EWC Controls BMPlus 3000 Service manual

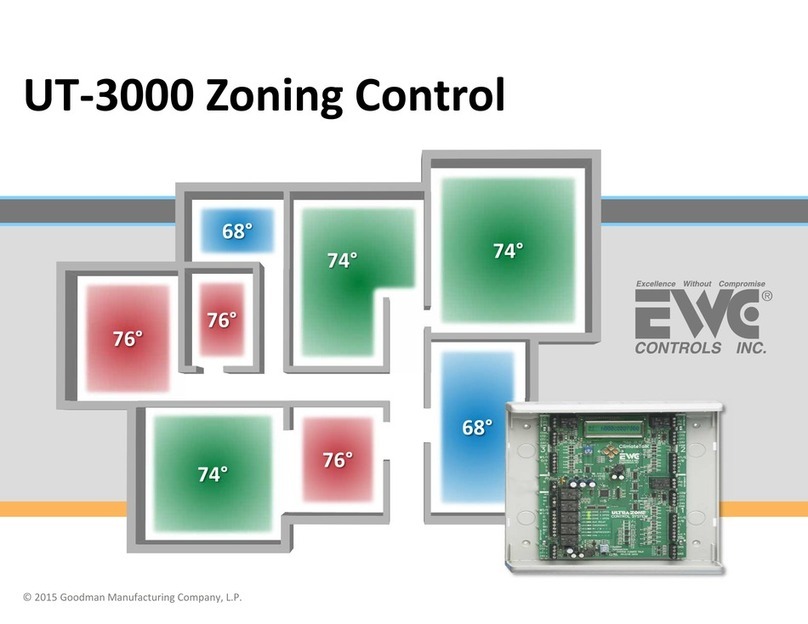

The BMPlus Zone Control System allows you to easily

upgrade an inefficient single zone HVAC system, into a

Multi-zone, Energy savings, Comfort producing, HVAC

system. The Superior Design, Intuitive Firmware, Simple

Setup Options, Easy to Understand wiring and Backwards

Compatibility, makes the BMPlus Zoning system the

Contractors dream. Combined with EWC Motorized

Dampers and any off-the-shelf Thermostats, EWC Controls

sets another high standard in the residential & light

commercial Forced Air Zoning Industry.

The main module controls three zones

using motorized dampers and may be

expanded to 5 or 7 zones, using 1 or 2

Model XM2 Expansion Modules.

Controls 2 & 3 stage conventional or dual

fuel heat pumps, without the need for dual

fuel kits. Also single or two-stage gas, oil,

& hydronic heating systems, with single or

two stage air conditioning. Constant or

variable speed fan systems.

Compatible with any off the shelf

Heat Pump Thermostat

(2heat/1cool). You may also use any

regular Heat/Cool thermostat

(1heat/1cool). You may still use

regular Heat/Cool thermostats to

control a Heat Pump system.

The BMPlus Zone system features

automatic changeover from any

thermostat allowing for individual zone

comfort from the HVAC system.

A green STATUS LED pulses as a steady

heart beat to indicate Micro- processor

activity and 24v power is present.

Function specific colored LED’s illuminate

to indicate the HVAC system mode of

operation and active zone identification.

See page 10 for details.

Green LEDs labeled Zone 1 thru Zone 7

indicate which dampers are energized to

the open position.

INPUT VOLTAGE: 19-30VAC 60 Hz

Transformer 40-100VA MAX. NEC Class 2.

CURRENT DRAW: Max 15VA @ 24VAC.

OVER-CURRENT PROTECTION: 4.0 amp

The BMPlus module has a Thermal

circuit breaker that protects the

module(s) from shorts in the damper

and thermostat field wiring. It will

not protect against shorts in the

HVAC system wiring.

CAUTION: When the circuit breaker

is tripped it will get quite hot. To

reset the breaker: Shut off power to

the panel. Find and repair the short.

Restore the 24VAC power.

Any zone can activate the indoor fan

and only the dampers in zones calling

for continuous fan operation will open.

Continuous fan operation will only

occur when there are no active or

pending, heat or cool demands. A dip

switch is provided to enable automatic

fan operation in heat mode. Useful for

straight electric heat or hydronic heat

applications.

Zone

Capacity

Compatible

HVAC

Systems

Compatible

Thermostats

Automatic

Heat/Cool

Changeover

Status LED

System LEDs

Damper LEDs

Operating

Power

Thermal

Circuit

Breaker

Indoor Fan

Control

Models BMPlus 3000/5000/7000 Rev. B

(DISPONIBLE EN ESPAÑOL EN EWCCONTROLS.COM)

ewccontrols.com/acrobat/090375a0244.pdf

TB-228

P/N 090375A0228 REV. L 06.01.18

Box Contents * BMPlus 3000 Control Panel

* Supply Air Sensor

* Technical Bulletin TB228

* Mounting Hardware

Leave this bulletin on the job site for future reference!

Operating

Conditions

J1

ZONE3

MOTOR

ZONE2

MOTOR

MOTOR

ZONE1

24

T’FORMER

VAC

SYSTEM

M6

M4

M2

M1

M6

M4

M2

M1

M6

M4

M2

M1

R

C

G

Y2

Y1

O

RH

RC

W1

B

W2

E

LINK

RH

RC

D

43

D

C

1

C

2

+

+

SAS

SAS

OAS

OAS

C

W/E

O/B

Y

R

G

ONE

ZONE

EM

NORM

SW

4

ZONE1

STAT

T

D

11

D

12

D

13

D

10

2

ND STAGE HEAT

DIFFERENTIAL

LIMIT

HIGH

TEMPLOW TEMP

LIMIT

TIMER OAS

STAGING

47

5

40

33

26

19

12

110

120

130 140 150

160

170

52

49

46

43

40

37

34

42

35

28

21

14

7

OFF

BMPlus3000 rev B

W

2

EM

B

1

W

1

2

Y

Y

ZONE

ZONE

ZONE

FAN

1

2

3

STATUS

OAS

SAS

38

39

R

R

R

37

R

36

R

76

77

R

72

R

73

R

R

70

69

R

67

R

68

R

65

R

R

64

71

R

R

63

62

R

R

61

60

R

59

R

58

R

R

57

56

R

55

R

54

R

R

78

79

R

53

R

52

R

R

51

50

R

49

R

48

R

R

47

46

R

45

R

81

R

R

40

43

R

R

42

41

R

10

LED

9

LED

8

LED

7

LED

6

LED

5

LED

4

LED

3

LED

2

LED

1

LED

11

LED

6

U

U

7

U

8

5

U

4

U

U

2

3

U

U

1

1

K

2

K

3

K

4

K

5

K

6

K

7

K

8

K

R

12

R

3

R

4

R

RESET

1

D

2

D

C

11

8

C

7

C

15

C

5

C

R

35

C

10

13

CY

1

21

D

1

Z

14

C

SW

3

33

R

32

R

31

R

30

R

8

D

29

R

R

28

27

R

26

R

7

D

25

R

R

24

23

R

22

R

6

D

21

R

R

20

R

19

5

D

D

934

R

GAS

OFF

OFF

OAS

HC

HP

OTHER

HP

TIMER

ON

HYDRONIC

ON

O B

DF

<

<

<

<

<

< >

>>

>

>>

>

<>

<

SYSTEM

HP CONV

50

TSTATS

RV

STAGING

RULE

SAS

FAN

E

W

C

SYSTEM

CONTROL

%

C

C

W/E

O/B

Y

R

G

ZONE3

STAT

T

F1

C

W/E

O/B

Y

R

G

9

C

66

R

82

R

R

44

R

14

R

R

15

16

U

9

12

C

R

13

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 1

Copyright ©2007 EWC Controls All Rights Reserved

Figure 1

TEMPERATURE: -20° to 160°F (-29° to 71°C)

HUMIDITY: 0% - 95% RH Non-Condensing.

