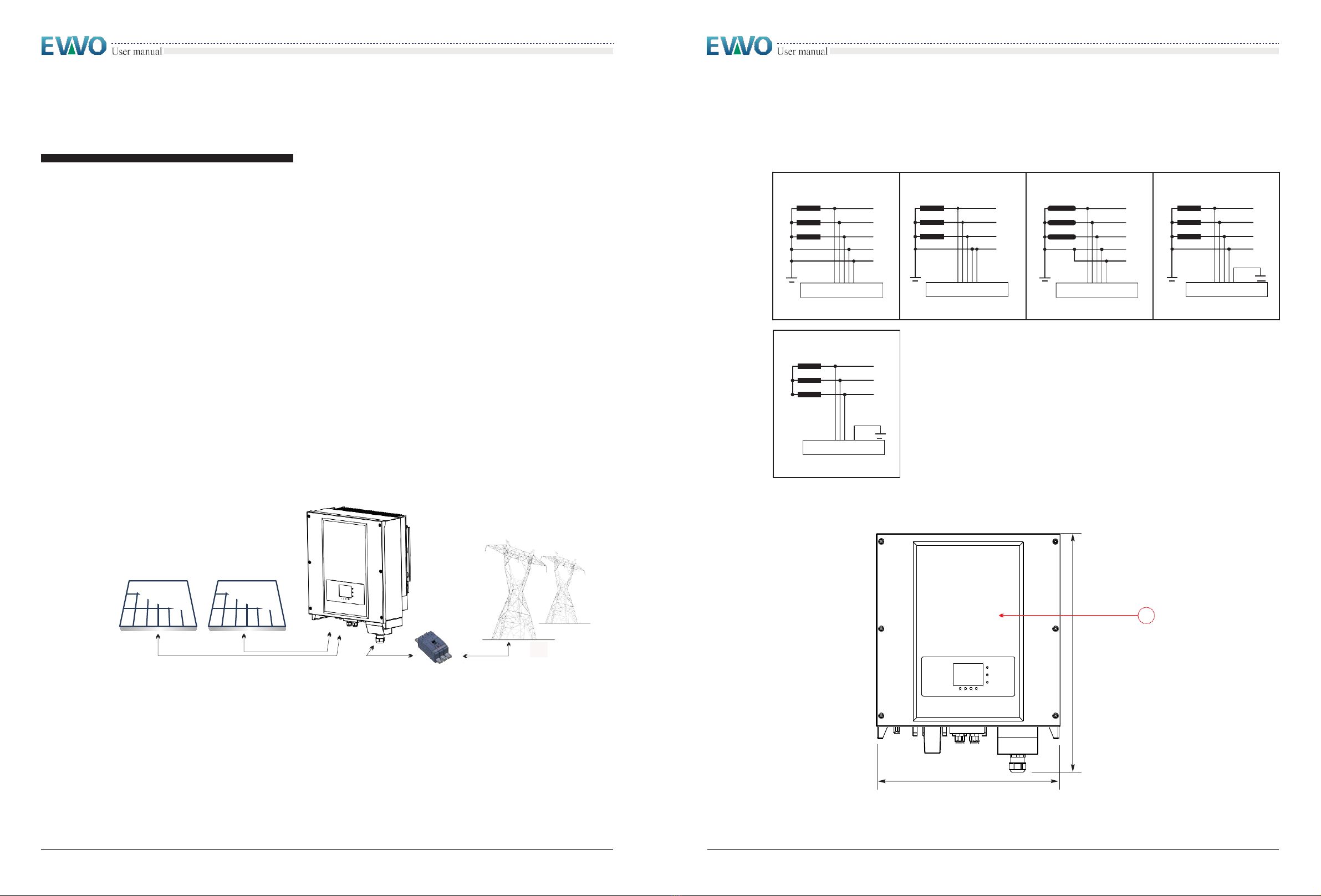

Assembly situation requirements

Please install and start inverter according to the following sections. Put the inverter in

appropriate bearing capacity objects (such as wall and components and so on), to ensure

that inverter vertical placed. Choose suitable place for installing electrical equipment. And

assure

enough fire exit space, convenience for maintenance. Maintain proper

ventilation and ensure thathave theenough air-coolingcycle.

