Table of Contents

1. Preamble .......................................................................................................................................................................... 4

1.1 Important information about the manual .............................................................................................................. 4

1.2 Important notice..................................................................................................................................................... 4

2. Safety instructions............................................................................................................................................................ 4

2.1 Precautions for the use of ez-Wheel® products...................................................................................................... 4

2.2 Precautions for the use of the batteries ................................................................................................................. 5

3. ez-Wheel® product overview and compatibility............................................................................................................... 6

4. Before use......................................................................................................................................................................... 7

5. Integration of the ez-Wheel® products............................................................................................................................. 7

5.1 Mounting of the wheel on the axle......................................................................................................................... 7

5.2 Mounting of the wheel to the application via an integration bracket .................................................................... 8

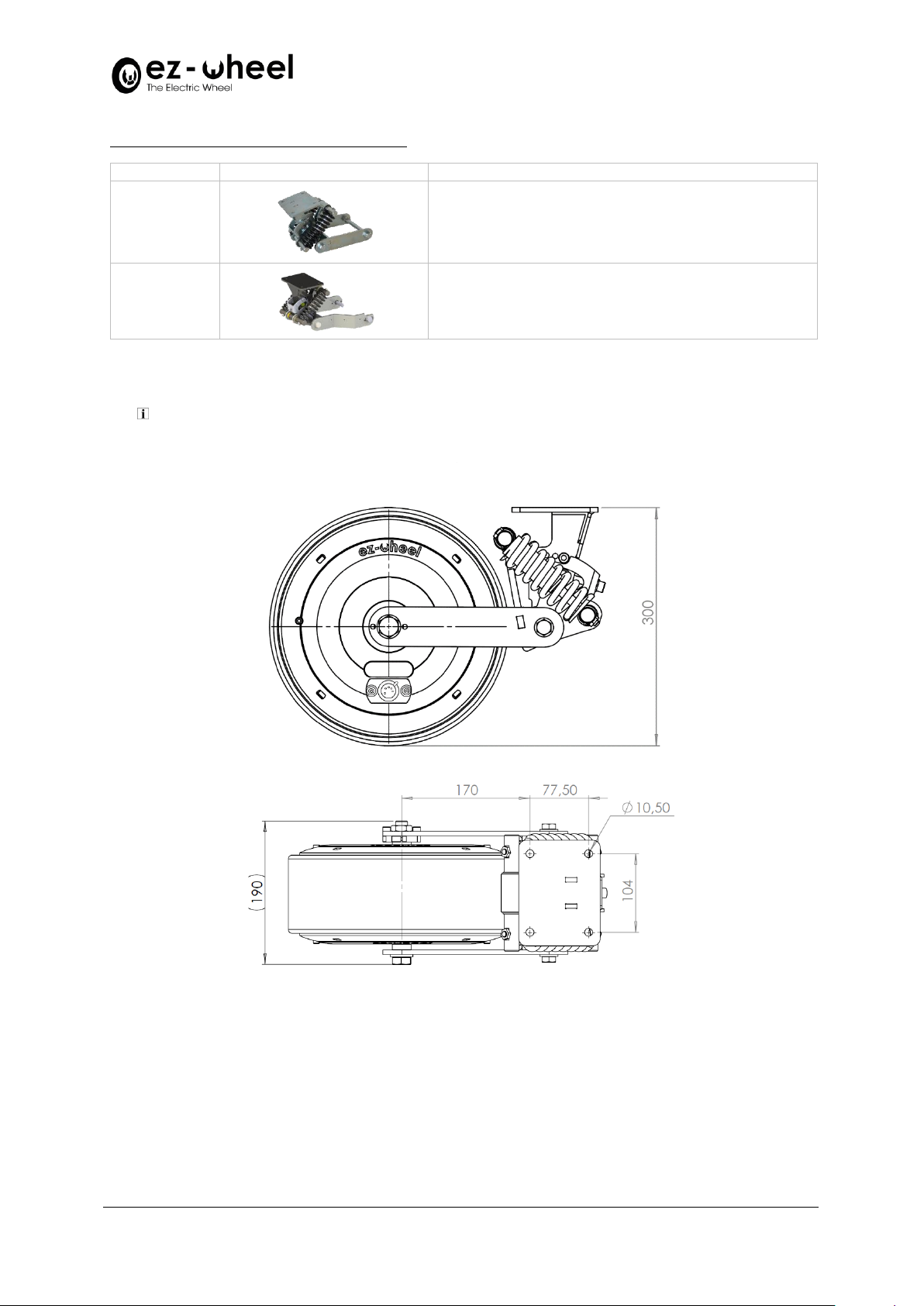

5.2.1 Size of the bracket/wheel assembly................................................................................................................... 9