ZONE2

STAT

T

OFF

7

14 21 28

35

42

STAGING

Timer / OAS

110

120

130 140 150

160

170

HIGH TEMP

LIMIT

34

37

40 43 46

49

52

LOW TEMP

LIMIT

The panel has seven built-in Delay Timers

that insure safe & reliable operation.

When all zone demands are

satisfied, the panel will not resume

the same mode of operation for a

minimum of 3 minutes.

A built-in timer prevents the system

from rapidly switching between

heating and cooling modes. At the

end of a call, a 4 minute timer is

started and the panel will not switch to

the opposing mode until the timer has

expired.

The STAGING TIMER sets the

amount of continuous call time in 1st

stage, before second stage heat or

cool is energized. NOTE: The

potentiometer also serves as the

Outside Air Changeover Setting.

The BMPlus 3000 can inhibit heat

staging based on a Timer or

Outside Air Temperature.

NOTE: An Optional OAS Sensor is

required to use the OAS feature.

NOTE: 2nd stage cool delay defaults

to 30 minutes, if OAS is chosen to

inhibit 2nd stage Heat.

The Adjustable Heating Limit

potentiometer sets the 1st stage heat

supply air temperature, at which the

heating is cycled off and the fan

continues to run, allowing the heat

exchanger or coil to cool down.

The Adjustable Cooling Limit

potentiometer sets the supply air

temperature at which the cooling is

cycled off and the fan continues to run,

allowing the coil to warm up.

*Built-In

Timer

Settings

*Short Cycle

Timer

*Changeover

Timer

Staging

Timer / OAS

Cooling and Heating Limit Controls

Reset

BUTTON

Emergency

Heat

Switch

*Opposing

Call

Delay Timer

A 20 minute delay must expire, or the

active zone(s) must satisfy, before

the panel will honor a thermostat

demand to changeover to the

opposite mode of system operation.

OFF, 7 to 42

minutes or 7

to 42

degrees F.

*Supply Air

Limit

Delay Timer

The time delay of 3 minutes must

expire before the BMPlus 3000 will

re-energize heat or cool mode. This

delay occurs when the processor

detects the supply air temperature is

higher or lower than the High or Low

temperature limit settings.

The Adjustable 2nd stage heat

differential potentiometer sets the 2nd

stage heat supply air temperature, at

which the heating is cycled off and the

fan continues to run, allowing the heat

exchanger or coil to cool down.

NOTE: Allows the supply air sensor to

be installed in the supply air plenum,

regardless of the coil/heat exchanger

configuration. Allows the installer to fine

tune virtually any multi stage heating

system!

RESET

EM

NORM

An On-Board Switch is provided that

allows the Customer to set the system

to the Emergency heat mode.

This switch is shown in the NORMAL

position.

This switch would be used for Heat

Pump applications where the

Customer chooses to use Regular

Heat/Cool thermostats instead of

Heat Pump thermostats.

2nd STAGE HEAT

DIFFERENTIAL

5

12

19 26 33

40

47

Example:

Hi Temp. Limit =130°F

plus 2nd stg. DT= 40°F

New Limit = 170°F.

BMPlus 3000 FIRMWARE/HARDWARE FEATURESBMPlus 3000 FIRMWARE/HARDWARE FEATURES

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

2

The separate reset buttons on the

old BMP3000 have been replaced by

a single button with dual functions.

Momentarily pressing the RESET

button clears the built-in timers

controlling the Startup delay timer,

Short cycle timer, W2 timer, Supply air

sensor timer and the Changeover

timer. This enables you to test the

installation faster. Caution should be

observed when using this button.

Always reset the CPU

anytime you make

dip-switch changes to

the BMP3000 panel!

DO NOT use a sharp

object to press the

button! Your finger tip

will work fine. Pressing the RESET button for 7

seconds will reset the CPU for

the entire zone system.

*Startup

Delay

Timer

The panel will not activate any

cooling or heating operation until

the startup delay has expired. This

occurs after any initial power up or

power failure. Press the Reset

button for 1 second to override.

* Start-up Delay Timer = 3 minutes-fixed

* Short Cycle Timer = 3 minutes-fixed

* Change Over Timer = 4 minutes-fixed

* Opposing Call Timer = 20minutes-fixed

* Staging Timer = OFF or 7-42 min. -Adj.

* Supply Air Limit Timer = 3minutes-fixed

* Purge Delay Timer = 90 seconds-fixed

*Purge Delay

Timer

The last Damper(s) will be held Open

for 90 seconds at the end of every call

allowing a system purge into the last

zone that was calling.

Any setting

below 7 is off!

DO NOT set to off

if using OAS

1

2

3

4

5

6

7

8

HP < SYSTEM > OTHER

DF < HP > CONV

HC < TSTATS > HP

O < RV > B

OAS < STAGING > TIMER

OFF < 50%RULE > ON

OFF < SAS > ON

GAS < FAN > HYDRONIC

Choose the type of HVAC system you want to control. Select HP, if your system is any type of Heat Pump. Select OTHER,

if your system is a standard Gas or Oil furnace. Other setting also applies to straight electric furnaces or hydronic

(hot water coil) heating systems.

Choose the type of Heat Pump you want to control. Select DF (Restricted Mode) if you wish to lock out the

compressor during auxiliary heat operation, typically set for Dual Fuel operation. Select CONV (Unrestricted Mode) if

you wish to have the compressor run during auxiliary heat operations, typically set for Electric Back-up.

Select HC, if you want to use regular Heat/Cool thermostats on your job. Select HP, if you want to use Heat Pump

thermostats on your job. Remember that you can use standard Heat/Cool Thermostats on a Heat Pump application.

Select the correct Reversing Valve signal for your particular Heat Pump. Choose “O” for any Heat Pump that energizes

the RV in the cooling mode. Choose “B” for any Heat Pump that energizes the RV in heating mode.

Select OAS, if you want to delay auxiliary heat based on the outside air temperature sensor. Select TIMER, if you

want to delay W2 and Y2 based on the adjustable on-board timer. NOTE: ‘Y2’ defaults to a 30

minute delay, when OAS is chosen.NOTE: An optional OutsideAir Sensor (OAS) is required to use the OAS feature.

Select OFF, if you do not want to inhibit Y2 and/or auxiliary heat based on the total number of zones calling.

Select ON, if you do want to inhibit Y2 and/or auxiliary heat based on the total number of zones calling. More than

half the total zones must be calling for the same mode of operation (heat or cool), or the BMPlus3000 will not

stage up. This feature is a great way to save energy. Emergency heat mode will override the 50% rule.

Select OFF, if you do not want to use the supply air sensor included with the BMPlus Zone Control system. Select ON, if

you intend to use the included supply air sensor. Refer to the data sheet included with the supply air sensor for details.

Select GAS, if your HVAC system is a gas or oil forced air furnace. Select HYDRONIC, if your HVAC system has a hot

water coil, or straight electric heat with no indoor blower support. Useful when you need the indoor blower to run

automatically in heat mode, just like it does in cool mode. NOTE: When you select HP on dip switch #1, the indoor fan

mode is automatically set for you. There is no need to move this switch when setting up for Heat Pump operations.

Programming and setting up the BMPlus

3000 to control your HVAC system is very easy!

Look below for an explanation of each dip

switch function and choose your settings.

Some functions may not apply to your application.

Then use a pencil to mark/record your settings. If the

settings get changed later on, you will

have a record of the original settings.

1

2

3

4

5

6

7

8

Selecting the Options Using the DIP Switches

RECORD YOUR OWN DIP SWITCH

SETTINGS HERE

ONON

HP < SYSTEM > OTHER FS

DF < HP > CONV FS

FS HC < TSTATS > HP

FS O < RV > B

OAS < STAGING > TIMER FS

FS OFF < 50%RULE > ON

FS OFF < SAS > ON

FS GAS < FAN > HYDRONIC

IMPORTANT NOTE: The BMPlus 3000 Zone Control System allows Heat Pump thermostats to be connected to all zones.