Transport requirements

Ifyoufindpackingproblemsthatmaycausethedamageof theinverter,orfindanyvisible

damage,pleaseimmediatelynoticetheresponsibletransportationcompany.Youcanask

solarequipmentinstallationcontractororEVOLVEENERGYGROUPCO.,LIMITEDforhelpif

necessary. Transport of the equipment, especially by road, must be carried out with by

suitable ways and means for protecting the components (in particular, the electronic

components)fromviolentshocks,humidity, vibration,etc.

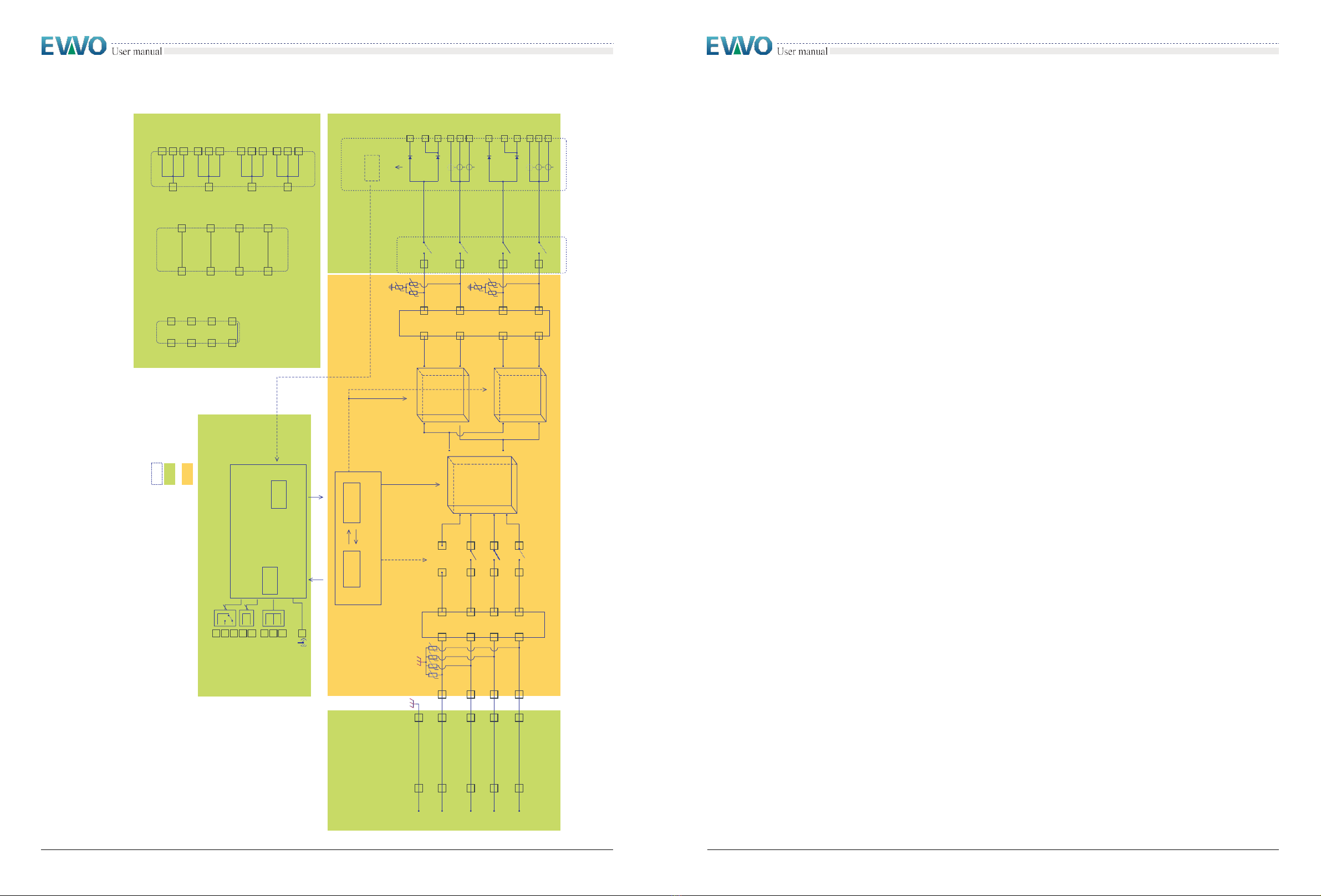

Electrical connection

Please comply with all the current electrical regulations about accident prevention in dealing

with the currentinverter.