EWM HIGHTEC WELDING PHOENIX R10 User manual

EWM

HIGHTEC WELDING GmbH

Dr. Günter-Henle-Straße 8 • D-56271 Mündersbach

Fon +49 2680 181-0 • Fax +49 2680 181-244

www.ewm.de • info@ewm.de

GB

Operating instructions

Remote control

PHOENIX R10

PHOENIX R20

PHOENIX R40

N. B. These operating instructions must be read before commissioning.

Failure to do so may be dangerous.

Machines may only be operated by personnel who are familiar with the appropriate safety

regulations.

The machines bear the conformity mark and thus comply with the

• EC Low Voltage Directive (2006/95/ EG)

• EC EMC Directive (2004/108/ EG)

In compliance with IEC 60974, EN 60974, VDE 0544 the machines can be used in environments

with an increased electrical hazard.

©The content of the operating instructions does not constitute grounds for any claims on the part

of the buyer.

The copyright to these operating instructions remains with the manufacturer.

Reprinting, including extracts, only with written approval.

© 2008 Subject to alteration. Item No.: 099-008088-EWM01 Revised: 04.11.2008

Dear customer,

Congratulations! You have chosen a quality product from EWM HIGHTEC WELDING GmbH.

EWM machines provide results of the highest perfection thanks to their PREMIUM quality. Therefore

we are happy to provide you with a full 3-year warranty according to our operating instructions.

We develop and produce quality! From individual components to the final product, we retain sole

responsibility for our machines.

In all their high-tech components, our welding machines embody future-oriented advanced technology

at the utmost level of quality. Each of our products is carefully checked; we guarantee that the material

and processing of our products is faultless.

These operating instructions contain everything about commissioning the machine, notes regarding

safety, maintenance and care, technical data as well as information regarding the warranty. Please

heed all these notes to ensure many years of safe operation of the machine.

Thank you for the trust that you have placed in us. We look forward to a long-term partnership with you

in the spirit of “ONCE EWM – ALWAYS EWM”.

Yours sincerely,

EWM HIGHTEC WELDING GmbH

Bernd Szczesny

Executive management

Machine and Company Data

Please enter the EWM machine data and your company’s data in the appropriate fields.

CE

EWM HIGHTEC WELDING GMBH

D-56271 MÜNDERSBACH

TYP:

ART:

SNR:

PROJ:

GEPRÜFT/CONTROL:

Name of Customer / company

Adress

Post code / Place

Country

Stamp / Signature of EWM-distibutor

Date of purchase

Name of Customer / company

Adress

Post code / Place

Country

Stamp / Signature of EWM-distibutor

Date of purchase

3

Contents

For your safety

4 Item No.: 099-008088-EWM01

1Contents

1Contents..................................................................................................................................................4

2Safety instructions.................................................................................................................................6

2.1 For your safety...............................................................................................................................6

2.2 Notes on the use of these operating instructions...........................................................................6

3Technical data.........................................................................................................................................7

3.1 PHOENIX R10, R20, R40..............................................................................................................7

4Machine description...............................................................................................................................8

4.1 General...........................................................................................................................................8

4.2 PHOENIX R10, R20, R40..............................................................................................................8

5Functional characteristics...................................................................................................................10

5.1 Basic functions.............................................................................................................................10

5.1.1 MIG/MAG operating point.............................................................................................10

5.2 Advanced functions......................................................................................................................11

5.2.1 Manual remote control R20 ..........................................................................................11

5.2.1.1 Program changeover.....................................................................................11

5.2.2 R40 manual remote control ..........................................................................................11

5.2.2.1 Program changeover.....................................................................................11

5.2.2.2 Program limit.................................................................................................11

5.2.2.3 Specify program down parameter.................................................................12

5.2.2.4 Changing over between standard MIG welding and pulse arc MIG

welding ...............................................................................................................13

5.2.2.5 Operating point setting changeover via wire feed speed or panel

thickness.............................................................................................................13

5.3 Switching on and system diagnosis.............................................................................................13

5.3.1 R40 manual remote control ..........................................................................................13

6Commissioning.....................................................................................................................................14

6.1 Proper usage................................................................................................................................14

6.1.1 For operation only with the following equipment..........................................................14

6.2 Establishing the connections .......................................................................................................14

7Maintenance and testing .....................................................................................................................16

7.1 General.........................................................................................................................................16

7.2 Cleaning.......................................................................................................................................16

7.3 Maintenance.................................................................................................................................16

7.4 Disposing of equipment................................................................................................................16

7.4.1 Manufacturer's declaration to the end user..................................................................16

8Warranty................................................................................................................................................17

8.1 General Validity............................................................................................................................17

8.2 Warranty Declaration ...................................................................................................................18

9Accessories, options ...........................................................................................................................19

9.1 Connection and extension cables................................................................................................19

