Exar XRP7740EVB-HIC Operating and maintenance instructions

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

July 2013

Rev. 1.0.0

Exar Corporation www.exar.com

48720 Kato Road, Fremont CA 94538, USA Tel. +1 510 668-7000 – Fax. +1 510 668-7001

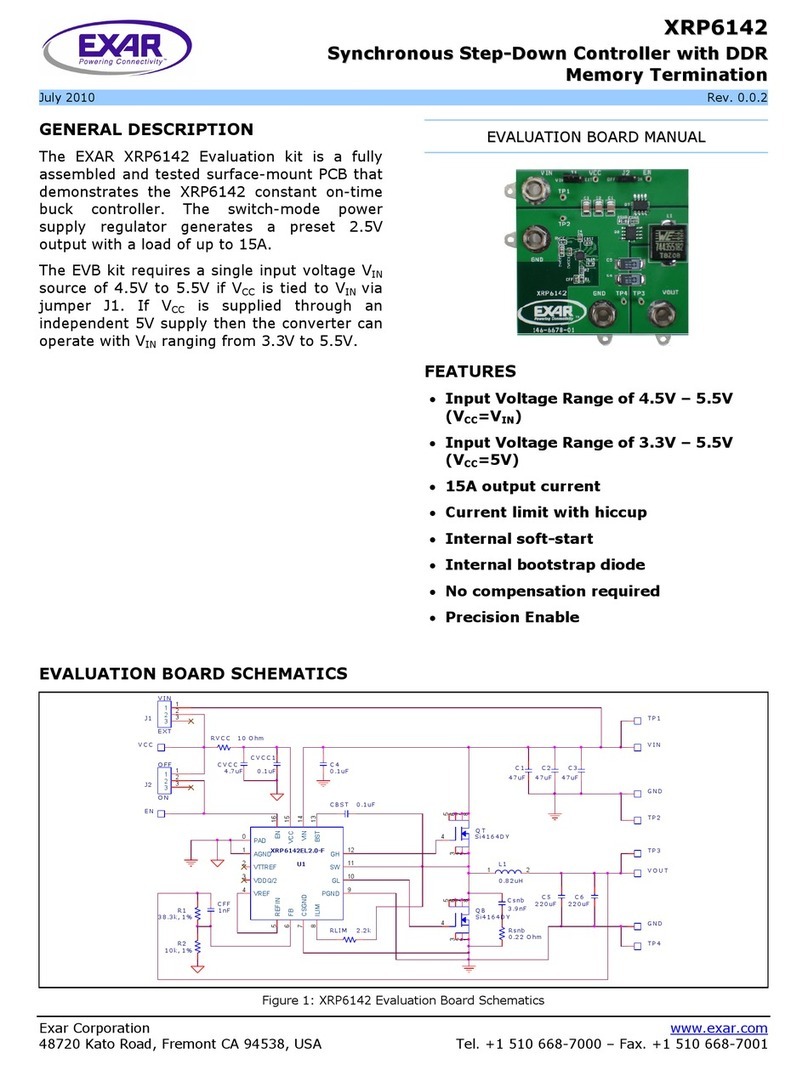

GENERAL DESCRIPTION

The XRP7740EVB-HIC Demo board is a

complete, four channel, power system

measuring 3.25” x 5” capable of delivering

over 60 watts. It provides 1.5V, 1.0V 1.8V and

1.0V at a maximum of 8A, 30A, 5A and 12A

on channels 1 through 4 respectively. All

power supply operations can be controlled

over an I2C interface. The supplies can be

adjusted in 50mV increments for voltages up

to 2.5V and in 100mV increments for voltages

from 2.6V to 5.1V. The order and ramp rates

for each supply can be programmed to

accommodate any sequencing requirement.

Faults, output voltages and currents can also

be monitored. Four GPIOs are available and

can be programmed to provide status of power

good signals, faults, and warnings or as enable

inputs. Unused GPIO pins can be programmed

as I/O expansion for a microcontroller. The

board is supported by PowerArchitectTM 4.21

and plugs directly onto the Exar Configuration

Module (XRP77XXEVB-XCM).

E

EV

VA

AL

LU

UA

AT

TI

IO

ON

N

B

BO

OA

AR

RD

D

M

MA

AN

NU

UA

AL

L

Figure 1: XRP7740EVB-HiC Demo Board

FEATURES

•XRP7740 Programmable Controller

•4 Channel Power System

•Wide Input Voltage Range: 4.5V-20V

•Over 60W Capable

•Form Factor: 3.25” x 5”

•Uses PowerArchitectTM 4.21

•I2C Interface

−Programming

−Monitoring

−Control

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2009 Exar Corporation 2/18 Rev. 1.0

