EWC Controls Ultra-Zone UZC4 Service manual

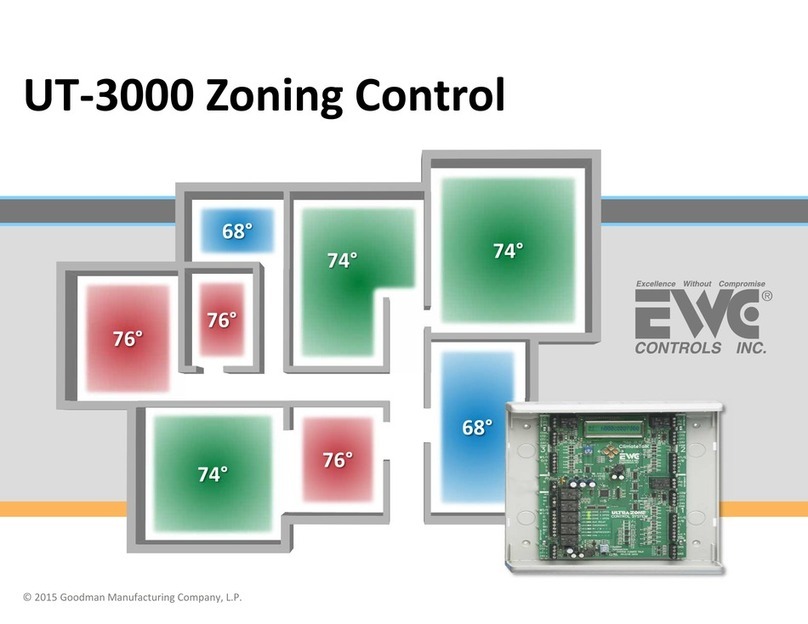

The UZC4 Universal Zone Control System allows you to easily

upgrade an inefficient single zone HVAC system, into an

Automated, Multi-zone, Energy saving, Comfort producing,

Safety Minded, HVAC system. With Superior design, Intuitive

firmware, Building Code Compliant support, Simple setup

options, and Easy to understand wiring, the UZC4 Zoning

system is the Designer/Contractors dream. Combined with

Patented EWC motorized dampers and practically any Off-the-

shelf Conventional or Heat Pump style Thermostats,

EWC has set a New Industry Standard in Large

Residential and Commercial HVACAir Zoning Systems.

The main module controls four air zones

using 24 vac motorized air dampers and

may be expanded up to 22 zones, using

ZXM2 Expansion Modules. See page 23.

The UZC4 will Control 2, 3 & 4 stage

Conventional, GeoThermal or Dual Fuel

Heat pumps, without the need for dual

fuel kits. Also single or multi-stage Gas,

Oil, & Hydronic HVAC systems, with

single or two stage cooling and Constant

or Variable speed fan systems.

Compatible with most Off the shelf 1 or 2

stage Conventional Heat/Cool or Heat

Pump Thermostats. All Mechanical,

Digital/Electronic, Dual Mode, and Internet

Compatible Thermostats that operate on

24vac. Battery powered or Power robbing

thermostats that draw less than 20 ma of

current are also compatible. Zone 1 will

accept One Zone Mode, Carbon Dioxide

Safety and Auxiliary/Dehumidify mode

inputs. See pages 9-11 & 14-17 for details.

The UZC4 Zone system features

automatic changeover from any

thermostat allowing for individual zone

comfort from the HVAC system.

The STATUS LED pulses as a steady

heart beat to indicate active Micro-

processor status.

On board Multi-colored LED’s will

illuminate to indicate system status,

HVAC system mode, and active / inactive

zone identification. See page 22 for details.

Damper 1 thru Damper 22 green LEDs

will indicate which zone dampers are

demanded to energize Open or Closed.

The main UZC4 module has a Manual

Reset circuit breaker with a Ground

Fault Indicator that protects all

connected modules and thermostat

circuitry. All modules have separate

damper motor Thermal Breakers too.

They protect the damper motor circuitry

from shorts in the field wiring. The

breakers will not protect against shorts

in the HVAC system wiring.

CAUTION: When the thermal

breaker is tripped it will get quite

hot. To reset the breaker: Shut off

power to the panel. Find and repair

the short. Restore the 24VAC power.

TEMPERATURE:-20° to 160°F (-29° to 71°C)

HUMIDITY: 0% - 95% RH Non-Condensing.

The UZC4 allows constant operation of

the Indoor Fan by Thermostat #1 only, or

by each individual thermostat. When

controlled by thermostat #1, All Zone

dampers will respond. When controlled

individually, Zones not calling for

continuous fan will close.

Zone

Capacity

Compatible

HVAC

Systems

Compatible

Thermostats

Automatic

Heat/Cool

Changeover

Status LED

System LEDs

Damper LEDs

Operating

Power

Manual

and

Automatic

Thermal

Circuit

Breakers

Operating

Conditions

Indoor Fan

Control

Model UZC4 Zone Control

TB-221

Box Contents * UZC4 Zone Control Panel

* Supply Air Sensor

* Technical Bulletin TB221

* Mounting Hardware

Leave this bulletin on the job site for future reference!

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 1

P/N 090375A0221 Revision S 09.04.12 Copyright ©2004 EWC Controls Inc., All Rights Reserved

FA

FA

24V

24V

TB1

R

C

JMP1

C1

D1

RESET

CB1

F1

K1

TB2

MXR

MXC

M6

M4

M2

M1

TB3

4

Z

O

N

E

K2

M6

M4

M2

M1

2

3

M6

M4

M2

M1

Z

O

N

E

Z

O

N

E

TB4

TB5

K3 K4

M6

M4

M2

M1

M6

M4

M2

M1

Z

O

N

E

O

A

D

M

P

R

TB6

1

K5

TB7

K7

M6

M4

M2

M1

NC

NO

C

E

B

D

TB8

K8 K9

G

Y2

Y1

O

B

W1

W2

E

RC

RH

RC

LINK

RH

H

V

A

C

S

Y

S

T

E

M

TB9

K10 K11 K12 K13

JMP3

K14

C

W

E

CONTROLS INC.