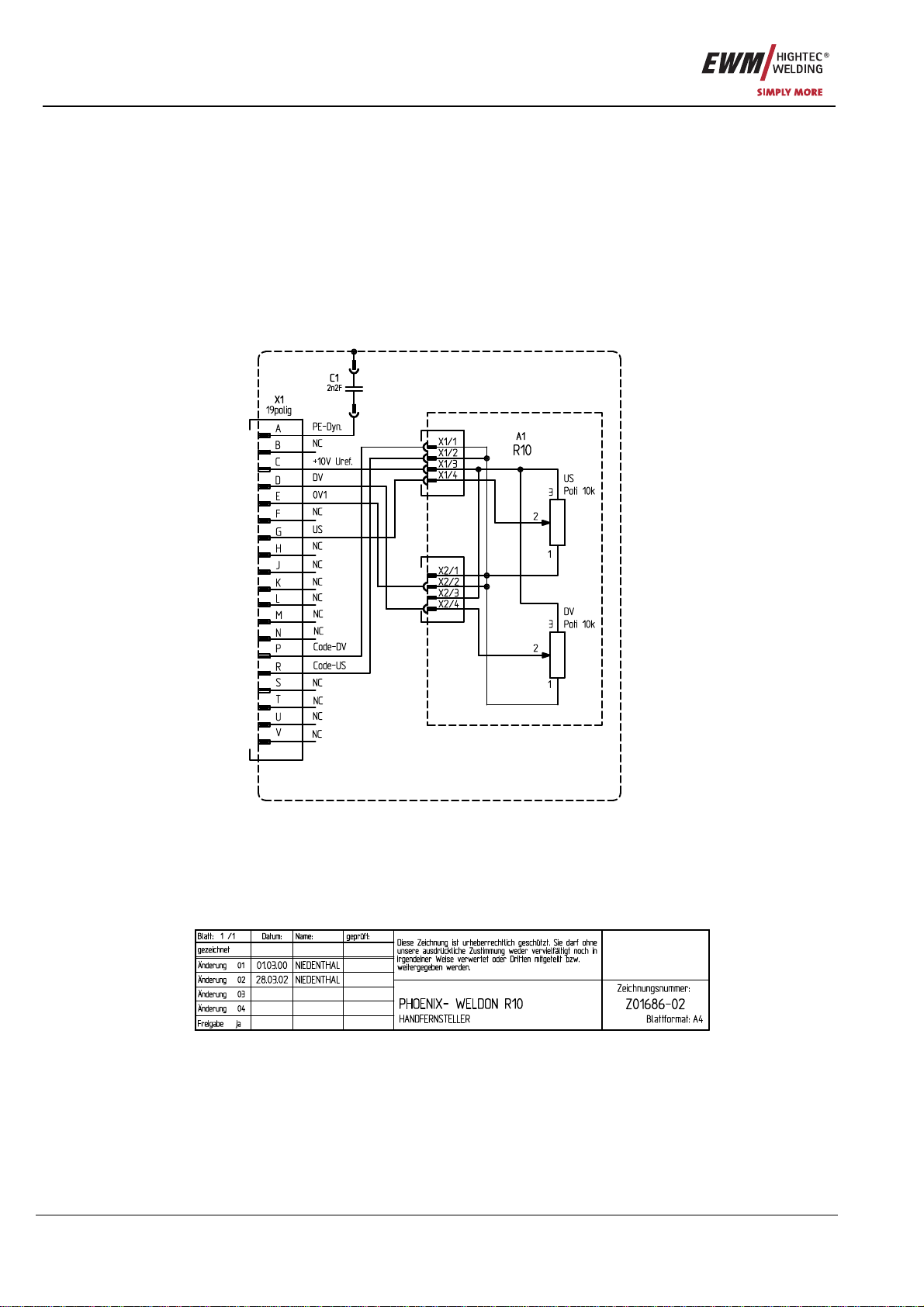

10 Circuit diagrams...................................................................................................................................20

10.1 PHOENIX R10 .............................................................................................................................20

10.2 PHOENIX R20 .............................................................................................................................21

10.3 PHOENIX R40 .............................................................................................................................22

Contents

For your safety

Item No.: 099-008088-EWM01 5

Safety instructions

For your safety

6 Item No.: 099-008088-EWM01

2Safety instructions

2.1 For your safety

Observe accident prevention regulations!

Ignoring the following safety procedures can be fatal!

Proper usage

This machine has been manufactured according to the latest developments in technology and

current regulations and standards. It is to be operated only for the use for which it was designed

(see chapter Commissioning/Area of application).

Improper usage

However, this machine may be a hazard to persons, animals and property if it is

• not used as directed

• used by unskilled persons who have not been trained

• modified or converted improperly

2.2 Notes on the use of these operating instructions

These operating instructions are arranged into chapters.

To help you find your way around more quickly, in the margins you will occasionally see symbols along

with the sub-headings. These symbols refer to particularly important passages of text which are graded

as follows depending on their importance:

Please note:

Technical features which users must observe.

Warning:

Working and operating procedures which must be followed precisely to avoid damaging or

destroying the machine.

Caution:

Working and operating procedures which must be followed precisely to avoid risk to persons and

includes the "Warning" symbol.

Instructions and lists detailing step-by-step actions in given situations can be recognised by bullet points,

e.g.:

• Insert the welding current lead socket into the relevant socket and lock.

Symbol Description

Press

Do not press

Turn

Switch

Technical data

PHOENIX R10, R20, R40

Item No.: 099-008088-EWM01 7

3Technical data

3.1 PHOENIX R10, R20, R40

Type R10 R20 R40

Port 19-pole, analogue 19-pole, analogue 7-pole, digital

Display - Single-digit 16-digit

Dimensions L x W x H in

mm 180 x 100 x 75 330 x 180 x 95 270 x 150 x 75

Weight in kg 0.86 2.3 1.4

Machine description

General

8 Item No.: 099-008088-EWM01

4Machine description

4.1 General

The remote controls are designed specifically for use with welding machines in the PHOENIX range and

offer various setting options, depending on the model.

Common features:

• Setting the operating point via the wire speed (single-dial operation)

• Arc length correction

PHOENIX R20:

• Changeover and display of up to ten welding programs.

PHOENIX R40:

• Change over, display, create or change up to 16 welding programs.

• Switch superpulse function on or off.

• Change over between standard MIG welding and pulse arc MIG welding

(if supported by the welding machine).

