Table of contents

Introduction

•This instruction manual explains installation, operation,

troubleshooting, maintenance and inspection, and discarding

procedures for the products below:

•Vacuum constant-temperature dryer

•Vacuum Dry Oven;

•VOS-210C/VOS-310C

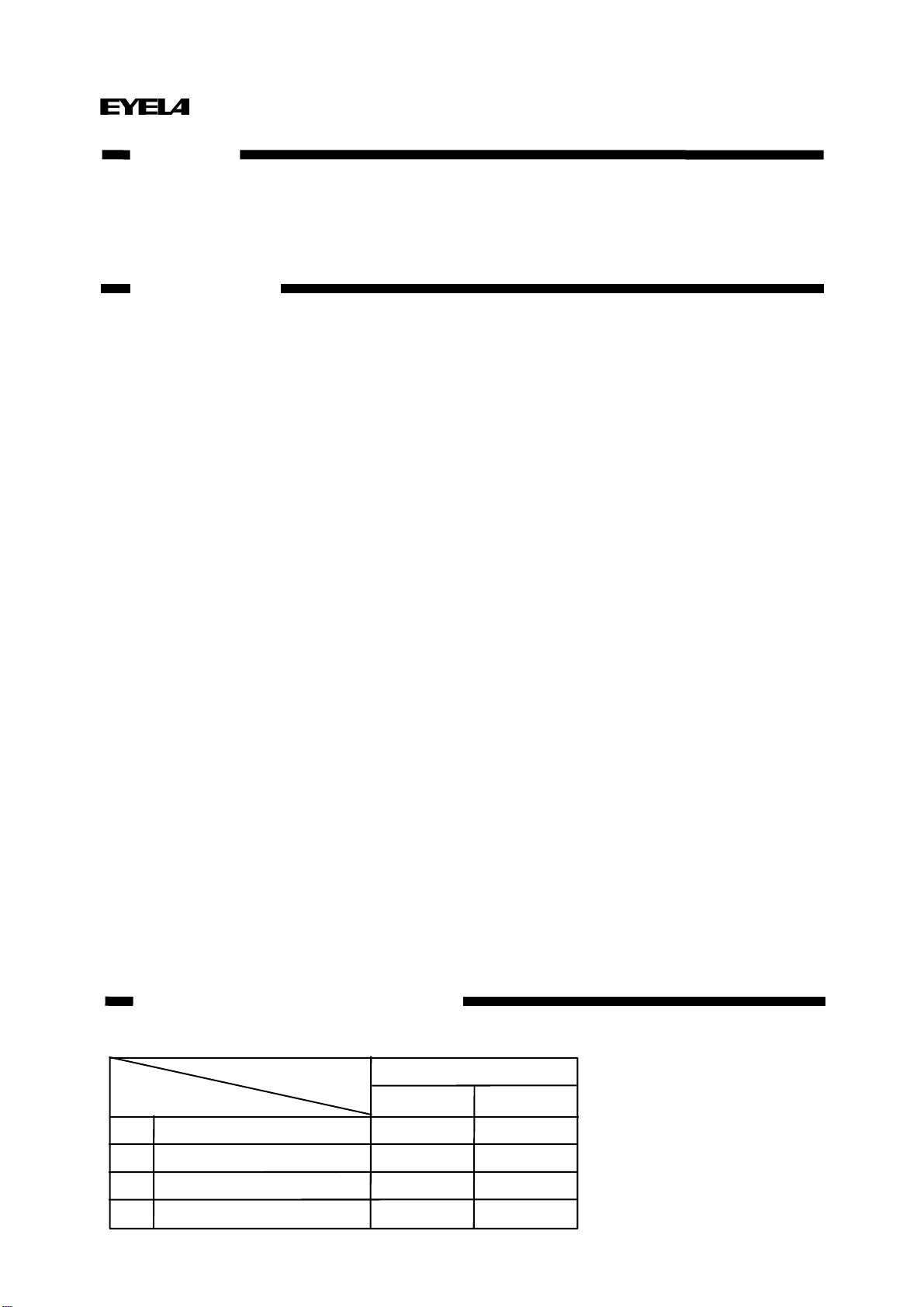

Items contained in your packing

Be sure to confirm the type and quantity of parts before setting.