Englishtown, NJ

HVAC ZONE

CONTROl SYSTEM

UZC4

SAS

SAS

OAS

OAS

RAS

RAS

S

E

N

S

O

R

S

TB11

TB10

T

S

T

A

T

4

C

W1

W2

O

Y1

Y2

R

G

B

E

C

W1

W2

O

Y1

Y2

R

G

B

E

TB12

T

S

T

A

T

3

C

W1

W2

O

Y1

Y2

R

G

B

E

T

S

T

A

T

2

TB13

C

W1

W2

O

Y1

Y2

R

G

B

E

T

S

T

A

T

1

TB14

CO

CO

ONE

ZONE

AUX R

TB15

2

2

EMERGENCY

NORMAL

RAS

SAS

OAS

STATUS

LIMIT

LIMIT

LIMIT

ZONE

ZONE

ZONE

ZONE OPEN

OPEN

OPEN

OPEN

3

1

2

4

OPENOA DMPR

DMPR

BYPASS

AUX RELAY

FAN

COMPRESSOR1

COMPRESSOR2

EMERGENCY

W2 HEAT

VALV E

REV

W1 HEAT

LED12

LED13

LED14

LED15

LED16

LED17

LED9

LED10

LED18

LED2

LED3

LED11

LED4

LED1

LED6

LED5

LED7

LED8

RESET

CPU

TIMER

RESET

OFF

SAS

ON

<>

GAS

FAN

HYDRO

<>

90

PURGE

180

ss

<>

OAS

STAGES

TMR

<>

DF HP

CONV

< >

HP

GAS

SYSTEM

>

>

OFF

FAN PRG

ON

<>

OFF

R

%

50

ON

<>

RA

<

AUX RLY

>

DA

ANY

<

FAN CTRL

>

Z

1

OFF

<

ZDL

>

ON

OFF

<

RAS

>

ON

0

RA LMT

+10

>

<

HC

HP

>

TSTAT

>

O

<

RV

>

B

12

CS#

>

<

BANK1

BANK2

R1

STAGING

TIMER OAS

7

OFF

14 21 28

35

42

37

34

40 43 46

49

52

R2

COOLING

LIMIT

1ST

R3

LIMIT

STAGE

HEATING

DIFFERENTIAL

MULTI STAGE HEAT

R4

J1

120

110

130

140

150

160

170

12

19 26 33

40

47

5

D6

D5

D4

R7

R6

R5

D3

JMP2

D10

D7

D8

D9

R10

R11

R9

R8

D14

D13

D12

D11

R15

R12

R13

R14

D16

D15

R17

R16

R18 R63

R55

R53

R52

R54

R61

R60

Z1

R56

R57

R19

C2 C54

D2

R20

R21

R22

A

U

X

R

L

Y

C25

C26

C27

R65

R66

R67

R68

R71

R70

R69

R72

R73

R28

R27

R26

R25

R24

R23

D17

D18

D19

D20

D21

D22

R64

C48

C47

C46

C51

C50

C49

C52

SW3

R134

R128

R129

R130

R130

R132

R133

R135

R127

R126

R125

R124

R123

R122

U17

U18

U19

C42

C41

C40

C45

C44

C43

R121

R120

R119

R118

R117

R116

R115

R114

R113

R112

R111

R110

R109

R108

R107

R106

D23

C3

R29

R30

R31

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R46

R45

R50 C28

C29

C30

C31

C32

C33

C5

C4

U2

U3

U4

R74

R75

R76

R77

R78

R79

R88

R87

R86

R85

R84

R83

R82

R81

R80

C34

C35

C36

C16

C6

C20

U6

U7

U5

R98

R97

R96

R95

R93

R94

R92

R91

R90

R89

C39

C38

C37

C23

C24

U8

U9

R105

R104

R103

R102

R101

R100

R99

J2

C8

C7

C10

C9

C11

C12

C13

C14

C15

U15

U14 R47

C17

C21

C22 C19

U1

Y1

SW2

SW1

R51

R50

R48

R49

R58

C18

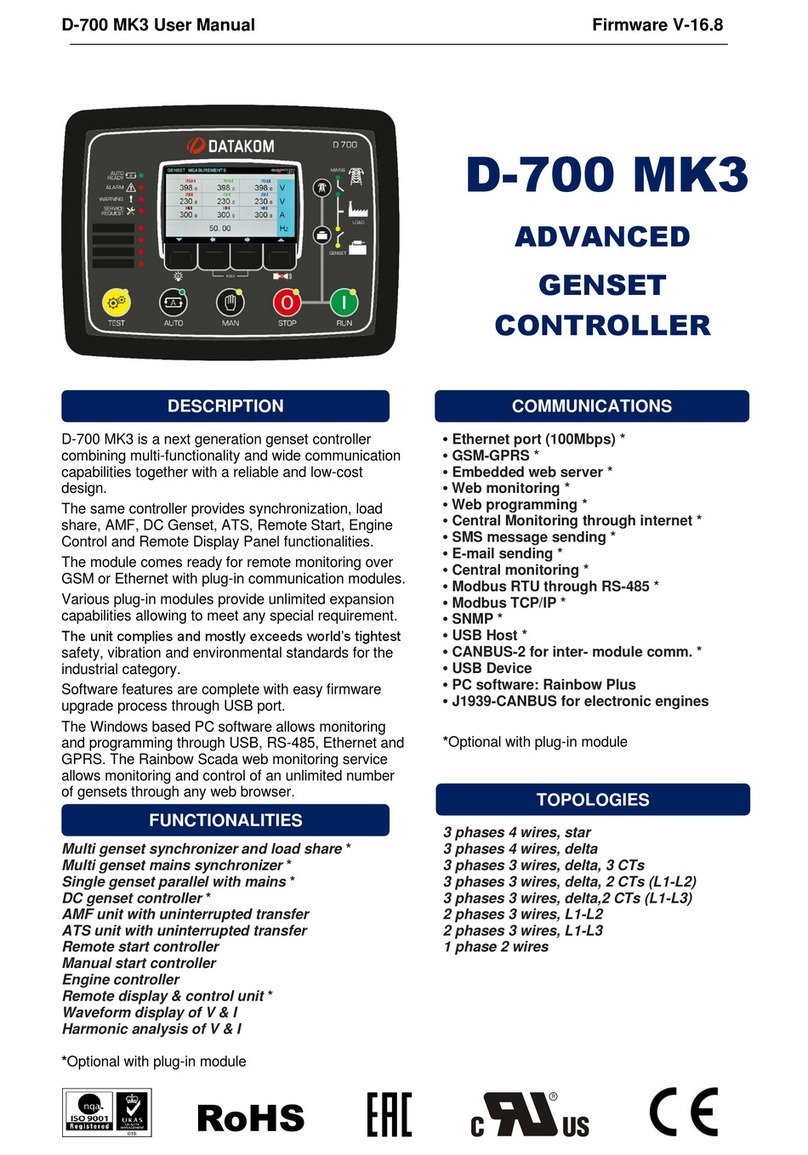

Figure 1.

LED19

GROUND FAULT

C53

INPUT VOLTAGE: 19-30VAC 60 Hz

Transformer 40-100VA MAX. NEC Class

2.

CURRENT DRAW: Max 22VA @ 24VAC.

OVER-CURRENT PROTECTION: 4.0

amp or 100VA.

Forced Air Zone Controls

®

OFF

7

14 21 28

35

42

MULTISTAGE

Timer / OAS

110

120

130 140 150

160

170

1st STAGE

HEAT LIMIT

34

37

40 43 46

49

52

COOLING LIMIT

A dip switch is provided to enable automatic fan

operation in heat mode. Useful for straight

electric heat or hydronic heat applications.

NOTE: Fan mode is automatically set when

Heat Pump is selected.

The panel has built-in delay timers that

insure safe & reliable operation.

When all zone demands are satisfied, the

panel will not resume the same mode

operation for a minimum of 3 minutes.

When a demand to Change Over has

been honored. A 4 minute delay timer

prevents the system from rapidly

changing between Heat to Cool, or Cool

to Heat mode.

The STAGING TIMER sets the

amount of continuous & cumulative

call time in 1st stage, before second

stage heat or cool is energized. Also

applies to 3rd & 4th stage heat.

NOTE: The potentiometer also

serves as the 2nd or 3rd stage Heat,

Outside Air Changeover Setting.

The UZC4 can inhibit 2nd or 3rd stage

heat based on Time or Outside Air

Temperature. All staging scenarios

depend upon the type of thermostat

used. See page 5 & 7 for details.

NOTE: An Optional OAS Sensor is required to

use the OAS feature. NOTE: Y2 Output

defaults to 30 minutes, if OAS is chosen and

single stage thermostats are used.

The Adjustable Heating Limit

potentiometer sets the 1st or 2nd stage

heat supply air temperature, at which

the heating is cycled off and the fan

continues to run, allowing the heat

exchanger or coil to cool down.

The Adjustable Cooling Limit

potentiometer sets the supply air

temperature at which the 1st & 2nd

stage cooling is cycled off and the fan

continues to run, allowing the coil to

warm up.

Indoor Fan

Control

During

Heating

Built-In

Timer

Settings

Definitions

are explained

below

*Short Cycle

Timer

*Changeover

Timer

*Staging

Timer / OAS

Cooling and Heating Limit Controls

*Short Cycle Timer

*Changeover Timer

*Opposite Mode

Delay Timer

*Staging Timer

OAS Setting

3 minutes - Fixed.

4 minutes - Fixed.

20 minutes - Fixed.

7 to 42 minutes

or 7 to 42 F°

Momentarily pressing the TIMER

RESET button will clear any Active

Time Delay. This enables you to test

and certify the installation faster.

NOTE: Do not use sharp objects to

press the button. Use your finger tip or

the eraser head of a pencil.

Press & Hold the SYSTEM RESET

button for 5 seconds. That will reset

the Main & Expansion modules on a

UZC4 Zoning System.

NOTE: A three minute startup delay

occ urs whene ver the CPU Reset button

is pushed, upon any initial pow er up, or

when a power failure has occurred.

Timer Reset

BUTTON

CPU Reset

BUTTON

Emergency

Heat

Switch

*Supply / Return

Air Limit Delay Timer

3 minutes - Fixed.

*Opposite

Mode

Delay Timer

A 20 minute delay must expire, or all

active zone(s) must satisfy, before

the UZC4 will honor a thermostat

demand to changeover to the

opposite mode of system operation. The

delay is fixed & cannot be changed or defeated.

OFF or

7 to 42

minutes or

7 to 42

degrees F.

Use when Timer

or Outside Air

Changeover is

required.

See Page 7

*Supply/Return

Air Limit

Delay Timer

The time delay of 3 minutes must

expire before the UZC4 will re-

energize heat or cool mode. This

occurs when the processor detects

the supply or return air temperature is

higher or lower than the Heat/Cool

limit settings.

The Adjustable Multistage Heat

differential potentiometer sets the 2nd

and/or, 3rd, & 4th stage heat supply air

temperature, at which the heating is

cycled off and the fan continues to run,

allowing the heat exchanger or coil to

cool down.

NOTE: Allows the supply air sensor to

be installed in the supply air plenum,

regardless of the coil/heat exchanger

configuration. Allows the installer to

fine tune virtually any multistage

heating system!

SYSTEM

RESET

EM

NORM

TIMER

RESET

An On-Board Switch is provided that

allows the user to set the system to the

Emergency heat mode. This switch is

shown in the NORMAL position.

NOTE: An Emergency terminal is also

provided at every Thermostat terminal

block, allowing Heat Pump

Thermostats to be connected to every

zone.

MULTI STAGE HEAT

DIFFERENTIAL

5

12

19 26 33

40

47

Example:

Hi Temp. limit=130

Plus M. stg T= 40

New limit F = 170°

Example:

Hi Temp. limit=130

Plus M. stg T= 40

New limit F = 170

UZC4 STANDARD FIRMWARE AND HARDWARE FEATURESUZC4 STANDARD FIRMWARE AND HARDWARE FEATURES

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

2

The operational sequence of the limit controls depends upon the

dip switch settings chosen on the UZC4 main module. Multistage

Heat Pump sequence will differ from Conventional Gas/Electric.

*Inter-stage Timer 2 minutes - Fixed.