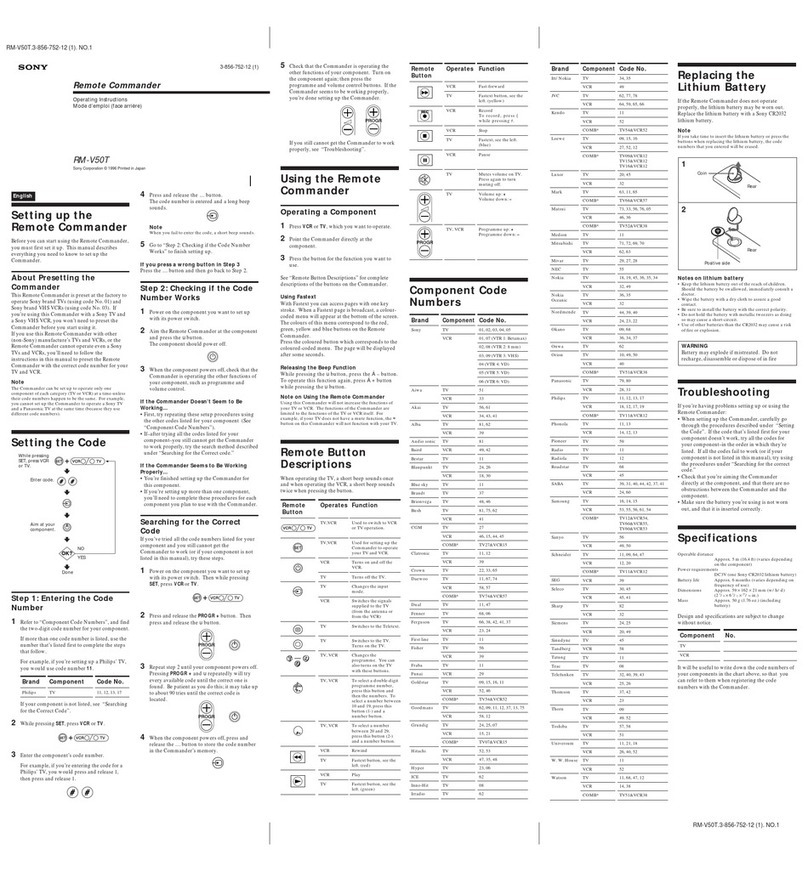

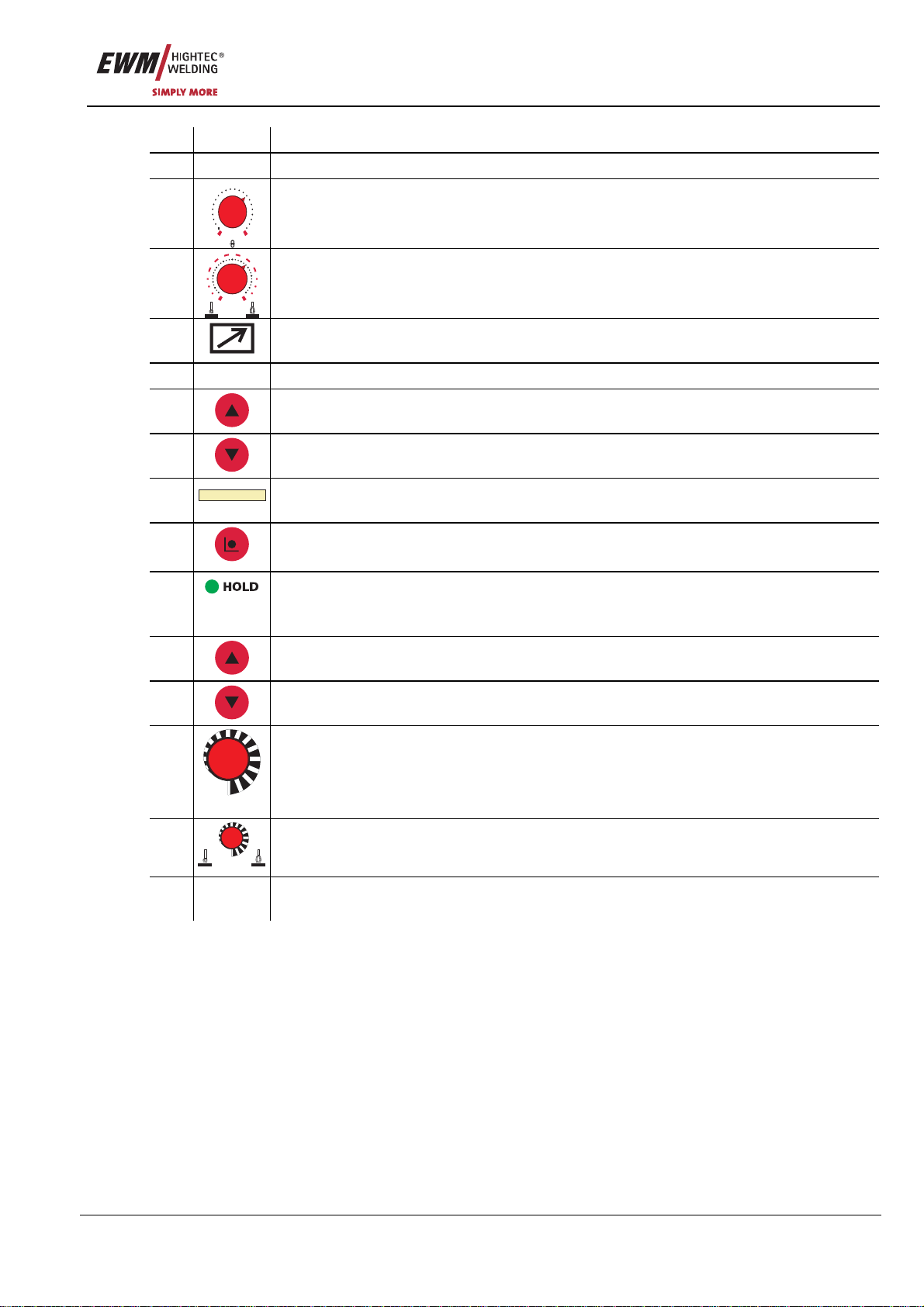

4.2 PHOENIX R10, R20, R40

6

7

4

3

2

1

5

15

1011

12

13

14

9

8

Figure 4-1

Machine description

PHOENIX R10, R20, R40

Item No.: 099-008088-EWM01 9

Item Symbol Description 0

1Holder for suspending the remote control

2

0,5

1

1,5

2

2,5

3

3,5

456

7

891011

12

13

14

15

16

18

20

m/min

Wire speed rotary dial

Infinitely adjustable setting of the wire speed from min. to max.

(welding output, one-dial operation)

3

01

1

22

33

77

55

10

10

- V +

“Arc length correction” rotary dial

Arc length correction from -10 V to + 10 V

4 19-pole connection socket (analogue)

For connecting the control lead.

5 Displays the current program number

6 Key button, program switching "Up"

Select program number up

7 Key button, program switching "Down"

Select program number down

8

500A 49,9V

Display, 16-digit

Display of all welding parameters and their values

9 Key button, "Mode"

To select the program runtime parameters

10 Signal light, "HOLD"

Lit: Display shows the last parameters used for welding.

Not lit: Display shows the setpoint values or current values during welding.

11 Key button, program switching "Up"

Select program number up

12 Key button, program switching "Down"

Select program number down

13

m/min

Rotary dial, wire speed

• Setting the wire speed

(0.5 m/min to 24 m/min in 0.1 m/min increments)

• Setting welding parameters

14

- V +

Rotary dial, arc length correction

• -9.9 V to +9.9 V in increments of 0.15 V

15 Connection socket, 7-pole (digital)

Connection to the digital remote control connection on power source or wire feed unit.

Functional characteristics

Basic functions

10 Item No.: 099-008088-EWM01

5Functional characteristics

5.1 Basic functions

5.1.1 MIG/MAG operating point

Operating point setting according to the MIG/MAG single-dial operating principle:

• One of the parameters wire speed, welding current or material thickness is set.

• The control calculates the optimum values for the remaining parameters

The wire speed is generally used to set the operating point.

In the situations given below, the wire speed is given to represent the operating point.

Operating

element Action Result Display (R40)

R10

R20

m/min

R40

Operating point setting via wire speed.

Display example: Wire speed 7.6 m/min

(Display for PHOENIX R40 only)

P0 : 7.6M +1.1V

The arc length can be corrected as follows.

Operating

element Action Result Display (R40)

01

1

22

33

77

55

10

10

- V +

R10

R20

- V +

R40

Arc length correction

Display example: Increase by 1.1 V

(Display for PHOENIX R40 only)

