www.eyc-tech.com

6

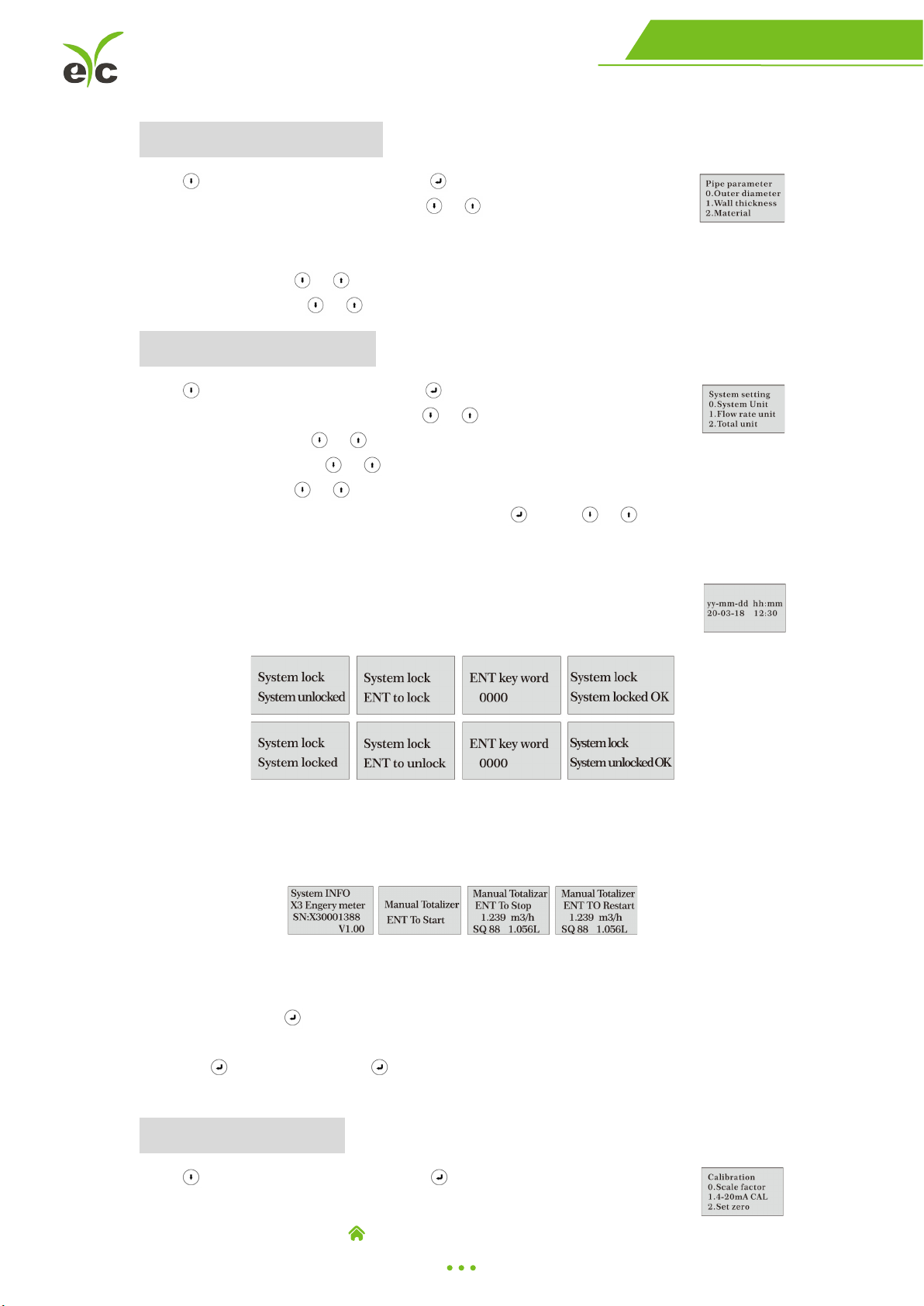

0. Scale factor

Refers to the ratio between “actual value”and “reading value”. For

example, when the measurement is 2.00, and it is indicated at 1.98 on the

instrument, the scale factor constant is 1.01.

1. 4 … 20 mA CAL:Check if the current loop has been calibrated

before leaving the factory. Press move to display 4 mA

or 24 mA, and at the same time, check with an ammeter to

verify that Current Loop output displayed values. It is necessary to re-calibrate the

current loop, if over the permitted tolerance.

2. Set zero Press ; reset “Zero Point” which was set by the

user.

3. Low flow cut:Flow rate falls below the low flow cutoff value.

The flow indication is driven to zero. This function can prevent the flow meter from

reading flow after a pump as shut down but there is still liquid movement in the pipe,

which will result in totalization error.

Generally, 0.03 m/s is recommended to enter as the low flow cutoff point. The low flow

cutoff value has no relation to the measurement results once the velocity increases over

the low flow cutoff value.

Setup Menu-Output

Press , Select 3. Output setting, and then display:

0. RS-485 setup

The window used to set serial port. It connection with the equipment of

its serial port set of parameters must match. The first choice of data that

baud rate:2400, 4800, 9600, 19200 choice. The second option that in check, None.

Data length fixed to eight; Stop bit for a fixed length; Factory serial port parameters

for the default “9600, 8, None, 1”.

1. 4 ... 20 mA range

Set the Current loop output value according to the flow

value at 4 mA, and 20 mA. The flow unit is m3/h.

2. Alarm value (Option)

Enter the low alarm value; any of the measured flow, which is lower

than the low value, will activate the alarm in the OCT hardware or relay

output signal. Enter the high alarm value; any of the measured flow, which is higher

than the high value, will activate the alarm in the OCT hardware or relay output

signal.