*Inter-stage

Timer

2 minute time delay that occurs between

thermostatic demands to stage up or down.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 3

UZC4 ADVANCED FIRMWARE AND HARDWARE FEATURES CONTINUEDUZC4 ADVANCED FIRMWARE AND HARDWARE FEATURES CONTINUED

*FIRE ALARM

INTERLOCK

FEATURE

Building

Code

Compliant

Support

Fire Alarm

Activation

Over-rides

ALL functions

and features

All Connected

Dampers will

close and the

HVAC system

will shut down

The UZC4 includes a Fire Alarm

system interlock feature.

Wire the UZC4 into your building

Fire Alarm system, and achieve full

HVAC system shutdown, and

Closure of all Duct dampers, in the

event of Fire Mode Activation.

The circuit is normally closed and

must open to activate this mode. A

Fail Safe dry contact is required on

the Fire Alarm System.

When the Fire alarm system resets

to normal, the UZC4 will also

resume normal operation. Clip the

on-board jumper and wire as shown

on page 17.

*Demand

Based

Ventilation

CO2MONITOR &

FRESH AIR

INTERFACE

FEATURE

Building

Code

Compliant

Support

The UZC4 includes a Carbon

Dioxide and Fresh Air interface

feature.

Wire the UZC4 up to a separate

CO2Monitor with auxilary dry

contacts. When the CO2Monitor

activates, the UZC4 will open a

fresh air damper connected to it’s

OA damper terminal block, and

start the HVAC system fan.

The circuit is normally open and

must close to activate this mode. A

normally open dry contact is

required on the C02Monitor or

Fresh air Timer or Other Device.

When the CO2monitor resets to a

normal CO2level, the UZC4 will

close the fresh air /auxilary damper.

Other external dry contact devices

can be connected to the CO2

terminals such as a Manual Switch,

Enthalpy Control, or ClockTimer.

See page 16.

NOTE: Cooling & Heating

operations are not affected by

activation of this feature.

NOTE: Activation of the Fire Alarm

Interlock feature will over-ride the

CO2Monitor feature.

AUXILARY or

DeHUMIDIFY

INTERFACE

RELAY

Enhanced

Comfort

Solution

Auxiliary “dry”

SPDT output

This feature is

affected by

Heat/Cool

Operations

Fire Alarm

Activation

Over-rides

this feature

The UZC4 includes an Auxiliary

Interface Input and SPDT action

Dry Contact Output. This allows

the Installer to connect various

Auxiliary controls such as

Humidify or DeHumidify controls.

Simply connect the Controlled

Device or Circuit to the “Output”

dry contacts and achieve

integrated control without 3rd

party isolating relays.

See Page 14 and 15 for example

control and wiring solutions.

The Auxiliary input logic can be

field selected as (DA) Direct Acting

to humidify or (RA) Reverse Acting

to Dehumidify.

The UZC4 activates a unique algorithm to

rapidly de-humidify the home without

over-cooling it. See page 14.

ELECTRONIC

BYPASS

DAMPER

SUPPORT

FEATURE

Enhanced

Airflow

Solution

Fire Alarm

Activation

Over-rides

this feature

The UZC4 includes support for

an Electronic Bypass Damper.

Wire up a EWC Model “EBD”

Bypass Damper to achieve

precise control of the HVAC

system static pressure and

bypass damper operations.

Wire up the Model “EBD” damper

as shown on page 17.

The UZC4 defaults the Bypass

Damper to the “Open” position

during “IDLE” periods. It will also

maintain that position for 45

seconds; at the start of any

thermostat demand for Heating,

Cooling, or Fan only Operation.

The 45 second time delay

allows a constant or variable

speed fan to start in a “Quiet

Mode” and does away with

noisy air duct velocities upon

system startup.

A Latent cooling effect is also

achieved by using this feature.

After 45 seconds the UZC4 will

release control of the system static

pressure to the EBD diaphragm

control and a gradual increase in

system static pressure is

achieved. NOTE: The UZC4 will not

resume control of the “EBD”, until the

next “IDLE” period begins.

This feature is

not affected by

Heat/Cool

Operations

Fire Alarm

Activation

Over-rides

this feature

UZC4 ADVANCED FIRMWARE AND HARDWARE FEATURES CONTINUEDUZC4 ADVANCED FIRMWARE AND HARDWARE FEATURES CONTINUED

RETURN AIR

MONITORING

FEATURE

Enhanced

HVAC System

Safety and

Energy

Savings

Solution

Note: If this

feature is

“Enabled”

but the “RAS” is

not connected or

is not detected;

The “RAS” LED

will blink rapidly

as a warning and

The UZC4 will

not allow RAS

operations to

occur.

Note: When the

Return Air sensor

detects a return

air temperature

between the

Stage Up Value

and

the Stage Down

Value, the “RAS”

LED will blink

slowly as a

warning. The UZC4

will also hold at the

current staging

until the system

status changes

sufficiently to

allow a stage up

or down.

The UZC4 includes a RETURN AIR TEMPERATURE SENSING feature.

Connect an OPTIONAL Return Air Sensor (#RAS) to the UZC4 and achieve the ability to

STAGE DOWN the HVAC system if the return air temperature exceeds the return air

temperature limit set points. Set the “RAS” Dipswitch #6 to the “ON” position, and

choose either (0) or (+10) at the “RA LIMIT” Dipswitch # 7. Both switches are located

on the Dipswitch Bank#2.

The UZC4 will now monitor the return air temperature and allow Stage up, or if necessary

Stage Down the cooling or heating operation to maintain a return air temperature within

the following values. As stated above, choose either (0) to accept the default return air

limit values for your particular HVAC system or choose (+10) to offset the default values

10 degrees higher. Note: The (+10) offset applies to heating operations only. The default

return air temperature limit set points for cooling operations cannot be offset.

RETURN AIR LIMITS DURING HEATING CYCLE FOR HEAT PUMPS ONLY:

Default (0) set points:

If the Return Air temperature is:

80 degree F. or below, Stage Up is allowed.

105 degree F. or above, Stage Down is forced.

Default (+10) set points:

If the Return Air temperature is:

90 degree F. or below, Stage Up is allowed.

115 degree F. or above, Stage Down is forced.

RETURN AIR LIMITS DURING HEATING CYCLES FOR GAS, OIL, STRAIGHT ELECTRIC:

Default (0) set points:

If the Return Air temperature is:

80 degree F. or below, Stage Up is allowed.

115 degree F. or above, Stage Down is forced.

Default (+10) set points:

If the Return Air temperature is:

90 degree F. or below, Stage Up is allowed.

125 degree F. or above, Stage Down is forced.

RETURN AIR LIMITS DURING COOLING CYCLES FOR ALLHVAC SYSTEM TYPES:

Default (0) set points:

If the Return Air temperature is:

65 degree F. or above, Stage Up is allowed.

55 degree F. or below, Stage Down is forced.

Default +10 applies to heating operations only.

The Return Air Sensing Feature cannot cycle the 1st stage equipment off-line. It can only force a

Stage Down when the equipment is in 2nd stage cool or 2nd, 3rd, or 4th stage heat, and the selected

return air set points above have been exceeded. The Supply Air Sensing feature is the only monitor

that can cycle the 1st stage equipment off-line.

A three minute delay will occur after a forced stage down. If a stage up demand is present, the UZC4

will allow the stage up to re-occur when the three minute delay has expired and the return air

temperature is back to normal.

The UZC4 will automatically adapt to the “GAS,OIL,ELECTRIC” set points when a Heat Pump

system stages up to Fuel or Auxiliary mode.

This powerful feature will enhance the efficiency of your Zoned HVAC system and protect the

equipment from excessive bypass temperatures during low load conditions.

4

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

5

UZC4 ADVANCED FIRMWARE AND HARDWARE FEATURES CONTINUEDUZC4 ADVANCED FIRMWARE AND HARDWARE FEATURES CONTINUED

DIRECT DUAL FUEL COMPATIBLE FIRMWARE

MODULE TO MODULE FACTORY POWER WIRING

RAPID DE-HUMIDIFY FIRMWARE

* 7 TO 42 MINUTE STAGE UP TIME DELAY SETTINGS

* 7 TO 42 DEGREE F. OUTSIDE AIR CHANGEOVER

* STATUS LED’s ARE INCLUDED ON ALL MODULES

*ONE ZONE MODE SETBACK CAPABILITY

* SIMPLIFIED WIRING AND SYSTEM SETUP

* FIRE ALARM INTERFACE

The UZC4 is fully compatible with Dual Fuel

Heat Pumps, and other Hybrid HVAC systems.

Dual Fuel kits are not required. Select staging

based on Adjustable Time Delay, an Optional

Outside Air temperature Sensor, or allow the

thermostats to control staging. The intelligent

firmware does the rest.

The UZC4 includes Factory Power Wiring on

all expanded systems. The 24 vac power to the

expansion modules is fed through the bus

cable. The bus cable feeds power to all module

processors & thermostats. Damper Motor

terminal blocks are isolated and powered

separately. This simplifies your wiring,

reduces the chances of polarity reversal and

allows more connected dampers per zone.

