Extreme Flight GB1 GAMEBIRD EXP User manual

Other Extreme Flight Toy manuals

Extreme Flight

Extreme Flight F3A User manual

Extreme Flight

Extreme Flight YAK-54 ARF User manual

Extreme Flight

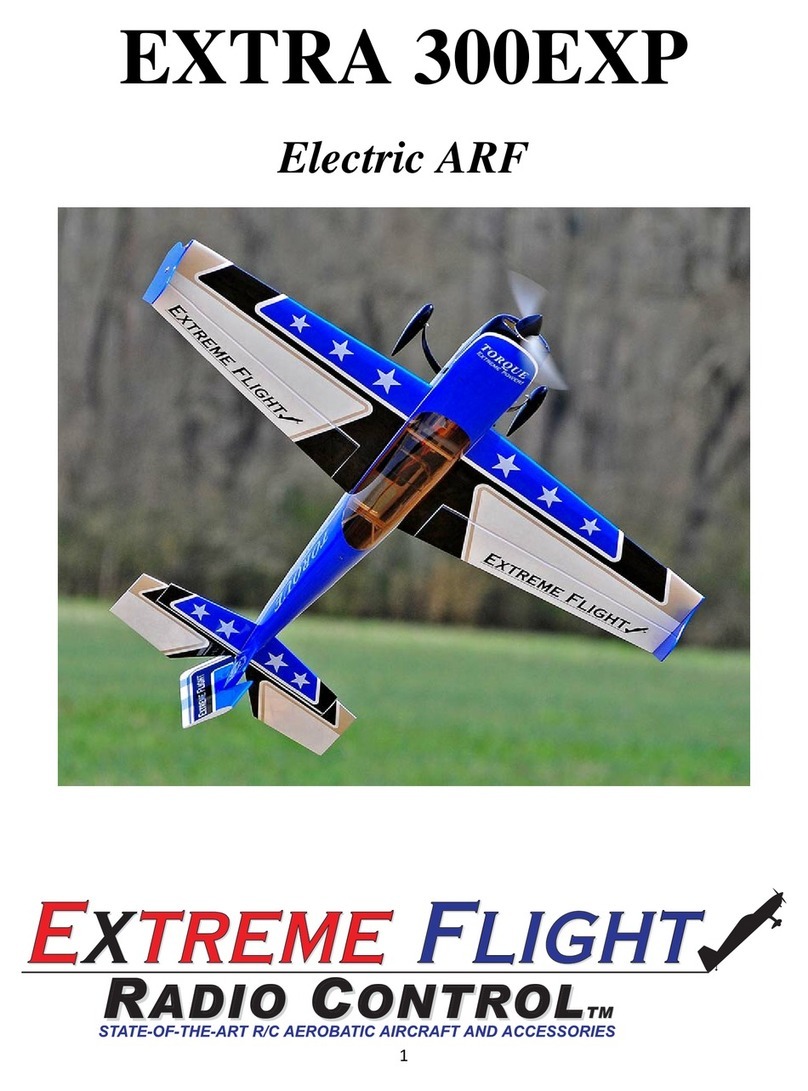

Extreme Flight 91" EXTRA 300EXP ARF User manual

Extreme Flight

Extreme Flight YAK-55SP User manual

Extreme Flight

Extreme Flight 110" YAK-54 V2 User manual

Extreme Flight

Extreme Flight LASER EXP ARF User manual

Extreme Flight

Extreme Flight 78" EXTRA 300 ARF User manual

Extreme Flight

Extreme Flight EXTRA 300-E User manual

Extreme Flight

Extreme Flight Legacy Aviation Turbo Bushmaster User manual

Extreme Flight

Extreme Flight 91" Yak-54 ARF User manual

Extreme Flight

Extreme Flight 60 EXTRA 300 EXP User manual

Extreme Flight

Extreme Flight EDGE 540T EXP User manual

Extreme Flight

Extreme Flight 60 EXTRA 300 EXP User manual

Extreme Flight

Extreme Flight slick 580 exp User manual

Extreme Flight

Extreme Flight 104 Laser EXP ARF User manual

Extreme Flight

Extreme Flight Laser EXP User manual

Extreme Flight

Extreme Flight YAK-54 ARF User manual

Extreme Flight

Extreme Flight 3DHobbyShop Edge 540 User manual

Extreme Flight

Extreme Flight 78" EXTRA 300 ARF User manual

Extreme Flight

Extreme Flight YAK-54 ARF User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions