s. 2

TABLE OF CONTENTS

BASIC INFORMATION......................................................................................................................................... 3

EY ‐DECLARATION OF CONFORMITY ................................................................................................................ 4

ACCEPTANCE INSPECTION ................................................................................................................................. 5

SAFETY INSTRUCTIONS ...................................................................................................................................... 6

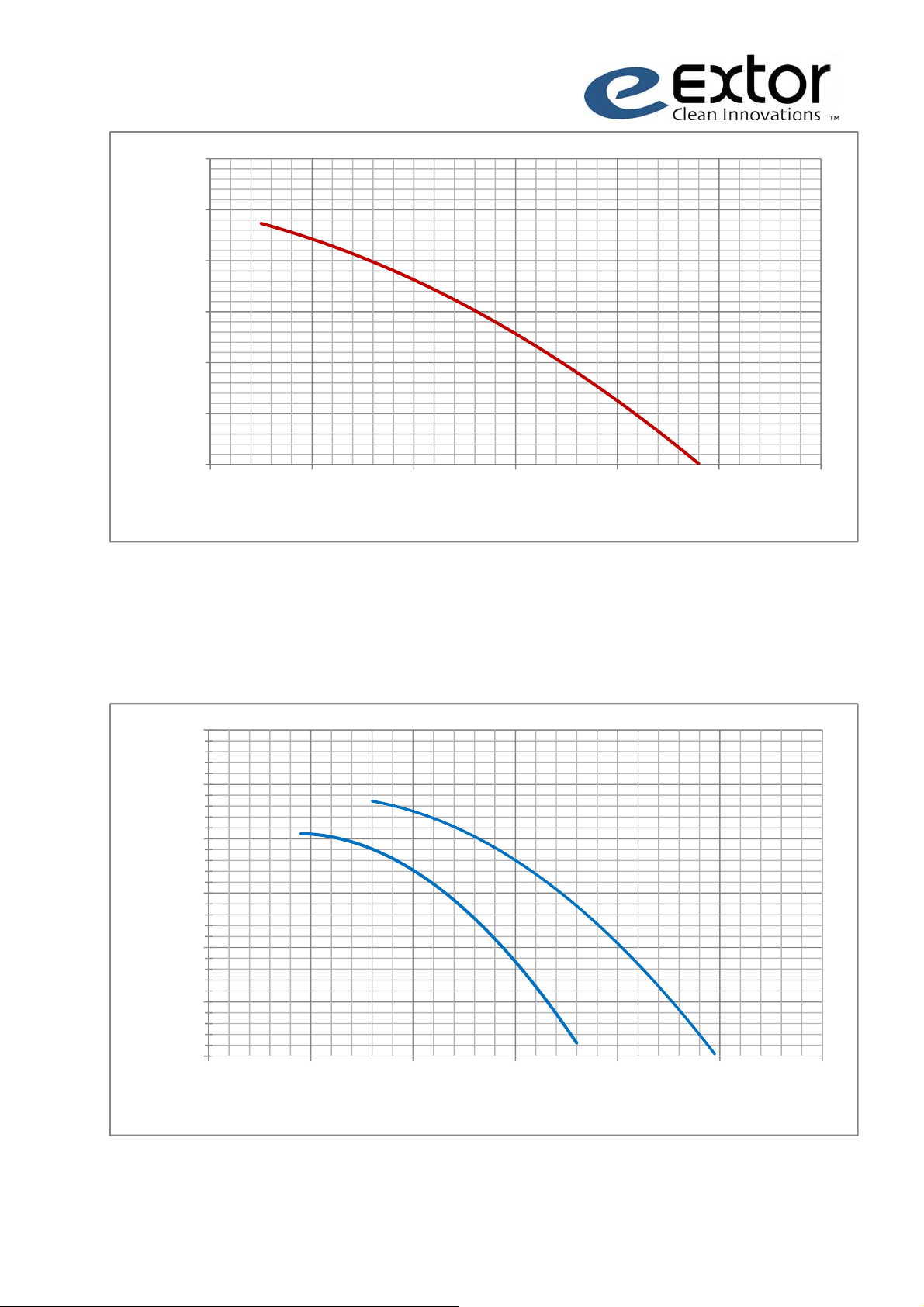

TECHNICAL SPECIFICATIONS.............................................................................................................................. 6

DIMENSIONS...................................................................................................................................................... 8