Using heat pump thermostats means that the zone panel will obey thermostatic demands. This comfort over-ride feature

provides a level of versatility to your zoning system and gives the homeowner comfort control over the system, instead of

waiting for the adjustable timer to energize 2nd stage heat. True thermostatic staging is not available when using 2 Stage

compressor heatpumps, it is advisable to use Heat/Cool thermostats and allow the BMPlus to stage via the on-board timer. If

true thermostatic staging is required, then it is recommended to upgrade to the Model UZC series of Control Panels.

***FS = Factory Settings

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 3

Figure 2d.

ZONE

T'STAT

C

W/E

Y

R

G

O/B

*

CW/E

BW2 Y1

ORC RH

MODEL EWT-955WH

HDY2

Model EWT-955WH Wireless Thermostat:

Configured for 2 heat 1 cool heat pump.

See thermostat instructions for further

*

Field installed jumper.

TYPICAL 24v WIRELESS THERMOSTAT

MODEL EWT-725

CO

BW2

W/E Y1 RG

*

Model EWT-725: configured for 2 heat 1 cool

heat pump. See thermostat

instructions for further details.

Figure 2c.

ZONE

T'STAT

*

C

W/E

Y

R

G

ONE

ZONE

O/B

Field installed jumper.

**

Common wire not required if batteries are used.

**

INSTALLATION & WIRING INSTRUCTIONS

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

4

WARNING: THESE PANELS ARE DESIGNED FOR USE WITH 24VAC. DO NOT USE OTHER VOLTAGES! USE CAUTION TO AVOID ELECTRIC

SHOCK OR EQUIPMENT DAMAGE. ALL WORK SHOULD BE PERFORMED TO LOCAL AND NATIONAL CODES AND ORDINANCES. USE 18

HEAT PUMP THERMOSTATS

HEAT/COOL THERMOSTATS

Mount the panel housing in a suitable/convenient location. Mounting hardware is provided. Avoid locations that may become wet or

produce condensation. Hot attics are OK. Use the knockouts on the panel housing as wire entryways. Strain relief fittings can be used

if desired. Use care and do not damage the circuit board when removing the knockouts and making wire connections. NOTE: The

24vac power supply should be supplied by a separate transformer. DO NOT use the 24vac power supply from the HVAC system

unless there is no other alternative. 2 zones and 2 dampers is the limit when stealing voltage from the HVAC system.

NOTE: The BMPlus 3000 allows the user to install Heat Pump

thermostats on all zones. You may still use regular

Heat/Cool type thermostats with a Heat Pump system and

use the Staging Timer to energize the auxiliary heat. If you

don’t have enough wires available. It is advisable to use

Heat/Cool thermostats with 2 stage compressor Heat Pumps.

A single 24vac, 40va

UL Listed transformer

can power the

BMPlus3000 Main

module with up to 12

genuine ND or URD

dampers. See page 9

for more load and

transformer data.

Line

Voltage

TRANSFORMER

24vac, 40 - 75va Max

UL LISTED

BMPlus 3000

Main Module

R - Hot

C - Common

Figure 2 BMPlus 3000 Power

POWER WIRING

Thermostat

Wiring

24 VAC

T’FORMER

R

C

PROVIDE

MEANS OF

DISCONNECT

Model EWT-725: Configured for 1 heat 1

cool. See thermostat instructions for further

details.

ZONE

T'STAT

C

W/E

Y

R

G

ONE

ZONE

O/B

Figure 2a.

MODEL EWT-725

CO

BW2

W/E Y1 RG

*

*

Common wire not required if batteries are used.

Typical “Wi-Fi” Thermostat Configured for

1 heat & 1 cool. See thermostat

Figure 2b

W/E

CG

W2 Y1 Y2 RC

EWT-855i “Wi-Fi” Thermostat

C

W/E

Y

R

G

ONE

ZONE

O/B

1

ZONE

DRY R

R

LED

RH O B

G

THERMOSTAT WIRING CONTINUED

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 5

Figure 5 Wiring a split circuit thermostat to operate a

Radiant floor heating or Baseboard heating

Hydronic system. The BMPlus 3000 controls the

cooling only in this type of configuration.

WIRING FOR RADIANT FLOOR HEAT

To Radiant floor / Baseboard heat

zone valve or pump relay

W

RH

GRC

Y

ZONE2

T’STAT

Y

R

G

O/B

W/E

C

Figure 6 Wiring for a Radiant floor loop as the first

stage of heat via the isolation relay and 2nd

stage Forced Air heat is controlled through the

zone panel.

ZONE2

T’STAT

Y

R

G

O/B

W/E

C

GW1

RH

RCY

W2

C

To Radiant floor / Baseboard heat

zone valve or pump relay

SPST 24vac

Isolation Relay

HEAT/COOL

THERMOSTAT

MULTISTAGE HEAT/COOL

THERMOSTAT

*

Thermostat should be battery powered.

*

Figure 3.

ZONE

T'STAT

C

W/E

Y

R

G

O/B

CW/E

BW2 Y1

ORC RH

MODEL EWT-955WH

HDY2

Model EWT-955WH Wireless Thermostat:

Configured for 1 heat 1 cool.

See thermostat instructions for further

TYPICAL 24v WIRELESS THERMOSTAT

Typical “Wi-Fi” Thermostat Configured for

2 heat & 1 cool Heat Pump. See

thermostat instructions for further details.

Figure 4

W/E

CG

W2 OY1 RC

EWT-855i “Wi-Fi” Thermostat

C

W/E

Y

R

G

ONE

ZONE

O/B

1

ZONE

DRY R

R

LED

RH Y2 B

TYPICAL 24v WiFi THERMOSTAT

*

*

Field installed jumper.

G

SYSTEM WIRING

Typical gas or Electric Furnace with

A/C. Note the common “C” wire is

connected to the SYSTEM terminal

block of the BMPlus 3000.

Typical heat pump system wiring with electric resistance or

Gas backup heat (No Dual Fuel kit required). This diagram

applies to air cooled or geothermal / ground source

systems.

Wiring diagram for a typical oil burner,

hydronic zone / Air handler with A/C.

Cut the Rc / Rh link on the BMPlus

Panel for systems requiring isolation.

Single

Transformer

Gas or Electric

Furnace & A/C

1 or 2 Stage Heat

Conventional or Dual Fuel 2 Heat / 1 Cool Heatpump

with O (Cool) Type Reversing Valve

Two

Transformer

Systems

Figure 7 Single transformer Conventional system.

Figure 9 -- 2 Heat / 1 Cool Heat Pump System

Figure 8 Two transformer Oil or Hydronic / A/C system.

Conventional or

Dual Fuel 3 Heat /

2 Cool Heat Pump

with O (Cool) Type

Reversing Valve

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

Y

R

C

T

T

Y

W

G

C

Figure 10 – 3 Heat / 2 Cool Heatpump System

HEAT PUMP

2 STAGE

BMPlus 3000

**Note that a Conventional & Dual fuel heat pump wire up more or less the

same. The difference is how auxiliary heat operates. In a Conventional

system, the indoor fan & the compressor continues to run when auxiliary

energizes. In a Dual Fuel system, the indoor fan & the compressor shuts

down when auxiliary energizes. The BMPlus 3000 will perform these

functions automatically. All you have to do is set the dip switches to the

correct settings. Select CONV or DF at dip switch #2. Install regular

Heat/Cool thermostats and choose to activate auxiliary heat by TIMER or by

OUTSIDE AIR TEMPERATURE. (Optional Sensor required). Or you may

choose to install Heat Pump Thermostats on all zones. When the thermostat

auxiliary heat demand is satisfied, the BMPlus 3000 will stage down, unless

DF or OAS has been selected and the outdoor temperature is lower than the

OAS changeover setting. In that case the system will continue in FUEL

mode, until all current heating demands are satisfied.

