10 E56-6001-000

02/16/2018

formed are based on the fan setting. If the fan setting is changed on the device

at a later date the pipe system must be re-verified.

ALARM AND RELAY CONFIGURATION

Alarm thresholds are set to default levels when shipped, but are configurable.

Each Alarm level has its own set of form C relay contacts. As the particulate

level crosses the threshold for the alarm level the corresponding indicator will

illuminate and the relay will activate. The Alarm thresholds and their associ-

ated relay outputs are configurable for latching or non-latching operation For

each alarm level, there is a configurable delay from 0 to 60 seconds. Configu-

rable thresholds for each alarm level are as follows:

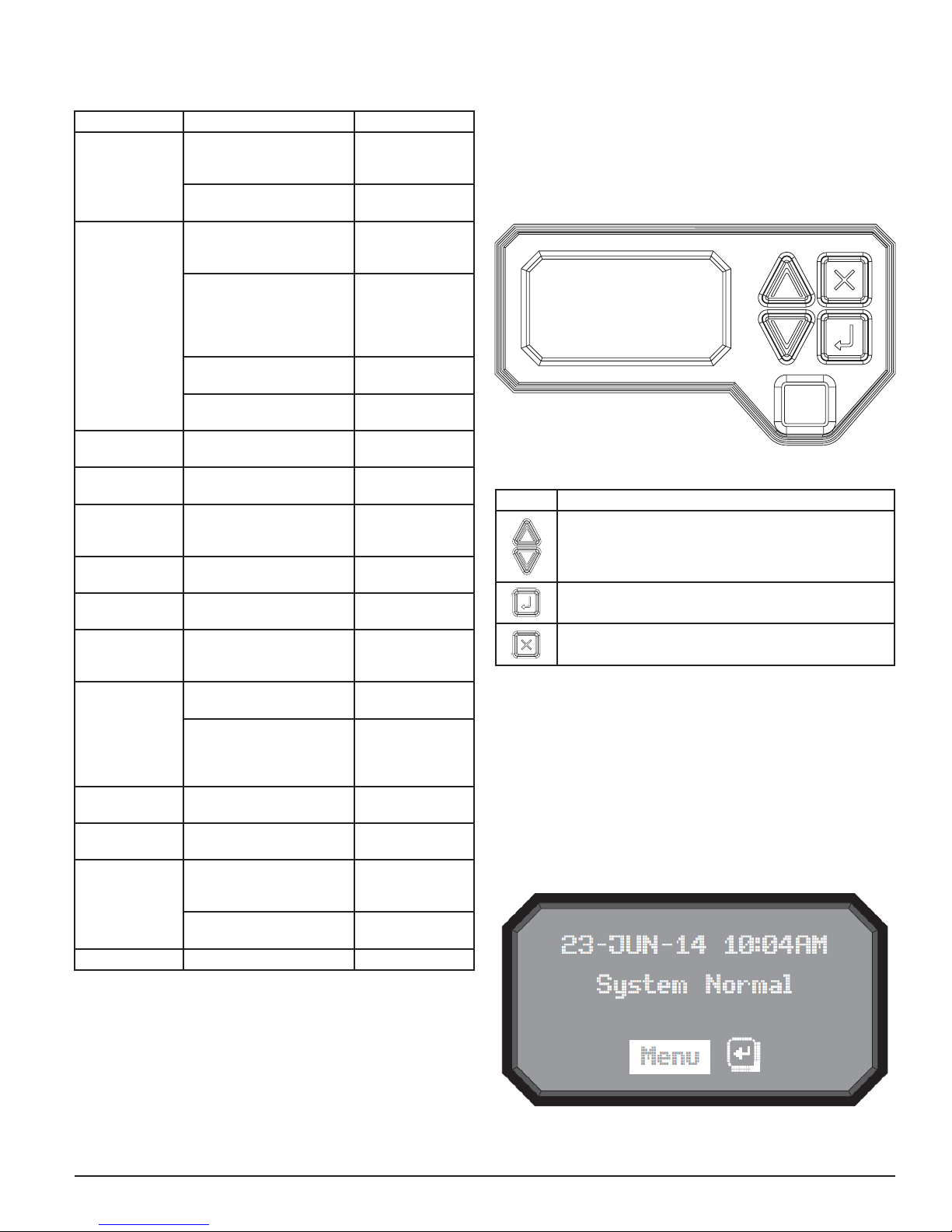

TABLE 5. PROGRAMMABLE ALARM LEVELS

ALARM

LEVEL

DEFAULT

THRESHOLD

%OBS/M

PROG.