* MULTI- STAGE HEAT ADJUSTABLE LIMIT CONTROL

* ELECTRONIC BYPASS DAMPER SUPPORT

* AUXILARY MULTI-FUNCTION SUPPORT RELAY

*ZONE DEMAND LIMITING FEATURE

CO2DEMAND BASED VENTILATION SUPPORT

The UZC4 includes support for Demand Based

Ventilation Control scenarios. Designed to

help meet or exceed local building codes and

ASHRAE ventilation standards. Simply

connect your CO2Monitor and a Fresh Air

damper to the UZC4.

The UZC4 is the first Zone Control System to allow 4 stage thermostats to be connected to all zones

The UZC4 is capable of numerous staging sequences depending on the type of HVAC system being

controlled, the type of thermostats connected, and the programmed staging sequence you desire.

As always you can still control a multi-stage HVAC system using inexpensive single stage thermostats

and sequence the staging by on-board adjustable time delay, or by using an optional outdoor air sensor

(OAS) and sequence the staging via an outdoor air set point.

You can still control a state of the art multi-stage Heat Pump using single or two stage conventional

thermostats and sequence the staging by time delay or outside air set point.

You can choose to control most any multi-stage Heat Pump or Conventional HVAC system with OEM

multi-stage thermostats on all zones. The UZC4 can be programmed to stage up or down based on the

thermostat inputs from each zone. The UZC4 allows a level of versatility that has never before been

offered by any zoning company. You can choose to install 3 or 4 stage thermostats on the largest zones, 2

stage thermostats on medium sized zones and single stage thermostats on the small zones.

To achieve staging via thermostatic demand only; Choose (TMR) Timer setting on Dipswitch #5 Bank 1

And then set the Multi-Stage Timer setting to (0) Zero. Setting the Timer to zero disables Timed Staging

and the UZC4 will stage up or down only when the thermostat(s) demand it.

THERMOSTATIC DEMAND STAGE UP ON ALL ZONES

The UZC4 will perform a unique de-humidify

function when a demand to de-humidify is

detected at the Auxilary Input terminal. The

UZC4 will energize the Emergency heat relay to

activate one electric strip bank at the same

time the Y1 cool is active, so long as the

demand to de-humidify is detected. This

powerful feature will rapidly de-humidify your

home, and tempers (reheats) the supply air to

prevent over-cooling. See Page 14 for details.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

Selecting the Options Using the DIP Switches

***FS = Factory Settings

CONTINUED ON NEXT PAGE...

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

FS HP < SYSTEM > GAS

DF < HP > CONV FS

FS OFF < FAN PRG > ON

90s < PURGE > 180s FS

OAS < STAGES > TMR FS

FS OFF < 50% R > ON

FS OFF < SAS > ON

FS GAS < FAN > HYDRO

SWITCH LEGEND

HC < TSTATS > HPFS

FS1 < CS# > 2

FS O < RV > B

FS OFF < ZDL > ON

RA < AUX RLY > DA FS

FS OFF < RAS > ON

FS 0 < RA LIMIT > +10

FS ANY < FAN CTRL > Z1

Bank1

Bank2

Detailed explanations of each Dip Switch Function are included on the following

pages. Please study and familiarize yourself with all of the functions and features, prior

to activating the Zoned HVAC system. Not all features will apply to your application.

The UZC4 comes from the factory pre-set to operate a 2 stage Heat Pump using

heat pump thermostats to control the staging.

Failure to properly set all dip switches to the correct and/or desired positions will result

in improper operation of the controlled HVAC System.

Please read and study the entire Technical Bulletin and if necessary, Call the EWC

Technical Support Hotline when assistance is required.

Leave this Technical Bulletin with the Home or Building Owner for future reference.

6

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

RECORD YOUR DIP SWITCH

SETTINGS HERE

Programming and setting up the

UZC4 is very easy! Check the

Switch Legend and refer to the

following pages for an explanation of

each dip switch function and choose

your settings. Some functions may

not apply to your application. Use a

pencil to fill in the square & record

your settings. If the settings get

changed later on, you will have a

record of the original settings.

NOTE: When you choose “HP” at

switch #1, Bank 1, the fan mode is

automatically set for you. There is no

need to move switch #8, Bank1.

Leave it in the “GAS” factory setting.

RECORD YOUR DIP SWITCH

SETTINGS HERE

HP < SYSTEM > GAS

DF < HP > CONV

Choose the type of HVAC system you want to control. Select HP, if your system is any type of heat pump. Select GAS,

if your system is a any type of Gas / Oil furnace, or any straight Electric furnace or Hydronic (hot water / steam)

heating system.

If you chose “HP” at switch #1, then choose the type of Heat Pump you want to control. Select DF, if your system is a Dual Fuel

heat pump with Gas or Oil furnace backup heat. Select CONV, if your system is a Conventional heat pump with Electric resistance

backup / supplemental heat. Also applies to Ground source / Geothermal heat pumps with Electric backup heat.

7

1

2

3

4

5

OFF < FAN PRG > ON

Select ON, if you want the UZC4 to force the indoor blower ON at the end of a heat/cool call to assist the zone purge cycle.

Selecting OFF will allow the HVAC system to operate the indoor blower, without interference from the UZC4.

6

CONTINUED ON NEXT PAGE...

Selecting the Options Using the DIP Switches - BANK1

90S < PURGE > 180S

Select 90S or 180S, if you want the zone dampers to hold position for 90 seconds or 180 seconds at the end of any heat or cool call.

This allows the HVAC system to purge the remaining hot or cold air, into the zone(s) that were calling for it.

7

Select OAS, if you want to delay multi-stage operations based on the outside air temperature sensor. Select TIMER, if you want to

delay stage up based on the adjustable on-board timer. Both features are very useful when using single stage thermostats on all zones.

NOTE1: Y2/W2 stage up defaults to a 30 minute delay, when OAS is chosen. NOTE2: An optional Outside Air Sensor (Part#OAS) is required

to use the OAS feature. NOTE3: Thermostat demands to stage up, will always over-ride the Timer or OAS staging operations, Unless the

50% rule has been enabled, or the Return Air temperature limit has been exceeded. NOTE4: Thermostatic demands to Stage Down will be

honored unless the Timer is also in use. NOTE5: Disable the Timer by setting to OFF, and the UZC4 will obey Stage up & Stage down

demands via the thermostats only!

OAS < STAGES > TMR

OFF < 50% RULE > ON

Select OFF, if you do not want to inhibit 2nd stage compressor cooling/heating operations based on the total number of zones calling.

Select ON, if you want to inhibit 2nd stage compressor cooling/heating operations based on the total number of zones calling. Half or more of

the total number of thermostats must be calling or stage up will not occur. NOTE 1: In All Modes, the 50% rule occurs between Y1 and Y2.

NOTE2: In Gas mode the 50% rule occurs between W1 &W2. NOTE3: Emergency mode is never affected by the 50% rule.

OFF < SAS > ON

Select OFF, if you do not want to use the Supply air sensor included with the UZC4 Zone Control system. Select ON, if

you want to use the included Supply air sensor. Refer to the data sheet included with the Supply air sensor for

installation details. Refer to page 2 for details on Supply air Sensing Limit Controls and settings. Mount the Supply

Air Sensor in the discharge duct and/or plenum.

8

GAS < FAN > HYDRONIC

Select GAS, if your HVAC system is a gas or oil forced air furnace. Select HYDRONIC, if your HVAC system has a hot

water / steam coil, or straight electric heat with no indoor blower support. Useful when you need the indoor blower to run

automatically in heat mode, just like it does in cool mode. NOTE: When you select HP on dip switch #1, the indoor fan

mode is automatically set for you. If so, then leave this switch in the factory GAS setting.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

IMPORTANT NOTE: The UZC4 Zone Control System allows Heat Pump or Conventional Multi-Stage

thermostats to be wired to all Zones!

Thermostat demands to stage up, will always over-ride any programmed staging operation. The UZC4 will

remain in Multi-stage mode until that terminal is de-energized. If this occurs in dual fuel mode or emergency mode,

the UZC4 will stay in that mode until all Heating demands are satisfied. On the next heating cycle, the UZC4 will

attempt to activate 1st stage heat unless, Emergency Mode is still active, or the outdoor temperature is low and

OAS / DF has been selected. This comfort over-ride feature provides true versatility to your zoning system, and

gives the homeowner comfort control capability over the system.

Selecting the Options Using the DIP Switches - BANK2

1

1 < CS# > 2

Choose the number of Condensing Unit Stages you want to control. Select 1, if your CU has a Y1 connection only. Select 2, if

your CU has a Y1 & Y2 connection. NOTE1: This feature must be set correctly for proper Timed & Outdoor Air Sensor staging

operations. NOTE2: Thermostat demands to stage up, will always Over-ride the Timer & OAS staging operations, unless the

50% rule has been enabled, or the Return air temperature limit has been exceeded. NOTE3: All stage up Operations depend upon

the correct setting of this switch.

HC < TSTAT > HP

Select the type of thermostats you want to use. Select HC, if your thermostats are the standard Heat/Cool type. Select HP, if your

thermostats are Heat Pump types. NOTE1: You cannot mix thermostat types. NOTE2: You do not need HP thermostats to control

a Heat Pump. NOTE3: Thermostat demands to stage up, will always over-ride the Timer or OAS staging operations, unless the 50%

rule has been enabled. NOTE4: Thermostatic demands to stage down will be honored unless the Timer is in use.