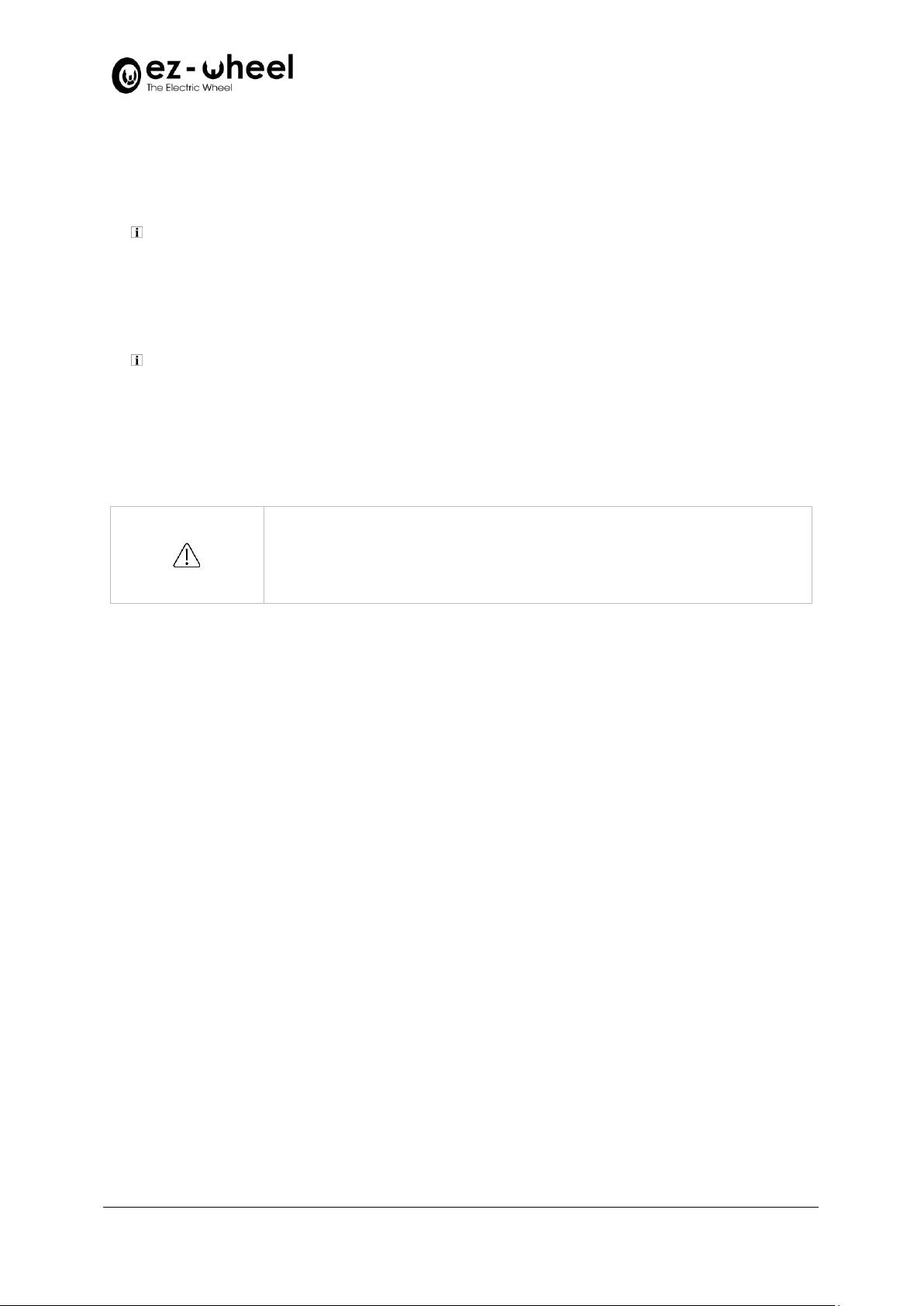

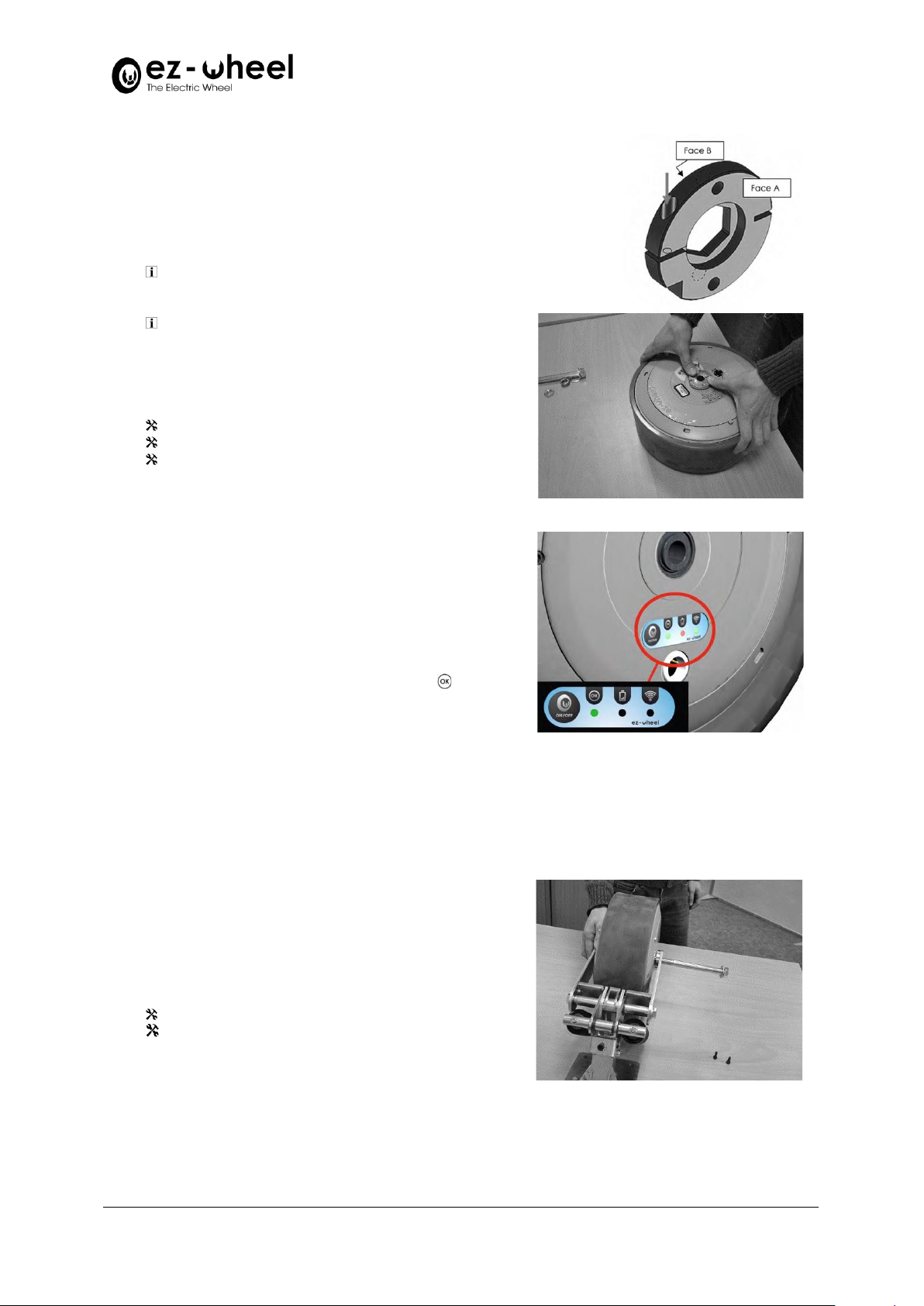

5.2.2 Integration of the anti-rotate ring on the wheel................................................................................................ 9

5.2.3 Fitting the wheel to the suspended bracket .................................................................................................... 10

5.2.4 Adjusting the tension ....................................................................................................................................... 11

5.2.5 Fixing the pre-assembled unit on the machine ................................................................................................ 12

5.3 Integration of directional controls ........................................................................................................................ 12

5.3.1 Integration of the tiller head............................................................................................................................ 13

5.3.2 Integration of the wireless interface box ......................................................................................................... 13

5.4 Setting of the system ............................................................................................................................................ 15

6. Starting up of the equipment ......................................................................................................................................... 15

6.1 Starting up of the tiller head................................................................................................................................. 15

6.1.1 Initial starting up of the tiller head................................................................................................................... 15

6.1.2 Use of the tiller head........................................................................................................................................ 16

6.2 Starting up of the wireless interface box .............................................................................................................. 16

6.2.1 Initial starting up of the wireless interface box................................................................................................ 16

6.2.2 Use of the wireless interface box..................................................................................................................... 17

7. Charging the ez-Wheel® products................................................................................................................................... 18