* Note: Your Air Handler may include a W terminal. That means

it may have it’s own isolation circuit. If you can confirm this,

simply connect the W1/B terminal to the W terminal on the air

handler. Do not cut the Rc/ Rh jumper. Wire up your Oil Burner,

Circulator relay, or Hydronic Zone valve to the isolation

contacts or wires provided in the air handler. The fan is

controlled via the time delay relay inside the air handler.

Don’t worry if you accidentally cut the Rc/Rh link. Just install your

own jumper across the Rc/Rh terminals!

AIR HANDLER

OR 1 0R 2 STAGE

GAS FURNACE

HEAT PUMP

1 STAGE

BMPlus 3000

Conventional or Dual Fuel Heat Pump wiring

with 3 Heat / 2 Cool. With electric or Gas

Furnace Backup (No dual fuel kit is required).

This diagram applies to air cooled or

geothermal / ground source systems.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

6

You may need

to Cut the

RC/RH Link

Boiler Control

OR

Zone Valve Control

OR

Circulator Control

OIL

BURNER

PRIMARY

CONTROL

OR

TYPICAL FAN

CENTER

TERMINAL

BLOCK

OUTDOOR

CONDENSING

UNIT

T

T

ISOLATION

TERMINALS

OR WIRES

BMPlus 3000

Y

C

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

Y

W1

W2

R

C

G

BMPlus 3000

GAS or Electric

Furnace

1or2 STAGE

OUTDOOR

CONDENSING

UNIT

To make troubleshooting

easier, connect the “C”

Common from the Furnace

to the BMPlus. If you don’t

connect it, it’s OK.

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

O

X/W

R

C

Y

O

W1

W2

R

C

G

Y

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

O

X/W

R

C

O

W1

W2

R

C

G

Y1

*

Y2

Y1

Y2

AIR HANDLER

OR 1 0R 2 STAGE

GAS FURNACE

SYSTEM WIRING CONTINUED

Typical 2 stage gas furnace with 2

stage A/C. Constant or variable

speed systems can be connected

and controlled. Choose Timer or

Outside air to delay 2nd stage.

Single

Transformer

Gas & A/C

2 stage heat

2 stage cool

Figure 11 Single transformer 2 Stage Heat & Cool system

2 STAGE GAS

FURNACE

BMPlus 3000

Figure 12 -- 3 Heat / 2 Cool Heat Pump with

B (Heat) Type Reversing Valve

Warning: All of the wiring diagrams provided are

general in nature and may not perfectly match your

particular application, due to differences in HVAC Mfr’s

design and terminal designations and functions!

Variations on these diagrams and other System or

Thermostat applications are available by contacting the

EWC Technical Support Hotline.

ENHANCED FEATURES AND FUNCTIONS

The BMPlus 3000 Zone Control System

includes the Shorted Zone Feature. This

feature allows the BMPlus to ignore demands

from a zone thermostat that is putting out

simultaneous demands for heat & cool. A

condition most likely due to a short in the field

wiring, incorrect wiring, or a defective

thermostat. The BMPlus will honor any

legitimate demands from any other zone(s),

except the shorted zone. When the problem is

identified and repaired, the BMPlus 3000 will

automatically recognize that zone.

DUAL FUEL COMPATIBLE

MODULE TO MODULE FACTORY POWER WIRING

SHORTED ZONE FEATURE FIRMWARE

* OFF, 7 TO 42 MINUTE STAGING TIME DELAY SETTINGS

* 7 TO 42°F. OUTSIDE AIR CHANGEOVER

* OPERATES WITH MULTI STAGE HEATPUMPS

* STATUS LED’s ARE INCLUDED ON ALL MODULES

*1 ZONE MODE COMPLIES WITH CALIFORNIA TITLE 24

* SIMPLIFIED WIRING AND EASY SYSTEM SETUP

The BMPlus 3000 is compatible with Dual Fuel

Heat Pumps. Dual Fuel kits are not required.

Select staging based on Adjustable Time

Delay or an Optional Outside Air temperature

Sensor. The intelligent firmware does the rest.

The BMPlus 3000 includes Factory Power

Wiring on all expanded systems. The 24 vac

power to the expansion modules is fed

through the bus cable. This simplifies your

wiring and minimizes the chances of reversing

polarity.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 7

* ADJUSTABLE DIFFERENTIAL LIMIT CONTROL

*SECOND STAGE 50% ZONE RULE SAVES ENERGY

NOTE: If desired, you can connect a “C” Common

wire back to the “System” terminal block. Use it as

a TEST point while troubleshooting.

NOTE: The “R” wire connection to the condensing

unit may not be required on your system.

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

2 STAGE

OUTDOOR

CONDENSING

UNIT

Y2

G

Y2

C

R

Y1

W1

W2

R

C

Y1

HEAT PUMP

2 STAGE

BMPlus 3000

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

B

X/W

R

C

B

W1

W2

R

C

G

Y1

Y2

Y1

Y2

Conventional or

Dual Fuel 3 Heat /

2 Cool Heat Pump

with B (Heat) Type

Reversing Valve

Conventional or Dual Fuel Heat Pump wiring

with 3 Heat / 2 Cool with B (Heat) Type

Reversing Valve. Electric or Gas Furnace

Backup (No dual fuel kit is required). This

diagram applies to air cooled or geothermal /

ground source systems.

AIR HANDLER

OR 1 0R 2 STAGE

GAS FURNACE

DAMPER WIRING AND CONFIGURATIONDAMPER WIRING AND CONFIGURATION

Note: All zone dampers default to the "OPEN"

position after a purge delay has occurred.

Dampers also default “OPEN” during

changeover & short cycle delays, and when

all zone demands are satisfied, and no

signals are detected from the thermostats.

6

4

1

PC

PO

COM

ZONE

MOTOR

M1

M6

M4

M2

ZONE

MOTOR

M1

M6

M4

M2

6

4

1

PC

PO

COM

Common 24vac

Constant 24vac HOT

24vac to Open a damper(s)

24vac to Close a damper(s)

Terminal M1

Terminal M2

Terminal M4

Terminal M6

ZONE MODULE DAMPER

MOTOR TERMINAL BLOCK

DESIGNATION & FUNCTION

.

.

A Spring Open Damper is wired to M1 & M6

A Spring Close Damper is wired to M1 & M4

{

MA-ESR

NC NO C M M

Auxilary

SPDT

End Switch

Dry Contacts

Rated for

24vac only

REFERENCE THESE DIAGRAMS PRIOR TO

INSTALLATION AND POWER WIRING. DOING SO WILL

SAVE TIME AND LABOR LATER ON.

Figure 13

Figure 15

Figure 16

All Models RSD Damper Wiring

All Models ND, URD and SID Damper Wiring

Figure 14

On all these dampers and most older style

dampers, including competitor’s dampers,

always wire up number to number or designation

to designation.

Do not overload your transformer!

Contact EWC Controls Technical Support when you

are on the job site for assistance with damper wiring.

Have a Multi-Meter, pocket screw driver and wire

snips on hand.

Multiple ND and/or URD

Damper Wiring on a Single Zone

(2-4 Dampers)

Figure 17

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

8

Either one

Not both

MA-RSD

A Spring Open Damper is wired to M1 & M6

A Spring Close Damper is wired to M1 & M4

All Models ESR Damper Wiring

ZONE

MOTOR

M1

M6

M4

M2

ZONE

MOTOR

M1

M6

M4

M2

ZONE

MOTOR

M1

M6

M4

M2

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

NOTE: Do not connect more

than 4 motor actuators in a

series configuration. That will

decrease the chances of poor

electrical connections and

voltage drop issues. If wiring

more than 4 dampers see figure

18.