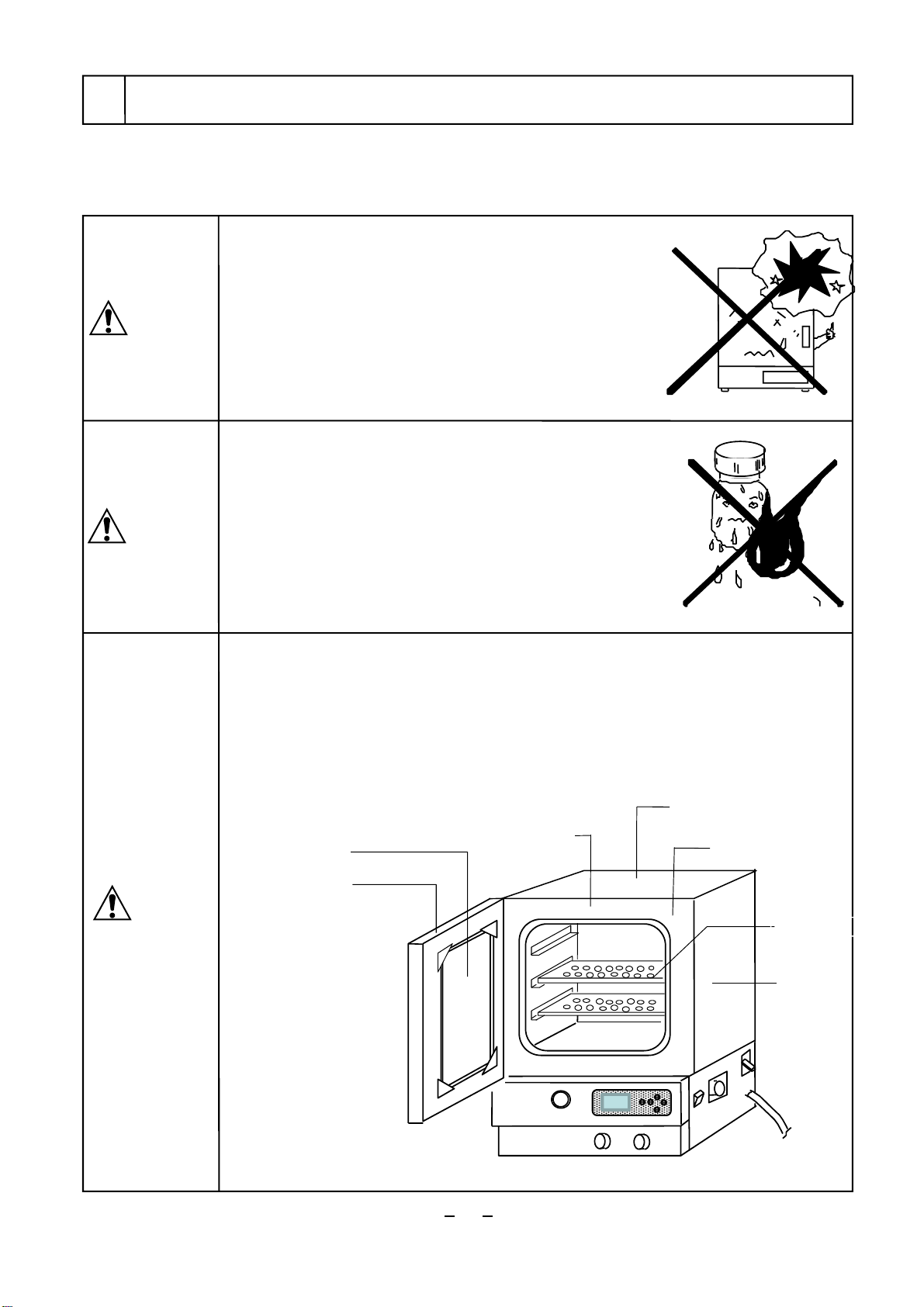

1. For safe operation 1

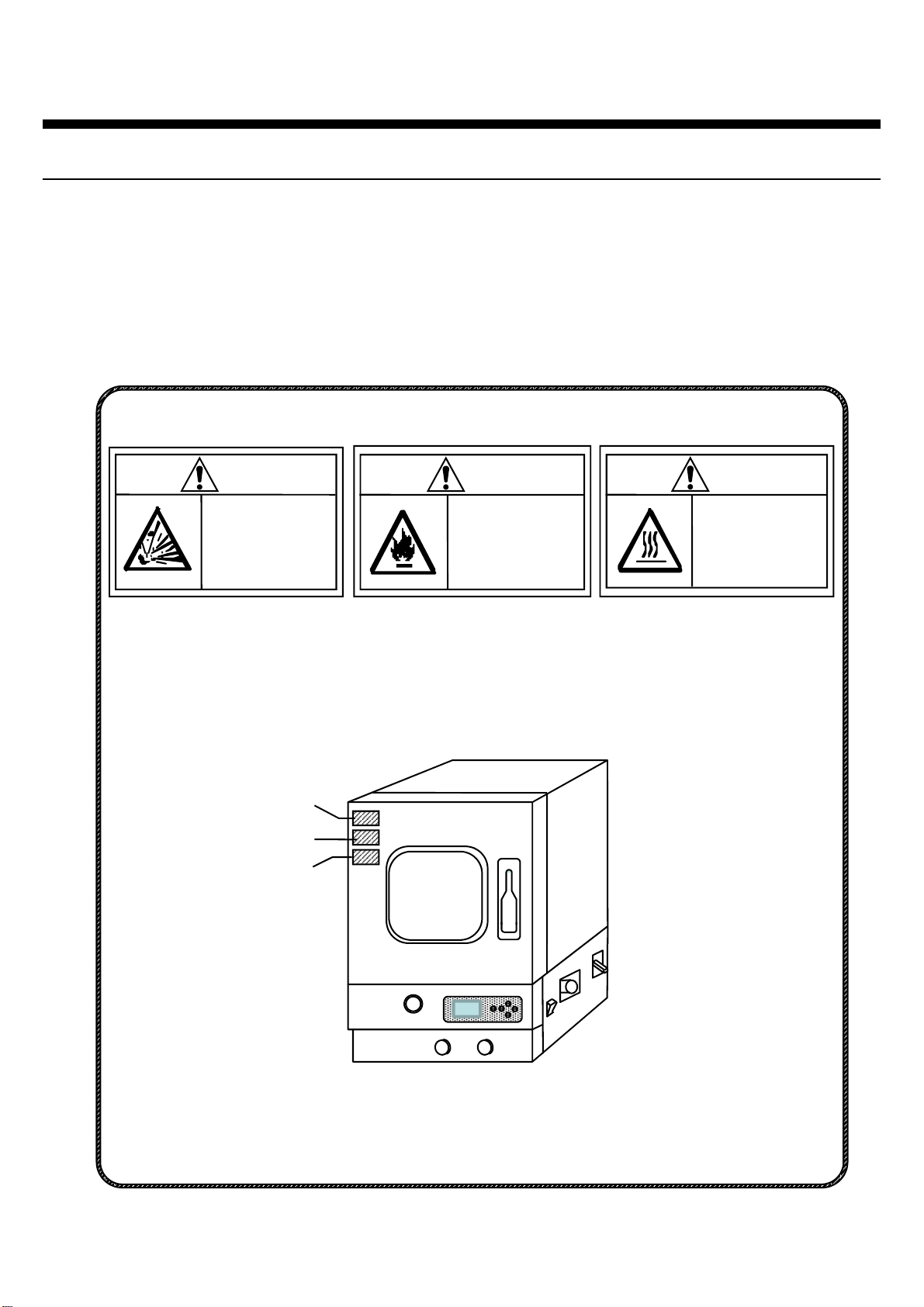

2. Product Summary

2-1 Intended use 2

2-3 Names of parts 3

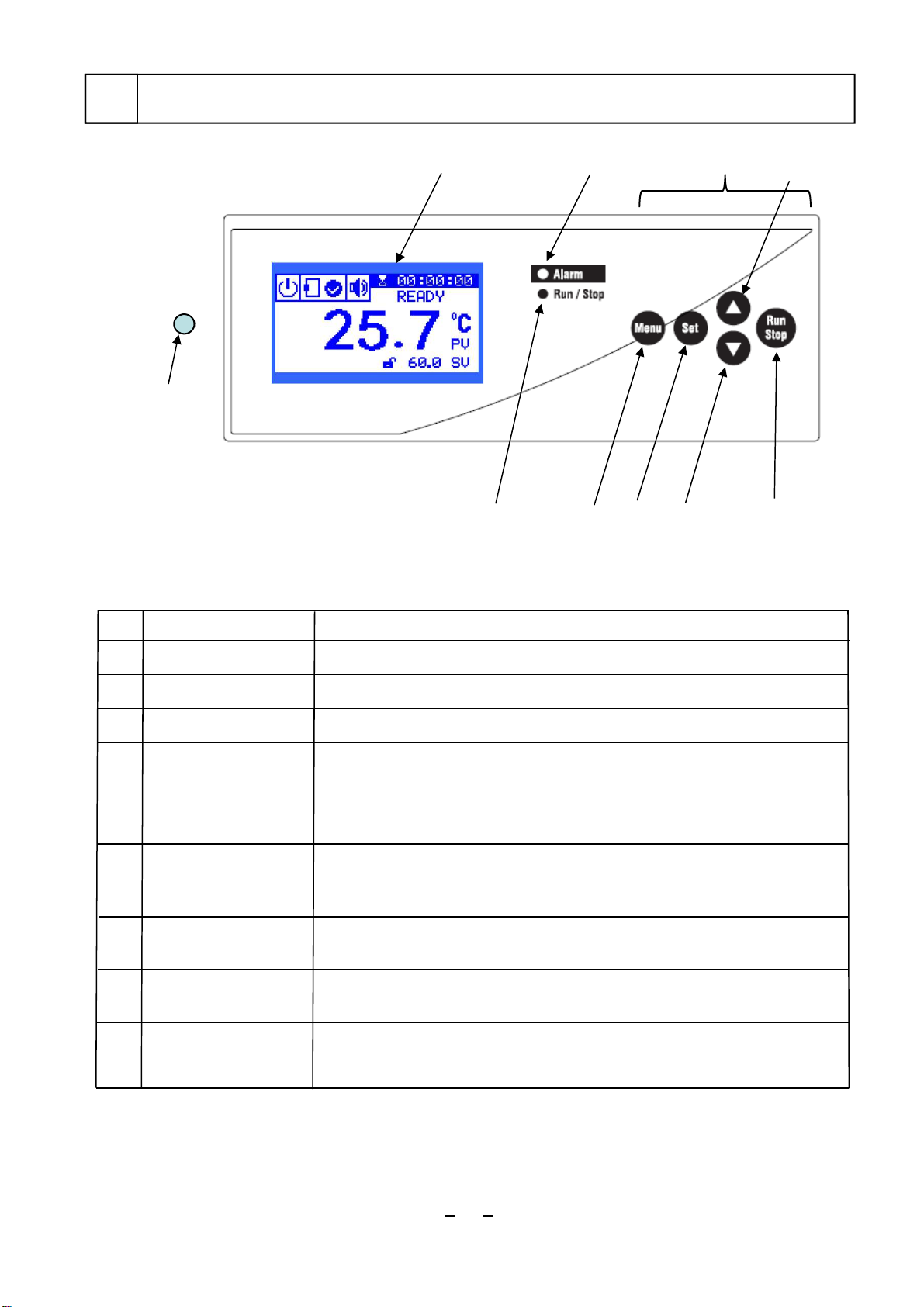

3. Names and Function of Operating Part

3-1 Control panel 4

3-5 Safety and alarm functions 9

4.Installation

4-3 Utility connections 13

5. Operation

