READ THIS PAGE FIRST

BEFORE STARTING INSTALLATION

Personal injury or property damage could result if you fail to

follow instructions in this manual.

It is recommended to annually inspect and service the

control valve. Frequent cleaning and/or replacement

of piston, seals, and/or spacers may be necessary

depending on how harsh the conditions are.

This system and its installation must comply with state

and local regulations. Check with your local public works

department for plumbing and sanitation codes. Local codes

should be followed in the event the codes con ict with any

content in this manual.

This water Softener must be operated on pressures

between 0.2MPa(30 psi) to 0.86MPa(125 psi). If the water

pressure is higher than 0.86MPa(125 psi), use a pressure

reducing valve in the water supply line to the softener.

This unit must be operated at temperatures between 4°C -

43°C(40°F and 110°F)

Do not use this water softener on hot water supplies.

Do not install this unit where it may be exposed to wet

weather, direct sunlight, or temperatures outside of the

range speci ed above.

This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way

and understand the hazards involved.

You must read and understand the contents of this manual

before installing or operating your water softener.

Softeners are exposed to high levels of iron,

manganese, sulfur, and sediments. Damage to pistons,

seals, and/or spacers within the control valve are not

covered in this warranty due to the harsh environment.

Do not use water that is microbiologically unsafe

without adequate disinfection before or after this

system.

This publication is based on information available when

approved for printing. Continuing design refinement

could cause changes that may not be included in this

publication.

Apply provided NSF certified lubricant to all o-rings

during installation. Do not use pinched or damaged

o-rings during installation.

The appliance is only to be used with the power supply

unit provided with the appliance.

The appliance must only be supplied at safety extra low

voltage corresponding to the marking on the appliance.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by

children without supervision.

INSTALL

NOTES &

SAFETY

MESSAGES

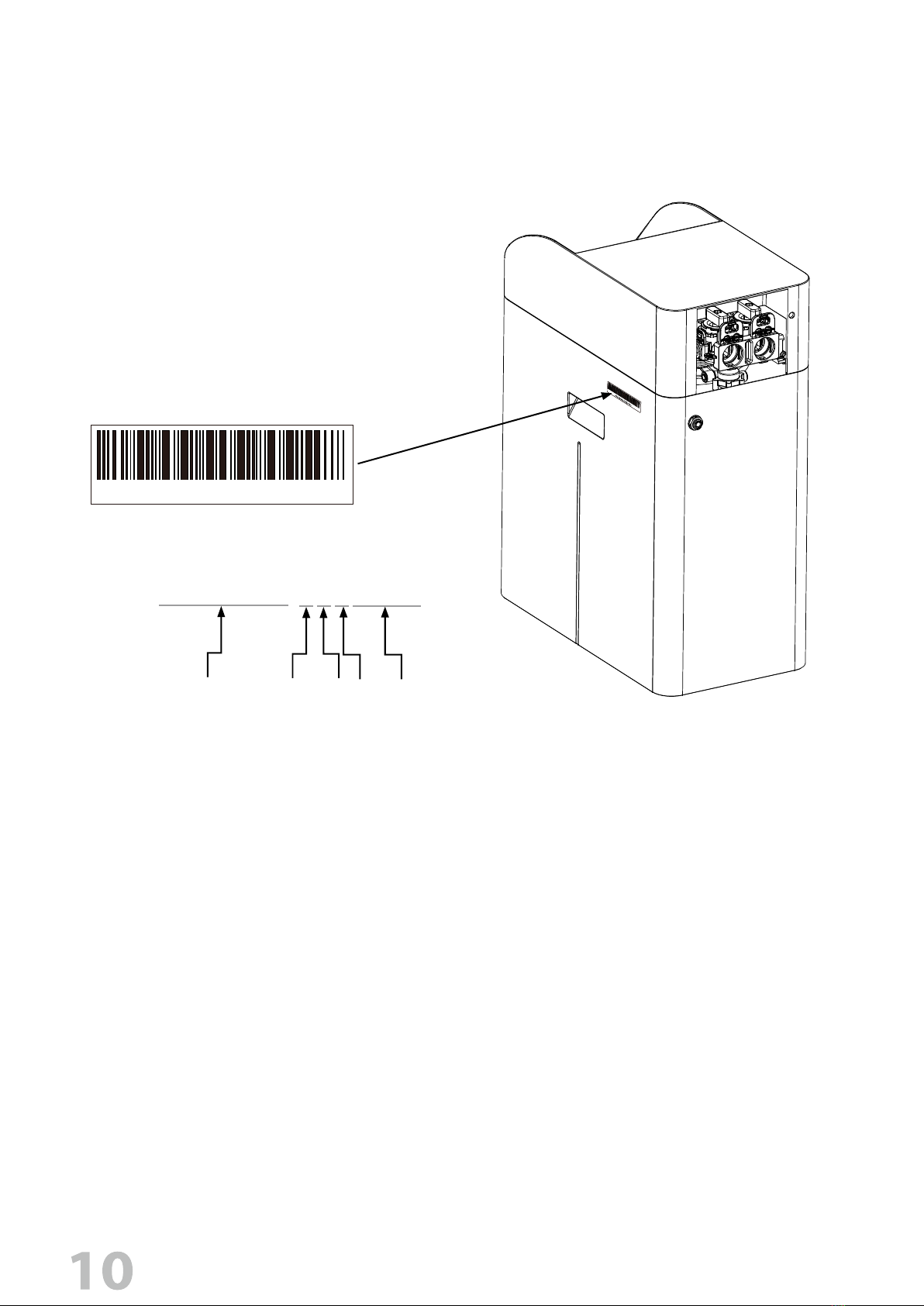

Watch for the

following messages

in this manual:

CAUTION

EXAMPLE:

Disassembly while under pressure

WARNING

Electrical Shock Hazard! Unplug the unit before removing

the cover or accessing any internal control parts.

EXAMPLE:

EXAMPLE:

Check and comply with

your state and local

codes. You must follow

these guidelines.

NOTE