2

3

O < RV > B

Choose the type of Reversing Valve you want to control. Select O, if your heat pump reversing valve energizes in cooling and

defaults to heat mode. Select B, if your reversing valve energizes in heating and defaults to cool mode. NOTE: The UZC4 will hold

the “O” output or the “B” output continuously, even during idle periods, until a thermostatic demand to change modes is detected.

NOTE: Proper setting of this switch is critical. The reversing valve will not function properly if this switch is not set correctly.

4

OFF < ZDL > ON

Select ON and the UZC4 will limit HVAC operations based on the total number of zones calling for conditioned air.

16% or 1/6 of the total number of zones (rounded up) must be calling for the same mode of operation, or the UZC4 will not

activate the HVAC system. This feature only activates at 8 or more zones. Select OFF if you do not want to utilize the Zone

Demand Limiter feature. NOTE: Zone 1 is not affected by this feature. Zone 1 demands are always honored. ZDL example:

A zone system has 20 total zones and the ZDL feature is active;At least 4 zones must be calling for the same mode of

operation (Heat or Cool) or the UZC4 will not activate the HVAC system. 18zone=3, 16zone=3, 14zone=3, 12zone=2, 10zone=2, 8zone=2.

5

RA < AUX RLY > DA

6

OFF < RAS > ON

If you connect an OPTIONAL Return Air Sensor to the UZC4, then Select ON, and Choose to use the default set points

for Return Air Temperature Limit Operations, or choose to Offset those set points by 10 degrees higher at the next Dip Switch.

Refer to the data sheet included with the Return air sensor for installation details. Mount the Return Air Sensor in the

return air duct as close to the Blower intake as possible, or in the blower cabinet. Read page 4 for Operational details.

7

If you connect an OPTIONAL Return Air Sensor and switch on the “RAS” switch above; then choose “0” to accept the

default set points for Return Air Temperature Limits, or choose “+10” to Offset the default set points 10 degrees higher.

Refer to the data sheet included with the Return air sensor for installation details. Read page 4 for Operational details.

8

0 < RA LIMIT > +10

ANY < FAN CTRL > Z1

8

Select which thermostat(s) can activate a demand for Continuous Fan Operation. Choose “ANY”, and the UZC4 will

honor any thermostat demand to activate continuous fan, and only the dampers connected to that zone will open. All others

will close. Choose “Z1”, and the UZC4 will honor a demand to activate continuous fan from zone 1 only. All connected

dampers on all zones will open. Demands to activate continuous fan from any other thermostat will be ignored.

NOTE: Continuous Fan Operations will only occur when there are no active or pending heat or cool operations.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

Select the control signal type you need, in order to activate your preferred Auxilary Relay function. Choose RA (Reverse

Acting) for De-Humidification Control, or Choose DA (Direct Acting) for Humidification Control, depending on the control input signal

you require. Then connect your controlled device or circuit to the SPDT dry output contacts and achieve integrated control without

the need for 3rd party relays or specialty relays. If this feature is not used, the switch must be in the DA position.

See Pages 14-16 for further information.

Installation should be performed by qualified

personnel only. Follow local & national electrical &

mechanical codes. Use multi-conductor 18 awg solid

copper conductors. Wire number to number or letter to

letter on each control or device.

WARNING: THESE PANELS ARE DESIGNED FOR USE

WITH 24-30vac. DO NOT USE OTHER VOLTAGES! USE

CAUTION TO AVOID ELECTRIC SHOCK OR

EQUIPMENT DAMAGE.

INSTALLATION INSTRUCTIONS and THERMOSTAT WIRING

A single 24vac, 40va

UL Listed transformer

can power the UZC4

Main module with one

damper on each zone.

A total of four zones

and four dampers. See

page 19 for more load

and transformer data.

NOTE: The 24 vac power required to operate a UZC4

system must be supplied by a separate transformer.

WARNING! DO NOT use the 24 vac power supply from

the HVAC manufacturer’s equipment.

NOTE: Unlike previous UZC series zone control

systems, the UZC4 supplies power to all connected

expansion modules. This improved design simplifies

the installation wiring and reduces the possibility of

polarity reversal or incorrect transformer phasing. The

UZC4 does allow you to isolate and power up the

damper terminal block separately for greater versatility.

Line

Voltage

PROVIDE

MEANS OF

DISCONNECT

TRANSFORMER

24vac, 40 - 100va

UL LISTED

UZC4

Main Module

R - Hot

C - Common

C

R

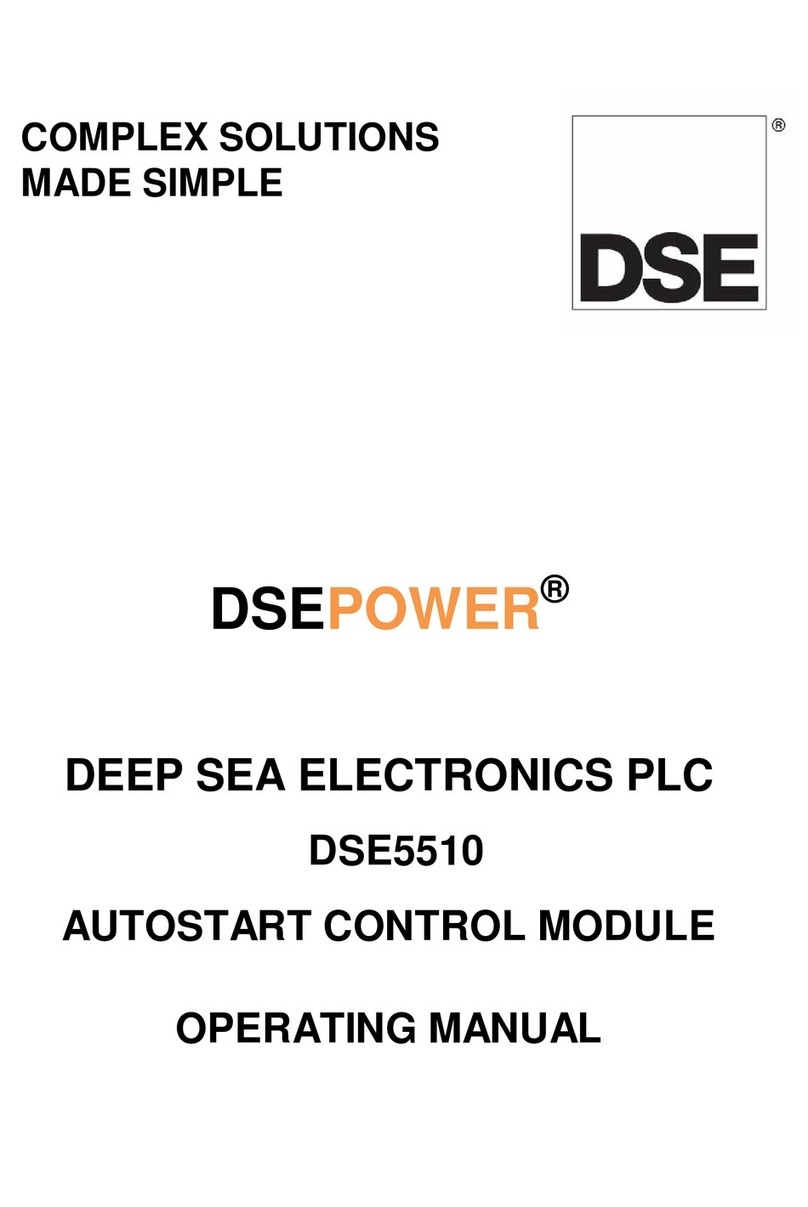

Figure 2. UZC4 Power wiring Supply

All of the preceding diagrams reflect conventional

(Non-Heat Pump) thermostats, controlling

conventional HVAC systems. However, the equipment

being controlled does not have to be the conventional

type. A heat pump system can be controlled using

conventional thermostats.

Figure 5.

Figure 4. Model EWT-725: Configured for typical 2 stage

Gas or Electric heating system with 1 stage

cooling.

C

W2

Y2

R

G

W1/E

CONVENTIONAL 2 HEAT / 1 COOL THERMOSTAT

POWER WIRING

TYPICAL 1 HEAT / 1 COOL THERMOSTAT WIRING

Mount the panel housing in a convenient location close to

the Air Handler. Mounting hardware is provided. Use the

knockouts provided on the panel housing as entryways

into the housing. Strain relief fittings can be used if

desired. Use care and do not damage the circuit board

when making wire connections.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 9

C

W2

Y1

R

G

W1/E

CONVENTIONAL 2 HEAT / 2 COOL THERMOSTAT

24 V

24 V

FA

FA

ANY ZONE

T’STAT

Y1

O/B

Y2

O/B

ANY ZONE

T’STAT

Model EWT-855 : Configured for typical 2 stage

Gas or Electric heating system with 2 stage

cooling.

Common wire not required if batteries are used.

*

Model EWT-725: Configured for 1 heat 1

cool. See thermostat instructions for further

details.

Figure 3.

MODEL EWT-725

CO

BW2

W/E Y1 RG

C

W2

Y2

R

G

W1/E

ANY ZONE

T’STAT

Y1

O/B

Common wire not required if batteries are used.