RANGE

%OBS/M

Alert 0.0396 0.0015 - 20.0

Action1 0.165 0.0015 - 20.0

Action2 0.33 0.0015 - 20.0

Fire1 0.825 0.0015 - 20.0

Fire2 1.65 0.0015 - 20.0

AUDIBLE INDICATOR CONFIGURATION

There is a built audible indicator on the FAAST XT which gives the option to

include a supplementary audible indication of alarms and faults. The settings

are configurable using the PipeIQ software. The sounder is capable of generat-

ing a pulsed or continuous tone. Both the alarm and fault can be selected to

do either tone.

FAILURE OF CONFIGURATION VALIDATION

If configuration validation fails during the configuration process, the software

configuration tool will indicate a failure and the device will illuminate the

fault indicator. Subsequently, the device will not accept any of the data as

valid and will revert back to its previous configuration.

POWER GLITCH DURING CONFIGURATION

During an upload of configuration data, the device will keep the last known

good configuration in memory until a complete validation is done on the new

configuration data. This prevents device corruption in the event of a power

loss or network failure. When power is restored the device will initialize with

the last known good configuration. The device will also indicate a Configura-

tion Fault on the user interface and set the Minor Fault Relay. This will only

occur once. When the next Reset or Power on Reset is performed the device

will continue to use the last known good configuration.

NORMAL

In Normal operating mode the FAAST XT displays the air flow and current

particulate levels on the user display. The time, date, address, and current

obscuration is shown on the LCD. The particulate level is compared to the

threshold levels programmed into the device and will activate the appropri-

ate alarm as the particulate exceeds that threshold. If any fault occurs it will

activate the fault LED and display the type on the LCD as well as set the cor-

responding relay.

TEST

Test mode is initiated through the PipeIQ Live View tab or through the LCD in-

terface. Test mode will simulate a fire condition by activating all ten segments

in the Particulate Level display and each segment in the Alarm display. Each

corresponding alarm relay will also activate after any programmed delay asso-

ciated with that relay. To remove the device from test, a RESET must be done.

SOUNDER TEST

The sounder test function can be accessed via the LCD user interface. Upon

initiation, the device will exercise the selected sounder tones for fault and

alarm conditions. The sounder may be configured to give continuous or pulsed

tones for alarm and fault conditions. Tones may be selected using PipeIQ.

RESET

Reset mode is initiated through the PipeIQ mimic view or through the LCD

interface. When RESET is activated all relays will be reset. It will then enter

Normal mode operation. If any fault or alarm states remain the device will re-

activate the state automatically.

RESET AIRFLOW BASELINES

The airflow baselines can be reset through the LCD screen on FAAST’s user

interface. Selecting this option will cause the FAAST unit to enter in to a five

minute baseline period, which will be displayed on the LCD user interface,

and reset its current air flow baselines.

WARNING

If a high or low condition exists perform a visual inspection of the pipe net-

work to ensure the integrity of the pipe network and that the flow condition is

not caused by breakages or blockages.

ISOLATION

From Normal Mode, Isolation mode is initiated through PipeIQ mimic tab or

through the LCD interface. The device will set the isolation relay and the

isolation fault will be shown on the user interface. The alarm and fault re-

lays will reset and subsequently not change state. In all other respects, the

unit will continue to operate normally. Any smoke exceeding alarm thresholds

will cause alarm conditions to appear on the detector’s front panel, but the

alarm condition will not be communicated to an attached system such as a

fire panel. The device will remain in this mode until it is explicitly removed by

the user, even in the event of power loss or reset.

DISABLE MODE

The user can initiate Disable Mode through the LCD interface only. When

Disable Mode is activated, the device will set the isolation relay and the user

interface will display the disable fault. In Disable Mode, the fan will cease

operation and the particulate, alarm and airflow displays on the user interface

will not be illuminated. The alarm and fault relays will reset and subsequently

not change state. This mode should only be used when the system needs to

be taken offline. This mode is active indefinitely until the user removes the

device from disable mode. All communication interfaces remain active when

the device operates in this state.

ACCLIMATE® MODE

The FAAST system includes an available Acclimate mode. By allowing the de-

vice to operate in Acclimate mode, a device’s susceptibility to nuisance alarms

can be reduced. This provides maximum protection for a device located in

changing environments. The sensitivity of the unit continuously adjusts over

time, within user defined limits, as the environment changes. Acclimate mode

ALARM LEVEL THRESHOLD HIGH

SENSITIVITY

THRESHOLD LOW

SENSITIVITY

CURRENT LEVEL

Alert Alert High Alert Low Acclimate Alert Level

Action 1 Action 1 High Action 1 Low Acclimate Action 1 Level

Action 2 Action 2 High Action 2 Low Acclimate Action 2 Level

Fire 1 Fire 1 High Fire 1 Low Acclimate Fire 1 Level

Fire 2 Fire 2 High Fire 2 Low Acclimate Fire 2 Level

TABLE 6. ACCLIMATE LEVELS