7.1 Charging the wheel ............................................................................................................................................... 18

7.1.1 Charging the wheel with charging connector................................................................................................... 18

7.1.2 Charging the wheel without charging connector ............................................................................................. 18

7.2 Charging the tiller head......................................................................................................................................... 20

8. Display ............................................................................................................................................................................ 20

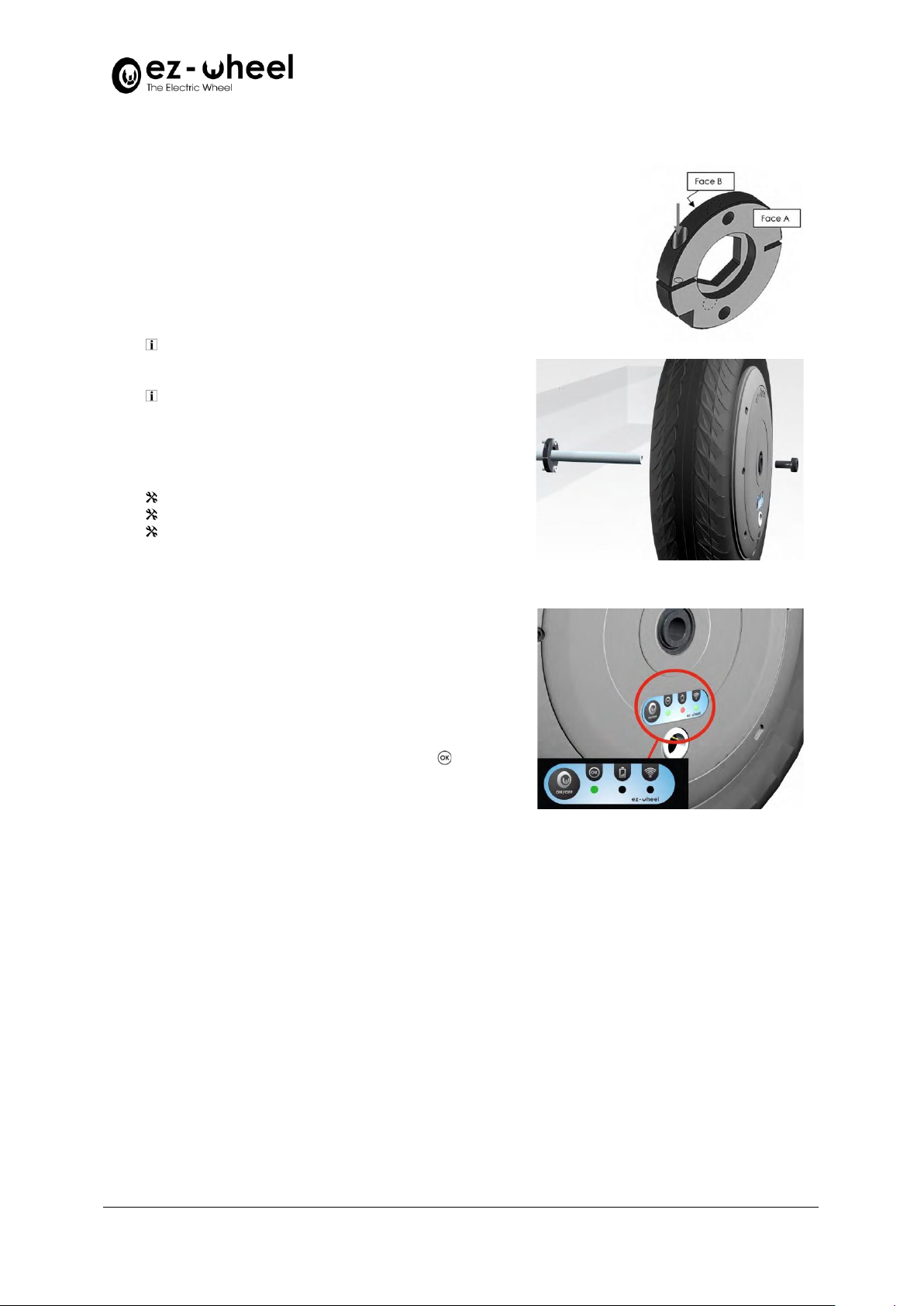

8.1 Wheel display........................................................................................................................................................ 20

8.2 Wireless interface box display .............................................................................................................................. 20

8.3 Tiller head display ................................................................................................................................................. 21

9. Maintenance................................................................................................................................................................... 21

9.1 Maintenance of wheels with connectors.............................................................................................................. 21