6

4

1

PC

PO

COM

DAMPER WIRING CONTINUED

If you need to connect numerous dampers to a single zone, or you are using dampers of unknown current draw

such as Spring Types, Isolation relays and separate power supplies may be required. Parallel as many dampers

as you want as long the total current load of the motor actuators does not exceed the VA rating of the

transformer. Other factors should also be considered, such as the full load amp rating of the isolating relay

contacts, voltage drops from long wire runs and feeder conductor sizing to junction points.

NOTE: Some older style dampers and competitor’s dampers cannot be paralleled and must be isolated or wired

in tandem. Contact EWC Controls Technical Support for assistance.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

Non-inherently current limiting transformers must have field provided over-current protection on the secondary 24 vac output. The table values

provided pertain to genuine ULTRAZONE Dampers and Competitors typical 24vac Spring loaded dampers. Included in these VA load ratings are the

correct number of thermostats, the BMPlus Zone System, and a 5% field factor. Spring loaded dampers draw higher currents & require more power.

BMPlus 3000, 5000, 7000, Revision “B” Recommended Power Solutions

TESTING DAMPER MOTORS

SR / ESR / RSD Power Open / Spring Close Dampers - Connect 24vac common & hot to the two motor (M) terminals.

Damper should Open. Remove 24vac hot. Damper should Close.

ND / URD / SMD / BMD Dampers - Connect 24vac common to terminal 1 and 24vac hot to terminal 4. Damper should

Open. Remove 24vac hot from terminal 4 and apply to terminal 6. Damper should Close.

RDN / SMDL / BMDL Dampers - Connect 24vac common to terminal 1 and 24vac hot to terminals 2 and 4. Damper

should Open. Remove 24vac hot from terminal 4. Damper should Close.

SR / ESR / RSD Power Close / Spring Open Dampers - Connect 24vac common & hot to the two motor (M) terminals.

Damper should Close. Remove 24 vac hot. Damper should Open.

9

Spring Types

@ 8 VA

per damper

ND / URD’s

@ 2 VA

per damper

Transformer Size

60VA

75VA

30

22

19 26

15 23

40VA

12

9

5

These charts show the maximum

number of dampers that can be

connected to the entire

BMPlus3000/5000/7000 based on the

transformer being used.

Maximum number of dampers

per ZONE is 12.

Use Class 2 UL Listed 1585 Inherently

current limiting transformers only!

Figure 18

Variations on this diagram and other damper solutions are available.

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

ZONE

MOTOR

M1

M6

M4

M2

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

12 Dampers wired to a single zone.

BMPlus

3000

Zone Panel

BMPlus

5000

BMPlus

7000

Transformer Size

60VA

75VA

7

5

46

3 5

40VA

3

2

1

BMPlus

3000

Zone Panel

BMPlus

5000

BMPlus

7000

BMPlus 3000

LED’s

The BMPlus is equipped with 11 function specific LED’s that indicate HVAC system operation

and zone damper status. Familiarize yourself with the LED functions and definitions, in order to

accurately determine the Zoned HVAC system status and mode of operation.

STATUS

GREEN

SAS

RED

OAS

RED

FAN

ZONE 3

ZONE 2

ZONE 1

The STATUS LED pulses as a steady heart beat to indicate proper Microprocessor system status.

The OAS LED illuminates solid to indicate that the Outdoor Temperature has fallen below the chosen

set point. The OAS LED will blink rapidly to indicate a shorted or open Outdoor Air Sensor circuit.

The SAS LED illuminates solid to indicate that the Supply Temperature has exceeded the chosen

set point on either the HIGH TEMP LIMIT or the LOW TEMP LIMIT. The SAS LED will blink rapidly

to indicate a shorted or open Supply Air Sensor circuit.

The ZONE 3 LED will illuminate solid to indicate that damper(s) is energized open, and the Zone is active.

The ZONE 2 LED will illuminate solid to indicate that damper(s) is energized open, and the Zone is active.

The ZONE 1 LED will illuminate solid to indicate that damper(s) is energized open, and the Zone is active.

The FAN LED will illuminate solid to indicate a demand for fan operation, during COOLING, HEATING,

PURGE, or CONTINUOUS FAN operations.

Y1

Y2

W1/B

RED

W2/E

RED

The Y2 LED illuminates solid to indicate the 2nd stage of DX COOLING or DX HEATING is energized.

The Y1 LED illuminates solid to indicate the 1ST stage of DX COOLING or DX HEATING is energized.

The W1/B LED illuminates solid to indicate 1st stage of HEATING is energized in Gas/Hydronic mode.

The W1/B LED illuminates solid to indicate ‘B’ reversing valve is energized in HEAT PUMP operation.

NOTE: In Heat Pump Operation, this LED will stay illuminated after the call for heat is completed.

The W2/E LED illuminates solid to indicate 2nd or 3rd stage of HEATING is energized in GAS/HYDRONIC

or HEAT PUMP mode.

The W2/E LED illuminates solid to indicate EMERGENCY HEAT is energized in HEAT PUMP mode.

NOTES:

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

10

LED’S

GREEN

GREEN

GREEN

GREENGREEN

GREENGREEN

YELLOW

YELLOW

GREENGREEN

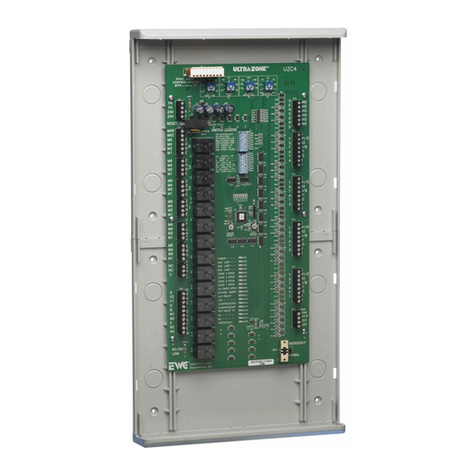

BMPlus3000

3 Zone Main

Module

Rugged 10 pin

Expansion Header

Supply Air

Sensor

Connections

Outdoor Air

Sensor

Connections

Rugged Damper

Motor Terminal

Blocks

User Friendly

Adjustable

Potentiometers

On-Board

Emergency Switch

On-Board

CUTTABLE

Rc/Rh Link

Isolated HVAC

System

Terminal

Block

Rugged

Thermostat

Terminal

Blocks

Multi

Functional

Zone 1

Thermostat

Terminal

Block

Easy Setup

8 switch Bank

Dual Function

Reset

Button

Polarized

Power Input

Terminals

The BMPlus 3000 Zone Control System includes Module to Module Factory Wiring. We power up the Expansion Modules

for you. The XM2 Expansion module includes a Status LED and Damper Status LED’s.

See page 11 and 12 for drawing representations of a 5 and 7 zone system and appropriate dip switch settings.

