Contents

Notes on the use of these operating instructions

099-008818-EW501

30.05.2018

1 Contents

1Contents..................................................................................................................................................3

2For your safety.......................................................................................................................................4

2.1 Notes on the use of these operating instructions ..........................................................................4

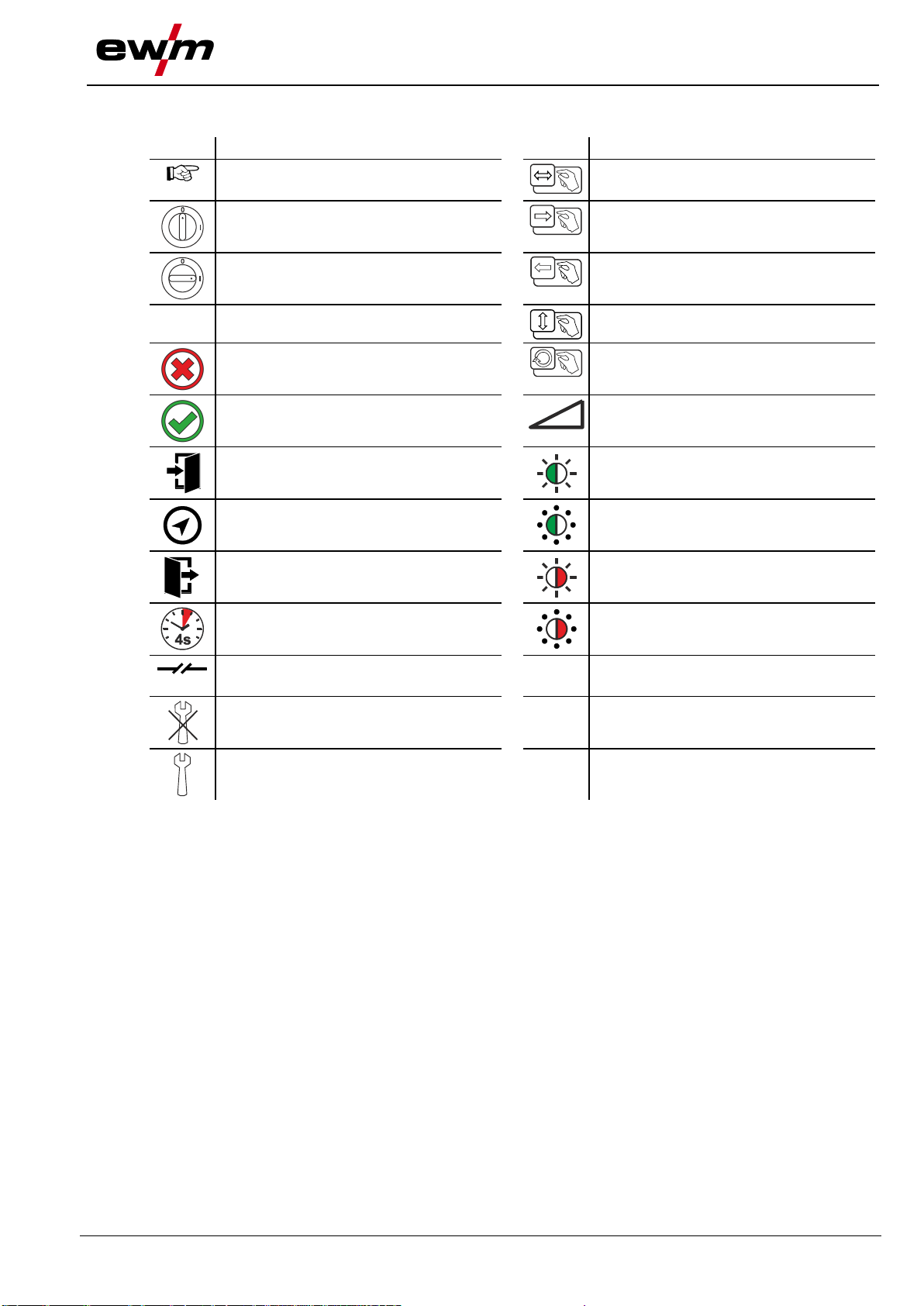

2.2 Explanation of icons.......................................................................................................................5

2.3 Part of the complete documentation..............................................................................................6

3Intended use...........................................................................................................................................7

3.1 Applications....................................................................................................................................7

3.1.1 For operation only with the following equipment............................................................7

3.2 Documents which also apply.........................................................................................................7

3.2.1 Warranty.........................................................................................................................7

3.2.2 Declaration of Conformity...............................................................................................7

3.2.3 Service documents (spare parts and circuit diagrams)..................................................7

4Machine description –quick overview ................................................................................................8