EVALUATION BOARD

Figure 2: XRP7740EVB-HIC Schematic

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 3/18 Rev. 1.0.0

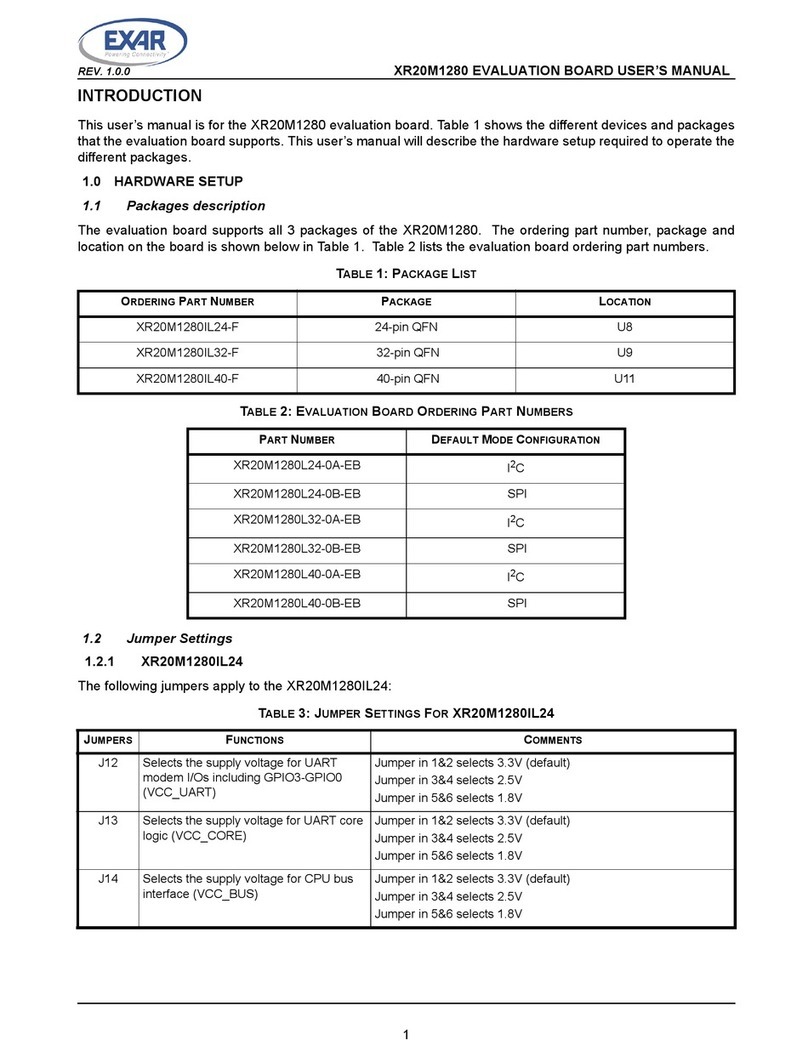

PIN ASSIGNMENT

30

29

28

27

26

25

24

23

21

22

19

18

16

17

15

14

12

13

11

10

1

2

3

4

5

6

7

8

9

32

33

35

34

36

37

39

38

40

2031

AVDD

DVDD

GPIO0

GPIO1

GPIO2

GPIO3

GPIO4_SDA

GPIO5_SCL

ENABLE

GL2

LX2

GH2

BST2

VCCD

BST4

GH4

LX4

GL4

PGND4

AGND

VOUT1

VOUT2

VOUT3

VOUT4

PGND3

GL3

LX3

GH3

BST3

LDOOUT

VIN1

VIN2

VCCA

PGND1

GL1

LX1

GH1

BST1

PGND2

DGND

Exposed Pad: AGND

XRP7740

TQFN

6mm X 6mm

Figure 3: XRP7740 Pin Assignment

Pin Description

Name Pin Number Description

VIN1 39

Power source for the internal linear regulators to generate VCCA, VDD and the Standby

LDO (LDOOUT). Place a decoupling capacitor close to the controller IC. Also used in

UVLO1 fault generation – if VIN1 falls below the user programmed limit, all channels are

shut down. The VIN1 pin needs to be tied to VIN2 on the board with a short trace.

VIN2 38 If the Vin2 pin voltage falls below the user programmed UVLO VIN2 level all channels are

shut down. The VIN2 pin needs to be tied to VIN1 on the board with a short trace.

VCCA 37 Output of the internal 5V LDO. This voltage is internally used to power analog blocks. This

pin should be bypassed with a minimum of 4.7uF to AGND

VCCD 26

Gate Drive input voltage. This is not an output voltage. This pin can be connected to

VCCA to provide power for the Gate Drive. VCCD should be connected to VCCA with the

shortest possible trace and decouple with a minimum 1µF capacitor. Alternatively, VCCD

could be connected to an external supply (not greater than 5V).

PGND1- PGND4

36,31,16,21

GL return connection. Ground connection for the low side gate driver. Connect at low side

FET source. Connecting to the ground plane at the chip will inject noise into the local

ground resulting in potential I2C communications problems and PWM jitter.

AVDD 1 Output of the internal 1.8V LDO. A decoupling capacitor should be placed between AVDD

and AGND close to the chip (with short traces).

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 4/18 Rev. 1.0.0

Name Pin Number Description

DVDD 2 Input for powering the internal digital logic. This pin should be connected to AVDD.

DGND 10 Digital Ground. This pin should be connected to the ground plane at the exposed pad with

a separate trace.

