INSTALLATION

86037360 03/05/07

4-1

DO NOT damage the

vehicle in any manner

during installation. Before drilling any mounting

holes in vehicle floor, make certain that when

drilling, you will not do any damage to fuel tank, fuel

lines or any vital components which might affect the

operation or safety of the vehicle.

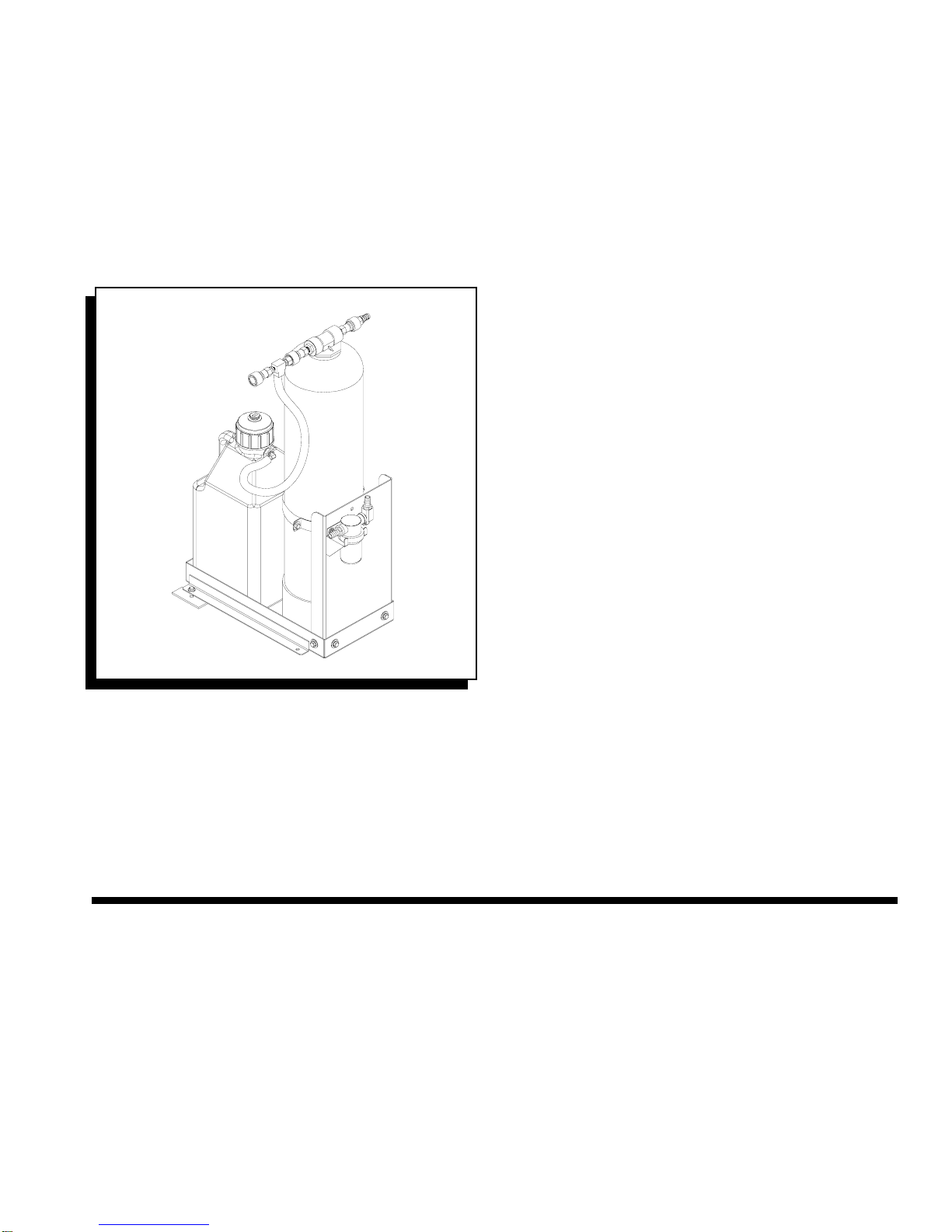

POSITIONING THE UNIT IN VEHICLE

Because vehicles vary in size and openings,

individuals have their own preference as to where

they want their softener installed. The following is a

suggested location that gives you ease of operation

and utilizes all aspects of the EZ-Charge Water

Softener.

1. Using the illustration below, locate the water

softener nest to the truck mount console where

the chemical draw lines are located. This will

allow you to use the bracket as a chemical jug

holder when the brine tank is not needed during

normal operation.

Be sure NOT to position the softener too close

that when routing hoses they don’t become

kinked or damaged due to rubbing against

abrasive edges.

2. Place the bracket in place you’ve located and

mark the mounting holes. You can also use the

dimensional data below to mark out the

mounting holes.

3. Using a drill with a 3/8” drill bit, drill 4 mounting

holes.

4. Using the hardware provided, bolt the bracket

into place (see mounting detail).

5. After securely bolting the bracket into position,

place the softener cylindrical tank into the

bracket and tighten the clamp around the tank

using the wingnuts provided.

6. Bolt the water filter bracket to the back of the

tank bracket and place the water filter hose

assembly into the filter bracket. Make sure to

route the long hose from the filter towards the

truckmount water inlet disconnect.

7. Connect the short hose from the filter to the

OUTLET disconnect of the water softener.

Connect the long hose from the filter to the

water inlet disconnect on the truckmount unit.

NOTE: The softener has the words “IN” and

“OUT” clearly marked on the tank manifold. The

water filter has a arrow mark on tip indicating

water flow

Your softener is now ready to use.

WATER

SOFTENER

BRACKET

LOCKWASHER

HEX HEAD

CAP SCREW

FLATWASHER

FLATWASHER NUT

VEHICLE

FLOOR