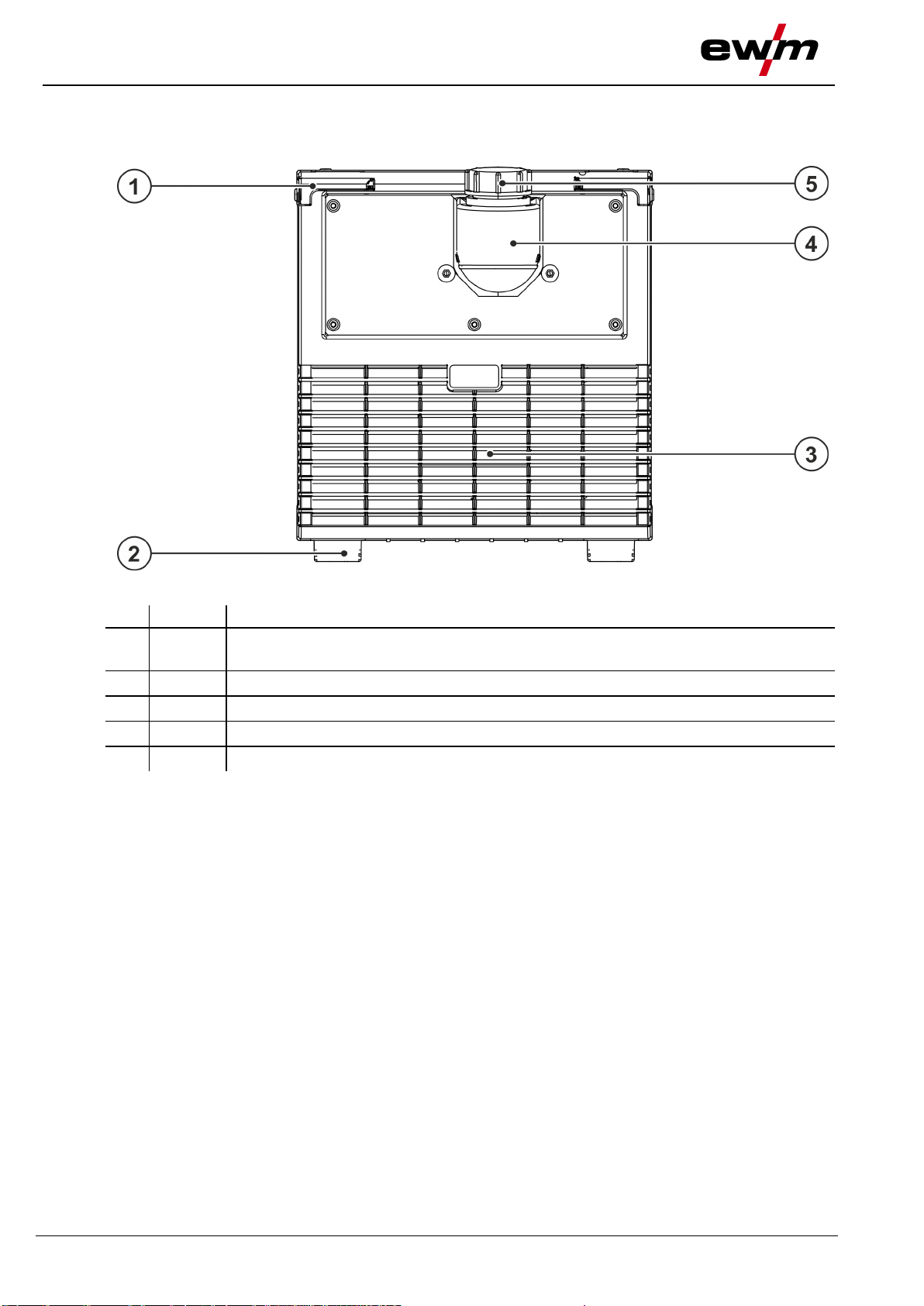

4.1 Front view ......................................................................................................................................8