5-1 Preparation for operation 14

5-1-1 Set shelf plates and connect to the vacuum

pump 146. Causes of Trouble and Countermeasures 39

7. Maintenance and Inspection

7-1 Leak breaker movement test 41

7-2 Cleaning and care of the product 41

8. Disposal of Product 42

9. Post-sale Service 43

4-2 Installation condition 12

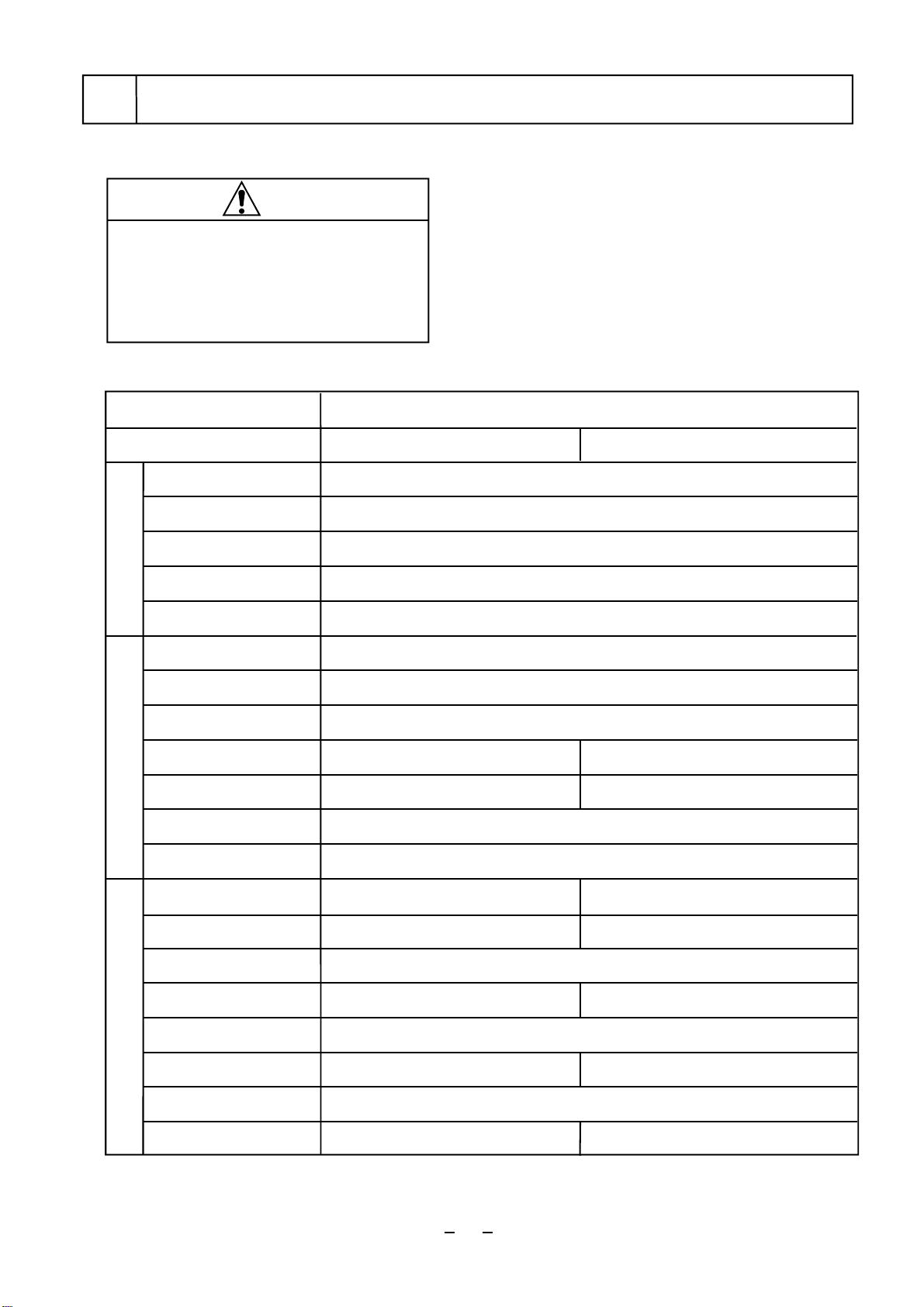

2-2 Specification 2

