Exo SONDE User manual

Popular Accessories manuals by other brands

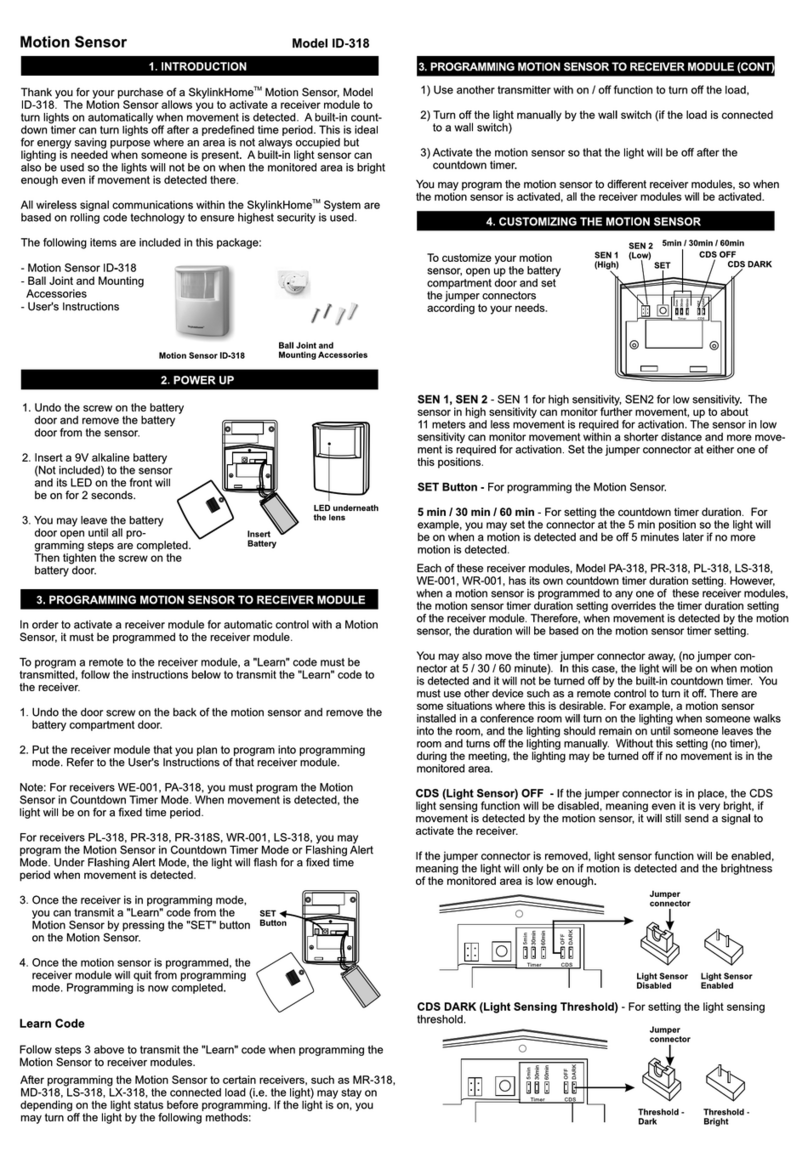

Fuel

Fuel NANO HUB LEVANTE 500 User and maintenance manual

MyCharge

MyCharge Sojourn 1000 owner's manual

Cognex

Cognex In-Sight 3400 manual

Arjo

Arjo Ninjo FD1600 Assembly and installation instructions

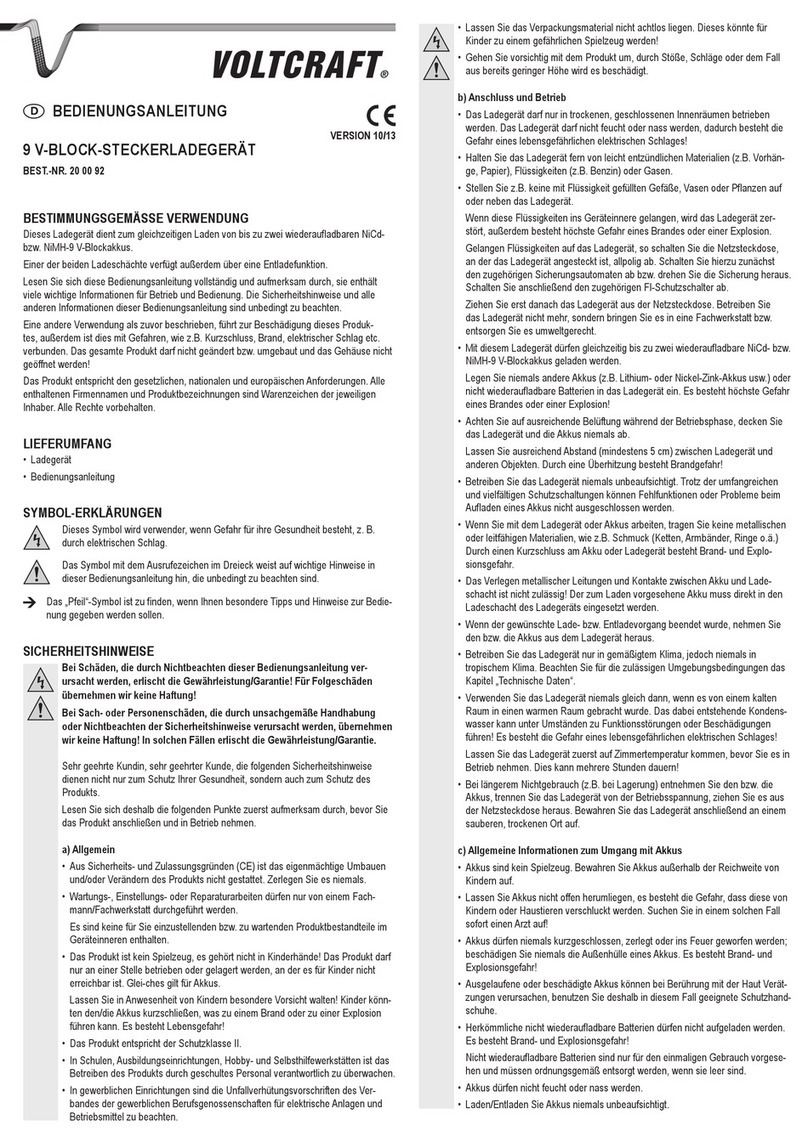

VOLTCRAFT

VOLTCRAFT 20 00 92 operating instructions

Heitronic