*

MODEL EWT-725

CO

BW2

W/E Y1 RG

*

*

W/E

CG

W2 Y1 Y2 RC

EWT-855i “Wi-Fi” Thermostat

RH O B

THERMOSTAT WIRING CONTINUED

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

10

Figure 7.

C

W2

Y2

R

G

W1/E

Y1

O/B

ANY ZONE

T’STAT

Figure 8.

C

W2

Y2

R

G

W1/E

Y1

O/B

ANY ZONE

T’STAT

Figure 9.

ANY ZONE

T’STAT

C

W2

Y2

R

G

W1/E

Y1

O/B

Figure 6.

C

W2

Y2

R

G

W1/E

Y1

O/B

ANY ZONE

T’STAT

WIRELESS THERMOSTAT: RECIEVER MODULE

MODEL EWT-955WH

Model EWT-955WH: Wireless Thermostat.

Configured for 2 heat 2 cool.

See Thermostat instructions for further details.

Model EWT-955WH Wireless Thermostat:

Configured for 3 heat 2 cool heat pump.

See thermostat instructions for further details.

Model EWT-855i: Configured for 3 heat 2 cool.

See thermostat instructions for further details.

Model EWT-725: Configured for 2 heat 1 cool

heat pump. See thermostat instructions for

further details.

**

*

*

Field installed jumper.

*

*

Field installed jumper.

*

Common wire not required if batteries are used.

*

**

MODEL EWT-725

CO

BW2

W/E Y1 RG

W/E

CRH

W2 OY1 Y2

MODEL EWT-855i “Wi-Fi” Thermostat

RC G B

C

W2

B

W/E

Y2

Y1 RC RH

HDOG

WIRELESS THERMOSTAT: RECIEVER MODULE

MODEL EWT-955WH

C

O

B

W/E

Y2

Y1 RC RH

HDW2 G

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 11

Wiring for automatic activation of “One Zone”

mode using a commercial grade thermostat in

Zone 1. Program or wire the thermostat to Energize

(close contact) the One Zone Terminal and setback

the temperature when the building is

Unoccupied....When the building is Occupied, the

thermostat will de-energize (open contact) the One

Zone Terminal.

WIRING FOR “ONE ZONE” MODE

Figure 11.

ZONE THERMOSTAT

#1

Commercial Grade

Thermostat

G

RY

W2W1

C

UNOCC / OCC

C

W2

Y1

R

G

O/B

ONE

ZONE

ZONE 1

T'STAT

W1/E

Y2

AUX R

CO2

CO2

Figure 12.

HEAT PUMP MODE WITH DE-HUMIDIFICATION

C

W2

Y1

R

G

O/B

ONE

ZONE

ZONE 1

T'STAT

W1/E

Y2

AUX R

CO2

CO2

Wiring for typical 3 stage Heat,2 stage cool Heat

Pump. Diagram reflects De-humidification

terminal wired to the Auxilary input. For auxilary

output wiring see page 14. Auxilary Relay Dip

Switch #5, Bank #2, should be set to Reverse

Acting. (RA)

Refer to Dehumidify

Operations on page 14.

Wiring a split circuit thermostat to operate a

Radiant floor heating or Baseboard heating

Hydronic system. The UZC4 controls the cooling

only, in this type of configuration.

To Radiant floor / Baseboard heat

zone valve or pump relay

WIRING FOR RADIANT FLOOR HEAT

ANY ZONE

T’STAT

C

W2

Y2

R

G

W1/E

Y1

O/B

Figure 13.

ANY ZONE

T’STAT

C

W2

Y2

R

G

W1/E

Y1

O/B

MODEL IZT-250

CB Y2

W1 W2 Y1 RH G

Model IZT-250 Internet Thermostat:

Configured for 2 heat 2 cool. See thermostat

instructions for further details.

Figure 10.

ORC

MODEL EWT-601-2

RH

COY1 RC G

W/E

B

W/E

W2 Y1 RC RH D

HCG

OY2

MODEL EWT-955WH

B

Typical gas / oil system with A/C.

A jumper wire between Rc and Rh is

provided. There is no need to install

a jumper.

Wiring diagram for a typical oil burner,

hydronic zone / Air handler with A/C.

Cut the Rc / Rh link on the UZC4

Panel for systems requiring isolation.

Single

Transformer

Gas/Oil Systems

1 or 2 Stage Heat

Two

Transformer

Oil/ Hydro

Systems

Figure 14. Single transformer Gas / A/C system.

Figure 16. Conventional Heat Pump System

Figure 15. Two transformer Oil or Hydronic / A/C system.

Dual Fuel

Heat Pump

with “O” Type

Reversing Valve

HVAC SYSTEM WIRING

Figure 17. Single stage heat pump and single stage furnace.

Note that a Conventional & Dual fuel heat pump could wire up more or less the

same. The difference is how staged heat operates. In a Conventional system,

the indoor fan & the compressor continues to run when stage up occurs. In a

Dual Fuel system, the indoor fan & the compressor shuts down when stage up

occurs. The UZC4 will perform these functions automatically. All you have to

do is set the dip switches to the correct settings. Select DF or CONV at dip

switch #2, Bank 1. Choose to activate 2nd stage heat by TIMER or by

OUTSIDE AIR TEMPERATURE. (Optional Sensor Required) You can also

use Multi-stage thermostats in any or all Zones. When the thermostat stage up

heat demand is satisfied, the UZC4 will stage down, unless DF/OAS has been

selected and the outdoor temperature is lower than the OAS changeover

setting. In that case the system will continue in FUEL mode, until all heating

demands are fully satisfied. Your Heat Pump may be capable of making

these decisions without the aid of the UZC4, in which case you may elect

to wire your system as shown in figure 17.

UZC4

Oil / Wood Burner

Primary Control

or

Boiler Control

or

Zone Valve

or

Pump Control

Terminals

Y

C

R

Y

G

C

TYPICAL FAN

CENTER

TERMINAL

BLOCK

OUTDOOR

CONDENSING

UNIT

*W W*

RC/RH

LINK

RC/RH

LINK

Cut Rc/Rh

Jumper

Cut Rc/Rh

Jumper

* Note: Your Air Handler may include a W terminal. That

means it may have it’s own isolation circuit. If you can

confirm this, simply connect the W1 terminal to the W

terminal on the air handler. Do not cut the Rc / Rh jumper.

Wire up your Oil Burner, Pump Control, or Hydronic Zone

valve to the isolation terminals or wires provided in the air

handler. (follow dashed lines)The fan is controlled via

time delay relay inside the air handler, or set the UZC4

“FAN “ Dip Switch to the “HYDRO” position.

T

T

Hi Efficiency Heat Pump with built-in Outside

Air Changeover Capability. The Heat Pump

makes the decision to run the Furnace. Note

that the UZC4 can still operate the furnace in

Emergency Mode!

GAS/OIL

Furnace

1or2 STAGE

Y

C

OUTDOOR

CONDENSING

UNIT

Y2

G

Y1

W2

C

R

W1

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

12

TT

ISOLATION TERMINALS

OR WIRES

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

W2

W1

RH

RC

Y2

O

Y1

G

B

E

H

V

A

C

-

S

Y

S

T

E

M

UZC4

*

*

GAS OR OIL

FORCED AIR

FURNACE

BACKUP HEAT

HEAT PUMP

1 STAGE

Wout

O

Y

C

R

UZC4

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

W

Y

G

C

R

Typical heat pump system wiring with

electric resistance backup heat. Wire

up the reversing valve to either O or B,

depending on your system type.

Applies to air cooled or geothermal /

ground source systems.

Conventional 4

Stage Heat Pump

with a “B” Type

Reversing Valve

AIR HANDLER

WITH 1 0R 2 STAGE

ELECTRIC RESISTANCE

BACKUP HEAT

HEAT PUMP

2 STAGE

X / W

B

Y

C

R

UZC4

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

W

Y

G

C

R

*

W2

O

B

Y2

Y2

Diagram reflects a Heat Pump with a “B” type

Reversing Valve NOT a neutral or Common

terminal designated as “B”.

W

Typical 2 stage gas or straight electric

furnace with 2 stage cooling. Choose

“Timer” or “Outside Air Sensor” to delay

2nd stage, or use 2 stage T-stats on all

zones.

Typical A/C

Split System

2 stage heat

2 stage cool

Figure 18. Single transformer 2 Stage Heat / AC system

SYSTEM WIRING CONTINUED

2 STAGE GAS

FURNACE

2 STAGE

OUTDOOR

CONDENSING

UNIT

Some HVAC manufacturers are designing HVAC Systems

with 5 - 18 vdc control circuits. Standard 24 vac thermostats

will not work on these systems. These systems can only be

controlled with their own thermostat. But the SYSTEM

connections on a UZC4 are all dry contacts! Virtually any

HVAC low voltage control circuit can be connected and

controlled. All you have to do is ask the manufacturer which

numbered terminals correspond to the standard terminals.

Theoretical diagram only shown below.

HVAC system with OEM Voltage Control Circuitry

W2

W1

Y1

G

C

R

W2

W1

Y1

G

C

R

Y2

Y2

Figure 20. OEM system with 5 - 18 vdc control circuit.