AGND 11 Analog Ground. This pin should be connected to the ground plane at the exposed pad with

a separate trace

GL1-GL4 34,30,17,22 Output pin of the low side gate driver. Connect directly to the respective gate of an

external N-channel MOSFET.

GH1-GH4 33,28,19,24 Output pin of the high side gate driver. Connect directly to the respective gate of an

external N-channel MOSFET.

LX1-LX4 34,29,23,18

Lower supply rail for the high-side gate driver (GHx). Connect this pin to the switching

node at the junction between the two external power MOSFETs and the inductor. These

pins are also used to measure voltage drop across bottom MOSFETs in order to provide

output current information to the control engine.

BST1-BST4 32,27,20,25

High side driver supply pin(s). Connect BST to an external boost diode and a capacitor as

shown in the front page diagram.

The high side driver is connected between the BST pin and LX pin.

GPIO0-GPIO3 3,4,5,6

These pins can be configured as inputs or outputs to implement custom flags, power good

signals and enable/disable controls. A GPIO pin can also be programmed as an input clock

synchronizing IC to external clock. Refer to the “GPIO Pins” Section and the “External

Clock Synchronization” Section for more information.

GPIO4_SDA,

GPIO5_SCL 7,8 I2C serial interface communication pins. These pins can be re-programmed to perform

GPIO functions in applications when I2C bus is not used.

VOUT1-VOUT4 12,13,14,15 Voltage sense.

Connect to the output of the corresponding power stage.

LDOOUT 40 Output of the Standby LDO. It can be configured as a 5V or 3.3V output. A compensation

capacitor should be used on this pin [see Application Note].

ENABLE 9

If ENABLE is pulled high, the chip powers up (logic reset, registers configuration loaded,

etc.). If pulled low for longer than 100us, the XRP7708/40 is placed into shutdown. See

applications section for proper sequencing of this pin.

AGND Exposed Pad Analog Ground. Connect to analog ground (as noted above for pin 11).

ORDERING INFORMATION

This board may be ordered from Exar as part XRP7740EVB-HIC. Refer www.exar.com for exact, up

to date ordering information.

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 5/18 Rev. 1.0.0

USING THE EVALUATION BOARD

INPUT VOLTAGE CONFIGURATION

The XRP7740EVB-HIC demo board has several

different input voltage options. The power

components have been optimized for a 12V

input rail. When running the board at an input

voltage other than 12V, use PowerArchitectTM

4.xx to evaluate the system performance.

Single Wide Range, Input Voltage Rail

The XRP7740EVB-HIC Board ships from the

factory configured for a single wide range

input. The normal input voltage range is from

7.0V to 20V. With the on board charge pump

enabled the input voltage range for the board

is 4.5V to 20V.

I2CINTERFACE

The XRP77XX family of controllers employs a

standard I2C interface. Pull-ups for the I2C

signals are included on the demo board and

may be selected by means of a configuration

jumper. If using the demo board with

something other than the XRP77xxEVB-XCM,

verify that the SDA and SCL lines are pulled

up, either by the external controller or with

the on board pull ups.

Channel Design and Limitations

Channel 1 is designed to provide an output

voltage from 0.9V to 5.0V. The default voltage

is 1.5V at 8A.

Channel 2 is designed to provide an output

voltage from 0.9V to 2.0V. The default voltage

is 1.0V at 30A. The limiting factors are the

output capacitors which has a 2.5V rating.

Channel 3 is designed to provide an output

voltage from 0.9V to 5.0V. The default

voltage is 1.8V at 5A.

Channel 4 is designed to provide an output

voltage from .9 to 5.0V. The default voltage is

1.0V at 12A.

ENABLE PIN

The ENABLE pin connects to an RC network

which delays turn on of the device. It is

connected to J3 pin 9 of the XCM connector

and J1 pin 15 with a 10K resistor and to

ground through a .1uF capacitor. These pins

can be used to turn on or turn off the device.

SPECIAL BOARD FEATURES

The board is comes from the factory wired for

7V to 20V operation. Input power can be

applied either through the Power Jack, J12, or

through the terminal block J13. The center

lead of the J12 connector is positive.

In addition to the four XRP7740 switching

power supplies. There are two other power

supplies on the board. One is an external 5V

LDO and the other is a charge pump tripler.

The external 5V LDO can be used to power the

gate drives for the switching FETs to decrease

the power dissipated by the internal chip 5V

LDO.

The charge pump runs off of the on board 5V

LDO and supplies a boosted voltage to the

XRP7740 Vin pin to allow for operation with

board input voltages down to 4.0V.

Configuring the Evaluation Board

The connections and test points on the board

are shown in Figure 5. Please observe the

correct voltage polarities for the inputs and

outputs.

As you go clockwise around the edge of the

board, the polarities are on the connectors are

negative first and then positive for all the

terminals. Also note that, again going

clockwise around the board, the channels are

Ch1, Ch2, Ch4, and then Ch3

. This was done

to match the XRP7740 pin out sequence to

optimize layout of the board.