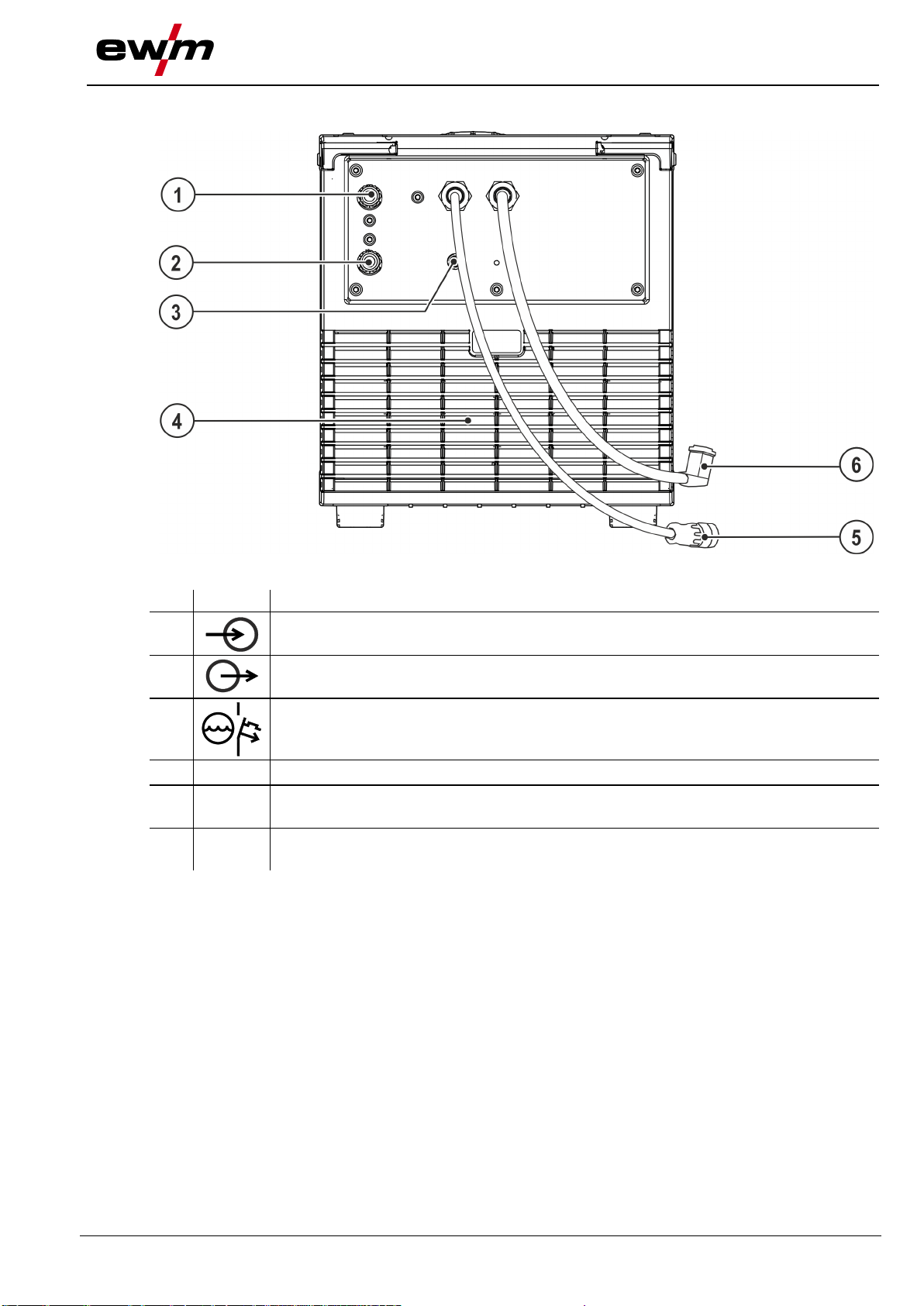

4.2 Rear view.......................................................................................................................................9

5Design and function.............................................................................................................................10

5.1 Assembly/disassembly ................................................................................................................10

5.1.1 Connecting the supply lines .........................................................................................10

5.1.2 Coolant line connections..............................................................................................11

5.2 Transport and installation ............................................................................................................11

5.2.1 Machine cooling............................................................................................................11

5.2.2 Ambient conditions.......................................................................................................11

5.2.2.1 In operation...................................................................................................12

5.2.2.2 Transport and storage...................................................................................12

5.2.3 Welding torch cooling system.......................................................................................12

5.2.3.1 Approved coolants overview.........................................................................12

5.2.3.2 Maximal hose package length ......................................................................13

5.3 Functional characteristics............................................................................................................13

5.3.1 Adding coolant..............................................................................................................14

6Maintenance, care and disposal.........................................................................................................15

6.1 General........................................................................................................................................15

6.2 Cleaning.......................................................................................................................................15

6.2.1 Dirt filter........................................................................................................................15

6.3 Maintenance work, intervals........................................................................................................16

6.3.1 Daily maintenance tasks ..............................................................................................16

6.3.2 Monthly maintenance tasks..........................................................................................16

6.3.3 Annual test (inspection and testing during operation)..................................................16

6.4 Disposing of equipment ...............................................................................................................17

7Rectifying faults ...................................................................................................................................18

7.1 Checklist for rectifying faults........................................................................................................18

7.2 Vent coolant circuit.......................................................................................................................19

7.3 Fixing the pump shaft (coolant circuit).........................................................................................19

8Technical data ......................................................................................................................................21

8.1 Cool 50 MPW50...........................................................................................................................21

9Accessories..........................................................................................................................................22

9.1 General accessories....................................................................................................................22

10 Appendix A ...........................................................................................................................................23

10.1 Searching for a dealer .................................................................................................................23