1

2

3

4

5

OEM Geothermal or Ground Source

Packaged Heat Pump. 3 stage heat &

1 stage cool with “O” type reversing valve.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 13

Note that you can route a Common wire back to the

“System” terminal block, but it should never be

connected! Use it as a TEST point while

troubleshooting. It should be marked as such and remain

capped off when not in use!

UZC4

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

Y1

C

Y2

R

*

*“R” wire may

not be required

on your Outdoor

Condensing Unit

6

UZC4

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

LUXAIRE High Efficiency “Acclimate” Heat

Pump System. Refer to Mfr’s data for

specific equipment dip switch settings and

logical program settings. Set up the UZC4 to

control the staging based on “Time” with

single stage Conventional Thermostats. Or

you can install 3 stage Heat Pump

Thermostats on all zones.

High Efficiency

Heat Pump.

3 or 4 Stage Heat

and 2 Stage Cool

Warning:

All of the wiring diagrams provided are general in

nature and may not perfectly match your particular

application. This is due to differences in the HVAC

Mfr’s terminal designations and functions!

Variations on these diagrams and other System or

Thermostat applications are available by

contacting the EWC Technical Support Hotline, or

visit our web site at www.ewccontrols.com

HEAT PUMP EMERGENCY OPERATIONS:

Any Thermostat can demand Emergency Mode!

When emergency mode is activated, the UZC4 will

energize the “E” output terminal and the “W1” terminal.

The “W2” terminal will also energize after a 3 minute

delay. There is no need to jumper the “E” terminal to the

“W” terminals. The UZC4 does this to ensure that the

Emergency backup system energizes, regardless of

which terminal it is connected to. In fact, the design of

the UZC4 encourages you to separate up to three (3)

electric strip banks, preventing large in-rush currents

when all banks are tied together. This will also reserve at

least one bank dedicated for Emergency mode and De-

humidify/Reheat operations .

Make sure that you have correctly selected either “Dual

Fuel” or “Conventional” Heat Pump to obtain the proper

staging operations for your particular system.

IMPORTANT NOTES:

Figure 19. 3 or 4 Stage High Efficiency Heat Pump System

Variable Speed

FURNACE OR AIR HANDLER

WITH 1 0R 2 STAGE

BACKUP HEAT

High Efficiency

HEAT PUMP

2 STAGE

W

O

Y1

C

R

UZC4

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

W/W1

Y1

G

C

R

O

W2

Y2

Y2 Out

HUM

W2 Out

W1 Out

Y2/Y

X/L

X/L

Optional Humidistat

See Mfr’s Data

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

14

SYSTEM WIRING CONTINUED - Specialty Applications

Variable Speed

AIR HANDLER

with 1 or 2 stage Heat

AND

DEHUMIDIFICATION

CAPABILITY

1 or 2 STAGE

HEAT PUMP

UZC4

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

W

O

Y1

C

R

Y2

NC

NO

C

A

U

X

R

L

Y

W1

Y1

C

R

O

W2

Y2

G

DH

HUM

Wiring for typical 3 stage Heat,2stage cool Heat Pump. Diagram reflects De-humidification

terminal wired to the Auxiliary input. Auxiliary Relay Dip Switch #5, Bank #2, should be set

to (RA) Reverse Acting. Contact EWC Controls Technical support or visit our web site for

additional diagrams and alternate control methods to achieve De-humidification.

Using the UZC4’s Auxiliary Feature to control Dehumidify Operations

The Auxiliary Feature

can be used to

activate DeHumidify

Operations on

Variable or Constant

Speed HVAC Systems.

The UZC4 can be set up

to control DeHumidify

operations on most any

Heat Pump or

Conventional HVAC

system. The UZC4 will

also activate a unique

Dehumidify Control

Algorithm when the De-

humidify demand is

detected. When a

separate control calls for

Dehumidification, the

UZC4 will activate “Y1”,

“G” and the Auxiliary

Relay, to signal the Air

Handler to slow the fan

down.

The UZC4 WILL ALSO

energize the (E)

Emergency output

terminal to REHEAT the

cold discharge air and

Rapidly Dehumidify the

home. Energizing the

“E” during this cycle

prevents over-cooling

the home. A common

Customer complaint with

the DeHumidify cycle in

these HVAC systems.

NOTE1: The UZC4 will not

activate dehumidify

operations unless the “Y1”

(cool) signal is also detected

at Zone 1.

NOTE2: A cooling or heating

demand detected at any other

zone can cause a delay to

activate or will terminate the

De-Humidify operations.

NOTE3:Dehumidify can only

be achieved In (RA) Reverse

acting mode.

NOTE4: Do not use this

feature for commercial

applications per ASHRAE

90.1-2013.

DHUM

G

R

O/W2

C

THERMIDISTAT

3 Heat 2 Cool HEAT PUMP

CONFIGURATION

C

W2

Y1

R

G

O/B

ONE

ZONE

ZONE 1

T'STAT

W1/E

Y2

AUX R

CO2

CO2

Carrier Bryant

R

W / W1

Y / Y2Y / Y2

Y1 / W2Y1 / W2

R

Wiring for typical 4 stage Heat,2 stage cool Heat Pump. Diagram reflects De-humidification

terminal wired to the Auxiliary output (NC) Normally Closed terminal. Auxiliary Relay Dip

Switch #5, Bank #2, should be set to (RA) Reverse Acting when using the type of control

shown below.

This type of control uses (RA) reverse acting

logic to signal De-humidify demands.

Figure 21.

Figure 22.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 15

SYSTEM WIRING CONTINUED - Specialty Applications

Variable Speed

FURNACE

with 1 or 2 stage Heat

1 or 2 STAGE

CONDENSOR

UZC4

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

R

C

Y1

Y2

NC

NO

C

A

U

X

R

L

Y

W1

Y1

C

R

O

W2

Y2

G

DS/BK

HUM

Wiring for typical 2 stage Heat, 2 stage cool Thermostat. Diagram reflects AUX R terminal

wired with a jumper to the R terminal. Auxiliary Relay Dip Switch #5, Bank #2, should be

set to (RA) Reverse Acting.

Using the UZC4’s Auxiliary Feature to control Fan Speed The Auxiliary Feature

can also be used to

Control the Fan speed

based on the Number

of Zones calling.

The UZC4 can be set up

to control the fan speed

on most any variable

speed air handlers or

furnaces during cooling

operations. The UZC4

will lower the fan speed

when 25% or less of the

total zones are calling

for cooling. When this

occurs the UZC4 will

activate the Auxiliary

relay output which will

de-energize the DS/BK

terminal on the Forced

air unit resulting in the

blower running at a

lower speed.

NOTE 1: A jumper is

required across the R

terminal on zone 1 and

the AUX R terminal.

NOTE 2: Other

configurations are

available. Contact

Technical Support for

further information.

G

Y2

C

2 Heat 2 Cool

Thermostat

C

W2

Y1

R

G

O/B

ONE

ZONE

ZONE 1

T'STAT

W1/E

Y2

AUX R

CO2

CO2

Wiring for typical 2 stage Heat,2 stage cool Gas Furnace.. Diagram reflects DS/BK terminal

wired to the Auxiliary output (NC) Normally Closed terminal. Auxiliary Relay Dip Switch #5,

Bank #2, should be set to (RA) Reverse Acting when using the type of control shown.

Figure 23.

Figure 24.

Y1 R

W2

W1

JUMPER

REQUIRED

G

R

W2

C

2 Heat 2 Cool

CONFIGURATION

W1

Y2Y2

Y1Y1

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

SYSTEM WIRING CONTINUED - Specialty Applications

Using the UZC4’s Auxiliary Feature to control Humidify Operations

16

Variable or Constant Speed

FURNACE

with 1 or 2 stage HEAT

and

1 or 2 stage COOL

1 or 2 STAGE

CONDENSING

UNIT

UZC4

W2

W1

RH

RC

Y2

O

Y1

G

RC/RH

LINK

RC/RH

LINK

B

E

H

V

A

C

-

S

Y

S

T

E

M

Y1

C

R

Y2

NC

NO

C

A

U

X

R

L

Y

W1

Y1

C

R

W2

Y2

G

Wiring for typical 2 stage Heat,2 stage cool conventional HVAC System. Diagram

reflects Humidification terminal wired to the Auxiliary output (NO) Normally Open

terminal. Auxiliary Relay Dip Switch #5, Bank #2, should be set to Direct Acting. (DA)

C

W2

Y1

R

G

O/B

ONE

ZONE

ZONE 1

T'STAT

W1/E

Y2

AUX R

CO2

CO2

Wiring for typical 2 stage Heat,2 stage cool Conventional HVAC System. Diagram

reflects a Direct Acting Humidification control wired to the Auxiliary input. Auxiliary Relay

Dip Switch #5, Bank #2, should be set to Direct Acting. (DA) Refer to the Ultra-Zone

072000 Tech. Bulletin.

The Auxiliary Feature

can be used to control

Humidify Operations

on any HVAC System.

Set the Auxiliary relay

Dip Switch to Direct

Acting and connect a dry

contact Humidity Control

to the “R” and “AUX R”

terminals.

When the UZC4 detects

a demand to Humidify, it

will energize the

Auxiliary Output Relay.