All you have to do is:

1. Set the dip switches to your specific application.

2. Connect your thermostats, dampers and system wiring.

3. Power up the Main Module

4. Check System Operation.

5. Enjoy.

Protective

header cap not

shown for clarity

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 11

Thermal Circuit

Breaker

Isolated Common

terminal. Useful

when HVAC

troubleshooting

System Status LED’s

Figure 19

J1

ZONE3

MOTOR

ZONE2

MOTOR

MOTOR

ZONE1

24

T’FORMER

VAC

SYSTEM

M6

M4

M2

M1

M6

M4

M2

M1

M6

M4

M2

M1

R

C

G

Y2

Y1

O

RH

RC

W1

B

W2

E

LINK

RH

RC

D

43

D

C

1

C

2

+

+

SAS

SAS

OAS

OAS

C

W/E

O/B

Y

R

G

ONE

ZONE

EM

NORM

SW

4

ZONE1

STAT

T

D

11

D

12

D

13

D

10

2

ND STAGE HEAT

DIFFERENTIAL

LIMIT

HIGH

TEMPLOW TEMP

LIMIT

TIMER OAS

STAGING

47

5

40

33

26

19

12

110

120

130 140 150

160

170

52

49

46

43

40

37

34

42

35

28

21

14

7

OFF

BMPlus3000 rev B

W

2

EM

B

1

W

1

2

Y

Y

ZONE

ZONE

ZONE

FAN

1

2

3

STATUS

OAS

SAS

38

39

R

R

R

37

R

36

R

76

77

R

72

R

73

R

R

70

69

R

67

R

68

R

65

R

R

64

71

R

R

63

62

R

R

61

60

R

59

R

58

R

R

57

56

R

55

R

54

R

R

78

79

R

53

R

52

R

R

51

50

R

49

R

48

R

R

47

46

R

45

R

81

R

R

40

43

R

R

42

41

R

10

LED

9

LED

8

LED

7

LED

6

LED

5

LED

4

LED

3

LED

2

LED

1

LED

11

LED

6

U

U

7

U

8

5

U

4

U

U

2

3

U

U

1

1

K

2

K

3

K

4

K

5

K

6

K

7

K

8

K

R

12

R

3

R

4

R

RESET

1

D

2

D

C

11

8

C

7

C

15

C

5

C

R

35

C

10

13

CY

1

21

D

1

Z

14

C

SW

3

33

R

32

R

31

R

30

R

8

D

29

R

R

28

27

R

26

R

7

D

25

R

R

24

23

R

22

R

6

D

21

R

R

20

R

19

5

D

D

934

R

GAS

OFF

OFF

OAS

HC

HP

OTHER

HP

TIMER

ON

HYDRONIC

ON

O B

DF

<

<

<

<

<

< >

>>

>

>>

>

<>

<

SYSTEM

HP CONV

50

TSTATS

RV

STAGING

RULE

SAS

FAN

E

W

C

SYSTEM

CONTROL

%

C

C

W/E

O/B

Y

R

G

ZONE3

STAT

T

F1

C

W/E

O/B

Y

R

G

9

C

66

R

82

R

R

44

R

14

R

R

15

16

U

9

12

C

R

13

ZONE2

STAT

T

BMPlus5000

DIP switch

settings

for 1st

Expansion

panel.

Zones 4 & 5

FACTORY

SUPPLIED

POWER & DATA

POLARIZED

BUS CABLE

Each expansion

module has a 2

position DIP

switch. Factory

set to insure the

main module

recognizes each

expansion

module in the

proper

sequence.

Setting the XM2

Expansion Panel

DIP Switches

Protective

header caps not

shown for clarity

DO NOT CONNECT

OR DISCONNECT

BUS CABLE

WHILE THE PANEL

IS POWERED.

To

Line

Voltage

24 vac transformer

Provide Over-Current

Protection

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

12

J1

ZONE3

MOTOR

ZONE2

MOTOR

MOTOR

ZONE1

24

T’FORMER

VAC

SYSTEM

M6

M4

M2

M1

M6

M4

M2

M1

M6

M4

M2

M1

R

C

G

Y2

Y1

O

RH

RC

W1

B

W2

E

LINK

RH

RC

D

43

D

C

1

C

2

+

+

SAS

SAS

OAS

OAS

C

W/E

O/B

Y

R

G

ONE

ZONE

EM

NORM

SW

4

ZONE1

STAT

T

D

11

D

12

D

13

D

10

2

ND STAGE HEAT

DIFFERENTIAL

LIMIT

HIGH

TEMPLOW TEMP

LIMIT

TIMER OAS

STAGING

47

5

40

33

26

19

12

110

120

130 140 150

160

170

52

49

46

43

40

37

34

42

35

28

21

14

7

OFF

W

2

EM

B

1

W

1

2

Y

Y

ZONE

ZONE

ZONE

FAN

1

2

3

STATUS

OAS

SAS

38

39

R

R

R

37

R

36

R

76

77

R

72

R

73

R

R

70

69

R

67

R

68

R

65

R

R

64

71

R

R

63

62

R

R

61

60

R

59

R

58

R

R

57

56

R

55

R

54

R

R

78

79

R

53

R

52

R

R

51

50

R

49

R

48

R

R

47

46

R

45

R

81

R

R

40

43

R

R

42

41

R

10

LED

9

LED

8

LED

7

LED

6

LED

5

LED

4

LED

3

LED

2

LED

1

LED

11

LED

6

U

U

7

U

8

5

U

4

U

U

2

3

U

U

1

1

K

2

K

3

K

4

K

5

K

6

K

7

K

8

K

R

12

R

3

R

4

R

RESET

1

D

2

D

C

11

8

C

7

C

15

C

5

C

R

35

C

10

13

CY

1

21

D

1

Z

14

C

SW

3

33

R

32

R

31

R

30

R

8

D

29

R

R

28

27

R

26

R

7

D

25

R

R

24

23

R

22

R

6

D

21

R

R

20

R

19

5

D

D

934

R

E

W

C

SYSTEM

CONTROL

C

C

W/E

O/B

Y

R

G

ZONE3

STAT

T

F1

C

W/E

O/B

Y

R

G

9

C

66

R

82

R

R

44

R

14

R

R

15

16

U

9

12

C

R

13

M6

M4

M2

M1

M6

M4

M2

M1

C

W/E

O/B

Y

R

G

E

W

C

4

R

R

1

2

R

3

R

R

6

5

R

R

17

J1

16

R

R

15

14

R

13

R

12

R

R

11

10

R

23

R

21

R

R

19

37

R

22

RR

20

18

R

27

R

26

R

25

R

R

24

R

28

29

R

30

R

7

D

5

D

6

D

D

4

3

D

2

D

1

D

C

1

3

C

>

<

0

A

A

0

<>

2

1

U

5

U

3

U

1

STATUS

U

4

Y

1

K

1

+

K

2

1

Z

D

M

P

R

D

M

P

R

T

S

T

A

T

T

S

T

A

T

38

R

40

R

39

R

8

D

U

2

36

R

35

R

34

R

Figure 20

BMPlus3000 rev B

C

W/E

O/B

Y

R

G

ZONE2

STAT

T

GAS

OFF

OFF

OAS

HC

HP

OTHER

HP

TIMER

ON

HYDRONIC

ON

O B

DF

<

<

<

<

<

< >

>>

>

>>

>

<>

<

SYSTEM

HP CONV

50

TSTATS

RV

STAGING

RULE

SAS

FAN

%

M6

M4

M2

M1

M6

M4

M2

M1

C

W/E

O/B

Y

R

G

E

W

C

4

R

R

1

2

R

3

R

R

6

5

R

R

17

J1

16

R

R

15

14

R

13

R

12

R

R

11

10

R

23

R

21

R

R

19

37

R

22

RR

20

18

R

27

R

26

R

25

R

R

24

R

28

29

R

30

R

7

D

5

D

6

D

D

4

3

D

2

D

1

D

C

1

3

C

>

<

0

A

A

0

<>

2

1

U

5

U

3

U

1

STATUS

U

4

Y

1

K

1

+

K

2

1

Z

D

M

P

R

D

M

P

R

T

S

T

A

T

T

S

T

A

T

38

R

40

R

39

R

8

D

U

2

36

R

35

R

34

R

C

W/E

O/B

Y

R

G

BMPlus7000

DIP switch settings for

1st Expansion panel.

Zones 4 & 5

DIP switch settings for

2nd Expansion panel.

Zones 6 & 7

Setting the XM2

Expansion Panel

DIP Switches

Each expansion

panel has a 2

position DIP switch.

Factory set to insure

the main module

recognizes each

expansion module in

the proper sequence.

