Page 2

Contents

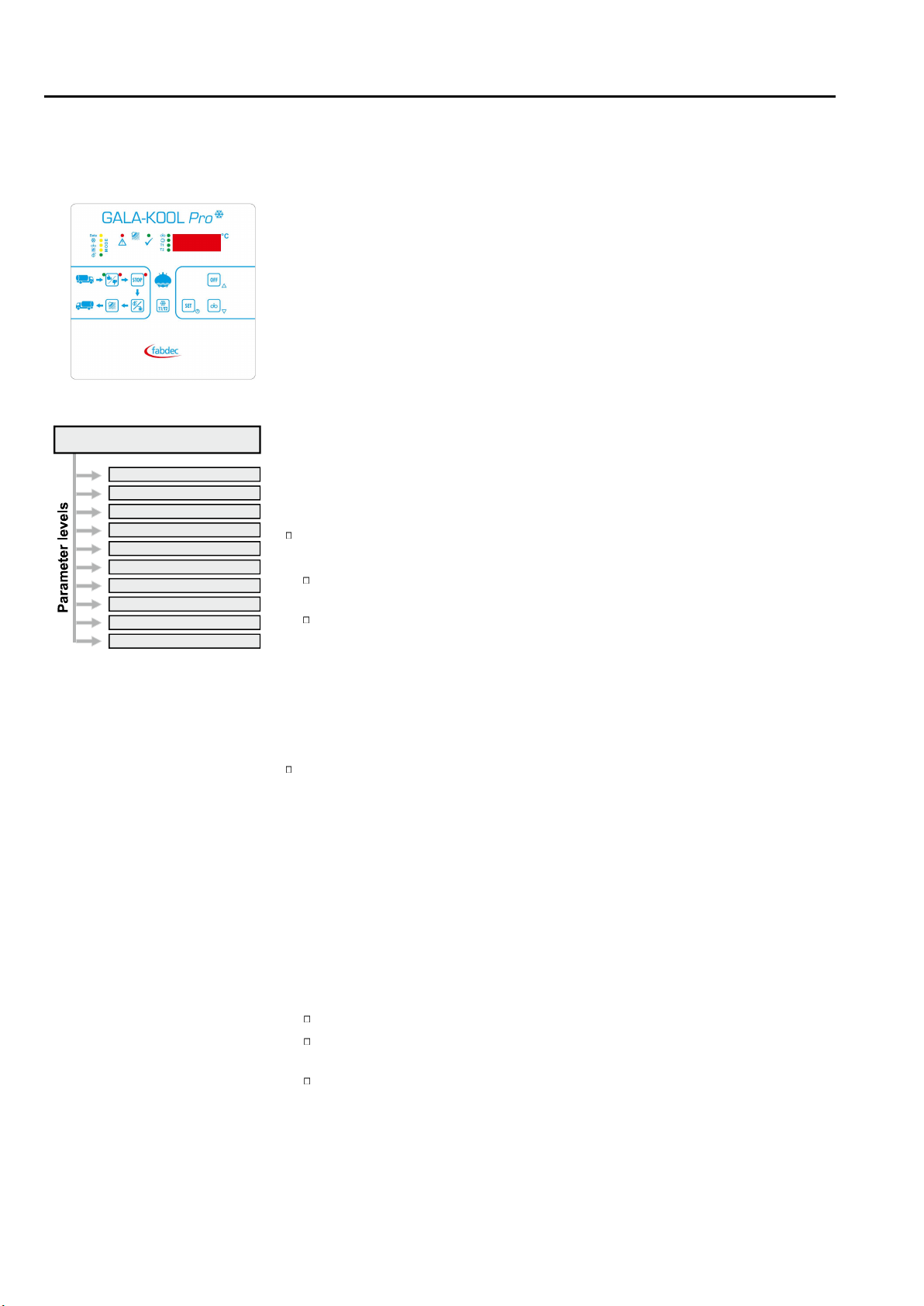

1 Introduction

1.1 Page 4Function overview

2 Safety

2.1 Electrical safety 6 Page

2.2 Intended use 7 Page

2.3 Wiring, screening, earthing Page 7

3 Electrical connection

3.1 Connection diagram 8 Page

4 Technical data

4.1 Technical data of control unit 9 Page

4.2 Fitting the sensor 9 Page

5 Operation

5.1 Setting the date and time 10 Page

5.2 Operation in levels 11 Page

5. 2.1 Button functions 12 Page

5.2.2 Meaning of the LED’s 13 Page

5. 2.3 Operation modes 14 Page

5. Operation of working level2.4 16 Page

6 Cleaning

6.1 Cleaning methods (cooling tank-configurations) Page 18

6.1.1 Circulation cleaning with a beaker Page 18

6.1.2 Circulation cleaning with two dosing pumps Page 18

6.1.3 Displacement cleaning with feed container, dosing pumps

Page in circulation line 19

6.1.4 Displacement cleaning with feed container dosing pumps and Page 19

6.2 Page 20Cleaning programme diagram

6.3 Page Explanation and programming of the cleaning process 22

6. Page 4 28 Service functions for testing the cleaning cycle

7. Tank monitor and general fault handling

7 Page .1 Description of tank monitor operation 30

7 Page .2 Tank monitor: Milk removal YES or NO 32

7 Page .3 Tank monitor: Handling multiple faults 35

7 Page .4 Tank monitor: Display fault memory 35

7 Listing fault codes and their description Page .5 36

.5.1 Critical tank monitor alarms (red)7 Page 36

.5.2 Informative tank monitor alarms (green)7 Page 37

.5.3 System alarms cleaning7 Page 38

.5.4 System alarms cooling7 Page 40

7. Page 5.5 System alarms external sensors 41

7.5.6 Test alarm Page 41

8. Setting of parameters

8 Page .1 Change and save parameter values 42

8 Level c-parameter Page .2 „General cooling parameters“ 44

8 Level P-parameter Page .3 „Extended cooling parameters“ 46

8 Level n-parameter Page .4 „General cleaning parameters“ 51

8 Level „ r-parameter Page .5 Extended cleaning parameters“ 54

8 Level E-parameter Page .6 „Service parameters“ 59

8 Level h-parameter Page .7 „General tank monitor parameters“ 60

8 Level H-parameter Page .8 „Extended tank monitor parameters“ 62

8 Level -> Event assignment F-parameter Page .9 „Alarm “ 64

8 Level A-parameter Page .10 „ “Configuration 66

8 Level o-parameter Page .11 „I-/O- test parameters“ 72