P0 : 7.6M +1.1V

Functional characteristics

Advanced functions

Item No.: 099-008088-EWM01 11

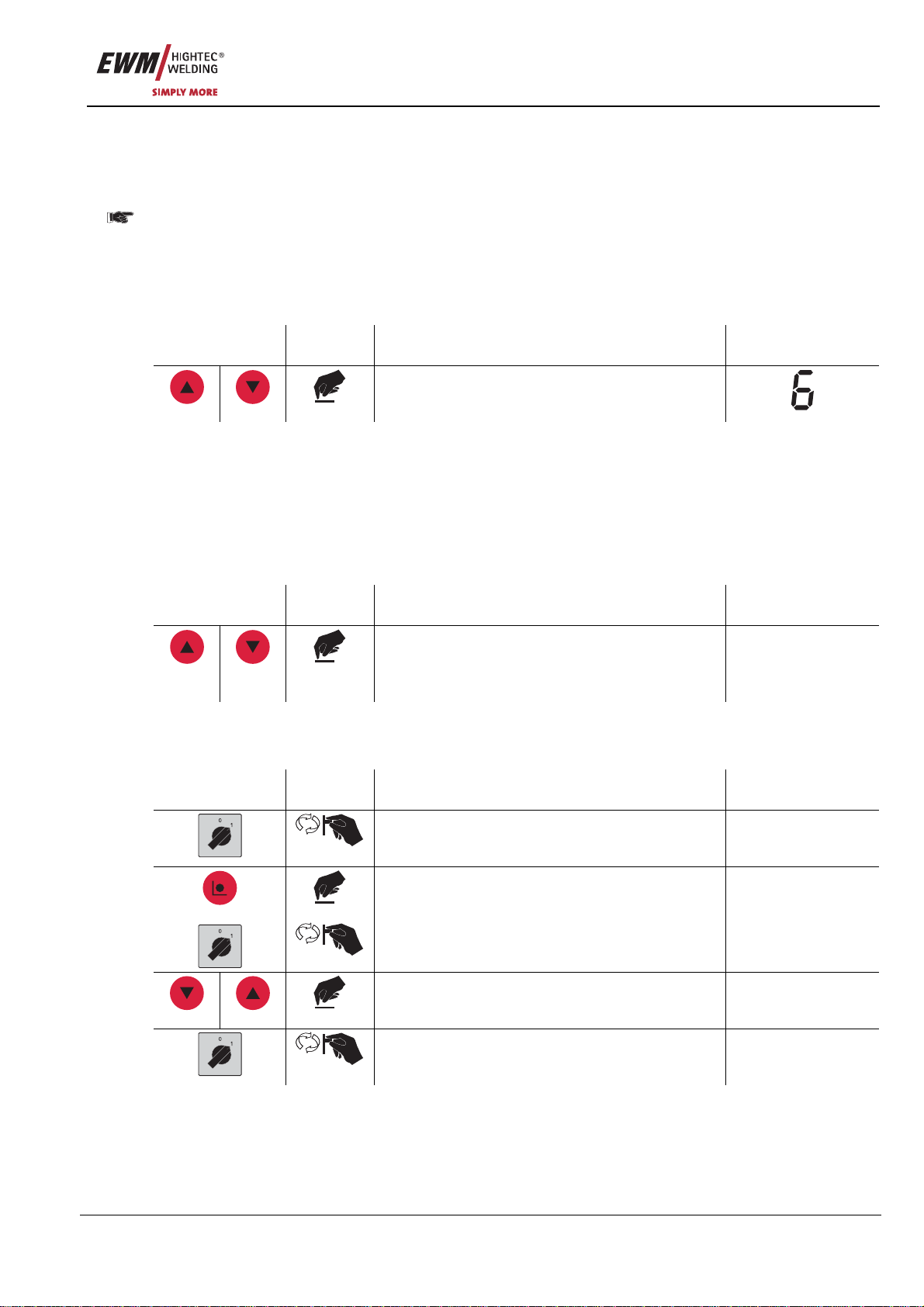

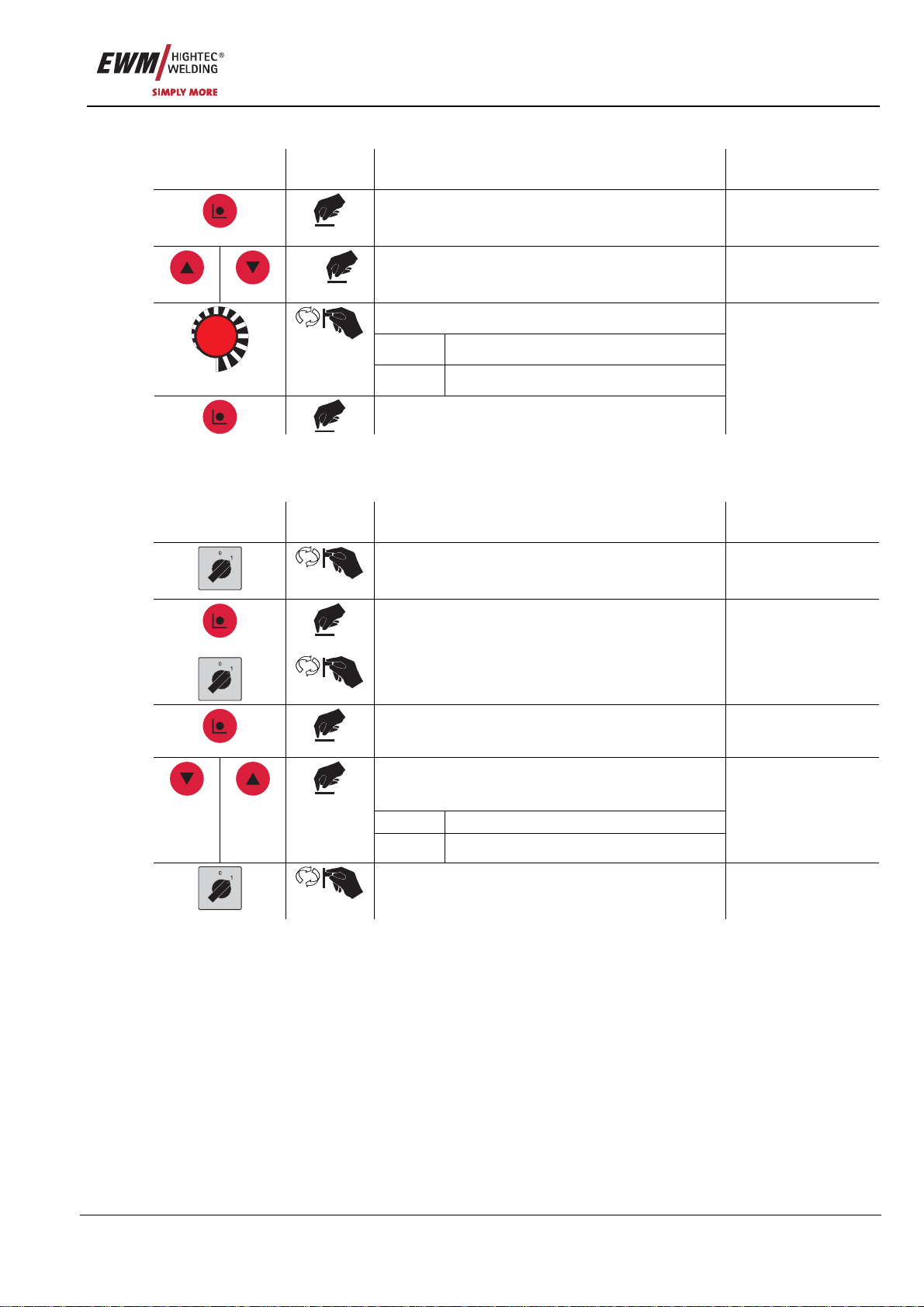

5.2 Advanced functions

5.2.1 Manual remote control R20

5.2.1.1 Program changeover

Set "Program or up/down mode" changeover switch on the welding machine or wire feed unit to

the "Up/down mode" position!

• Change between up to ten (0 to 9) welding programs.

• Welding programs are created using the control on the welding machine or wire feed unit. (see

operating instructions for the relevant machine, chapter "Main program mode A")

Operating

element Action Result Display

Select next or previous welding program.

5.2.2 R40 manual remote control

5.2.2.1 Program changeover

• Change between up to 16 (0 to 15) welding programs.

• Welding programs can be created using the control on the welding machine or wire feed unit or using

the remote control itself. (see operating instructions for the relevant machine, chapter "Main program

mode A", or the chapters following these instructions)

Operating

element Action Result Display

Select next or previous welding program. P0 : 7.6M +1.1V

...

