Excelsys Xgen Series User manual

Open Collector signal indicators.

Reverse Fan (Option 02)

Reverse direction of air flow through the Xgen.

Not available for 1200W models.

XCE/XVE model with Reverse Fan derate from

1250W at 210VAC to 980W at 100VAC

powerPacs

powerMods

powerMod maximum power ratings must not be exceeded

Permitted Power Ratings for Reliable Operation.

When specifying an Xgen in an application, it is necessary to ensure

that the powerPacs and powerMods are operating within their power

ratings as listed above, taking care to factor in the appropriate der-

ating if the ambient temperature exceeds 40°C (except for Xhite

models).

Unused Slots

UNUSED SLOTS MUST ALWAYS BE FITTED WITH APPROPRI-

ATE SLOT COVERS XB1,XB2 or XB3. Units must NOT be operat-

ed with empty slots.

Family Model Watts Lx H x W (mm)

Xlite XLA 200W 260 x 40.4 x 89

XLB 400W 260 x 40.4 x 89

XLC 600W* 260 x 40.4 x 89

Xkite XKA 200W 260 x 40.4 x 89

XKB 400W** 260 x 40.4 x 89

Xcite XCA 400W 260 x 40.4 x 127

XCB 700W 260 x 40.4 x 127

XCC 1000W*** 260 x 40.4 x 127

XCD 1200W**** 260 x 40.4 x 127

XCE 1340W***** 268 x 40.4 x 127

Xmite XMA 200W 260 x 40.4 x 89

XMB 400W 260 x 40.4 x 89

XMC 600W* 260 x 40.4 x 89

Xrite XRA 200W 260 x 40.4 x 89

XRB 400W** 260 x 40.4 x 89

Xvite XVA400W 260 x 40.4 x 127

XVB 700W 260 x 40.4 x 127

XVC 1000W*** 260 x 40.4 x 127

XVD 1200W**** 260 x 40.4 x 127

XVE 1340W***** 268 x 40.4 x 127

Xhite XHA 400W 260 x 40.4 x 127

XHB 600W 260 x 40.4 x 127

Xqite XQA 400W 260 x 40.4 x 127

XQB 900W****** 260 x 40.4 x 127

Xzite XZA 400W 260 x 40.4 x 127

XZB 900W****** 260 x 40.4 x 127

*Derate linearly from 600W at 200Vac to 410W at 100Vac nom.