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 6/18 Rev. 1.0.0

EVALUATION BOARD CONNECTIONS:

Channel 1

Channel 2

Channel 3

Channel 4

+

-

+

+

+

-

-

-

+

-

J3-XCM

LX1

LX2

LX3

LX4

Vin+

Vin-

Vin Vin

J1-Test

J2-Test

Figure 4: Board Connections

`

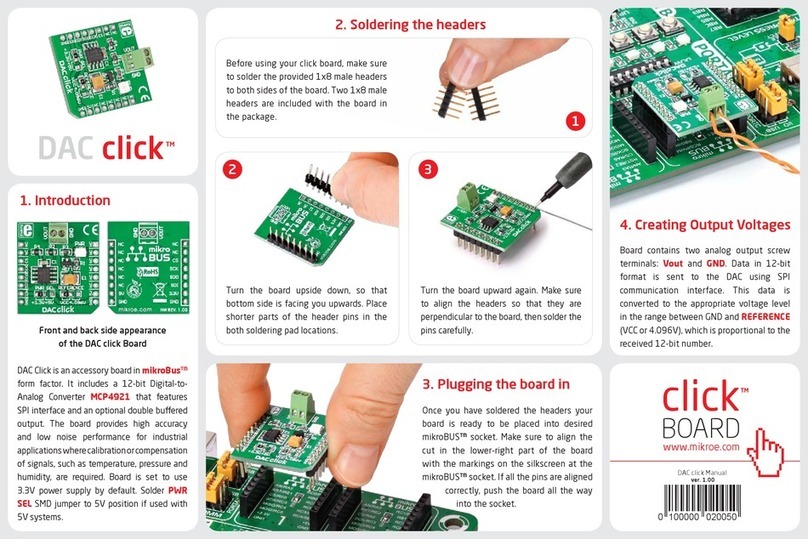

Board Jumper Configurations

There are five, three pin configuration

connectors on the board. The configuration

options are selected by adding a jumper to

either pins 1 and 2 or pins 2 and 3.

Figure 5 shows the factory jumper positions

and the above table describes the function of

each of the jumpers. The items that are

shown in bold are the default factory settings.

Figure 5: Factory Jumpers Setting

Jumper Pins to Select

Conn.

Function

1 - 2

2 - 3

J4

Power Source for Drivers

External 5V LDO

Internal 5V LDO

J5

I2C Pull Up Resistors

On Board Pull Ups

No Pull Ups

J6

External 5V LDO Supply

Enable Ext. 5V LDO

Disable Ext. 5V LDO

J7

7740 Pin 15 Connection

Vo4 Output

Do No Use

J8

Charge Pump Enable

Enable Charge Pump

Disable Charge Pump

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 7/18 Rev. 1.0.0

Operating the Evaluation Board

Make sure that all the jumpers on the board

are properly configured. For the first start up it

is recommended that the default jumper

settings be used.

Bring up Procedure

Connect the flat cable from J3 on the board to

XCM board. Pin 1 on J3 is next to J13 and is

also marked on the board. Since the board is

configured to pull up the I2C lines make sure

that all jumpers on the XCM board are

removed.

Connect a USB cable from the XCM board to

the host computer that will be running

PowerArchitectTM

On the USM memory stick that came with the

board is the “XRP7740 HiC, Default Config File,

rev 130723.cfg” file. This is the design file that

PowerArchitectTM uses to program and modify

the XRP7740 device settings to configure the

board to the particular application. Place this

file in a directory that you can browse to later

when you run PowerArchitectTM

Once the above is completed run the

PowerArchitectTM 4.xx software on the host

computer. A configuration start-up window

opens up as shown in Figure 6. Select the

“Load Existing Configuration” option at the

bottom of the window and browse to the

directory that contains the “7740 HiC, Default

Config File, rev 130723.cfg” file and select it.

This will bring you to the Overview tab of the

main window.

If the XCM board is recognized, there will be

an “XCM” tab. If not, “Ctrl-b” should initiate a

board search and find it. Also make sure that

power is applied to the board and the XCM as

outlined in the XRP77XXEVB-XCM manual.

Figure 6: PowerArchitectTM Start-Up Window

Apply Power to the board. Connect the input

supply by means of the power jack J12 or

between the VIN pin and the GND pin of J13.

Set the input voltage to 12V and turn on the

Power supply. The “DEMO” page should now

become live indicating communication with the

XRP7740. Click “Program Chip” and a window

should pop up indicating “Success”.

Refer to the Exar PowerArchitectTM Quick Start

Guide and release notes for information on

how to run the software.

Note: PowerArchitectTM 4.21 is the current

version as of the publication of this evaluation

board manual. This version only allows output

currents up to 20Amps to be entered. The

only effect on the design is that the current

limit register is set to a value that may limit

the output current to below 30Amps.

A short term work around is to use the

“Peek/Poke” function and write a new value

into the current limit register.

To raise the Io Limit to allow for 30A

operation, poke the value 0x52h into register

0x45. This is being addressed in the next

revision.

Now click on the box at the middle right

“Enable All”.