P0 : 7.6M +1.1V

5.2.2.2 Program limit

• The maximum number of retrievable welding programs can be limited.

Operating

element Action Result Display

Switch off the welding machine.

+

+

Hold down "Mode" button on the remote control,

switching on the welding machine. PROGRAMME: 0XX

Set program number. PROGRAMME: 0XX

Switch off the welding machine and restart in

order to put the change into effect.

Functional characteristics

Advanced functions

12 Item No.: 099-008088-EWM01

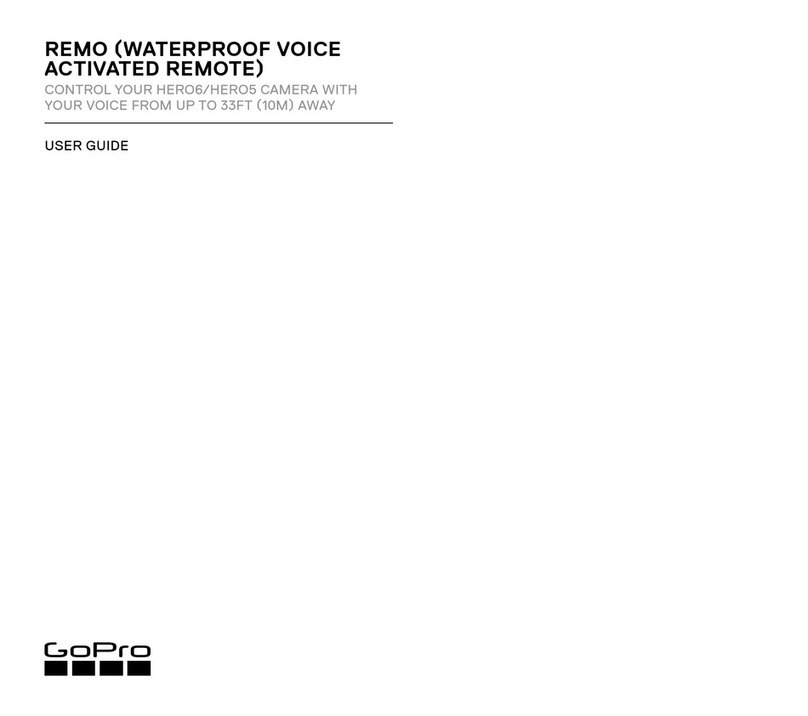

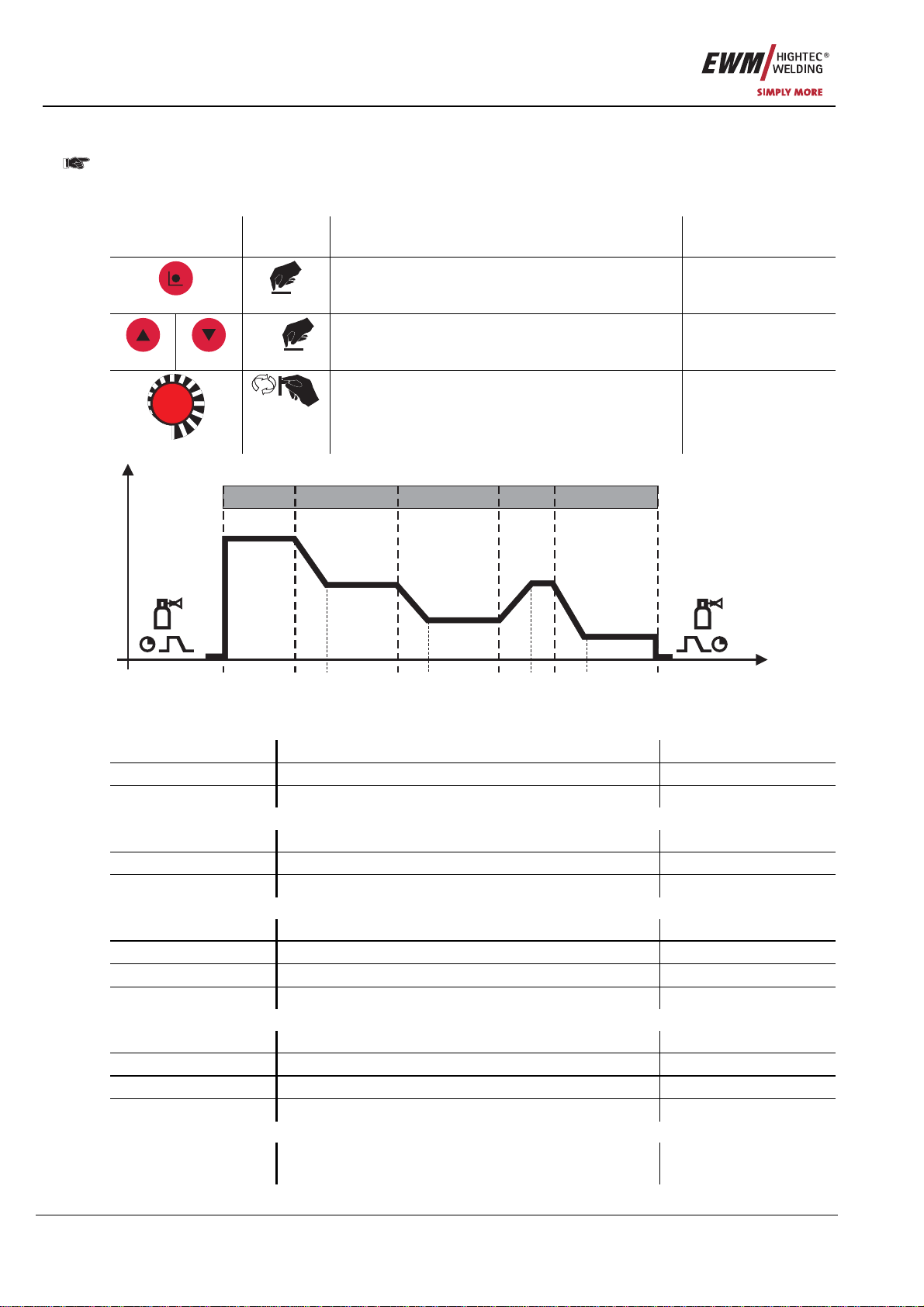

5.2.2.3 Specify program down parameter

After the initial selection of a program, the relevant operating point is set as described in the

"MIG/MAG operating point" chapter.

Operating points are saved and will be available once again after the program is selected.