FACTORY

SUPPLIED

POWER & DATA

POLARIZED

BUS CABLE

To

Line

Voltage

24 vac transformer

Provide Over-Current

Protection

Figure 21

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 13

J1

ZONE3

MOTOR

ZONE2

MOTOR

MOTOR

ZONE1

24

T’FORMER

VAC

SYSTEM

M6

M4

M2

M1

M6

M4

M2

M1

M6

M4

M2

M1

R

C

G

Y2

Y1

O

RH

RC

W1

B

W2

E

LINK

RH

RC

D

43

D

C

1

C

2

+

+

SAS

SAS

OAS

OAS

C

W/E

O/B

Y

R

G

ONE

ZONE

EM

NORM

SW

4

ZONE1

STAT

T

D

11

D

12

D

13

D

10

2

ND STAGE HEAT

DIFFERENTIAL

LIMIT

HIGH

TEMPLOW TEMP

LIMIT

TIMER OAS

STAGING

47

5

40

33

26

19

12

110

120

130 140 150

160

170

52

49

46

43

40

37

34

42

35

28

21

14

7

OFF

W

2

EM

B

1

W

1

2

Y

Y

ZONE

ZONE

ZONE

FAN

1

2

3

STATUS

OAS

SAS

38

39

R

R

R

37

R

36

R

76

77

R

72

R

73

R

R

70

69

R

67

R

68

R

65

R

R

64

71

R

R

63

62

R

R

61

60

R

59

R

58

R

R

57

56

R

55

R

54

R

R

78

79

R

53

R

52

R

R

51

50

R

49

R

48

R

R

47

46

R

45

R

81

R

R

40

43

R

R

42

41

R

10

LED

9

LED

8

LED

7

LED

6

LED

5

LED

4

LED

3

LED

2

LED

1

LED

11

LED

6

U

U

7

U

8

5

U

4

U

U

2

3

U

U

1

1

K

2

K

3

K

4

K

5

K

6

K

7

K

8

K

R

12

R

3

R

4

R

RESET

1

D

2

D

C

11

8

C

7

C

15

C

5

C

R

35

C

10

13

CY

1

21

D

1

Z

14

C

SW

3

33

R

32

R

31

R

30

R

8

D

29

R

R

28

27

R

26

R

7

D

25

R

R

24

23

R

22

R

6

D

21

R

R

20

R

19

5

D

D

934

R

GAS

OFF

OFF

OAS

HC

HP

OTHER

HP

TIMER

ON

HYDRONIC

ON

O B

DF

<

<

<

<

<

< >

>>

>

>>

>

<>

<

SYSTEM

HP CONV

50

TSTATS

RV

STAGING

RULE

SAS

FAN

E

W

C

SYSTEM

CONTROL

%

C

C

W/E

O/B

Y

R

G

ZONE3

STAT

T

F1

C

W/E

O/B

Y

R

G

9

C

66

R

82

R

R

44

R

14

R

R

15

16

U

9

12

C

R

13

M6

M4

M2

M1

M6

M4

M2

M1

C

W/E

O/B

Y

R

G

E

W

C

4

R

R

1

2

R

3

R

R

6

5

R

R

17

J1

16

R

R

15

14

R

13

R

12

R

R

11

10

R

23

R

21

R

R

19

37

R

22

RR

20

18

R

27

R

26

R

25

R

R

24

R

28

29

R

30

R

7

D

5

D

6

D

D

4

3

D

2

D

1

D

C

1

3

C

>

<

0

A

A

0

<>

2

1

U

5

U

3

U

1

STATUS

U

4

Y

1

K

1

+

K

2

1

Z

D

M

P

R

D

M

P

R

T

S

T

A

T

T

S

T

A

T

38

R

40

R

39

R

8

D

U

2

36

R

35

R

34

R

C

W/E

O/B

Y

R

G

ZONE2

STAT

T

BMPlus3000 rev B

Protective

header caps not

shown for clarity

DO NOT CONNECT

OR DISCONNECT

BUS CABLE

WHILE THE PANEL

IS POWERED.

G

R

W

C

ZONE 3 THERMOSTAT

HEAT

Y

68

To Line Voltage.

Provide Over-Current

Protection.

24vac transformer

40va

OUTDOOR

HEAT PUMP

2STAGE GAS

FURNACE

ND / URD DAMPERS

SUPPLY AIR SENSOR OUTDOOR AIR SENSOR

BMPlus 3000Wiring Diagram

Dual Fuel Heat Pump

Auxiliary Heat Activates via

OutdoorairTemperature or

HeatPump Thermostat EmergencyInput

Allwiring shouldbedone to local and

national codesand ordinances. Use

color-coded, multi-conductor wire. Wire

number to number or lettertoletter on

eachcontrol.

WARNING: THESE PANELSARE DESIGNED

FOR USE WITH 24VAC. DO NOTUSE OTHER

VOLTAGES! USE CAUTIONTOAVOID

ELECTRICSHOCK OREQUIPMENTDAMAGE.

EWCControls Inc. 385 Highway 33 Englishtown, NJ07726 800-446-3110 FAX 732-446-5362 E-Mail- info@ewccontrols.com

J1

ZONE3

MOTOR

ZONE2

MOTOR

MOTOR

ZONE1

24

T’FORMER

VAC

SYSTEM

M6

M4

M2

M1

M6

M4

M2

M1

M6

M4

M2

M1

R

C

G

Y2

Y1

O

RH

RC

W1

B

W2

E

LINK

RH

RC

D

43

D

C

1

C

2

+

+

SAS

SAS

OAS

OAS

C

W/E

O/B

Y

R

G

ONE

ZONE

EM

NORM

SW

4

ZONE1

STAT

T

D

11

D

12

D

13

D

10

2

NDSTAGEHEAT

DIFFERENTIAL

LIMIT

HIGH

TEMP

LOW TEMP

LIMIT

TIMER OAS

STAGING

47

5

40

33

26

19

12

110

120

130140150

160

170

52

49

46

43

40

37

34

42

35

28

21

14

7

OFF

W

2

EM

B

1

W

1

2

Y

Y

ZONE

ZONE

ZONE

FAN

1

2

3

STATUS

OAS

SAS

38

39

R

R

R

37

R

36

R

76

77

R

72

R

73

R

R

70

69

R

67

R

68

R

65

R

R

64

71

R

R

63

62

R

R

61

60

R

59

R

58

R

R

57

56

R

55

R

54

R

R

78

79

R

53

R

52

R

R

51

50

R

49

R

48

R

R

47

46

R

45

R

81

R

R

40

43

R

R

42

41

R

10

LED

9

LED

8

LED

7

LED

6

LED

5

LED

4

LED

3

LED

2

LED

1

LED

11

LED

6

U

U

7

U

8

5

U

4

U

U

2

3

U

U

1

1

K

2

K

3

K

4

K

5

K

6

K

7

K

8

K

R

12

R

3

R

4

R

RESET

1

D

2

D

C

11

8

C

7

C

15

C

5

C

R

35

C

10

13

CY

1

21

D

1

Z

14

C

SW

3

33

R

32

R

31

R

30

R

8

D

29

R

R

28

27

R

26

R

7

D

25

R

R

24

23

R

22

R

6

D

21

R

R

20

R

19

5

D

D

934

R

GAS

OFF

OFF

OAS

HC

HP

OTHER

HP

TIMER

ON

HYDRONIC

ON

O B

DF

<

<

<

<

<

<>

>>

>

>>

>

<>

<

SYSTEM

HPCONV

50

TSTATS

RV

STAGING

RULE

SAS

FAN

E

W

C

SYSTEM

CONTROL

%

C

C

W/E

O/B

Y

R

G

ZONE3

STAT

T

F1

C

W/E

O/B

Y

R

G

9

C

66

R

82

R

R

44

R

14

R

R

15

16

U

9

12

C

R

13

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

Y2

O/B

X/W

R

C

Y1

O/B

W1

W2

R

C

Y1

G

R

W

C

ZONE 2 THERMOSTAT

HEAT

Y

72

G

R

W

C

ZONE1 THERMOSTAT

HEAT

Y

70

ZONE2

STAT

T

Y2

G

BMPlus3000 rev B

ZONE 3 THERMOSTAT

HEAT

68

GR

YW

C

24vac transformer

40va

ND / URDDAMPERS

SUPPLYAIR SENSOR

BMPlus 3000 WiringDiagram

2STAGE GAS HEAT WITH 2 STAGEA/C

2nd Stage Heat & 2nd Stage Cool Activates via

The Adjustable Timer.