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 8/18 Rev. 1.0.0

Evaluation Board Schematics

Figure 7: Board Schematic

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 9/18 Rev. 1.0.0

BILL OF MATERIAL

Ref Qty Part Number Manufacturer Size Description

U1 1 XRP7740ILB-F EXAR CORP. 40-

PIN,6X6mm,TQFN

Quad Channel Digital PWM Step

Down Controller

U2 1 SPX2951ACS-L-5-0 EXAR CORP. 8-SOIC 150mA Low Dropout Voltage

Regulator

U3 1 SP6661EN-L EXAR CORP. NSOIC8 High Frequency 200mA Charge

Pump Invert.

U4 1 SPX431LM1-L EXAR CORP. SOT89-3 Precision Adjustable Shunt

Regulator

Q1,Q6 2 FDML7610S FAIRCHILD MLP 3X4.5 Dual N-Ch. PowerTrench MOSFET

Q2 1 FDMS7692 FAIRCHILD Power56 N-Ch. powerTrench MOSFET

Q3,Q4 2 FDMC7660S FAIRCHILD Power 33 N-Ch. PowerTrench SyncFET

Q5,Q5 11 FDMC8200 FAIRCHILD Power 33 Dual N-Ch. PowerTrench MOSFET

Q7 1 MMBT3906 FAIRCHILD SOT-23 PNP General Purpose Amplifier

D1 1 BAT54C FAIRCHILD SOT-23 Schottky Diode

D2,D4,D6,D7,D8 5 MBRS130L FAIRCHILD SMB/DO-214AA Schottky Rectifier

D3 1 BAT54A FAIRCHILD SOT-23 Schottky Diode

D5 1 MMSZ5221B Diode Inc. SOD-123 500mW SMT Zener Diode

D9 1 BAT54S FAIRCHILD SOT-23 Schottky Diode

L1 1 744323100 Wurth Elektronik 10.6x10.6mm WE-HCI SMD Flat Wire High

Current Inductor

L2 1 744301025 Wurth Elektronik 11.3x11.0mm POWER-CHOKE WE-HCM 1190

L3 1 74437349012 Wurth Elektronik 7.3x6.6mm WE-LHMI SMD Power Inductor

L4 1 744373680045 Wurth Elektronik 11x10mm WE-LHMI SMD Power Inductor

C1,C38 2 GRM32ER71E226KE15L Murata Corp. 1210 CAP CER 22uF, 25V, 10%, X7R

C2,C3,C4,C11,C12,C15,C16,C3

9,C42,C44,C45,C55,C57,C58,C

67,C68,C69

17 GRM32ER7YA106KA12L Murata Corp. 1210 CAP CER 10uF, 35V, 10%, X7R

C5,C23,C46,C60 4 GRM188R71H472KA01D Murata Corp. 0603 CAP CER 4700pF, 50V, 10%, X7R

C6,C7,C8,C9,C29,C30,C31,C32,

C49,C61,C62,C63,C64 13 GRM31CR60J107ME39L Murata Corp. 1206 CAP CER 100uF, 6.3V, 20%, X5R

C10,C17 2 GRM21BR71C475KA73L Murata Corp. 0'0805 CAP CER 4.7uF, 16V, 10%, X7R

C13 1 GRM31CR71E106KA12L Murata Corp. 1206 CAP CER 10uF, 25V, 10%, X7R

C14,C22,C26,C27,C35,C41 6 GRM188R71C105KA12D Murata Corp. 0603 CAP CER 1uF, 16V, 10%, X7R

C18,C21,C24,C25C18,C21,C24,

C25 44 2R5TPF680M6L2R5TPF680M6L Panasonic D3LD3L CAP POSCAP 680uF, 2.5V,

6mOhm

C19 1 GRM188R71A225KE15D Murata Corp. 0603 CAP CER 2.2uF, 10V, 10%, X7R

C20,C28,C36,C37,C43,C54,C70

,C71 8 GRM21BR71H104KA01L Murata Corp. 0805 CAP CER 0.1uF, 50V, 105, X7R

C33,C34,C52,C53,C66 5 GRM21BR61C106KE15L Murata Corp. 0805 CAP CER 10uF, 16V, 10%, X5R

C40 1 EEE-FK1E471P Panasonic 10x10.5mm CAP ALUM 470uF, 25V, 20%, SMD

C47,C48 2 GRM31CR60J476ME19L Murata Corp. 1206 CAP CER 47uF, 6.3V, 20%, X5R

C50,C51,C56,C59,C65 5 GRM188R71H102KA01D Murata Corp. 0603 CAP CER 1000pF, 50V, 10%, X7R

R1,R4,R19,R27 4 CRCW0'080510R0FKEA Vishay/Dale 0805 RES 10.0 OHM, 1/8W,1%, SMD

R2,R7,R21,R28 4 CRCW0'08051R00FKEA Vishay/Dale 0805 RES 1.00 OHM, 1/8W, 1%, SMD

R3,R8 2 CRCW06031R00FKEA Vishay/Dale 0603 RES 1.00 OHM, 1/10W, 1%, SMD

R5,R6,R9,R10,R14,R16 6 CRCW06030000Z0EA Vishay/Dale 0603 RES 0.0 OHM, 1/10W,JUMP SMD

