Please take a few moments to read this instruction manual before beginning assembly. We have outlined a

fast, clear and easy method to assemble this aircraft and familiarizing yourself with this process will aid in a

quick, easy build.

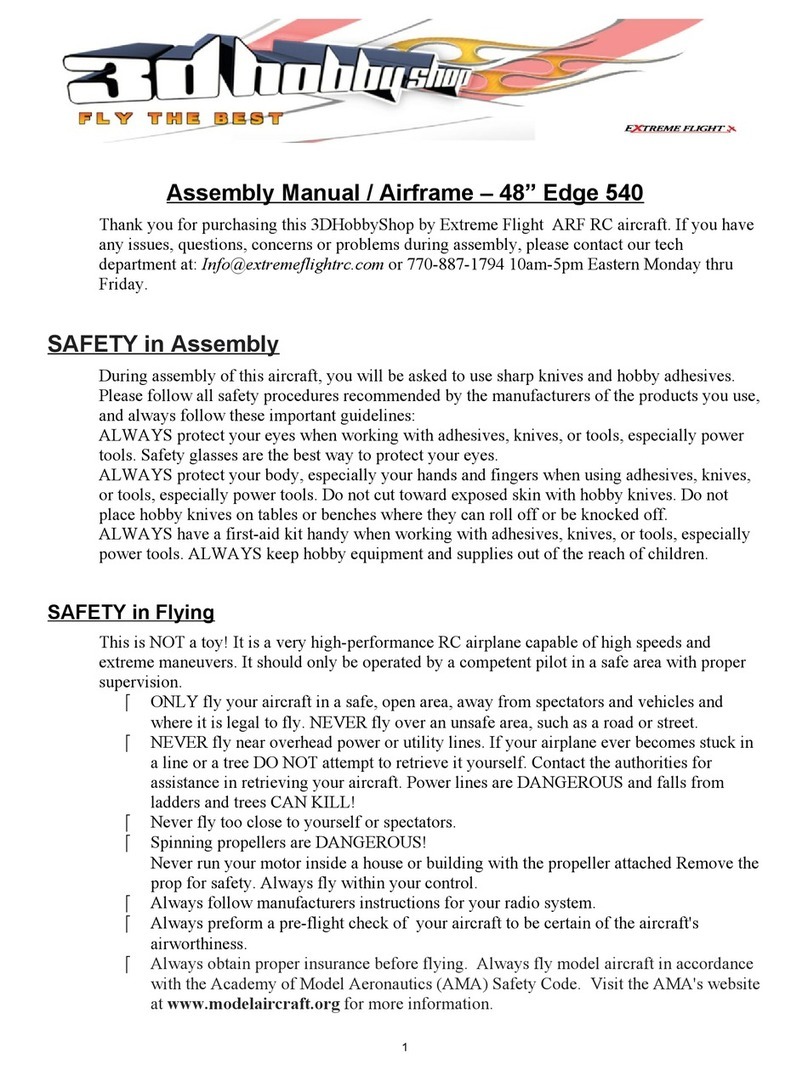

Please read the following paragraph before beginning assembly of your aircraft!

THIS IS NOT ATOY! Serious injury, destruction of property, or even death may result from the misuse of this product. Extreme

Flight RC is providing you, the consumer with a very high quality model aircraft component kit, from which you, the consumer,

will assemble a flying model. It is beyond our control to monitor the finished aircraft you produce. Extreme Flight RC will in no

way accept or assume responsibility or liability for damages resulting from the use of this user assembled product. This aircraft

should be flown in accordance to the AMA safety code. It is highly recommended that you join the Academy of Model Aero-

nautics in order to be properly insured, and to operate your model at AMA sanctioned flying fields only. If you are not willing to

accept ALL liability for the use of this product, please return it to the place of purchase immediately.

Extreme Flight RC, Ltd. guarantees this kit to be free of defects in materials and workmanship for a period of 30 DAYS from the

date of purchase. All warranty claims must be accompanied by the original dated receipt. This warranty is extended to the origi-

nal purchaser of the aircraft kit only.

Extreme Flight RC in no way warranties its aircraft against flutter. We have put these aircraft through the most grueling flight

tests imaginable and have not experienced any control surface flutter. Proper servo selection and linkage set-up is absolutely es-

sential. Inadequate servos or improper linkage set up may result in flutter and possibly the complete destruction of your aircraft.