4-1 Installation environment 12

7-3 Consumable Parts 42

Product

Description of Package

1 Main body

2 Shelf plate

3Instruction Manual

4Warranty

VOS-

310C

1

2

1

10.List of Consumable and Replacing Components/Parts

44

210C

1

2

1

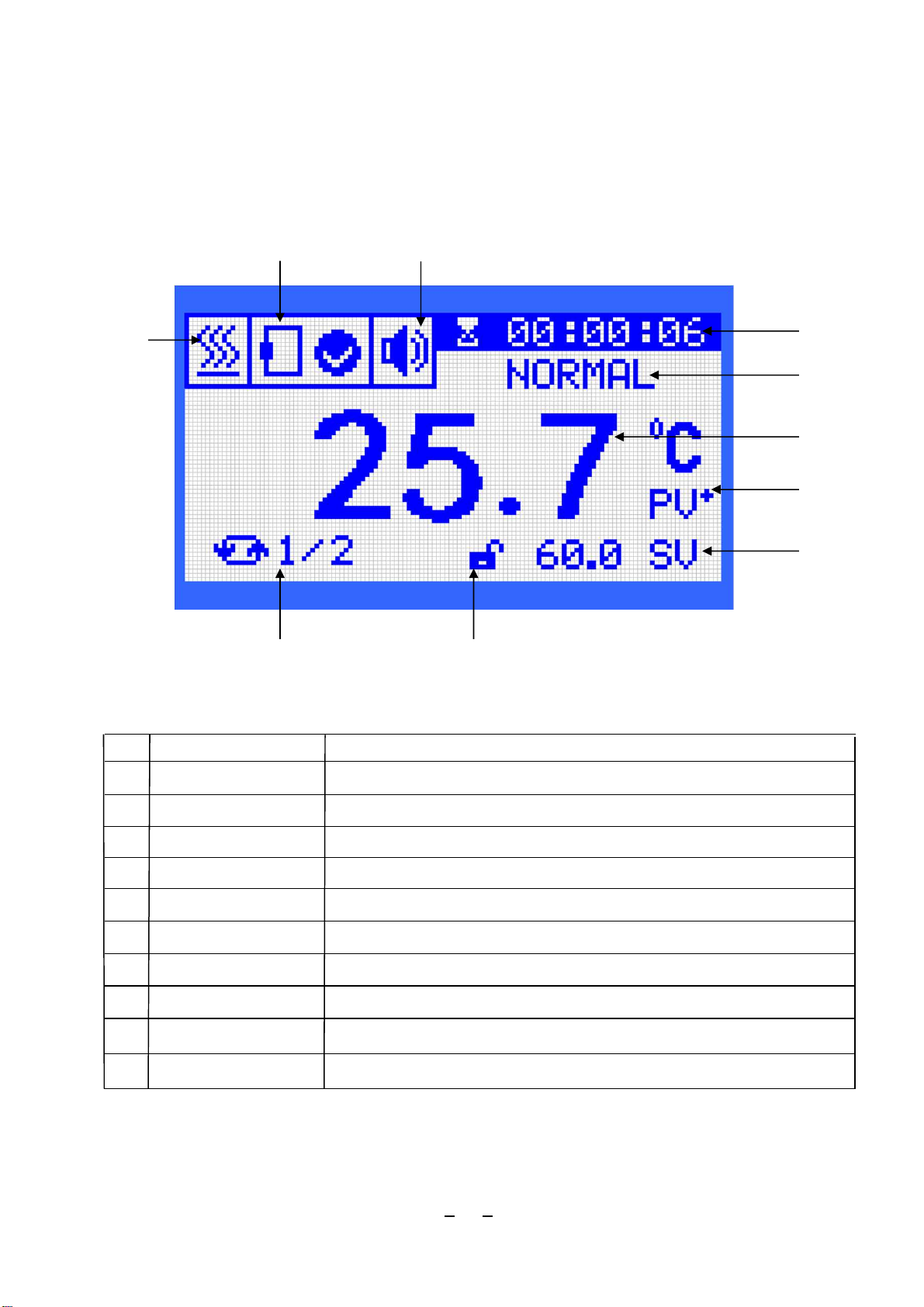

3-2 Display part 5

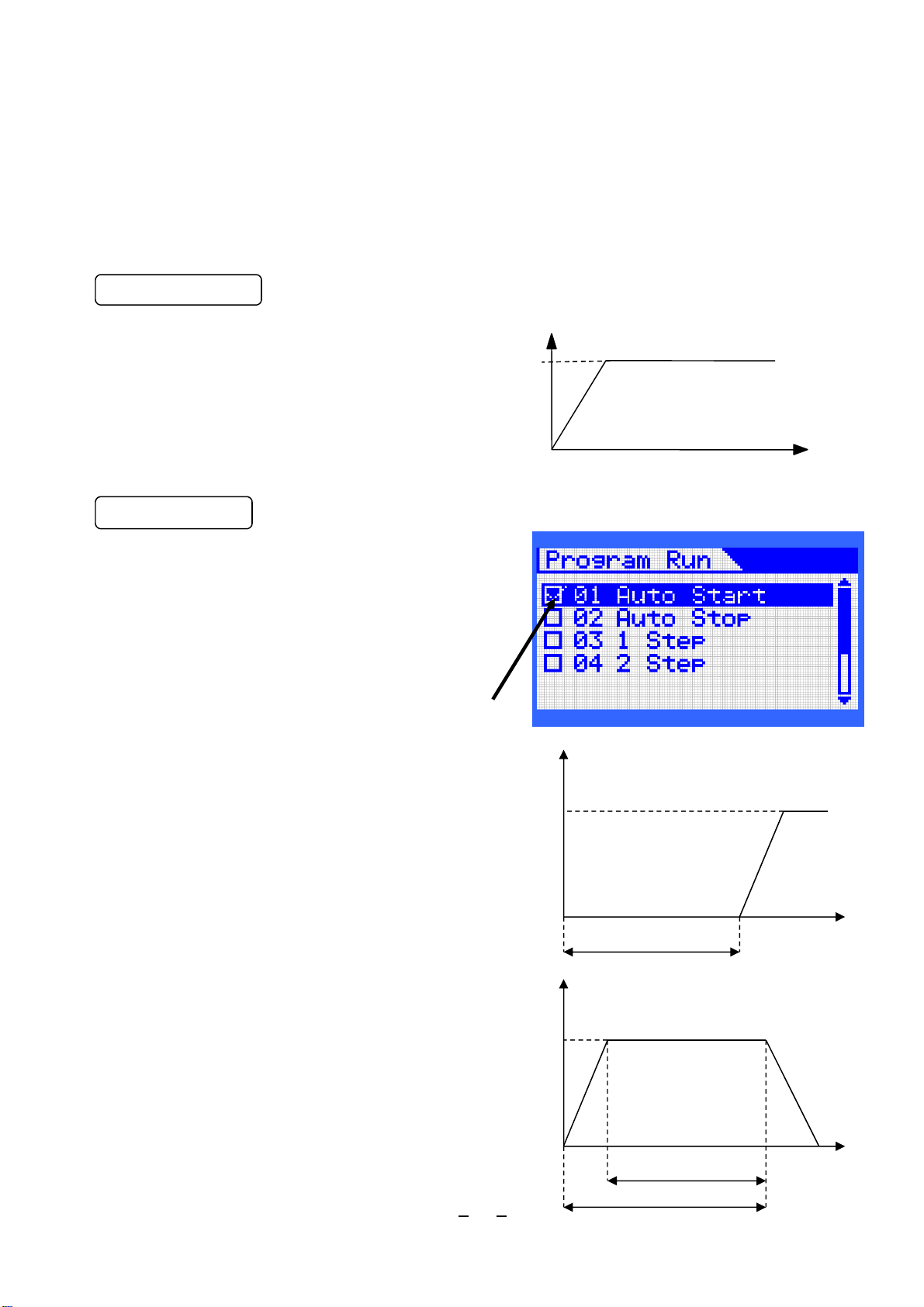

3-3 Constant-value operation and program run 6

3-4 Setting 8

5-5 Vacuum operation method 37

11

5-1-2 Setting sample and container in the chamber

14

5-1-3 Connect power plug 14

5-2 Operating method 15

5-2-1 Set overheat protector 15

5-2-2 Setting, running and stopping constant-value

operation 16

5-2-3 Setting, running and stopping program run 18

5-3-1 How to display alarm screen on the

temperature controller 25

5-4-6 Blackout recovery function 32

Always read this manual before use to ensure

familiarization of the product.

5-3 Alarm function of temperature controller 25

5-3-3 How to set Temp. Alarm 1 Upper/Lower

Limiter 26

5-3-4 How to set Temp. Alarm 2 Temperature

Setting Upper/Lower Alarm 27

5-4 Setting mode operating method 28

5-4-1 How to display setting mode28

5-4-2 PID channel 29

5-4-3 Custom PID 29

5-4-4 How to use Auto-Tuning 30

5-4-5 Measured temperature correction function

31

5-4-7 Optional features 33

5-4-8 Reset setting items 34

5-4-9 Lock operation keys 35

5-4-10 Adjust the display screen contrast 36

5-3-2 Temperature control alarm function 26

5-6 Gas replacing operation method 38

Thank you for purchasing our

product.