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 10/18 Rev. 1.0.0

R11,R12,R35 3 CRCW060334K75FKEA Vishay/Dale 0603 RES 4.75K OHM, 1/10W, 1%,

SMD

R13,R22,R32 3 CRCW060310K0FKEA Vishay/Dale 0603 RES 10.0K OHM, 1/10W, 1%,

SMD

R24,R25,R36,R37 4 CRCW06031K00FKEA Vishay/Dale 0603 RES 1.00K OHM, 1/10W, 1%,

SMD

R15,R17,R18,R20,R29,R15,R17,

R18,R20,R29

55 CRCW0603100RFKEA Vishay/Dale 0603 RES 100 OHM, 1/10W, 1%, SMD

R23 1 CRCW06033K74FKEA Vishay/Dale 0603 RES 3.74K OHM, 1/10W, 1%, SMD

R26 1 CRCW06031K24FKEA Vishay/Dale 0603 RES 1.24K OHM, 1/10W, 1%,

SMD

R30 1 CRCW0603301RFKEA Vishay/Dale 0603 RES 301 OHM, 1/10W, 1%, SMD

R31 1 CRCW06039K53FKEA Vishay/Dale 0603 RES 9.53K OHM, 1/10W, 1%,

SMD

R33 1 CRCW060347K5FKEA Vishay/Dale 0603 RES 47.5K OHM, 1/10W, 1%,

SMD

R34 1 CRCW06032K49FKEA Vishay/Dale 0603 RES 2.49K OHM, 1/10W, 1%,

SMD

J12 1 RAPC722X Switchcraft Inc. 2.1mm D, 5.5mm

OD

CONN POWERJACK MINI R/A T/H

J1,J2 2 61304011121 Wurth Elektronik 2.54mm Pin Header WR-PHD, 15Pins

J3 1 61301021021 Wurth Elektronik 2.54mm THT Angled Dual Pin Header,

10Pins

J4,J5,J6,J7,J8 5 61304011121 Wurth Elektronik 2.54mm Pin Header WR-PHD, 3Pins

P1,P2,P3,P4,P5 5 609 002 115 121 Wurth Elektronik 2.54mm Pin Jumper w/Test Point

J13 1 691 218 410 002 Wurth Elektronik 12.0X7.62mm CONN. TERM. BLOCK 2POS

J9,J14,J15 3 691 216 510 002 Wurth Elektronik 9.5x5.08mm CONN. TERM. BLOCK 2POS

J10,J11 2 1202 KEYSTONE 10/32, 0.62" Terminal Screw 10/32, .062"

Brass

TP1,TP3,TP5,TP7,TP9,TP10 6 5010 KEYSTONE 0.38X0.81mm Test Point PC Multi Purpose, RED

TP11,TP12,TP13,TP14,TP15 5 5011 KEYSTONE 0.38X0.81mm Test Point PC Multi Purpose, BLK

TP2,TP4 TP6,TP8 4 5014 KEYSTONE 0.38X0.81mm Test Point PC Multi Purpose, YEL

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 11/18 Rev. 1.0.0

EVALUATION BOARD LAYOUT

Figure 8: Layout – Components

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 12/18 Rev. 1.0.0

Figure 9: Layer 1, Top

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 13/18 Rev. 1.0.0

Figure 10: Layer 2, Power Ground

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 14/18 Rev. 1.0.0

Figure 11: Layer 3, Internal

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 15/18 Rev. 1.0.0

Figure 12: Layer 4, Internal

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 16/18 Rev. 1.0.0

Figure 13: Layer 5, Analog Ground

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 17/18 Rev. 1.0.0

Figure 14: Layer 6, Bottom

X

XR

RP

P7

77

74

40

0E

EV

VB

B-

-H

HI

I

C

C

F

Fo

ou

ur

r

C

Ch

ha

an

nn

ne

el

l

D

Di

ig

gi

it

ta

al

l

P

PW

WM

M

D

De

em

mo

o

B

Bo

oa

ar

rd

d

s

s

© 2013 Exar Corporation 18/18 Rev. 1.0.0

DOCUMENT REVISION HISTORY

Revision Date Description

1.0.0 07/31/13 Initial release of document

BOARD REVISION HISTORY

Board Revision

Date Description

REV1.0 07/31/2013 Initial release of evaluation board 7740EVB-HIC-01

FOR FURTHER ASSISTANCE

Email: powertechs[email protected]om

customersupport@exar.com

Exar Technical Documentation: http://www.exar.com/TechDoc/default.aspx?

EXAR CORPORATION

HEADQUARTERS AND SALES OFFICES

48720 Kato Road

Fremont, CA 94538 – USA

Tel.: +1 (510) 668-7000

Fax: +1 (510) 668-7030

www.exar.com

NOTICE

EXAR Corporation reserves the right to make changes to the products contained in this publication in order to improve

design, performance or reliability. EXAR Corporation assumes no responsibility for the use of any circuits described herein,

conveys no license under any patent or other right, and makes no representation that the circuits are free of patent

infringement. Charts and schedules contained here in are only for illustration purposes and may vary depending upon a

user’s specific application. While the information in this publication has been carefully checked; no responsibility, however,

is assumed for inaccuracies.