**Derate linearly from 400W at 134Vac to 315W at 100Vac nom.

***Derate linearly from 1000W at 134Vac to 900W at 100Vac nom.

****Derate linearly from 1200W at 134Vac to 900W at 100Vac nom.

*****Derate linearly from 1340W at 210Vac to 1070W at 100Vac nom.

******Derate linearly from 900W at 134Vac to 600W at 100Vac nom

powerPacs

Xlite, Xcite Standard 200W-1340W

Xmite, Xvite Medical 200W-1340W

Xhite High Temperature 400W-600W

Xqite, Xkite Lo-Noise Standard 200W-900W

Xrite, Xzite Lo-Noise Medical 200W-900W

powerMods

XG1, XG2, XG3, XG4, XG5, XG7, XG8 1.5V to 58V

gen

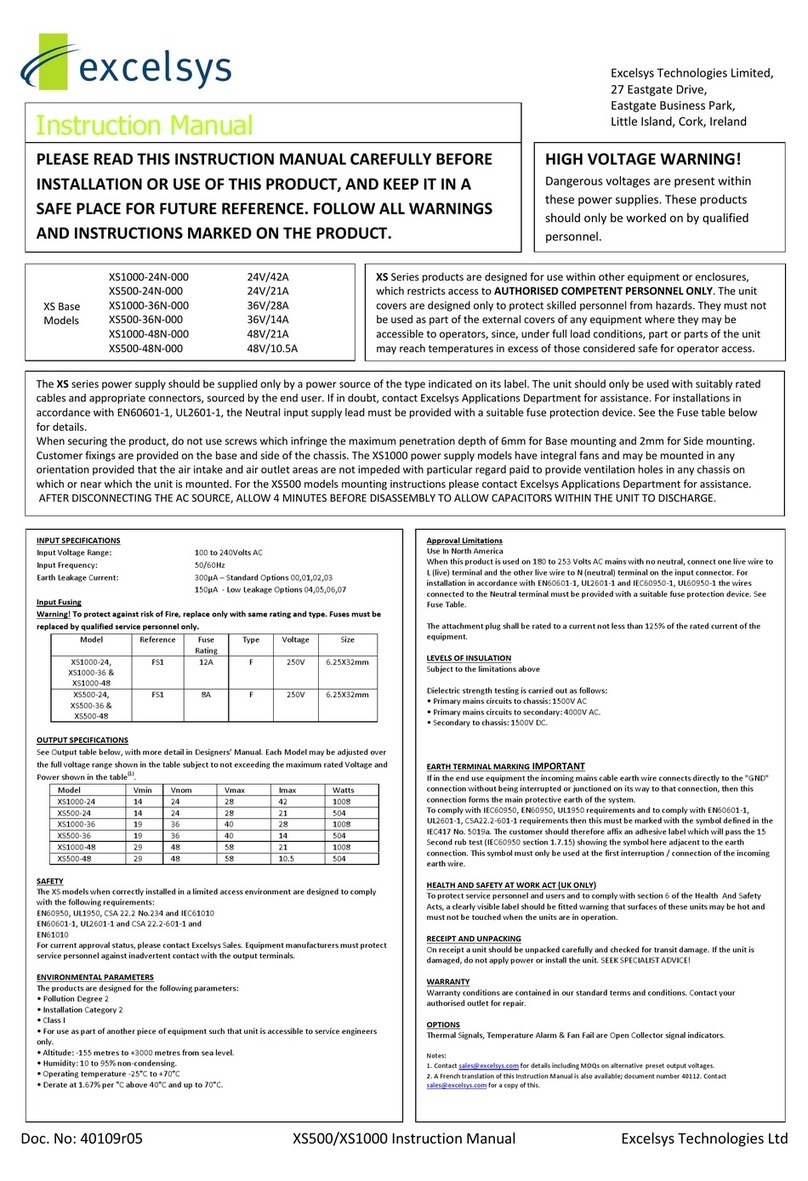

Instruction Manual

PLEASE READ THIS INSTRUCTION MANUAL CAREFULLYBEFORE

INSTALLATION OR USE OF THIS PRODUCT, AND KEEP IT IN ASAFE PLACE

FOR FUTURE REFERENCE. FOLLOW ALL WARNINGS AND INSTRUCTIONS

MARKED ON THE PRODUCT.

HIGH VOLTAGE WARNING!

Dangerous voltages are present within these

power supplies. These products should only be

worked on by qualified personnel.

Xgen Series products are comprised of:

powerPac Chassis Converters intended for use in Xgen series ONLY.

These must NOT be used for any other purpose.

and

powerMod Plug-In Modules intended for use in Xgen series ONLY. These

must NOT be used for any other purpose.

Xgen Series products are designed for use within other equipment or

enclosures, which restrict access to authorised competent personnel

only. The unit covers are designed only to protect skilled personnel from

hazards. They must not be used as part of the external covers of any

equipment where they may be accessible to operators, since, under full

load conditions, part or parts of the unit may reach temperatures in excess

of those considered safe for operator access.

INPUT SPECIFICATIONS (powerPac only)

Input Voltage Range 100 to 240Volts AC

Input Frequency 50/60 Hz

Earth Leakage Current 1.5mA Xlite, Xcite,Xhite,Xqite,Xkite

300µA Xmite,Xvite,Xrite,Xzite

Input Fusing

WARNING ! To protect against risk of fire, replace only with

fuses of same rating and type. Fuses must be replaced by

qualified service personnel only.

OUTPUT SPECIFICATIONS (powerMod only)

See powerMod table below, with more detail in Designers’ Manual.

Each module may be adjusted over the full voltage range shown in

the table subject to not exceeding the maximum rated Voltage

and Power shown on the table.

SAFETY

The Xgen, when correctly installed in a limited access environment

are designed to comply with the following requirements

Xlite, Xcite, Xhite, Xqite, Xkite : IEC60950, EN60950, UL1950, CSA

22.2 No. 234 and IEC61010

Xmite, Xvite, Xzite, Xrite: EN60601-1, UL2601-1 and CSA 22.2-601-

1 and EN61010

For current approval status, please contact Excelsys Sales.

Equipment manufacturers must protect service personnel against

inadvertent contact with the module output terminals.

Environmental Parameters

The Xgen Series is designed for the following parameters:

• Pollution Degree 2

• Installation Category 2

• Class I

• For use as part of another piece of equipment such that

unit is accessible to service engineers only.

• Altitude: -155 metres to +2000 metres from sea level.

• Humidity: 10 to 95% non-condensing.

• Operating temperature 0°C to 70°C

• Derate at 1.67% per °C above 40°C and up to 70°C .

• Derating applies to both powerPacs and powerMods

Approval Limitations

Use In North America

When this product is used on 180 to 253 Volts AC mains with no

neutral, connect one live wire to L (live) terminal and the other live

wire to N (neutral) terminal on the input connector. For installation

in accordance with EN60601-1, UL2601-1 and IEC60950-1,

UL60950-1 the wires connected to the Neutral terminal must be pro-

vided with a suitable fuse protection device. See Fuse Table.