Operating

element Action Result Display

Select program down parameter setting DVstart : 120%

n x Select down parameter to be set Ustart : +0.0V

m/min

Set down parameter Ustart : +4.2V

DVstart

DV3

U3 DVend

Uend

Ustart

tstart tS1 t2 tS2 t3 tS3 tSe tend

P

START

P

A

P

A

P

B

P

END

t

I

Figure 5-1

Start program PSTART

DVstart Wire-feed speed, relative 1% to 200%

Ustart Arc length correction -9.9 V to +9.9 V

tstart Duration 0.0 s to 20.0 s

Main program PA

tS1 Slope duration from PSTART to PA0.0 s to 20.0 s

t2 Duration (spot time and superpulse) 0.01 s to 20.0 s

tS2 Slope duration from PAto PB0.00 s to 20.0 s

Reduced main program PB

DV3 Wire-feed speed, relative 1% to 200%

U3 Arc length correction -9.9 V to +9.9 V

t3 Duration 0.01 s to 20.0 s

tS3 Slope duration from PBto PA0.00 s to 20.0 s

End program PEND

tSe Slope duration from PAto PEND 0.0 s to 20 s

DVend (r) Wire-feed speed, relative 1% to 200%

Uend Arc length correction -9.9 V to +9.9 V

tend Duration (superpulse) 0.0 s to 20 s

Superpulse function

Superpuls xx Superpulse function On

Off

Functional characteristics

Switching on and system diagnosis

Item No.: 099-008088-EWM01 13

5.2.2.4 Changing over between standard MIG welding and pulse arc MIG welding

Operating

element Action Result Display

3 s

Select setting option Pul / Nor?

n x Select program Px: _Nor

Changeover

^Pul MIG pulse arc welding

m/min

_Nor Standard MIG welding

Confirm and save change

Px: ^Pul

5.2.2.5 Operating point setting changeover via wire feed speed or panel thickness

• The operating point in program 0 can also be set via the panel thickness parameter.

Operating

element Action Result Display

Switch off the welding machine.

+

+

Hold down "Mode" button on the remote control,

switching on the welding machine. PROGRAMME: 0XX

Press "Mode" button once DV

Operating point setting changeover via wire

speed or panel thickness.

DV Wire speed

th/mm Panel thickness

th/mm

Switch off the welding machine and restart in

order to put the change into effect.

5.3 Switching on and system diagnosis

5.3.1 R40 manual remote control

The remote control runs through a system diagnostics process on being switched on. The following

values are displayed.

• PHOENIX R40,001 (Type and initialisation status)

• SV: 00.00.00.XX (Software version)

The current values for the welding voltage and current are then displayed.

• U: 0.0V I: 0A

Commissioning

Proper usage

14 Item No.: 099-008088-EWM01

6Commissioning

6.1 Proper usage

Only connect to remote control connection on the welding machine or wire feed unit.

• Observe the operating instructions for the welding machine or wire feed unit.

• Switch off the welding machine first.

6.1.1 For operation only with the following equipment

PHOENIX R10 PHOENIX R20 PHOENIX R40

• PHOENIX BASIC

• PHOENIX PROGRESS

• PHOENIX EXPERT

• PHOENIX PROGRESS

• PHOENIX EXPERT

• PHOENIX PROGRESS

• PHOENIX EXPERT

PHOENIX R20: An M3.70 or M3.71 type wire feed control is mandatory.