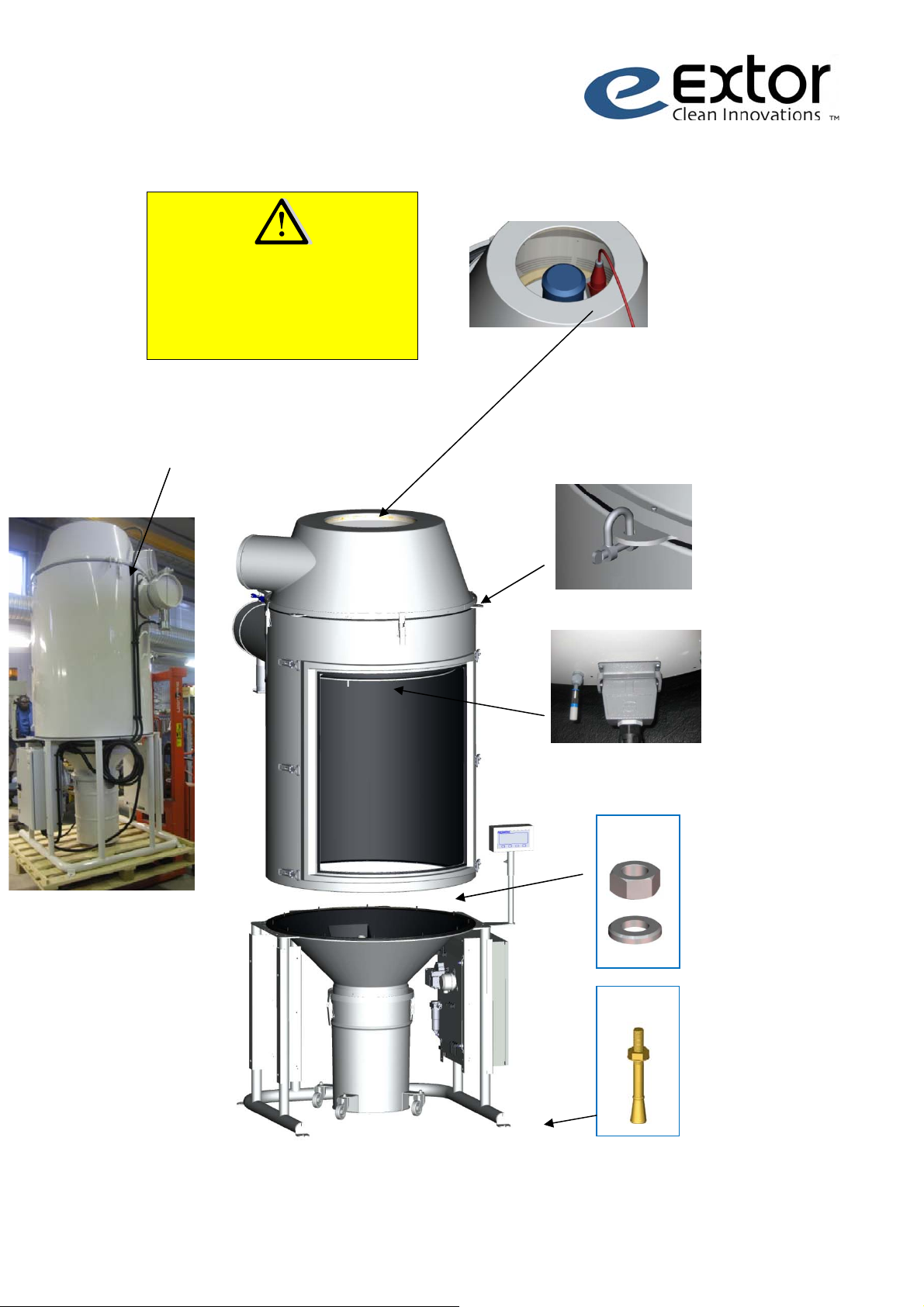

INSTALLATION.................................................................................................................................................... 8

ASSEMBLY.......................................................................................................................................................... 9