The attachment plug shall be rated to a current not less than 125%

of the rated current of the equipment

Levels Of Insulation

Subject to the limitations above

Xlite, Xcite, Xhite, Xkite and Xqite

• Primary mains circuits to earth: 2.5mm spacing

• Primary mains circuits to secondary: 5mm spacing

Dielectric strength testing is carried out as follows:

• Primary mains circuits to chassis: 1500V AC

• Primary mains circuits to secondary: 3000V AC.

Xmite, Xvite, Xrite and Xzite

• Primary mains circuits to earth: 4mm spacing

• Primary mains circuits to secondary: 8mm spacing

Dielectric strength testing is carried out as follows:

• Primary mains circuits to chassis: 1500V AC

• Primary mains circuits to secondary: 4000V AC.

Earth Terminal Marking IMPORTANT

If in the end use equipment the incoming mains cable earth wire

connects directly to the "GND" connection Xgen without being inter-

rupted or junctioned on its way to that connection, then this connec-

tion forms the main protective earth of the system. To comply with

IEC60950, EN60950, UL1950 requirements and to comply with

EN60601-1, UL2601-1, CSA22.2-601-1 requirements then this must

be marked with the symbol defined in the IEC417 No. 5019a. The

customer should therefore affix an adhesive label which will pass

the 15 Second rub test (IEC60950 section 1.7.15) showing the sym-

bol here adjacent to the earth connection. This symbol must only be

used at the first interruption / connection of the incoming earth wire.

Health And Safety At Work Act (UK only)

To protect service personnel and users and to comply with section 6

of the Health And Safety Acts, a clearly visible label should be fitted

warning that surfaces of these units may be hot and must not be

touched when the units are in operation.

Receipt And Unpacking

On receipt a unit should be unpacked carefully and checked for tran-

sit damage. If the unit is damaged, do not apply power or install the

unit. SEEK SPECIALIST ADVICE!

Warranty

Warranty conditions are contained in our standard terms and condi-

tions. Contact your authorised outlet for repair.

Options

Thermal Signals (Option 01)

Temperature Alarm & Fan Fail

Model Vmin Vnom Vmax Imax Watts

Xg1 1.5 2.5 3.6 50 125

Xg2 3.2 5.0 6.0 40 200

Xg3 6.0 12.0 15.0 20 240

Xg4 12.0 24.0 30.0 10 240

Xg5 28.0 48.0 58.0 6288

Xg7 524.0 28.0 5120

Xg8 5/5 24/24 28/28 3/3 72/72

The powerPac should be supplied only by a power source of the type indicated on its label. Asocket outlet shall be installed near the equipment and shall be easily accessible. The unit should only

be used with a suitably rated mains cord and appropriate IEC320 type connector, sourced by the end user, and in accordance with the requirements of Table 3B of IEC60950-1 (latest edition). If in

doubt, contact Excelsys Engineering Department for assistance. For installations in accordance with EN60601-1, UL2601-1, the Neutral input supply lead must be provided with a suitable fuse pro-

tection device. See the Fuse table below for details. When adding or removing powerMods from the powerPac, care must be taken to handle the powerMods by the output terminals ONLY, ensur-

ing that all other surface mount components are not unduly damaged.

When securing the product, do not use screws which infringe the maximum penetration depth of 6mm. Customer fixings are provided on the base of the unit in addition to the Excelsys ‘fleximount’

system which allows the unit to be mounted on either side of the powerPac chassis. The Xgen series of power supplies have integral fans and may be mounted in any orientation provided that the

air intake and air outlet areas are not impeded with particular regard paid to provide ventilation holes in any chassis on which or near which the unit is mounted. AFTER DISCONNECTING THE AC

SOURCE, ALLOW 4 MINUTES BEFORE DISASSEMBLY TO ALLOW CAPACITORS WITHIN THE UNIT TO DISCHARGE.