EXAR Corporation does not recommend the use of any of its products in life support applications where the failure or

malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly affect its

safety or effectiveness. Products are not authorized for use in such applications unless EXAR Corporation receives, in

writing, assurances to its satisfaction that: (a) the risk of injury or damage has been minimized; (b) the user assumes all

such risks; (c) potential liability of EXAR Corporation is adequately protected under the circumstances.

Reproduction, in part or whole, without the prior written consent of EXAR Corporation is prohibited.

Table of contents

Other Exar Motherboard manuals

Exar

Exar Power XR Series User manual

Exar

Exar SP338 User manual

Exar

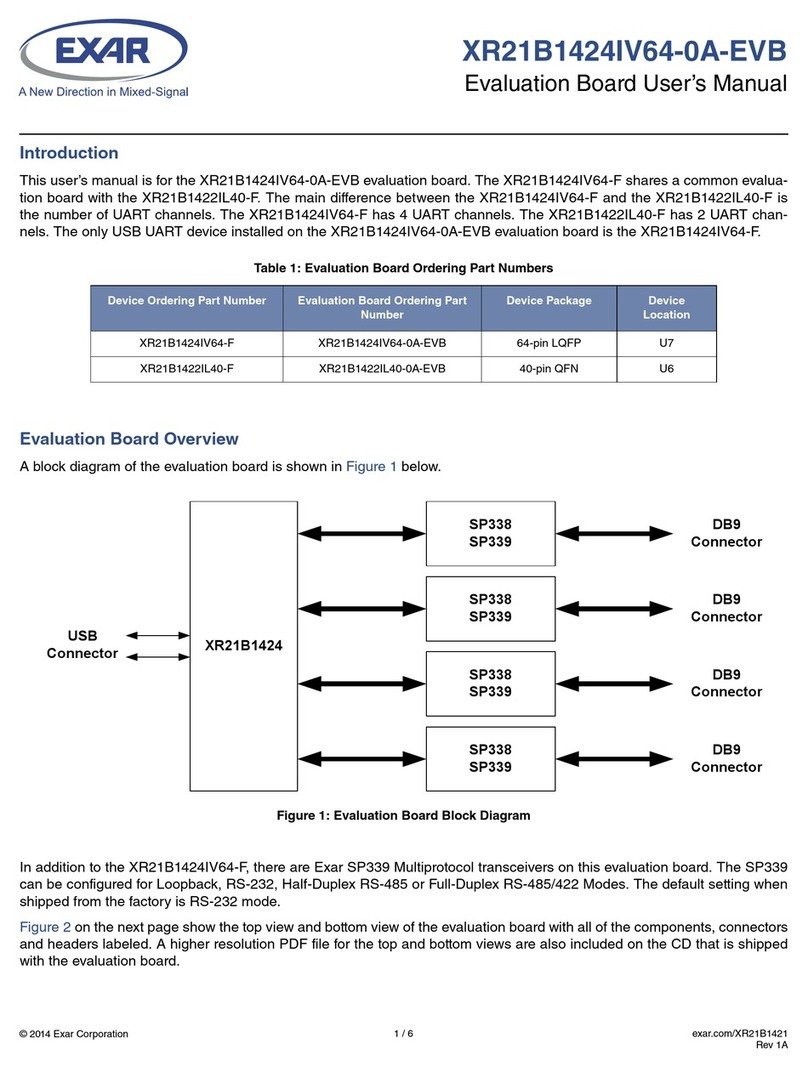

Exar XR21B1424IV64-0A-EVB User manual

Exar

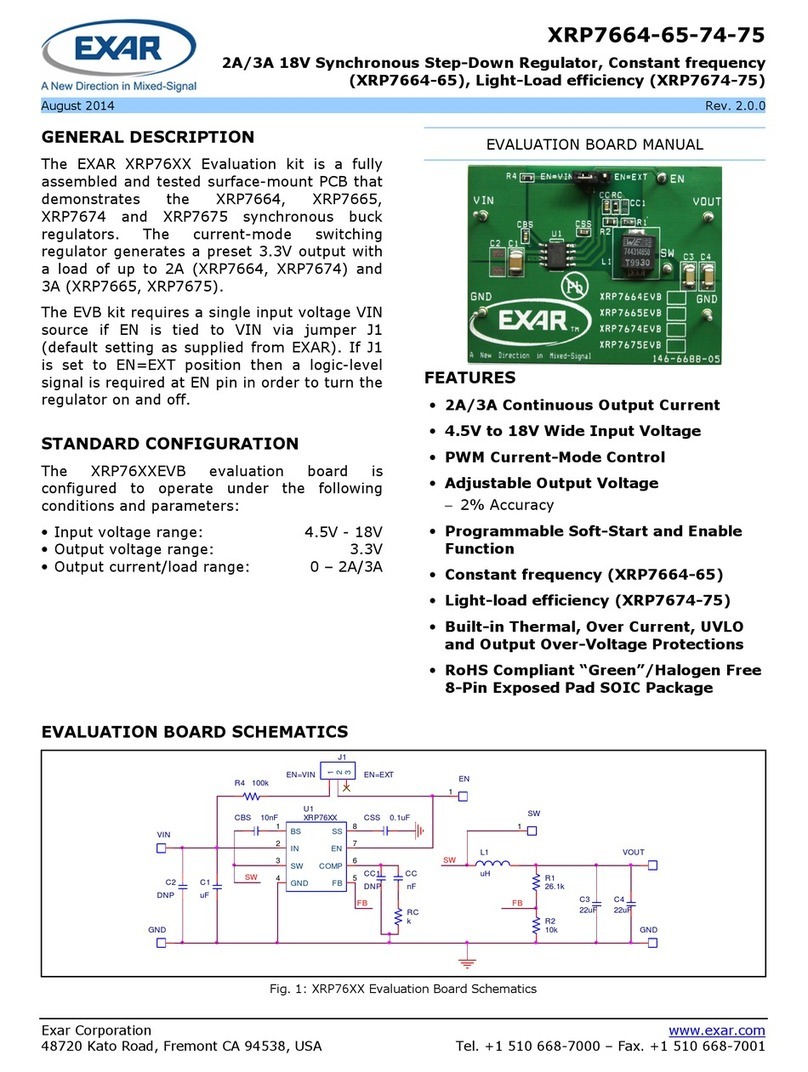

Exar XRP7664-65-74-75 User manual

Exar

Exar XRA1403IL24-F User manual

Exar

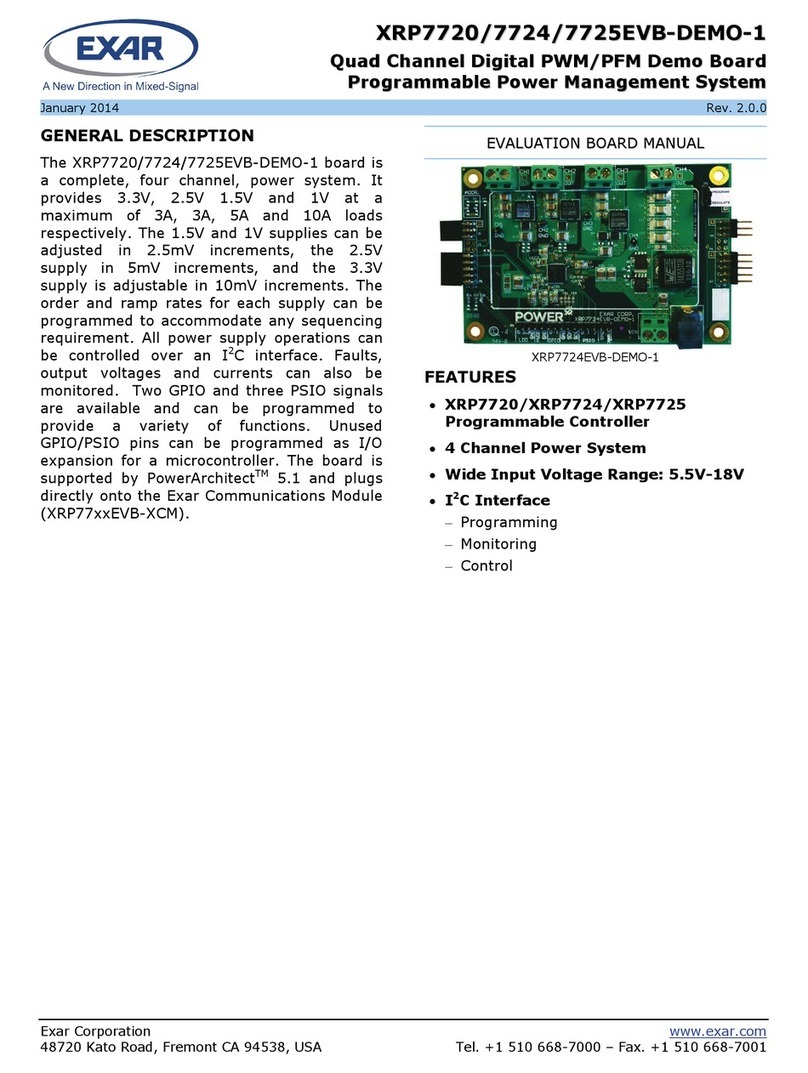

Exar XRP7720EVB-DEMO-1 User manual

Exar

Exar SP336E User manual

Exar

Exar XR21V1414 User manual

Exar

Exar XR22414-EVB User manual

Exar

Exar XRP6141 User manual

Popular Motherboard manuals by other brands

Taiwan Commate Computer Inc.

Taiwan Commate Computer Inc. P4BEA user manual

Asus

Asus M3A78 - Motherboard - ATX owner's manual

Biostar

Biostar P4M890-M7 TE Setup manual

Roland

Roland GT-001 quick start guide

Silicon Laboratories

Silicon Laboratories EZR32HG user guide

Wurth Elektronik

Wurth Elektronik Proteus-E user manual