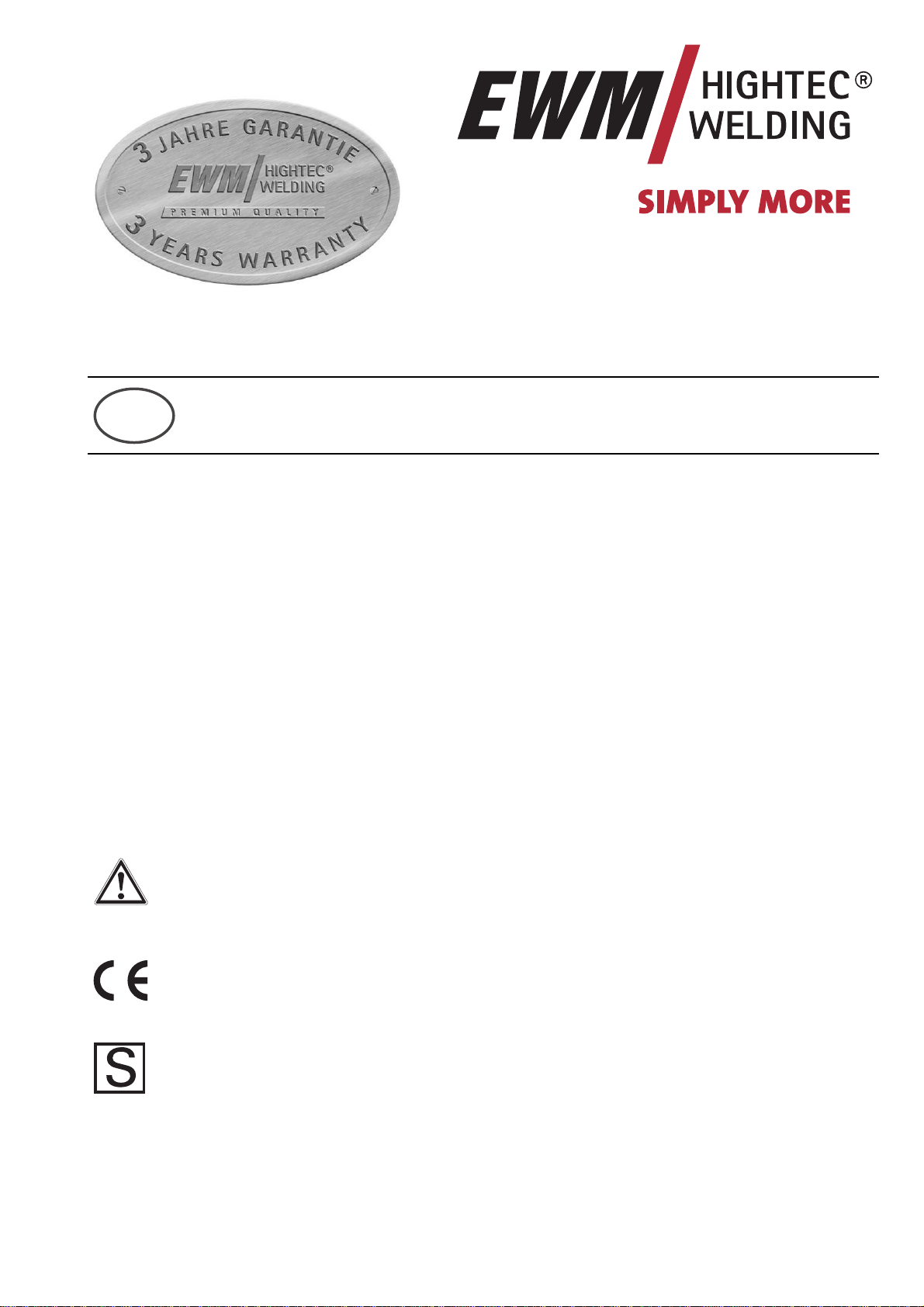

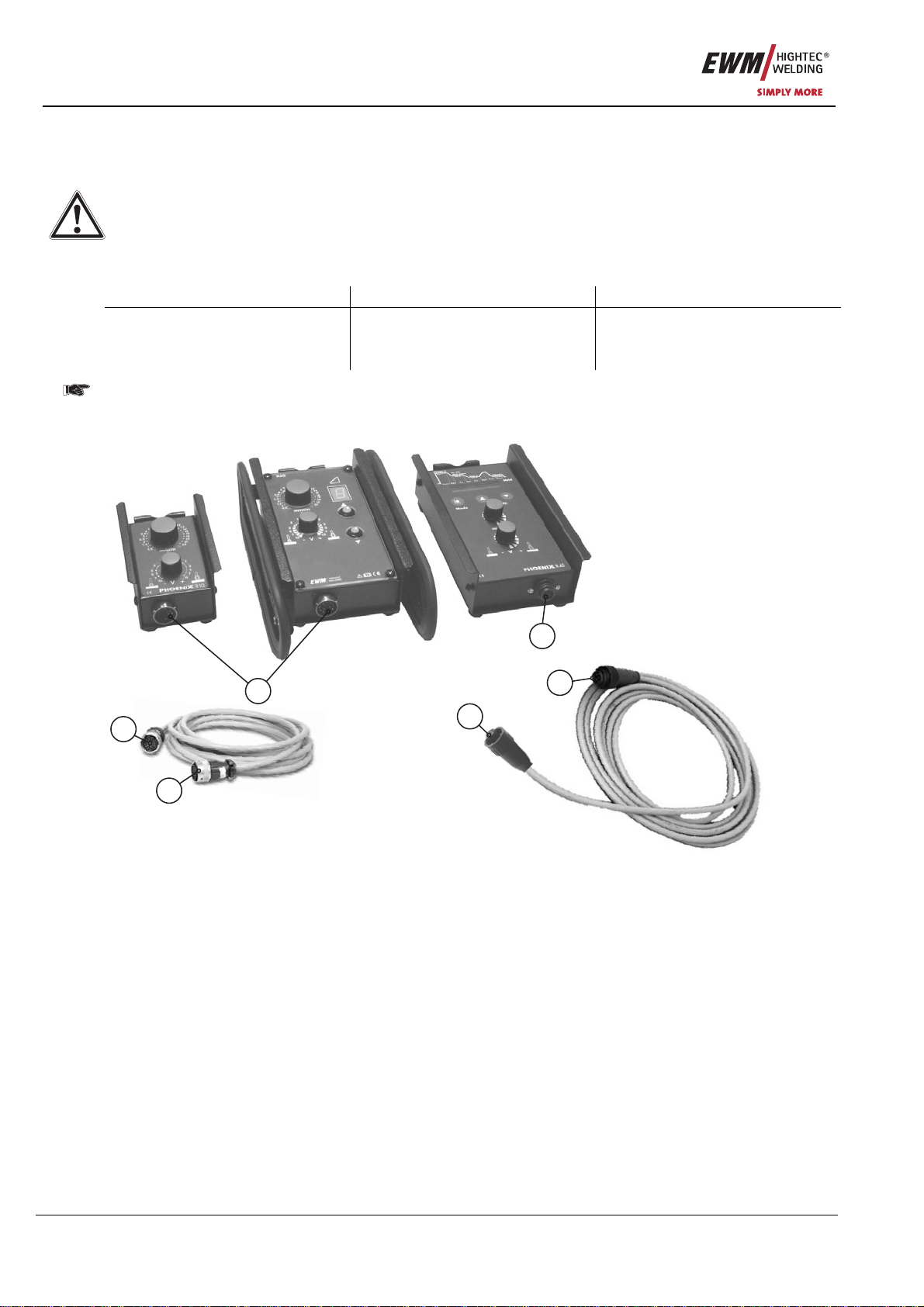

6.2 Establishing the connections

1

2

3

6

4

5

Figure 6-1

Commissioning

Establishing the connections

Item No.: 099-008088-EWM01 15

Item Symbol Description 0

1 Connection socket, 7-pole (digital)

Connection to the digital remote control connection on power source or wire feed unit.

2 Connector plug, 7-pole, female

3 Connector plug, 7-pole, male

4 19-pole connection socket (analogue)

For connecting the control lead.

5 Connector plug, 19-pole, female

6 Connector plug, 19-pole, male

• Switch off the welding machine.

• Insert female connector plug into the remote control connection socket and lock by turning to the right.

• Insert male connector plug into the remote control connection socket on the welding machine and lock

by turning to the right.

The welding machine detects the remote control automatically after being switched on.

Maintenance and testing

General

16 Item No.: 099-008088-EWM01

7Maintenance and testing

7.1 General

When used in the specified environmental conditions and under normal operating conditions, this

machine is largely maintenance-free and requires a minimum of care. However, a number of points

should be observed to guarantee fault-free operation. These include regular cleaning and checking, as

described below, depending on the level of contamination in the environment and the usage time.

7.2 Cleaning

To do this, carefully disconnect the machine from all electrical contacts.

For machines with a separate power supply it is not sufficient simply to switch off the machine

(including the fuse).

In this case, unplug the mains plug and wait for at least two minutes.

Surfaces and glass can be cleaned using standard household cleaners; other elements can be cleaned

as follows:

• Only ever vacuum electrical or electronic components using a vacuum cleaner; never blast with

compressed air.

7.3 Maintenance

All electrical connections and all moveable parts must be tested regularly for correct functioning and to

identify any defects.

In the event of damage, the machine may only be repaired by a specialist engineer, or your contractual

partner.

7.4 Disposing of equipment

This machine does not belong in household waste, in accordance with the German Law on

Electrical Equipment Waste.

In Germany, waste equipment from private households can be disposed of free of charge at local

community collection points. Your administrative office will be pleased to inform you of the options.

EWM participates in an approved waste disposal and recycling system and is registered in the Used

Electrical Equipment Register (EAR) under number WEEE DE 57686922.

In addition, within Europe the machine can also be returned to your EWM sales partner.

7.4.1 Manufacturer's declaration to the end user

• In accordance with European guidelines (Directive 2002/96/EC from the European Parliament and the

Council of 27.01.03), it is no longer permissible to dispose of used electrical and electronic equipment

in unsorted household waste collections. It must be kept separate from other waste. The symbol on

the wheeled bins indicates the requirement to separate this waste.

Help to protect the environment and ensure that this equipment, when you no longer want to use it, is

disposed of in the relevant system of separated waste disposal.

• In Germany, (German Law on the Distribution, Return and Environmentally-Friendly Disposal of

Electrical and Electronic Equipment (ElektroG) of 16.03.05) you are required to take old equipment to

a waste collection point separated from household waste. The public waste disposal contractor (local

authorities) have set up collection points for this purpose where old equipment from private

households in your area can be collected for you free of charge.

It is also possible that the legally responsible waste disposal company will collect old equipment from

private households.

• Please obtain the relevant information from your local waste calendar or from your town council or

local authority on the options available in your area for returning or collecting old equipment.

Warranty

General Validity

Item No.: 099-008088-EWM01 17

8Warranty

8.1 General Validity

3-year warranty

on all new EWM machines*:

• Power sources

• Wire feeds

• Cooling units

• Trolleys

* If these are operated with genuine EWM accessories (such as intermediate tube package, remote

control, remote control extension cable, coolant, etc.).

1-year warranty on:

• Used EWM machines

• Automation and mechanisation components

• Remote control

• Inverters

• Intermediate tube packages

6-month warranty on:

• Spare parts supplied separately (such as circuit boards, ignition units)

Manufacturer/supplier warranty on:

• All additional parts used by EWM, but manufactured by other companies (e.g. motors, pumps, fans,

torches, etc.)