IMPORTANT CONSIDERATIONS

Model Reference Fuse Type Voltage Size

XLA FS1 5A F250V 5.0 x 20mm

XLB FS1 6.3A F250V 5.0 x 20mm

XLC FS1 8A F250V 5.0 x 20mm

XKA FS1 5A F250V 5.0 x 20mm

XKB FS1 6.3A F250V 5.0 x 20mm

XCA FS1 8A F250V 6.25 x 32mm

XCB FS1 10A F250V 6.25 x 32mm

XCC FS1 12A F250V 6.25 x 32mm

XCD FS1 12A F250V 6.25 x 32mm

XCE FS1 15A F250V 6.25 x 32mm

XMA FS1 5A F250V 5.0 x 20mm

XMB FS1 6.3A F250V 5.0 x 20mm

XMC FS1 8A F250V 5.0 x 20mm

XRA FS1 5A F250V 5.0 x 20mm

XRB FS1 6.3A F250V 5.0 x 20mm

XVA FS1 8A F250V 6.25 x 32mm

XVB FS1 10A F250V 6.25 x 32mm

XVC FS1 12A F250V 6.25 x 32mm

XVD FS1 12A F250V 6.25 x 32mm

XVE FS1 15A F250V 6.25 x 32mm

XHA FS1 8A F250V 6.25 x 32mm

XHB FS1 10A F250V 6.25 x 32mm

XQA FS1 8A F250V 6.25 x 32mm

XQB FS1 12A F250V 6.25 x 32mm

XZA FS1 8A F250V 6.25 x 32mm

XZB FS1 12A F250V 6.25 x 32mm

J1 J2

INPUTAC 100V-240V 50/60Hz

SEE INSTRUCTION MANUAL

70C MAX OPERATINGTEMPERATURE

29.50

40.40

122.00

46.00

23.50

23.50

80.00

92.00

19.00

19.00 127.00

SLOT F

SLOT E

SLOT D

SLOT C

SLOT B

SLOT A

19.00

Third angle projection

TOP VIEW

All dimensions in mm.

Mounting Holes

4 M4 threaded holes on Base. Max screw penetration is 6mm from Base.

Fleximount Side Mounting Slots

Use with self-clinching studs type FH-M4-X or FH-832-X (X= stud length) from PEM, or equivalent

Alternatively, use Xgen Side Clamps from Excelsys. Part No. Z165 (drawing 61401)

50.00 97.75

Excelsys Technologies Ltd. reserves the right to alter or improve the specification, internal design or manufacturing process with-

out notice. Please check with your Excelsys represenative or visit www.excelsys.com to ensure that you have the current and com-

plete specification for your product before use. For information and instructions on use, please consult the Xgen Designers’ Manual.

Excelsys Technologies Ltd.

27 Eastgate Drive,

Eastgate Business Park,

Little Island, Co. Cork, Ireland

tel: +353 214354716

fax: +353 214354864

email: [email protected]

Pin J2 powerPac

1Common

2+5V Bias

3

4AC Fail

5Fan Fail*

6Global Enable

7 Temp Alarm*

8Global Inhibit

J1: Input Mains Connector

IEC320

Note: For use in ambient temperatures >60C, a

hot condition mating connector and cable must be

used.

J2: powerPac Signal Connector

J3: powerMod Signal Connector

J3

J4

Voltage

Adjust

M4 Screws

2 1

2

1

J3

J4

V1 Adjust

2 1

1

3

4

2

V2 Adjust

powerMod Type B

powerMod Type A

Pin Type AType B

1+Sense -PG (V2)

2-Sense +PG (V2)

3Vtrim Inhibit (V2)

4Itrim Common (V2)

5+Inhibit/Enable -PG (V1)

6-Inhibit/Enable +PG (V1)

7+Power Good Inhibit (V1)

8- Power Good Common (V1)

J4: powerMod Output Connector

Pin Type AType B

1-Vout - V2

2+Vout +V2

3-V1

4+V1

Type A: M4 Screw Terminals

Type B : Mating part:

Camden - CTB9200/4A

Note: Cables must be rated 105C minimum (style

UL1015 or equivalent)

Connectors and Pin-Outs

Labeling and Model Numbers

powerMod

powerMod labels contain:

..Minimum, Nominal & Maximum voltage adjustment range.

..Maximum current (Imax)

..Maximum power (Watts)

..Model number

Model numbers are easily identified by the number marked on the top of signal con-

nector J3.

powerPac

powerPac labels contain:

..Input Freq

..Input Voltage

..Fuse rating

..Serial Number

..Maximum combined power rating of inserted powerMods

..Maximum Line current under rated conditions

..Model Number in the format XCD [] [] [] [] [] [] - 01 as an example for a 1200W Xcite

model, with optional Thermal Signals.

When the powerPac has no powerMods inserted, its Model number is simply XCD-01.

When the powerPac has one or more powerMods inserted, its model number may be

easily read to be XCD012340-01 as an example, where powerMods XG1, XG2, XG3,

XG4 are inserted in Slots B,C,D,E respectively with slot covers in the remaining slots A

and F.

Model

Slot A

Slot B

Slot C

Sum of option codes

‘-’ = standard; ‘P’ = preset

Slot F

Slot E Use ‘0’ for

Slot D

unused slots.

Factory use only

}

XCC 031 3 4 5 P A62

Xgen Series Part Numbering System

Document No. 41002 Rev. 11

Mating parts:

Housing Molex p/n 51110-0850 or -0860

Crimp Terminal Molex p/n 50394

Mating parts:

Housing Molex p/n 51110-0850 or -0860

Crimp Terminal Molex p/n 50394

This manual suits for next models

16

Other Excelsys Power Supply manuals