This document should serve as a basic guide for Extreme Equipment Rental clients for

planning and executing a successful PowerDrive Orbit or X6 job in North America.

Contents

1JOB PLANNING...........................................................................................................................................3

1.1 BHA DESIGN.........................................................................................................................................3

1.1.1 Stabilization....................................................................................................................................3

1.1.2 Motor Selection..............................................................................................................................3

1.1.3 Bit Selection...................................................................................................................................3

1.1.4 Additional Considerations ..............................................................................................................3

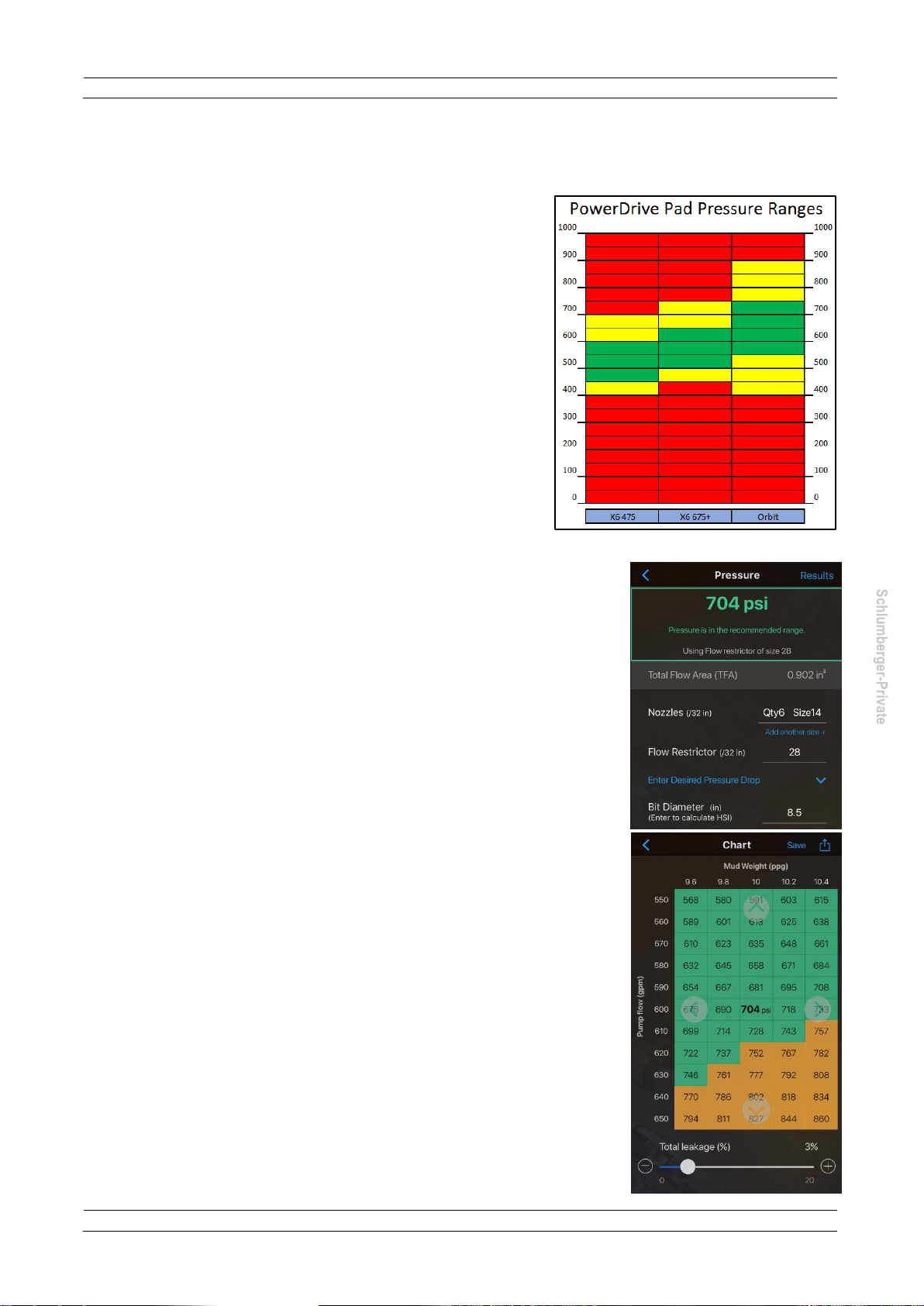

1.2 HYDRAULICS .........................................................................................................................................4

1.2.1 Optimizing Hydraulics ....................................................................................................................4

1.2.2 Pressure Calculator on the PowerDrive App .................................................................................4

1.2.3 Flow Restrictor Use and Availability ..............................................................................................5

1.3 MAGNETIC MATERIAL REMOVAL .............................................................................................................5

1.4 TOOL SPECIFICATIONS...........................................................................................................................5

2TOOL PREPARATION.................................................................................................................................6

2.1 REVIEWING TOOL PAPERWORK ..............................................................................................................6

2.1.1 Tool Configuration..........................................................................................................................6

2.1.2 Flow Loop Results .........................................................................................................................9

2.1.3 Operating Envelope.....................................................................................................................10

2.2 FLOW RESTRICTOR INSTALLATION........................................................................................................11

2.3 BHA MAKEUP......................................................................................................................................11

2.4 SURFACE TESTING –NOT ADVISED ......................................................................................................11

3JOB EXECUTION.......................................................................................................................................12

3.1 TRIPPING IN /FILLING PIPE...................................................................................................................12

3.2REAMING /BACK-REAMING ..................................................................................................................12

3.3 CASING DRILLOUT ...............................................................................................................................13

3.4 DOWNLINKING .....................................................................................................................................13

3.4.1 Downlinking Basics......................................................................................................................13

3.4.2 Sending the Downlink ..................................................................................................................14

3.5 KICKING OFF FROM VERTICAL ..............................................................................................................15

3.6 INCLINATION HOLD (IH) &HOLD INCLINATION AND AZIMUTH (HIA)..........................................................15

3.6.1 Inclination Hold (IH) .....................................................................................................................15

3.6.2 Hold Inclination and Azimuth (HIA)..............................................................................................16

3.6.3 Rate of Penetration Ranges ........................................................................................................17

3.7 POWERVLOCK/UNLOCK......................................................................................................................18

3.8 SIDETRACKING ....................................................................................................................................19

3.9 CLEANUP CYCLES................................................................................................................................22

3.10 RE-RUN EVALUATION ..........................................................................................................................23

4TROUBLESHOOTING................................................................................................................................24

4.1 LOW DOGLEG WORKFLOW...................................................................................................................24

4.2 ANTI-JAMMING PROCEDURE.................................................................................................................24

4.3 SHOCK &VIBRATION............................................................................................................................25

5REQUIRED END OF RUN DATA...............................................................................................................26

6DOCUMENT REVISION HISTORY............................................................................................................27

APPENDIX 1 –REAL-TIME D-POINTS:..........................................................................................................28

APPENDIX 2 –FISHING DIAGRAMS:.............................................................................................................29