Non-reproducible software errors and parts subject to mechanical ageing are excluded from the warranty

(e.g. wire feed unit, wire feed rollers, replacement and spare wire feed parts, wheels, solenoid valves,

workpiece leads, electrode holders, connection tubes, replacement torches and spare torch parts, mains

and control leads, etc.).

These terms shall apply without affecting the customer’s legal rights to a warranty and subject to our

General Terms and Conditions of Business and our terms on the warranty declaration. Agreements to the

contrary must be confirmed by EWM in writing.

Our General Terms and Conditions of Business are available for access anytime online at www.ewm.de.

Warranty

Warranty Declaration

18 Item No.: 099-008088-EWM01

8.2 Warranty Declaration

Your 3-year warranty

Regardless of statutory warranty rights and based on our General Terms and Conditions, EWM

HIGHTEC WELDING GmbH provides a 3-year warranty for its welding products starting on the date of

purchase. Different warranty periods apply to accessories and spare parts; please see the “General

Validity” section for these periods. Parts subject to wear are naturally exempt from the warranty.

EWM guarantees the error-free condition of the products in terms of materials and processing. If the

product proves to be defective in terms of materials or processing within the warranty period, you are

entitled to free repair or to replacement with an appropriate product, at our discretion. On receipt by EWM

the returned product becomes the property of EWM.

Condition

The prerequisite for receiving the full 3-year warranty is simply to operate the products in accordance with

the EWM operating instructions observing the relevant legal recommendations and guidelines and having

annual maintenance work and testing conducted by an EWM sales partner (see “Maintenance and

testing” chapter). This is because only machines that are maintained regularly function correctly in the

long term.

Making a claim

When making a claim under the warranty, please contact your EWM authorised sales partner only.

Warranty exclusions

No warranty claims can be accepted if the EWM products in question are not operated using genuine

EWM accessories (such as intermediate tube package, remote control, remote control extension cable,

coolant, etc.). The warranty does not apply to products that are damaged due to accidents, misuse,

improper operation, incorrect installation, use of force, disregard of the specifications and operating

instructions, inadequate maintenance (see chapter “Maintenance and testing”), exterior influences, acts of

God or personal misfortunes. Furthermore, it is not valid in the case of improper changes, repairs or

modifications. In addition, a claim for warranty does not exist in the case of partially or completely

dismantled products and interventions by persons who are not authorised by EWM, as well as in the case

of normal wear.

Limitation

All claims regarding fulfilment or non-fulfilment on the part of EWM from this declaration in connection

with this product are limited as follows to the replacement of the actual damages. EWM’s liability

stemming from this declaration in connection with this product is fundamentally limited to the amount that

the purchaser originally paid for the original purchase. This limitation does not apply to personal injuries

or damage to property caused by negligent behaviour on the part of EWM. In no way will EWM be

responsible for lost profits, indirect or subsequent damage. EWM is not liable for damages based on the

claims of third parties.

Place of jurisdiction

If the person making the claim is a business person, the sole place of jurisdiction for all disputes resulting

directly or indirectly from the contractual relationship shall be the headquarters or the branch office of the

supplier, at the discretion of the supplier. The purchaser gains ownership of the products supplied as

replacements within the framework of the warranty adjustment at the time of the exchange.

Accessories, options

Connection and extension cables

Item No.: 099-008088-EWM01 19

9Accessories, options

9.1 Connection and extension cables

Type Designation Item no.

RA5 19POL 5M Remote control e.g. connection cable 092-001470-00005

RA10 19POL 10M Remote control e.g. connection cable 092-001470-00010

RA20 19POL 20M Remote control e.g. connection cable 092-001470-00020

FRV5-L 7POL Extension/connecting cable 092-000201-00003

FRV10-L 7POL Extension/connecting cable 092-000201-00000

FRV20-L 7POL Extension/connecting cable 092-000201-00001

Circuit diagrams

PHOENIX R10

20 Item No.: 099-008088-EWM01

10 Circuit diagrams

10.1 PHOENIX R10

Figure 10-1

This manual suits for next models

2

Table of contents

Popular Remote Control manuals by other brands

Sanyo

Sanyo POA-RCKIT04 operating instructions

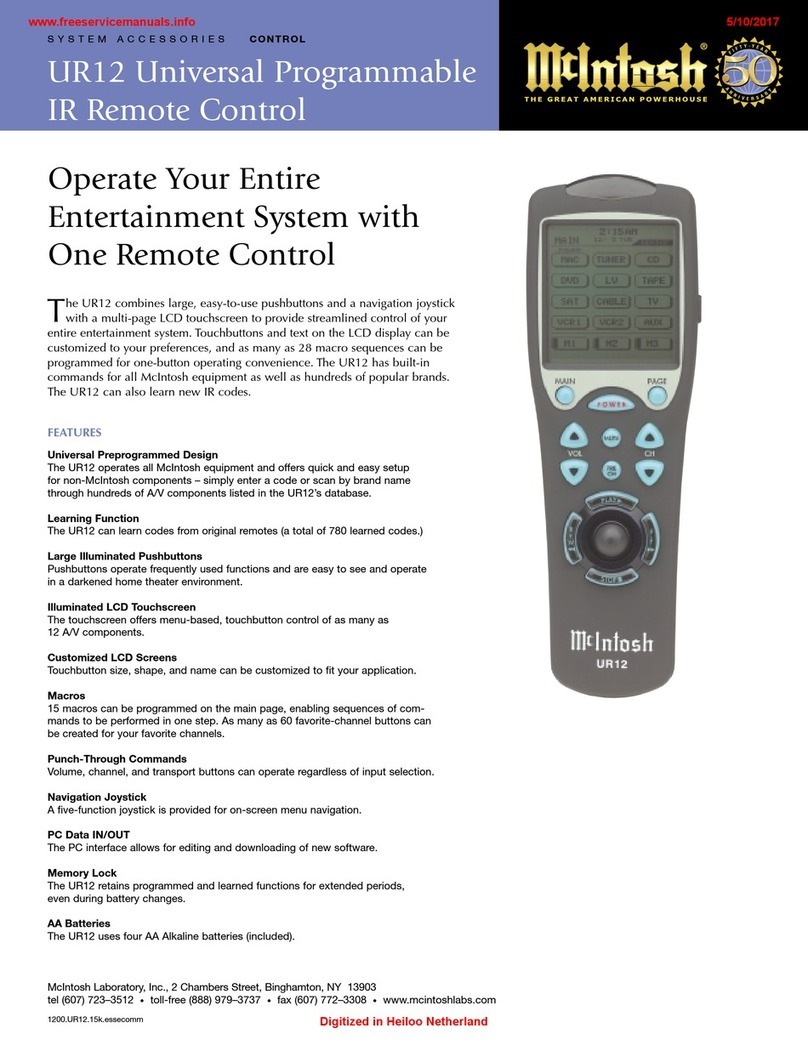

McIntosh

McIntosh UR12 owner's manual

Universal Remote Control

Universal Remote Control ORION MX-850 owner's manual

Zte

Zte ZXSDR R8860 Technical manual

Magnum Energy

Magnum Energy ME-ARC owner's manual

Sony

Sony CDX-T68PKG - Cdxt68x & Rmx69rf operating instructions