2 STAGE GAS

FURNACE

OUTDOOR

CONDENSING

UNIT

All wiringshould be done to local

and nationalcodesandordinances.

Use color-coded, multi-conductor

wire. Wire number to number or

letter to letter on each control.

WARNING: THESEPANELS ARE DESIGNED

FOR USE WITH24VAC. DO NOT USE OTHER

VOLTAGES! USECAUTION TO AVOID ELECTRIC

SHOCKOREQUIPMENTDAMAGE.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

To Line Voltage.

Provide Over-Current

Protection.

J1

ZONE3

MOTOR

ZONE2

MOTOR

MOTOR

ZONE1

24

T’FORMER

VAC

SYSTEM

M6

M4

M2

M1

M6

M4

M2

M1

M6

M4

M2

M1

R

C

G

Y2

Y1

O

RH

RC

W1

B

W2

E

LINK

RH

RC

D

43

D

C

1

C

2

+

+

SAS

SAS

OAS

OAS

C

W/E

O/B

Y

R

G

ONE

ZONE

EM

NORM

SW

4

ZONE1

STAT

T

D

11

D

12

D

13

D

10

2

ND STAGE HEAT

DIFFERENTIAL

LIMIT

HIGH

TEMPLOW TEMP

LIMIT

TIMER OAS

STAGING

47

5

40

33

26

19

12

110

120

130 140 150

160

170

52

49

46

43

40

37

34

42

35

28

21

14

7

OFF

W

2

EM

B

1

W

1

2

Y

Y

ZONE

ZONE

ZONE

FAN

1

2

3

STATUS

OAS

SAS

38

39

R

R

R

37

R

36

R

76

77

R

72

R

73

R

R

70

69

R

67

R

68

R

65

R

R

64

71

R

R

63

62

R

R

61

60

R

59

R

58

R

R

57

56

R

55

R

54

R

R

78

79

R

53

R

52

R

R

51

50

R

49

R

48

R

R

47

46

R

45

R

81

R

R

40

43

R

R

42

41

R

10

LED

9

LED

8

LED

7

LED

6

LED

5

LED

4

LED

3

LED

2

LED

1

LED

11

LED

6

U

U

7

U

8

5

U

4

U

U

2

3

U

U

1

1

K

2

K

3

K

4

K

5

K

6

K

7

K

8

K

R

12

R

3

R

4

R

RESET

1

D

2

D

C

11

8

C

7

C

15

C

5

C

R

35

C

10

13

CY

1

21

D

1

Z

14

C

SW

3

33

R

32

R

31

R

30

R

8

D

29

R

R

28

27

R

26

R

7

D

25

R

R

24

23

R

22

R

6

D

21

R

R

20

R

19

5

D

D

934

R

GAS

OFF

OFF

OAS

HC

HP

OTHER

HP

TIMER

ON

HYDRONIC

ON

O B

DF

<

<

<

<

<

< >

>>

>

>>

>

<>

<

SYSTEM

HP CONV

50

TSTATS

RV

STAGING

RULE

SAS

FAN

E

W

C

SYSTEM

CONTROL

%

C

C

W/E

O/B

Y

R

G

ZONE3

STAT

T

F1

C

W/E

O/B

Y

R

G

9

C

66

R

82

R

R

44

R

14

R

R

15

16

U

9

12

C

R

13

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

6

4

1

PC

PO

COM

Y2

G

Y2

C

R

Y1

W1

W2

R

C

Y1

ZONE 1 THERMOSTAT

HEAT

70

GR

YW

C

ZONE 2 THERMOSTAT

HEAT

72

GR

YW

C

ZONE2

STAT

T

BMPlus3000 rev B

ISOLATING 24vac SHORTS

Dampers not responding and THE

BMPLUS 3000 LED’s are off.

HVAC system not responding and

BMPLUS 3000 LED’s are off.

DETECTING 24vac SHORTS

Check HVAC & BMPlus system transformer supply voltage.

Check HVAC & BMPlus system 24vac transformer voltage, fuse & the BMPlusB

circuit breaker.

Check HVAC & BMPlus system wiring for shorts/miswiring.

Check HVAC system wiring for shorts/miswiring.

Check HVAC system wiring for proper connections.

Check HVAC thermostat for proper connections.

Refer to Technical Bulletin for correct Setup/Wiring/Dip Switch settings.

Check HVAC system wiring for proper connections.

Check HVAC system wiring for shorts/miswiring.

Check HVAC System.

Refer to Technical Bulletin for correct Setup/Wiring/Dip Switch settings.

SOLUTIONS

TROUBLESHOOTING

REFER TO THE DAMPER MOTOR TESTING PAGE 9

LED’s illuminate and HVAC system

functions normally but dampers do

not respond.

Check damper motor wiring for proper connections.

Check damper motor 24vac transformer voltage/fuse/BMPlus circuit breaker.

Check damper motor wiring for shorts/miswiring.

Refer to Technical Bulletin for correct Setup/Wiring.

F1 circuit breaker protects the

BMPlus 3000 and reacts to a short in

the damper motor or thermostat

component and field wiring.

CHECK YOUR WIRING

EWC Controls provides superior toll free Troubleshooting Support for the BMPlus 3000 when you are on the job site!

Call 1-800-446-3110 Monday - Friday 8am to 5pm EST

Otherwise call 1-732-446-3110 for information on the BMPlus 3000 and other ULTRA-ZONE products..

When calling for Technical Support, please have a multi-meter, pocket screwdriver, and wire cutter/stripper handy.

TECHNICAL SUPPORT

LED’s do not illuminate and HVAC

system does not respond.

LED’s are not responding properly

and HVAC system is malfunctioning.

LED’S are responding properly but

HVAC system is malfunctioning.

SYMPTOM

Disconnect the wire(s) from the ‘R’ terminals on the BMPlus 3000 thermostat

terminal blocks , and the “M2/M4/M6’’ terminals on the BMPlus 3000 damper

motor terminal blocks. Restore power. If the short is no longer present, Ohm

out the thermostat and damper field wiring for shorts/misconnections. Replace

or repair wires as necessary. Restore power. Module(s) will resume operation.

SOLUTIONS: Remove 24vac power from BMPlus 3000 and allow circuit breaker to cool!

Find and repair short(s) in damper and/or thermostat field wiring. Restore 24 vac power.

If 24vac short has occurred, 24vac will be present at the BMPlus 3000 Module

Input terminals R & C; but 24vac will not be present at the Thermostat R&C.

SYMPTOMS: Module(s) appear to be dead!

TESTING THERMOSTATS

Check to make sure that the thermostat Rc and Rh terminals are connected together, unless your application requires

separation of these circuits.

Use the (C) Common terminal provided at each thermostat terminal block to wire up full 24 vac hard-wired thermostats.

You should reference the (C) Common terminal when troubleshooting incoming thermostat demand signals, even if no wire is

connected there.

Make sure that you wire and configure your thermostats for the correct application. Most thermostats built today can be field

configured to operate as regular Heat/ Cool type or as Heat Pump type. Remember that you can use regular Heat/Cool

thermostats on the BMPlus 3000 for Heat Pump applications.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected]

16

Other manuals for BMPlus 3000

1

This manual suits for next models

2

Table of contents

Other EWC Controls Controllers manuals