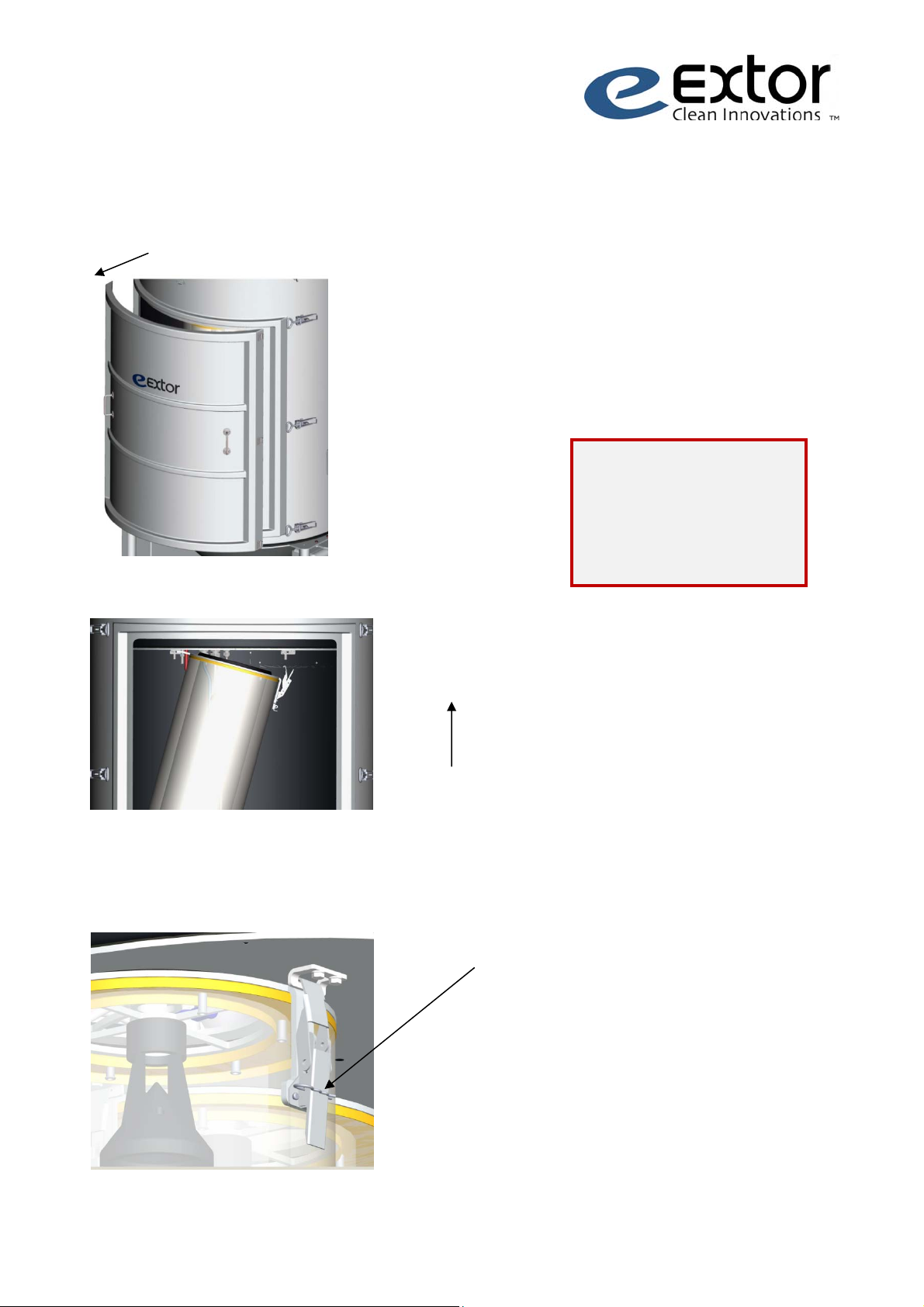

INSTALLATION OF THE FILTERS........................................................................................................................ 10

ALIGNMENT OF THE BLOWING OUTLET.......................................................................................................... 11

PRESSURIZED AIR CONNECTION...................................................................................................................... 11

ELECTRICAL CONNECTION ............................................................................................................................... 12

MANUAL CLEANING*....................................................................................................................................... 12

DESCRIPTION OF FUNCTIONALITY................................................................................................................... 13

STARTING AND STOPPING............................................................................................................................... 14

SYSTEM CONTROL SETTINGS ........................................................................................................................... 15

EMPTYING THE COLLECTING BIN (WITH A CLOSING FLAP*) ........................................................................... 17

TESTING OF THE CLEANING SYSTEM ............................................................................................................... 18

REPLACEMENT OF THE FILTERS ....................................................................................................................... 18

REGULAR MAINTENANCE ................................................................................................................................ 19

TROUBLESHOOTING CHART ............................................................................................................................ 20

PART LIST ......................................................................................................................................................... 21

ACCESSORIES ................................................................................................................................................... 22

INSPECTION LIST .............................................................................................................................................. 23