The Auxiliary relay

contacts are dry, so you

can connect and control

most any humidifier you

want.

These drawings show

an Ultra-Zone 072000

Smart

Humidistat connected to

the Auxiliary Input, and

an S2000/S2020 Steam

Humidifier connected to

theAuxiliary Output.

Refer to the Technical

Bulletins on the Ultra-

Zone S2000/S2020 and

the 072000 Smart

Humidistat for additional

details.

The UZC4 humidity

control logic allows a

Humidity demand to

occur at any time. There

is no need for a Heating

demand to occur first.

Bear this in mind when

field wiring your system.

You may have to

interlock your Humidifier

to run during a heating

call only! Steam

Humidifiers can run at

any time and do not

require a heating

demand to occur first.

NOTE: Humidify

operations can only be

achieved in (DA)

Direct acting mode.

OD OD C R H H

Ultra-Zone 072000 HUMIDISTAT

S2000/S2020 STEAM HUMIDIFIER

RG1 G2 H H

“R” WIRE MAY NOT

BE REQUIRED ON

YOUR CONDENSING

UNIT!

To OAS

Figure 25.

Figure 26.

SYSTEM WIRING CONTINUED - Specialty Applications

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

This diagram reflects the UZC4 CO2terminals wired to the (NO) normally open contacts

of a third party device. The circuit is normally open and the contacts must close to

activate this feature. This feature operates regardless of all other functions except the

FIRE Mode interlock.

ZONE THERMOSTAT

#1

Commercial Grade

Thermostat

G

RY

W2W1

C

UNOCC / OCC

C

W2

Y1

R

G

O/B

ONE

ZONE

ZONE 1

T'STAT

W1/E

Y2

AUX R

CO2

CO2

CO2Monitor

Using the UZC4’s CO2Feature to satisfy Building Fresh Air Ventilation Codes

The UZC4 features a CO2

Monitoring interlock system

that will activate a Fresh Air

Damper and the indoor Fan

on the HVAC system in

response to a Separate CO2

Monitor. This powerful

feature allows Demand

Based Ventilation of a large

home or commercial

building, based on the daily

occupancy levels. Demand

Based Ventilation saves

energy, reduces over-

ventilation, and optimizes

air quality in the building.

Wire up the UZC4 to a

separate CO2Monitor with

auxilary dry contacts as

shown. Also install and wire

up a fresh air damper as

shown.

Set the PPM trip threshold on

the CO2Monitor per the

Mfr’s. Instructions or local

requirements.

Upon activation, the UZC4

will open the Fresh Air

Damper and Start the Indoor

Fan if it is not already

running. The UZC4 will

continue the ventilation

process, until the CO2

Monitor resets. Other

devices can be connected to

the CO2terminals such as a

Clock Timer, Manual Switch

or Enthalpy Control.

NOTE: Cooling & Heating

operations are not affected

by activation of this feature.

NOTE: Activation of the Fire

Alarm Interlock Feature will

over-ride (shutdown) the

fresh air ventilation process.

NC

NO

C

A

U

X

R

L

Y

E

B

D

O

A

D

M

P

R

M1

M2

M4

M6

M6

M4

M2

M1

UZC4

MA-ESR

NC NO C M M

EWC Controls

Spring Return

Motor Actuator

This diagram reflects the UZC4 OA DMPR Output terminals wired to an UltraZone

Spring Closed type damper. When the UZC4 detects a Ventilation Demand, it will

energize the damper open and force the Indoor Fan to run. The UZC4 will stay in this

mode until the CO2Monitor detects an acceptable CO2level in the building.

This Damper Actuator is wired to

Power OPEN and Spring CLOSE

Power OPEN & Power CLOSE

dampers can also be used.

17

Figure 28.

Figure 27.

C

NC

NO

This diagram reflects the UZC4 Fire Alarm Output terminals wired to a FIRE ALARM

System with a Fail Safe, Normally Open Dry Contact. The circuit is normally closed and

must OPEN to activate the UZC4 FIRE MODE. Be sure to cut the Jumper 1 resistor when

you interlock the UZC4 to the Fire Alarm System. When the UZC4 activates Fire Mode,

the HVAC System will shutdown and all connected dampers will close to Isolate &

Compartmentalize the HVAC Duct System. The Fire Alarm System must reset to NORMAL

before the UZC4 will allow HVAC Operations to resume.

SYSTEM WIRING CONTINUED - Specialty Applications

Using the UZC4’s “FIRE Interlock” Feature to satisfy Building Fire Codes

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

18

NC

NO

C

A

U

X

R

L

Y

E

B

D

O

A

D

M

P

R

M1

M2

M4

M6

M6

M4

M2

M1

M6

M4

M2

M1

RESET

CB1

R

C

24V

24V

FA

FA

MXC

MXR

UZC4

FIRE ALARM

SYSTEM

NC C NO

CUT

Separate 24vac

Transformer

To Line Voltage

Provide over current

protection

The UZC4 has a “FIRE”

interlock feature that allows

the UZC4 to satisfy HVAC Fire

Code in Residential &

Commercial buildings.

Coordinate with the Fire

Systems Contractor to

interlock the UZC4 into the

building Fire Alarm system as

shown and cut the Jumper 1.

When properly interlocked to

the buildings Fire Alarm

system, the UZC4 becomes

an integral part of the Fire

Safety System. If the Fire

Alarm system activates, the

UZC4 will shutdown the

controlled HVAC system and

force all connected dampers to

the closed positions,

effectively isolating the duct

work and the Fan system.

This action will reduce the

spread of smoke advancing

through the building assisted

by Fan and Duct systems that

are not interlocked with a Fire

Alarm system, or equipped

with the capability to do so.

The UZC4 has a set of

dedicated terminals to power

up and control an (EBD)

Electronic Bypass Damper.

The UZC4 will assume control

of the EBD and force it to the

OPEN position during the Idle

periods, Short cycle delays or

Changeover delays. It will also

maintain that open position for

45 seconds at the start of any

thermostat demand for

Heating, Cooling, or Fan only

operation. After 45 seconds

the UZC4 will release control

of the EBD, resulting in a

smooth gradual increase in

static pressure. The 45 second

startup delay allows a

Constant speed fan to start in a

“Quiet Mode” eliminating air

noise upon system startup. It

also eliminates hunting on

variable speed systems and it

enhances the latent cooling

capacity of any HVAC system.

Field Wiring =

Factory Wiring =

46

1

WHITE “COMMON” WIRE

NC

NO

C

Pressure Control

Wiring Compartment

“EBD” Motor

WIRE

NUT

GREEN

RED

Using the UZC4’s “ON BOARD BYPASS DAMPER SUPPORT”

Wire up the “EBD” straight to the UZC4 to obtain integrated Bypass Damper operational

support via the UZC4’s bypass firmware. The UZC4 defaults the bypass damper open

during idle periods and releases control to the EBD 45 seconds after the Fan starts. This

action results in a smooth, quiet startup and gradual increase in static pressure.

UZC4

JMP1

Figure 29.

Figure 30.

Note: All zone dampers default to the "OPEN"

position after a purge delay has occurred.

Dampers also default “OPEN” during

changeover & short cycle delays, and when

all zone demands are satisfied, and no

signals are detected from the thermostats.

DAMPER WIRING AND CONFIGURATIONDAMPER WIRING AND CONFIGURATION

Common 24vac

Constant 24vac HOT

24vac to Open a damper(s)

24vac to Close a damper(s)

Terminal M1

Terminal M2

Terminal M4

Terminal M6

ZONE MODULE DAMPER

MOTOR TERMINAL BLOCK

DESIGNATION & FUNCTION

.

.

2 Wire Spring Return Motor Wiring

EWC Controls

Spring Return Motor Wiring

A Spring Open Damper is wired to M1 & M6

A Spring Close Damper is wired to M1 & M4

M1

M2

M4

M6

{

MA-ESR

NC NO C M M

Auxilary

SPDT

End Switch

Dry Contacts

Rated for

24vac only

M1

M2

M4

M6

REFERENCE THESE DIAGRAMS PRIOR TO

INSTALLATION AND POWER WIRING. DOING SO WILL

SAVE TIME AND LABOR ON THE JOB SITE.

Patented Optical

Damper Motor Actuators

Figure 31.

Figure 33.

Figure 34.

All Models SMDL & BMDL Damper Wiring

24

1

M1

M2

M4

M6

All Models MA-ND & MA-URD Damper Wiring

46

1

Patented Optical

Damper Motor Actuators

Figure 32.

M1

M2

M4

M6

On all these dampers and most older style

dampers, including competitor’s dampers,

always wire up number to number.

Contact EWC Controls Technical Support

when you are on the job site for assistance

with damper wiring.

NOTE: Some older style dampers cannot be

wired in parallel. Do not overload your

transformer!

Multiple MA-ND & MA-URD

Damper Wiring on a Single Zone

46

1

M1

M2

M4

M6

46

1

46

1

Multiple dampers

wired to operate

together on a single

zone

Figure 35.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

Either one

Not both

Z

O

N

E

Z

O

N

E

Z

O

N

E

Z

O

N

E

Z

O

N

E

19

Non-inherently current limiting transformers must have field provided over-current protection on the secondary 24 vac output. The table values