If you are not experienced in this type of linkage set-up or have questions regarding servo choices, please contact us at info@

extremeflightrc.com or 770-887-1794. It is your responsibility to ensure the airworthiness of your model.

Congratulations on your purchase of the Extreme Flight RC 74” Slick 580 EXP ARF! Designed specifically

to handle the high G loads of Xtreme Aerobatics (XA), Freestyle routines, aggressive 3D maneuvers and

precision aerobatics, the Slick was born of the desire to meet the demands of today’s top ultra-aggressive

pilots.

Featuring carbon fiber square tube wing spars, D-tube wing design, carbon fuselage longerons, compos-

ite-reinforced fuselage formers, tank/battery tray, firewall, motor box and fuselage sides, as well as alu-

minum landing gear mount, quick-mount cowl, dual hatch latches, pre-jigging stabilizer, multi-airfoil wing

design, carbon fiber wing tube, carbon landing gear, complete competition-grade hardware package, and

many other features, the Slick 580 is the ultimate 35CC aerobatic aircraft on the market.

Please refer to the ARF Assembly Resources page on our website

under the Multimedia drop down menu for informative videos to

aid in the assembly and set-up of your aircraft.

A few tips to ensure success:

1. We are very pleased with the level of craftsmanship displayed by the builders in our factory. Through hundreds of grueling

test flights containing maneuvers that no aircraft should be subjected to, our prototypes have remained rigid and completely

airworthy. Having said that, it is impossible for us to inspect every glue joint in the aircraft. Take a few minutes and apply some

medium CA to high stress areas such as the aileron servo mounting trays , landing gear mount, anti rotation pins, wing and stab

root ribs, etc.

2. Having survived the journey half way around the world while experiencing several climate changes, it is not uncommon for a

few wrinkles to develop in the covering. Fear not! These are not manufacturing defects, and are easily removed with a little bit of

heat. Use a sealing iron to go over all seams, stripes and sharp points in the covering scheme. You may want to apply a drop of

clear fingernail polish at the tip of all sharp points to prevent them from lifting. To remove wrinkles use a 100% cotton tee-shirt

or microfiber cloth and your heat gun and heat the covering while gently rubbing the covering onto the wood with the t-shirt or

cloth. Be careful not to use too much heat as the covering may shrink too much and begin to lift at the edges. Take your time,

and a beautiful, paint like finish is attainable. If you need to repair any covering during the life of your aircraft, the colors are:

Yellow scheme: Bright Yellow, Black and Deep Blue in the Ultracote system.

Red/white/blue scheme:True Red, White, Midnight Blue in the Ultracote system.

3. By the time your aircraft arrives at your door step it will have been handled by a lot of people. Occasionally there are small

dings or imperfections on some of the surfaces. An eective method to restore these imperfections to original condition is to use

a very fine tipped hypodermic needle to inject a drop of water under the covering material and into the ding in the wood. Apply

heat to the area with a sealing iron and the imperfection will disappear. Deeper marks may require that this process be repeated

a couple of times to achieve the desired result, but you will be surprised at how well this technique works.

4. DO NOT SKIMP ON SERVOS! Your aircraft is equipped with very large control surfaces that deflect over 45 degrees. A lot of

servo power is required to prevent flutter and to maintain the required deflection for maneuvers. We absolutely recommend the

use of METAL GEARED servos with a minimum of 300 oz. inches of torque.

5. Use a high quality epoxy for installing the composite control horns and hinges. We highly recommend the use of Pacer

Z-Poxy 30 minute formula. We have used this glue for many years with zero failures.

6. You may want to add a bead of RC-56 Canopy glue to the intersection of the canopy/hatch and its wood frame for additional

strength and resistance to vibration. DO NOT USE CA here as it will fog the canopy.

7. Your aircraft is built using very modern construction techniques and is very light weight for its size. As with any high per-

formance machine, regular inspection and maintenance is a must. While disassembling your aircraft after a flying session, pay

close attention and inspect glue joints, linkages and loose covering to be sure the airframe is sound. A few minutes spent doing

this will help maintain airframe longevity.

8. Be sure to put a drop of blue Loctite thread locker on every bolt on this aircraft! Failure to do so may cost you your aircraft!

This includes servo screws!

9.We highly recommend a Desert Aircraft DA-35 gasoline engine if you prefer gas power in your slick. If you prefer electric, we

recommend the Extreme Flight XPWR 30CC motor with Castle Creation Edge HV speed controller, and 2 x 6S 3000-3700mah

lipo batteries, arranged in series for 12S.