Heitronic 500032 Installation and operating instructions

GAI-Tronics

GAI-Tronics XAAB002A Installation and service manual

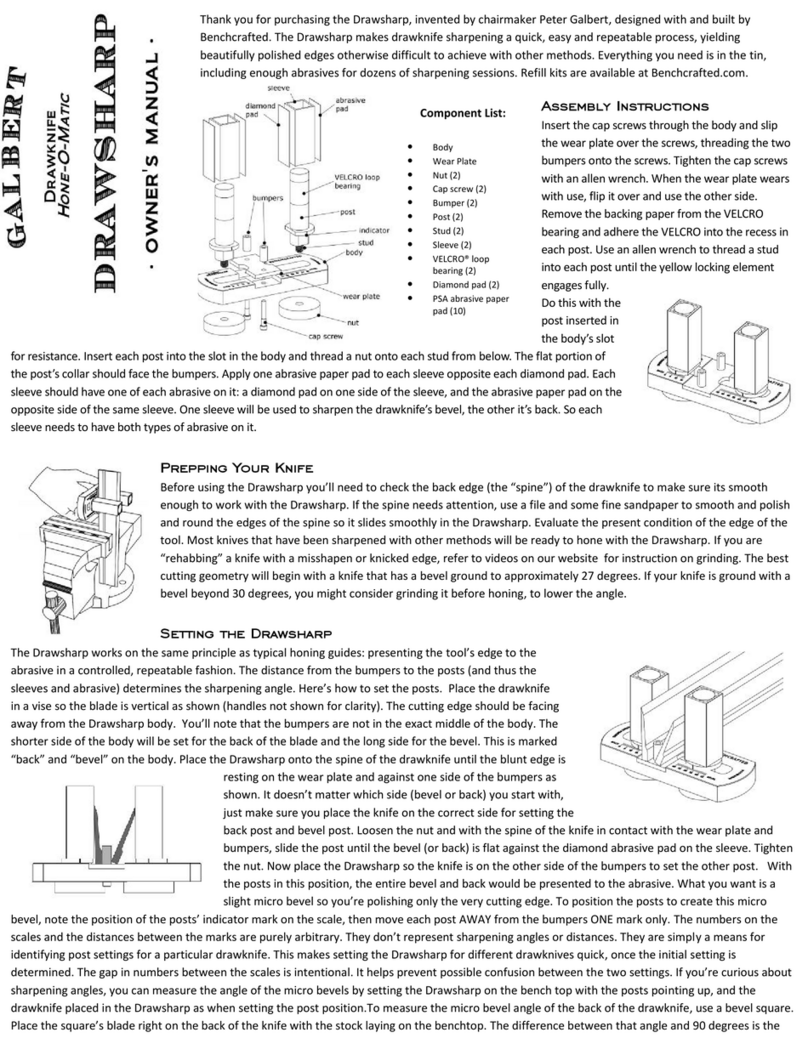

Benchcrafted

Benchcrafted Drawnknife Hone-O-Matic Drawsharp manual

TP-Link

TP-Link TL-PBB3000 How to use

Eaton

Eaton GHG 521 operating instructions

OPTICOM

OPTICOM CV-11T - datasheet

iOptron

iOptron SkyHunter Portable EQ GOTO System instruction manual